Just recently, a new solid fuel for stoves and boilers appeared on the domestic construction market, the manufacturers of which position it as a cost-effective alternative to conventional firewood. The fuel is called Eurowood or fuel briquettes, and it is made from the remains of natural materials, for example, wood, paper, straw, seed husks, nut shells.

The process of producing fuel briquettes is simple, it is necessary to prepare the raw materials and compress them under high pressure, or heat treatment can also be carried out. The resulting product will be dense, dry, and ready for use in the oven. In this article we will talk about what equipment is needed for the production of fuel briquettes, consider the composition of an industrial production line and alternative equipment options for home production of such products.

Production line for creating RUF fuel briquettes

Features of the production of fuel briquettes

Fuel is made from the following types of raw materials:

- sawdust, wood chips, shavings, bark;

- cake, sunflower husks, husks of other seeds, incl. croup;

- peat;

- coal dust.

Briquettes made from wood waste are the most common.

Physics of the process

A portion of crushed raw materials is loaded into a mold and compressed with a press with a force of up to 3000 kg/sq.cm.

The output is a block with a higher density than wood: 1.08–1.40 g/cc versus 0.75–0.85. This fuel burns longer and does not produce sparks.

Application of adhesive

A binder is required to adhere fine particles to each other. Industrial production uses lignin contained in the raw materials themselves. It is a complex biopolymer synthesized by plants. Under the influence of high pressure and the resulting heating, the binder comes out of the cells and impregnates the briquette.

An adhesive is required to hold the particles together.

Thus, factory-made fuel does not contain chemical additives and is therefore environmentally friendly.

Most homemade presses are not capable of developing pressure sufficient to destroy plant cells and squeeze out lignin. Therefore, in home production, third-party binders are used:

- Clay solution. Add in an amount of 5–10% of the total weight of the mixture.

- Corrugated cardboard and other paper (contains lignin). The material is pre-soaked.

- Wallpaper glue. The cheapest one will do.

The proportion of glue and paper is selected experimentally - it depends on the humidity of the raw material and the pressure developed by the press.

The higher the lignin concentration in the wood, the lower the force required to squeeze it out. Data on the most common breeds are given in the table:

| Tree name | Mass fraction of lignin, % |

| Birch | 19 |

| Aspen | 22 |

| Spruce | 27 |

| Pine | 27 |

| Fir | 30 |

If a homemade press develops a lot of pressure, you should first try to make briquettes from softwood sawdust. It is possible that a third-party binder will not be needed.

Requirements for raw materials used

A properly prepared starting mass has the following parameters:

- Humidity – 4–10%. Excessive amounts of water impair combustion.

- Fraction or chip thickness – 2 mm. Large chips are pre-crushed in crushers.

- Lack of grass, sand, leaves, soil; bark content – no more than 5% by weight of the mixture. Such components disrupt the monolithic structure of the bar and make it crumbly.

At enterprises, the moisture content of raw materials is adjusted to the required value in heated dryers. In home production, it is kept in the sun and draft.

When using a third-party binder, sawdust is soaked in it, and the finished product is dried.

Do-it-yourself briquetting - pros and cons

It is possible to make a press yourself and set up the production of fuel briquettes. But this requires material costs, physical effort and time. It is also necessary to take into account that it is unlikely that it will be possible to achieve the quality of European firewood produced in factories. Of course, you can purchase a machine that is not much inferior to a production one, but the acquisition costs will be colossal.

You need to have a good idea of why you need your own production, what the conditions are for this, and what the costs will be. Maybe you shouldn’t give up regular firewood or it might be better to buy ready-made briquettes for heating.

pros

The positive aspects of homemade are as follows. Your own fuel briquettes will not provide the same combustion quality as purchased briquettes, but they will be more efficient than firewood.

If it is possible to obtain a large amount of wood waste - sawdust, small trimmings, shavings, bark - then it is more profitable to make compressed firewood from them. Sawdust and shavings in their pure form are of little use for combustion, but after processing on a sawdust pressing machine they produce good fuel.

You can use not only wood, but also any other combustible waste - straw, dry leaves, paper, cardboard. Separately, none of them are flammable material, but briquettes will be useful. Briquetted fuel is convenient for storage and loading into the firebox.

Minuses

But there are also disadvantages to keep in mind. Attempts to improve the quality of home-made European firewood can lead to the purchase of expensive equipment or the constant addition of existing equipment. As a result, it turns out that producing your own briquettes will not justify the costs.

Homemade fuel briquettes require space for proper drying. Drying in the sun is not always justified. A spacious, dry room is required. Homemade briquettes should also be stored so that they do not absorb moisture.

Homemade Bonding Materials

Using homemade machines, it is almost impossible to achieve the pressure at which lignin is released from wood pulp. Therefore, it is necessary to add materials to the raw materials for independent briquetting that will help bind and glue the raw materials into a monolithic briquette. Most often used for these purposes:

- clay. Volume proportion 1 to 10 wood raw materials;

- glue. Any will do, but, naturally, it’s better to take the cheapest one;

- shredded paper or cardboard. In addition to the fact that it is also a flammable material, paper contains lignin. And paper lignin exhibits its adhesive properties when soaked. True, then you will need additional time to dry the briquettes containing paper.

In order for binding additives to fully demonstrate their properties, they must be thoroughly mixed with combustible raw materials, and then this mixture must be soaked in water.

Note! In industrial production, the raw materials are thoroughly dried before pressing, and in homemade production, they are thoroughly soaked.

This is the main difference between homemade ones. Fuel briquettes are dried after pressing so that they harden, hold their shape and burn well.

General information about briquetting press

The equipment is produced in a variety of designs. The developed force varies from 500 to 3000 kgf/sq.cm.

Approximate cost in rubles:

- mini presses – 70,000–100,000;

- budget class models – 200,000;

- multifunctional machines with a long service life - from 300,000 to 1,000,000.

A homemade unit can be made at home from scrap materials.

Purpose

The press compresses fine-grained raw materials until they turn into a dense briquette. Expensive models simultaneously heat the source material to a temperature of +150...300°C, which promotes the release of lignin from plant cells.

The press compresses the raw materials into a dense briquette.

Machines designed for the continuous production of Euro firewood cut them into individual bars.

Design features: main elements

The main components of the press:

- Mixer. Mixes several types of raw materials until a homogeneous mixture is achieved.

- Matrix. Gives raw materials the desired shape.

- Punch. Applies pressure on the original mass.

- Operating mechanism with drive. Converts electrical energy into compression force.

- Bed. The base to which all components are attached.

Some models are additionally equipped with a heater and a knife.

Principle of operation

The mixture enters the matrix, where it is subjected to pressure from the punch. The raw material is compacted with simultaneous molding.

Operating principle of a briquette press.

According to the principle of operation, machines are divided into 2 types:

- Intermittent. During production, the cycle is repeated many times: loading of raw materials – compression – removal of the finished product from the mold.

- Continuous (extruders). Adding raw materials and squeezing out the product occurs constantly, while at the same time the latter is cut into bars.

Basic elements of the press

The most important element of the press is the mold. The press mold device has a simple design. Its cross-section is chosen arbitrarily; it depends more on the preferences of a particular person, since the shape gives an understanding of what the finished product will look like.

The elements of the device also include a piston and a mechanism that creates pressure. The minimum force that must be applied to obtain Euro firewood is 30 MPa. In this case, there is no need to add a binder, since lignin will bind the material quite firmly.

Species diversity

There are several types of presses:

- hydraulic;

- screw;

- shock-mechanical;

- granulators.

The differences lie in the method of creating pressure and the characteristics of the briquettes.

Hydraulic

Machines of this type have the following characteristics:

- The production method is intermittent.

- The working mechanism is hydraulic: force is created by pumping oil into the cavity of the hydraulic cylinder.

- Specific pressure – 500–1500 kg/sq.cm.

The hydraulic machine has an intermittent production method.

Raw materials are loaded in portions into a mold (glass). After compression, the finished briquette is removed.

Hydraulic presses have 2 advantages:

- low cost;

- briquettes are shaped like bricks (RUF), which makes transportation and storage easier.

Flaws:

- low productivity;

- relatively low pressure - the density of the bars does not exceed 0.75–0.8 kg/cc.

Screw

Press characteristics:

- The manufacturing method is continuous.

- The working body is a rotating auger (like in a kitchen meat grinder).

- Specific pressure – up to 3000 kg/sq.cm.

The press operates on the principle of extrusion: a screw forces the mixture through a gradually narrowing hole - a die. Due to the conical shape of the channel, the compression force from its walls is several times higher than the pressure developed by the screw. A similar effect is observed when driving a wedge into a crack, which leads to the splitting of a tree trunk.

A screw press forces the mixture through a tapering hole.

Installation benefits:

- High density of briquettes – 1.08–1.40 kg/cc. This fuel burns for a long time and produces a lot of heat.

- High performance. Thanks to the continuous operation of the extruder, it is possible to produce more briquettes per unit of time than with a hydraulic installation.

- The log has a Pini&Kay format - with a hexagonal cross-section and a through hole in the middle. The channel ensures the flow of air to the internal layers and, as a result, the most complete combustion and minimum ash content.

The disadvantage of a screw press is its high cost.

Impact-mechanical

Equipment characteristics:

- The production method is continuous.

- The working body is a rotating crankshaft with a connecting rod attached to it (crank mechanism).

- Specific pressure – up to 2500 kg/sq.cm.

There is another type of extruder, when the raw material is forced through a die by a piston moving back and forth.

In terms of cost and productivity, mechanical impact presses occupy a middle position between hydraulic and screw models. The same can be said about the density of the bar: it is 1–1.15 kg/cc. It has a round cross-section (Nestro type) with a through hole.

The mechanical impact press operates continuously.

The disadvantage of the equipment is accelerated wear of the bearing due to impact.

Despite this, such presses have become widespread due to the optimal combination of installation price and product quality.

Press granulator

This is a universal extruder for the production of fine-grained pressed products. If the raw material is crushed grain, the output is compound feed; if sawdust, peat, seed husks, etc. - fuel granules (pellets). The advantage of small-caliber briquettes is the possibility of automatically feeding them into the combustion chamber of the boiler using a screw or piston feeder. The heat generator must be equipped with a special pellet burner.

Types of presses

There are 4 types of press. The difference between them is the principle of operation and the cost of the device.

Kinds:

- mechanical impact press;

- Hydraulic Press;

- screw press;

- press granulator.

The operating principle of a mechanical impact press is based on impacts, under the influence of which chips are forced through a die. The advantage of this device is that in addition to wood waste, you can press the remains of MDF or coal dust. The device can operate for a long time without human intervention.

The hydraulic type sawdust briquetting press is similar in principle to the use of a hydraulic jack. The mold is filled with raw materials and pressure is applied to it by a hydraulic cylinder. The disadvantage of this model can be considered the low volume of products. To press sawdust and create euro-firewood in a hydraulic press, it is necessary to use a binder.

The production of pellets using a screw press is carried out under high temperatures. The chopped wood is fed to the auger through a die. Under the applied pressure, the raw material is pressed. Due to the high temperature, the wood loses its natural binder, as a result of which the pressed timber has sufficient strength. The briquetting line has similar features to the operation of a meat grinder, that is, the finished raw material is placed in a hole, mixed in a hopper and exits through a tapering channel.

Pressing sawdust using a granulator press is a fairly quick process. It will only be possible to produce small-sized products. A significant advantage of this product can be considered its cost and the availability of various additional devices that can improve the quality of the product.

To obtain fuel from sawdust, it is necessary to prepare it using any type of press. The moisture level of the raw materials should be in the range of 4-10%, and it must first be crushed into fractions measuring 25x25 mm.

Press selection criteria: what to look for

When choosing a machine, consider the following:

- Electric motor power. It is limited by the capacity of the circuit breaker at the entrance to the house and the cross-section of the cables. The most energy-intensive are screw units.

- Distance to the supplier's service department. The closer it is located, the faster the repairs will be completed and the less losses there will be from equipment downtime.

- Telephone consultation. A useful service from a supplier or dealer can help you avoid mistakes and save money.

- Volume of available raw materials and market capacity. The costs of purchasing a machine with excessive productivity will be unreasonably high, and along with them the cost of repairs. These factors will increase the payback period of the equipment and lead to a decrease in production profits.

When choosing a machine, consider the power of the electric motor.

Room equipment

The production premises are subject to certain requirements from sanitary services and fire inspectors. The required voltage in the electrical network is 380 V.

Be sure to have sewerage and running water. Also, you should take care of the ventilation of the room.

The area of the production facility depends on the capacity and set of equipment . There are strict safety standards that allow you to calculate the required area.

How to organize the production of double-glazed windows? What equipment is needed for this business? In the material, watch a video about the production of double-glazed windows and learn the important points of this business.

What is the secret of the population's demand for dumplings? Tasty and healthy food will always be fashionable. On this page you will learn how a machine for producing dumplings works.

A confectionery business has every chance of success if all technological requirements are met. From the material you can learn how the production of mini bakeries for confectionery shops is organized.

Methods for creating a device

It is impossible to make an extruder at home. All homemade machines press briquettes into a mold (glass) in an intermittent manner.

The main task of the designer is to ensure a specific pressure of at least 150 kg/sq.cm. This value is determined by 2 factors:

- force generated by the press (direct relationship);

- cross-sectional area of the mold (reverse).

By selecting the ratio of these parameters, the desired characteristics are achieved.

For example, a machine presses on a portion of raw materials with a force of 1350 kgf. If the block has a cross-section of 5x5 cm, the specific pressure will be:

P = 1350 / (5 x 5) = 54 kgf/sq.cm

At such low rates, the briquette will crumble. By reducing the dimensions of its cross-section to 3x3 cm, the designer will increase the specific pressure to:

P1 = 1350 / (3 x 3) = 150 kgf/sq.cm

There are several ways to achieve high force.

The designer's task is to ensure the specific pressure of the press.

Use of muscular strength and leverage

This is the simplest version of the press; all its elements can be made at home.

A strong pipe is used as a lever, for example a reinforced water pipe with a diameter of 40–50 mm and a wall thickness of 4–4.5 (mm). One end of it is equipped with an axis and fixed in a bracket so that the other side can be raised and lowered.

A rod with a punch is attached at a short distance from the point of rotation.

The compression force will be equal to Q = P * (L / L1), where:

- P – operator’s weight acting on the free end of the lever;

- L – pipe length;

- L1 – distance from the point of rotation to the junction of the rod and the punch.

Example:

- operator weighs 90 kg;

- lever length – 3 m;

- the distance from the pipe rotation point to the punch is 0.3 m.

Under these conditions, the compression force will be:

Q = 90 * (3 / 0.3) = 900 kgf

It must be taken into account that the same force acts on the bracket at the point of rotation of the lever, so it must be strong.

To achieve a pressure of 150 kgf/sq.cm, the cross-sectional area of the bar must be equal to:

S = 900 / 150 = 6 sq.cm

The lever installation is designed so that briquetting is carried out in one step. Otherwise, you will have to waste time adding raw materials, which will lead to a decrease in productivity.

The immersion depth of the punch depends on the volume of the portion. It is calculated using the formula A = H * (1 – (p1 / p2)), where:

- H – height of the glass;

- p1 and p2 are the density of raw materials and briquettes, respectively.

The larger A, the further the rod needs to be moved from the point of rotation. But this leads to a decrease in compression force.

The parameters are selected as follows:

- Calculate the cross-sectional area of the pipe from which the glass will be made.

- The required force is calculated and based on this the distance of the rod to the point of rotation is determined.

- A test briquette is made.

- If in 1 approach it was not possible to achieve the required degree of compression, cut off part of the glass to reduce its length.

Formula for calculating the piston pressure force (m) depending on the force applied by a person (M), the distance from the piston to the lever attachment point (l) and its total length (L)

If high productivity is not needed, the briquette is made in several stages, adding more raw materials.

To increase the pressure on the lever, you can attract an assistant.

Application of hydraulic jack

A household hydraulic jack develops a force of 30–40 tf. If you equip a press with it, the available mold area will be:

S = 30000 / 150 = 200 sq.cm

The hydraulic jack develops a lot of force.

This machine can be equipped with several forms. Then the frame for the punches is made of durable rolled products, for example an I-beam or a thick-walled profiled pipe.

The disadvantage of a press based on a hydraulic jack is the long cycle time. But it has higher productivity, and the briquettes are more similar to those made industrially.

The design of a typical hydraulic press consists of a frame and a movable beam on which a jack is placed. The system returns to its original position due to the action of springs

Screw pressing mechanism

Another device for enhancing muscle strength is a screw. The amount of pressure it creates is calculated based on the “golden rule of mechanics”.

L1 / L2 = Q2 / Q1, where:

- L1 – path traveled by the point of application of muscular force;

- L2 – movement of the punch mounted on a screw or lever;

- Q1 – muscular strength;

- Q2 – pressure developed by the press.

Example:

- the length of the handle in the screw shank is 80 cm (2 arms of 40 cm each);

- force applied by the operator – Q1=40 kgf;

- screw thread pitch – 3 mm.

The screw pressing mechanism enhances muscle strength.

For 1 revolution, the point of application of muscular force, i.e. the end of the handle will go the following way:

L1 = 2 * P * 40 = 2 * 3.14 * 40 = 251.2 cm

The punch will drop to L2 = 3 mm = 0.3 cm. The force of its influence on the raw material is equal to:

P2 = (L1 * P1) / L2 = (251.2 * 40) / 0.3 = 33493 kgf

The actual force will be less because The operator will spend part of the energy to overcome friction in the screw-nut pair. The average efficiency of such devices is 25–30%. This means that the press considered in this example presses on a portion of raw materials with a force of 33493.3 * 0.25 = 8373.3 kgf.

Advantages of screw presses:

- the greatest strength among hand-held devices;

- compactness;

- simple design.

Flaws:

- the cycle is longer;

- The manufacture of the screw and nut will have to be ordered by a turner.

The operator must control the applied force, otherwise the thread may be stripped.

It is recommended to increase the pressure little by little and, as soon as an acceptable result is obtained, put a mark on the screw indicating the extreme position.

Equipment for pressing raw materials

As it becomes clear from the description of the technological process, to organize the full-fledged production of fuel briquettes, a whole complex of technical devices is needed. This includes:

- drying equipment, which is mainly used drum-type installations;

- machine for grinding raw materials;

- equipment for forming briquettes, which can be a production line or a separate press for sawdust and other raw materials.

Diagram of an impact briquette production line complete with a chopper and a drying unit

Both the composition of production lines for the production of fuel briquettes and the type of equipment with which they are equipped are selected depending on the planned production volumes and the type of raw materials used.

In addition to the main equipment, briquette production lines are equipped with auxiliary technical devices:

- belt or screw type conveyors, which provide transportation of raw materials and finished products;

- storage hopper with dosing device and agitator;

- magnetic type traps, which ensure the extraction of metal impurities from the raw material, if they are present in it;

- vibration type sorter;

- calibrators, with the help of which particles of the wrong size are screened out from raw materials;

- fans;

- packaging installation equipped with weighing equipment.

A modern technological line for the production of briquettes is characterized by low energy intensity and pays for itself in a short time

Among all the technological equipment used for the production of Euro-firewood, the most important role is played by briquetting machines, with the help of which a briquette is formed from a crumbly sawdust mass, characterized by a high density of internal structure.

Instructions for making a press

To create a homemade machine you will need the following tools:

- welding machine;

- grinder with cutting discs for metal;

- drill;

- roulette;

- pencil or marker.

To create a homemade machine, you need a welding machine.

The procedure depends on which drive will be used.

Manual

They start with making the frame. This part absorbs all the forces arising in the structural elements, so it must be strong. The bed is a frame made of a thick angle or profiled pipe with reinforcement in places subject to the greatest pressure.

At the next stage, a mold is made. To do this, a fragment of the required length is cut from a round or square pipe with thick walls. Several thin holes are made at the bottom of the glass to allow air and moisture to escape.

You need to think about a way to remove the finished briquette from the mold.

There are 3 options:

- The glass is equipped with a movable bottom with a spring underneath. It pushes out the briquette after the load is removed. The disadvantage of this solution is that the spring wears out quickly, losing its elasticity.

- They make a removable bottom. It is dismantled at the end of the cycle, then the finished briquette is pushed out by a press.

- Use a collapsible glass of 2 halves. Before pressing, 2 rings of reinforcement are put on it.

The mold is placed in a container or scalded around the perimeter so that the water that spills out of it during the pressing process does not spread.

A hand press begins with the manufacture of a bed.

The punch is cut from a steel sheet with a thickness of at least 3 mm.

Finally, a bracket is welded to the frame, after inserting the lever axis into it, or 4 stands with a nut for the screw mechanism.

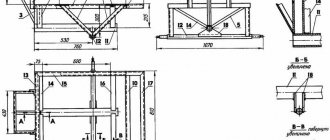

Drawings of a press for making briquettes

With electric motor

The model based on a hydraulic jack with a pump and motor is subject to higher requirements in terms of strength. Proceed in this order:

- Make a welded frame from channels.

- Weld 1.5 m long posts in the corners.

- Between them, attach a drum for mixing sawdust and binder, removed from an old washing machine or made from a large diameter pipe.

- Below, install a galvanized steel tray to feed the mixture into the mold.

- Attach a hydraulic jack to the racks.

- Make and then install the glass and punch in place, as in the manual version.

The press is ready for use.

Eurowood production technology

Euro firewood is produced from waste from the wood processing industry (branches, shavings, sawdust, straw). For many furniture and lumber manufacturers, waste disposal is a serious problem that requires additional costs. It may well be that you don’t even have to pay for raw materials - it will be enough to regularly export them using your own transport.

The production of Euro-firewood from sawdust and other waste consists of several stages:

- Crushing of raw materials.

- Drying.

- Pressing into briquettes of the desired shape.

- Drying of finished products.

The type of wood does not play a special role in the briquetting process.

But, in order to achieve maximum machine productivity and high quality products that will satisfy demanding European buyers, several rules must be followed:

- Do not mix shavings and sawdust.

- The fraction of raw materials should not exceed 3 mm.

- It is advisable to use wood of the same species.

- Maximum performance is achieved with hardwood.

How is cheese made and what is needed for it? Find out why the technological scheme of cheese production is interesting, find out the strengths of this business.

The market for waste disposal equipment today is growing quite quickly. Find out how plastic bottles are converted into fuel here.

Useful tips and general recommendations

The creators of homemade briquetting machines advise doing this:

- Start designing with a detailed drawing indicating dimensions. This will avoid mistakes and accurately determine the amount of materials needed.

- Entrust the strength calculations of parts to a mechanical engineer or builder who is well versed in the strength of materials.

- Periodically check the product for bends and distortions and, if found, eliminate them. Otherwise, the quality of the briquettes will suffer.

- Dry the finished bars in the sun or in a ventilated area. This will ensure high calorific value of the fuel.

Using clay as a binder, make sure there is no soil in it. Otherwise, the briquettes will crumble.