Cast iron is the most common iron-carbon non-malleable casting material, containing over 2% carbon, up to 4.5% silicon, up to 1.5% manganese, up to 1.8% phosphorus and up to 0.08% sulfur. In practice, cast irons containing 3÷3.5% carbon are used.

Cast iron has high casting properties, therefore it is widely used in foundries as a structural material. It is easy to cut. Sliding bearings are made from cast iron, which has a low coefficient of friction. Specially treated cast iron (high-strength) successfully competes with cast steel and forged steel in terms of quality.

The insufficient strength and high fragility of cast iron are explained by the presence of large carbon inclusions in it in the form of graphite.

The introduction of a small amount of magnesium and cerium into liquid cast iron changed the shape of graphite, it became spherical. Cast iron gained strength and lost brittleness. Such cast iron (called high-strength) is not inferior in quality to structural carbon steels. The durability of parts made from this cast iron has increased almost threefold.

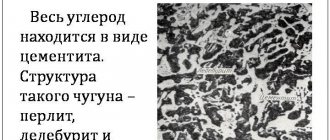

Carbon in cast iron can be in the form of a chemical compound - cementite (such cast iron is called white) or partially or completely in a free state in the form of graphite - (such cast iron is called gray).

Cast irons consist of a metal base (perlite, ferrite) and non-metallic graphite inclusions. They differ mainly in the shape of graphite inclusions. White cast iron has limited use. Some castings that require increased surface hardness are made from bleached cast iron. Its surface layer consists of white cast iron, and the core is gray. The size and hardness of the bleached layer is controlled by changing the chemical composition of the cast iron and the rate of solidification of the casting.

Gray cast iron

Gray cast iron is widely used in mechanical engineering. It received this name from the gray color of the fracture, due to the presence of free carbon in the form of graphite in the cast iron structure. Based on the type of metal base, gray cast irons are pearlitic, pearlitic-ferritic and ferritic.

Table 1. Gray cast irons, their main properties and applications

| Brand | σin MPa | NV | Properties and Application |

| Sch10 | 275 | 139-274 | Low-critical castings with wall thicknesses up to 15 mm (cases, covers, casings, etc.), parts for which strength characteristics are not mandatory - flasks, fittings, frames, frying pans, decorative parts, massive building columns, foundation slabs |

| SCH15 | 314 | 160-224 | Low-critical castings with a wall thickness of 10 - 30 mm (pipes, valve bodies, valves at pressures up to 20 MPa, etc.), low-load housing parts, sub-motor plates, levers, pulleys, flywheels, containers for oil and coolant, filter housings, flanges, covers, chain sprockets |

| SCH18 | 354 | 167-224 | Critical castings with a wall thickness of 10 - 20 mm (pulleys, gears, frames, calipers, etc.) |

| SCH20 | 397 | 167-236 | Critical castings with wall thicknesses up to 30 mm (cylinder blocks, pistons, brake drums, carriages, etc.), for the manufacture of basic body parts of increased strength and wear resistance, parts that are subject to tightness requirements at pressures up to 8 MPa (80 kgf/cm2 ), housings, gearboxes, spindle heads, balancers, faceplates, sleeves, carriages, cylinders, pumps, spools, fittings, compressors |

| SCH25 | 450 | 176-245 | Critical castings with wall thicknesses up to 40 mm (chill molds, piston rings, etc.), for the manufacture of basic body parts with increased strength and wear resistance, parts that are subject to increased requirements for tightness |

| SCH3O | 490 | 177-250 | Critical castings with wall thicknesses up to 60 mm (pistons, diesel liners, frames, dies, etc.), for the manufacture of brackets, table slides and calipers, surface-hardened parts, cylinders, pump housings, diesel engines and internal combustion engines, piston rings, crankshafts and camshafts |

| SCh35 SCh45 | 540 | 193-264 | Critical, highly loaded castings with wall thicknesses up to 100 mm (small crankshafts, parts of steam engines, etc.) of parts for which production requirements are required for tightness at pressures above 8 MPa |

Graphite has low mechanical properties. It violates the integrity of the metal base. Located between the grains of the metal base, graphite weakens the bond between them. Therefore, gray cast iron has poor tensile strength and has very low ductility and toughness. The larger and straighter the graphite inclusions, the worse the mechanical properties of cast iron. The hardness of gray cast iron, as well as its resistance to compression, is close to that of steel, which has the same structure as the metal base of cast iron.

Graphite also has some positive effects on the properties of cast iron, in particular, it increases its wear resistance, acting similarly to a lubricant, increases machinability by making chips brittle, helps dampen vibrations of products, and reduces shrinkage during the manufacture of castings.

The mechanical properties of gray cast iron can be improved by uniformly distributing fine-lamellar graphite in the casting. This is achieved through special processing - modification, when additives are introduced into liquid cast iron before casting, which form additional graphitization centers, resulting in fine-plate graphite. Cast iron with such graphite is called modified. It differs from ordinary gray cast iron in its higher tensile strength, but its ductility and toughness do not improve when modified.

According to GOST 1412-85, the letters SCH in the designation of the cast iron grade mean gray cast iron. A two-digit figure corresponds to the tensile strength σin MPa. The standard normalizes the tensile strength of gray cast iron σв = 274÷637 MPa, hardness - 143÷637 HB and chemical composition.

The main properties of gray cast iron and its application are given in Table 1.

Chemical composition

The basic properties and chemical composition of gray cast iron are regulated by GOST 1412-85.

The optimal carbon content is 2.4-3.7%. At a lower concentration it will completely dissolve in iron, and exceeding it will lead to loss of hardness and elasticity.

Silicon – 1.2-2.5%. It participates in the graphitization process, increasing the hardness of the metal and reducing its viscosity. The influence of carbon and silicon is considered together, taking into account their total concentration.

Sulfur combines with iron to form FeS sulfide, which reduces the strength and ductility properties of the alloy. The allowed sulfur content is no more than 0.12-0.15%.

Manganese mitigates the harmful effects of sulfur and promotes the formation of free iron carbides. Its amount is determined by the sulfur content, and is usually 0.5-1.1%.

The phosphorus concentration does not exceed 0.2-0.3%. The element forms inclusions of phosphide eutectic, increasing hardness and wear resistance.

Depending on the brand, the following may be included in the composition of gray cast iron:

- chromium - it increases carbide formation, and with this process the hardness and strength of the material increases;

- tin, which promotes uniform distribution of hardness over different sections;

- nickel and molybdenum - to increase resistance to corrosion processes and improve machinability;

- copper - its presence accelerates graphitization, increases elasticity and resistance to corrosion, and improves machinability;

- antimony - up to 0.08%, affects crystallization processes.

High-strength cast iron with nodular graphite

Ductile iron is produced by introducing magnesium (up to 0.9%) and cerium (up to 0.05%) into liquid gray iron before pouring it into molds. The main part of these modifiers evaporates, oxidizes and turns into slag, so that no more than 0.01% of these elements are found in the solid metal. Magnesium and cerium actively remove sulfur from cast iron. But their main role is to change the flake-plate shape of graphite to spherical. After modifying the cast iron with magnesium or cerium, 75% ferrosilicon (an alloy of iron and silicon) is added to the ladle. Unlike modified gray cast iron, ductile iron has a higher carbon and silicon content and a lower manganese content.

The metal base of ductile iron consists of ferrite and perlite or only perlite. This cast iron combines the valuable properties of steel and cast iron. It has relatively high strength with sufficient ductility and toughness. High-strength cast iron successfully replaces steel casting and even steel forgings, which gives a great economic effect. Products made of high-strength cast iron, due to its increased wear resistance, can work under friction conditions. High-strength cast iron retains its strength better than gray cast iron when heated, so it can be used for work at temperatures up to 400°C (gray cast iron can withstand temperatures up to 250°C).

GOST 7293-85 normalizes the tensile strength σв, yield strength σт, relative elongation δ and hardness НВ of high-strength cast irons. Requirements for castings made from these cast irons are established by regulatory and technical documentation. The principle of marking high-strength cast iron (DC) differs from the marking of gray cast iron. The designation of their brand includes two numbers - the first indicates the tensile strength, the second - the relative elongation. For example, the grade of cast iron HF 42-12 means that this cast iron has a tensile strength σв = 412 N/mm2 (42 kgf/mm2) and elongation δ = 12%.

The standard provides for 10 grades of high-strength cast iron: VCh 38-17, VCh 42-12, VCh 45-5, VCh 50-7, VCh 50-2, VCh 602, VCh 70-2, VCh 80-2, VCh 100-2, HF 120-2. The standard or reference book provides additional information about this cast iron: yield strength σt = 274 N/mm2 (28 kgf/mm2), hardness 140÷200 HB.

Many parts (including shaped ones) are made from high-strength cast iron, which were previously made from steel, base and body parts of increased strength (cases and frames of machine tools, large faceplates, sleeves, carriages, cylinders, brackets, gears, overhead guides of machine tools and parts with surface hardening). They replace Steel 20L, 25L, ZOL and 35L steels.

White and gray cast iron

Gray and white cast iron differ sharply in properties. White cast iron is very hard and brittle, is difficult to process with cutting tools, is used for smelting into steel and is called pig iron. Part of the white cast iron is used to produce malleable cast iron.

Gray cast iron is foundry cast iron. Gray cast iron comes into production in the form of castings. Gray cast iron is a cheap construction material. It has good casting properties, is easy to cut, resists wear, and has the ability to dissipate vibrations under vibration and variable loads. The ability to dampen vibrations is called damping capacity. The damping capacity of cast iron is 2-4 times higher than steel. High damping capacity and wear resistance have led to the use of cast iron for the manufacture of frames of various equipment, crankshafts and camshafts of tractor and automobile engines, etc. In accordance with GOST 1412-80, the following grades of gray cast iron are produced (the numerical values of hardness NV are indicated in brackets): SCh 10 ( 143-229), SCh 15 (163-229), SCh 20 (170-241), SCh 25 (180-250), SCh 30 (181-255), SCh 35 (197-269), SCh 40 (207- 285), SC 45 (229-289).

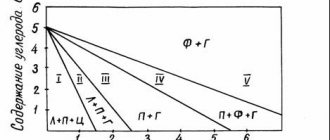

Gray cast iron is produced by adding substances to molten metal that promote the decomposition of cementite and the release of carbon in the form of graphite. For gray cast iron, the graphitizer is silicon. When about 5% silicon is introduced into the alloy, gray cast iron cementite almost completely disintegrates and a structure of a plastic ferrite base and graphite inclusions is formed. With a decrease in silicon content, cementite, which is part of pearlite, partially disintegrates and a ferrite-pearlite structure with graphite inclusions is formed. With a further decrease in silicon content, a pearlite-based gray cast iron structure with graphite inclusions is formed.

The mechanical properties of gray cast iron depend on the metal base, as well as the shape and size of graphite inclusions. The most durable are gray cast irons with a pearlite base, and the most ductile are gray cast irons with a ferritic base. Since graphite has very low strength and has no connection with the metal base of cast iron, cavities occupied by graphite can be considered as voids, cuts or cracks in the metal base of cast iron, which significantly reduce its strength and ductility. The greatest reduction in strength properties is caused by graphite inclusions (Fig. 25, a) in the form of plates, the smallest being point or spherical inclusions.

Rice. 25. Microstructure of cast iron with different forms of graphite: a – flake graphite in gray cast iron, b – nodular graphite in high-strength cast iron, c – flake graphite in ductile cast iron

According to physical and mechanical characteristics, gray cast iron can be divided into four groups: low strength, high strength, high strength and with special properties. Low-strength gray cast iron is based on the microstructure of ferrite or ferrite and pearlite with lamellar graphite (Fig. 25, a). This cast iron has a tensile strength of 300 MPa and corresponds to grades up to SCh 30. In the grade, the letters abbreviate the name of the cast iron, and the following two-digit number is the tensile strength.

High-strength gray cast iron has a pearlitic base and a finer, swirling graphite structure. It corresponds to grades from SCh 35 to SCh 40. The strength of these cast irons is ensured by alloying and modifying the cast iron.

Alloyed gray cast iron has a fine-grained structure and a better graphite structure due to the addition of small amounts of nickel and chromium, molybdenum, and sometimes titanium or copper.

Modified gray cast iron has a uniform structure across the cross-section of the casting and a finer swirled form of graphite. The chemical composition of the charge for the production of modified cast iron is selected so that ordinary unmodified cast iron would solidify in the casting with chill (i.e., white or half-coloured). Modifiers - ferrosilicon, silicoaluminum, silicocalcium, etc. - are added in an amount of 0.1-0.3% by weight of cast iron directly into the ladle during its filling. The structure of modified gray cast iron castings does not contain ledeburite cementite. Due to the small amount of modifier introduced into cast iron, its chemical composition remains practically unchanged. Liquid modified cast iron must be immediately poured into casting molds, since the modification effect disappears after 10-15 minutes.

Malleable cast iron

In the structure of malleable cast iron, graphite has a flaky shape. This type of graphite is called annealed carbon. Compared to gray cast iron, ductile cast iron has higher strength, ductility and toughness. It got its name because it has increased plasticity. Cast iron is not subject to forging in the truest sense of the word.

The process of producing castings from malleable iron includes two stages: the production of shaped castings from white cast iron and annealing of the resulting castings for the purpose of graphitization of cementite. During annealing, white cast iron cementite decomposes to form flake-shaped graphite. As a result, brittle and hard castings become ductile and softer. Depending on the conditions and annealing mode, the structure of cast iron can have a ferritic (F), pearlitic (P) and ferrite-pearlite metal base. The most widely used is ductile ferritic ductile iron. Annealing of malleable cast iron is a very lengthy process, taking 70-80 hours. However, it can be accelerated by hardening white cast iron castings before graphitization, as well as modifying cast iron with aluminum, boron, bismuth or titanium. There are other ways to speed up the annealing process. The use of these methods allows you to reduce the annealing time to 35-40 hours.

Table 2. Malleable cast irons, their main properties and applications

| Brand | NV | Properties and Application |

| CC 35-10 CC37-12 | 160 | Ferritic cast irons are used for the production of parts, operated under high dynamic and static loads (cases, gearboxes, hubs, hooks, brackets, rear axles, brackets) |

| CC 30-6 CC 33-8 | 160 | For the manufacture of less critical parts (clamps, nuts, valves, parts of agricultural machines, mufflers, flanges, couplings, brake parts, pedals, wrenches, pads, brackets) |

| CC 45-7 | 203 | Malleable cast irons of pearlitic class grades have high strength, moderate ductility and good anti-friction properties. They are used to produce cardan shaft forks, gears, worm wheels, pistons, bearings, links and rollers of conveyor chains, bushings, clutches, brake pads, crankshafts |

| CC 50-5 | 226 | |

| CC 55-4 | 236 | |

| CC 60-3 | 264 | |

| CC 65-3 | 264 | |

| CC 70-2 | 280 | |

| CC 80-1.5 | 314 |

According to GOST 1215-79, malleable cast iron is marked according to the same principle as high-strength cast iron. For example, the grade of cast iron KCH 33-8 means that this cast iron has a tensile strength σв = 32.4 N/mm2 (33 kgf/mm2) and elongation δ = 8%.

Ductile iron castings can be obtained with a cross-section of up to 55 mm. With a larger cross-section, lamellar graphite is formed in the core of the castings and the cast iron becomes unsuitable for annealing. In mechanical engineering, high-strength cast iron is more often used, which is obtained using less complex and cheaper technological processes than the production processes of malleable cast iron.

The main properties of malleable cast iron and its application are given in Table 2.

Cast iron sch 40

?For example, gray cast iron (plate form of graphite) has short mechanical characteristics, since the plates of graphite inclusions act as force concentrates in the casting. However, gray cast iron has a number of privileges: it has high fluidity and low casting shrinkage; graphite inclusions make the chips brittle, allowing cast iron to be easily processed by cutting ; due to the lubricating effect of graphite, cast iron has good anti-friction properties; good dampens vibrations and resonant vibrations. from high-strength cast iron (spherical graphite): gears, crankshafts.

1' alt='Interesting ways to use salt (“Science tip of the day”) How do you use salt? According to data from the Special Salt Institute, salt can be used in 14,000 ways! There is no other mineral that has so many uses. The use of salt for food preservation has been known since ancient times, because food preservation made people less dependent on seasonal products, and also made it possible to transport supplies over long distances. However, salt was quite difficult to obtain. Thanks to modern production methods, salt has become the most accessible non-metallic mineral in the world, but salt reserves are being depleted. Back in the Middle Ages, table salt was used as a cleaning agent; the secrets of its use were passed down from generation to generation. Of course, nowadays you can find stronger means of fighting stains and dirt in the store, but unlike many other products, salt is not toxic, it is quite inexpensive, and it can always be found in sufficient quantities in any home. In the kitchen 1. Boiling water Many housewives are sure that if you add a pinch of salt to the water, it will boil faster. Actually this is not true. Salt, on the contrary, causes water to boil at a higher temperature, so the cooking time in such water is reduced. 2. Cooking Eggs Since salt raises the boiling point of water, it helps the egg whites cook faster. In this case we are talking about poached eggs, a French dish of broken eggs that are carefully lowered into boiling water. 3. Checking the freshness of eggs Add 2 teaspoons of salt to a glass of water, and then lower the egg into the water. A fresh egg will sink, but a stale egg will float on the surface. As the air cavity in the egg increases over time, older eggs will float. Sometimes this does not mean that the egg is rotten, it is just that it is older, but it can still be eaten. In order to check whether an egg is rotten or not, you will have to break it. It is also believed that if eggs are difficult to peel after boiling, then they are fresh. 3. Meringue To make the whites easier and better, add a pinch of salt to them. 4. Preventing fruit from browning Many people use lemon juice or vinegar to prevent peeled apples from browning, but you can do this by dipping the fruit in lightly salted water. 5. Cleaning walnuts To make walnuts easier to clean, immerse them in salt water for several hours. 6. Preventing crystallization of the glaze To prevent the icing on the cakes from crystallizing, add a little salt to it. 7. Getting rid of odor on your hands If you cut onions or garlic, their smell is absorbed into the skin of your hands for a long time. You can easily get rid of the smell by rubbing salt mixed with vinegar into your hands. 8. Extending the shelf life of cheese Some cheeses may become moldy when stored in the refrigerator for several days. To preserve the cheese better, wrap it in a cloth soaked in salt water. 9. Removing dirt from the stove If, while cooking, liquid spills on the stove, sprinkle it with salt and continue cooking. The salt will not smoke or give off an odor, and the dirt will be easier to remove later. Cleaning 10. Cleaning the drain systems In order to get rid of odors and clean the drain systems from grease, regularly pour hot water and salt into the sink. 11. Cleaning wooden tables In order to get rid of white marks from hot plates or glasses, wipe the stains on the wooden table with a mixture of salt and vegetable oil. 12. Cleaning cast iron pans Pots can be easily cleaned of grease if you first wipe them with a paper towel and salt. 13. Cleaning Dirty Cups Mix salt with a small amount of liquid dish detergent and wash cups that have coffee and tea stains on them. The stains will come off easily. 14. Cleaning the refrigerator A mixture of salt and carbonated mineral water will help get rid of the smell in the refrigerator. It's eco-friendly and doesn't contain any chemicals, so you don't have to worry about your products. 15. Cleaning copper utensils Mix equal amounts of salt, flour and vinegar to form a paste, then rub it into the metal utensils. Leave the mixture on the dish for an hour, then rinse with water and dry. 16. Getting rid of rust Mix salt with cream of tartar and water until a paste forms, treat the rust with the mixture and leave until completely dry, then wipe with a brush and polish with a dry soft cloth. If you can't find cream of tartar, you can also use salt and lemon juice. 17. Cleaning glass coffee pots and pitchers If the neck of the pitcher is too narrow and it is difficult to reach the bottom, you can clean it with salt and small pieces of ice. Add them to the jug and shake vigorously. The salt will help clean the bottom, and the ice will stir it well. Washing clothes 18. Removing wine stains If you spill wine on a tablecloth or clothes, immediately sprinkle the stain with salt. This will help the wine quickly soak into the salt and not into the fabric. Then soak the laundry in cold water for 30 minutes and wash it. 19. Foam when washing Usually you use a certain amount of powder when washing, but if you overdo it a little, you can get a lot of foam. A pinch of salt will help reduce the amount of foam. 20. Drying Laundry in Winter If you dry your laundry outside in the winter, it may freeze, making it more difficult to dry. To prevent your laundry from freezing, add a little salt at the end of the wash while rinsing. 21. Removing sweat stains Mix 4 tablespoons of salt in 1 liter of hot water and wash the item in this solution. 22. Removing blood stains Soak the item in cold salt water, and then wash it in warm water with soap, then boil the laundry. Only cotton, linen or other natural fabrics that can withstand high temperatures can be boiled. 23. Bright colors To maintain the bright color of the fabric, add salt when washing. To refresh the color of the fabric fibers, thoroughly wipe the fabric with a cloth soaked in water with plenty of dissolved salt, and then wring it out. 24. Fighting mold and rust stains Treat the stains with a mixture of lemon juice and salt, hang the item to dry in the sun to bleach, then rinse and dry it. 25. Cleaning the Iron Place salt on a paper towel and wipe the sticky surface of the hot iron. 26. Coloring Fabrics Salt is commonly used in the textile industry, but it can also be used at home on colored items. If the fabric's dye fades or washes off, soak the item in a solution of 2 quarts of water, half a cup of vinegar and half a cup of salt. Then rinse in clean water. If the water turns coloured, repeat the procedure. Use this method only with solid colored items. Housekeeping 27. Repelling Ants Sprinkle salt on the threshold, on the windowsill and in places where ants appear. 28. Putting out a fire on the stove Keep a box of salt near the stove or oven, and if the grease starts to burn, you can easily put out the flames with salt. Do not extinguish the flame with water. 29. Preserving picked flowers If you add salt to water, the flowers that will stand in it will stay fresh longer. Aspirin and a pinch of sugar have the same effect. 30. Bouquets of artificial flowers You can make beautiful bouquets from artificial and dried flowers; salt will help with this. To conveniently arrange flowers in a vase, you can pour salt into it and add a little water. As the salt begins to dry, it will harden and the flowers will remain in place. 31. Candle drips If you soak a candle in very salty water for several hours, then dry it well and light it, the wax will not drip too much. 32. Wall Repairs To seal nail holes or cracks in drywall or plaster walls, you can make a paste of 2 tablespoons salt, 2 tablespoons cornstarch, and 5 tablespoons water. 33. Grass on Decks If you want to get rid of grass that appears between the bricks or blocks of the deck floor, carefully fill the cracks with salt and then spray with water or wait until it rains. 34. Ice on sidewalks To prevent the paths around your house from being slippery in winter, you can sprinkle them with salt. However, this method should be used very carefully so as not to harm plants and animals. The salt causes the ice to melt but ends up in the soil and on your shoes. Many cities have already stopped using salt during icy conditions and are replacing it with regular sand. 35. Kebabs When cooking meat and vegetables on the grill, so that the coals do not produce too much heat, you can sprinkle them with salt. Usually liquids are used: wine, beer, water, but the liquid cools the coals and the fire loses its heat. Salt reduces the amount of flame and smoke without cooling the coals. Carefully pour salt directly onto the coals so as not to over-salt the dish itself. Personal Hygiene 36. Extending the Life of Your Toothbrush Before using a new toothbrush, soak it in salt water to help it last longer. 37. Brushing your teeth Mix 1 part iodized salt and 2 parts baking soda, and then brush your teeth with this mixture. The same mixture, but dissolved in water, can be used to rinse the mouth. 38. Getting rid of sores in the mouth Boils in the mouth can be treated with a weak salt solution. Rinse your mouth with the solution several times a day. 39. Treatment of bee stings Immediately after a sting, apply a moistened pinch of salt to the wound to relieve pain and swelling. 40. Treating Mosquito Bites A salt water compress can help treat mosquito bites. You can also lubricate the bite areas with olive oil and salt.' /> 1

Antifriction properties, taking into account wear resistance, run-in, wear of the mating part and other factors, are optimal for malleable cast iron with a perlite-ferritic structure, including 70 - 80% pearlite. Such cast iron has not only high wear resistance, but also due ductility in some cases. The coefficient of friction of pearlitic ductile cast iron on steel is equal to liquid friction 0.05 - 0.10 and thin friction 0.30 - 0.45. GOST 1585 - 57 provides for special grades of antifriction ductile cast iron (see section “Wear-resistant and antifriction cast irons”) .

The structure of castings is determined by the chemical composition of cast iron and the technological features of its heat treatment. The mechanical properties of gray cast iron depend on the properties of the metal matrix, the shape and size of graphite inclusions. The properties of the metal matrix of cast iron are close to the properties of steel. , which cannot be canceled out by low strength, reduces the strength of cast iron. The fewer graphite inclusions and the higher their dispersion, the greater the strength of cast iron. Graphite inclusions cause a reduction in the tensile strength of cast iron. Graphite particles have almost no effect on the compressive strength and hardness of cast iron. The property of graphite to form lubricating films causes a decrease in the coefficient of friction and an increase in the wear resistance of gray cast iron products. Graphite improves machinability.

The charge is selected so as to obtain the required chemical composition of cast iron, depending on the purpose of the castings. When compiling the charge, possible changes in the composition of the cast iron during smelting are also taken into account. They lie in the fact that during the smelting process, contact with fuel changes the amount of carbon in the cast iron, the sulfur content increases, and partial oxidation of the silicon and manganese contained in the cast iron occurs. As a result of reducing the silicon content, the release of graphite decreases, and the cast iron is bleached, i.e., in the outer layer of the castings, carbon remains in a chemically bonded state with iron in the form of very hard cementite.

wedding ' alt='Weddings by year. Green wedding Marriage day. This is the very first anniversary. It is the wedding day itself and the starting point for new anniversaries. The green wedding is celebrated during the first year after the conclusion of the marital union every month on the wedding day. Usually only flowers are given as a gift, especially paying attention to how long they will last. The symbol of this anniversary is myrtle leaves in a wedding wreath, which the bride weaves for herself on her wedding day. — 1 year — Calico wedding or Gauze wedding First anniversary of family life. On this day, the young wife puts on a chintz dress and the spouses give each other chintz handkerchiefs. — Year 2 — Paper wedding The second year is a test of patience and tolerance in a young family. Very often, on the second anniversary, a baby appears in the family, and it is very important to be kinder to each other in order to build a friendly and strong family. Paper is a symbol of fragility, so it depends only on the husband and wife whether they can maintain the fragile balance of the marriage. Guests give books with tips, recipes, beautiful paintings, and photo albums as souvenirs. — 3 years — Leather wedding The family seems to be strong, but changes are still happening in it, relationships continue to change like skin. For this anniversary, try to give genuine leather products that will serve young people for a long time: bags, purses, folders, belts. — 4 years — Wax wedding On the festive table, flickering lights should be a mandatory attribute, and beautiful candles as a gift. As a test of the marital relationship, on the Anniversary Day, a paired candle is lit and should remain in the room throughout the day. How many hours does it stand without going out, how many happy years will the husband and wife spend together. — 5 years — Wooden wedding A tree symbolizes the strength of family relationships; it is no longer chintz, paper or even leather. On this day, guests bring the spouses wooden dishes, spoons, boxes, and small pieces of furniture. The spouse himself must make some kind of wooden craft for the house to prove that he has not forgotten how to work with his hands. And the wife, in turn, will cover this craft with varnish as proof of her feminine compliance. — 6 years — Cast iron wedding Another crisis in marital relations. Cast iron, despite its external strength and weight, is a very fragile metal that can crack from any blow. The relationship between young people, despite a considerable period of time, must be maintained, just like the fire of the family hearth. Guests can give cast-iron pots and frying pans, and the wife must bake some family specialty in a cast-iron dish to prove her worth as the mistress of the house. — 7 years — Copper wedding The first noble and confident anniversary. And although copper is not such a strong metal, it is still noble. Spouses exchange copper coins to make happiness ringing. - 8 years - Tin wedding The strength of the family increases over the years, so tin becomes a symbol - a strong but flexible structure. On this anniversary, it is customary to give: tin products, such as trays, baking trays, baking dishes, as well as kitchen utensils and household electrical appliances. All this adds respect to the owner of the house. - 9 years - Earthenware wedding No one argues about the strength of the family anymore. She's stronger than ever. Therefore, for the anniversary, faience cups are given as gifts, which attract with their beauty. In addition, these cups are a symbol of a close-knit and friendly family (you can give sets), which fills its family cup with prosperity. The best gift for spouses on this day is earthenware and crystal products. — 10 years — Pink wedding The symbol of the decade is roses, which are given to spouses so that their life will be beautiful and bloom like roses. — 11 years — Steel wedding The countdown of the new decade of family life shows that relationships have hardened, become stronger and stronger. It is customary to give souvenirs made of steel, as well as various power tools. — 13 years — Lace wedding or Lily of the Valley wedding Life goes on as usual and weaves its laces. On this day, spouses are given lace napkins, tablecloths, and openwork items knitted from fine wool. On this anniversary, you can give each other lilies of the valley, as light and tender as your love. — 14 years — Agate wedding Every year, relationships acquire new colors, the family hearth acquires more and more new colors, like the agate stone itself, known for its various forms. It is customary for spouses to give items made of agate or ivory. - 15 years - Glass wedding or Crystal wedding This anniversary is the personification of the purity and clarity of family relationships, the cloudless happiness of two loving people, which is so fragile that it can break at any moment. This is more of an anniversary of faith in yourself and family. On this day it is customary to give gifts made of glass. — 17 years — Tin wedding (practically not celebrated) — 18 years — Turquoise wedding (practically not celebrated) — 19 years — Krypton wedding (practically not celebrated) — 18 years — Turquoise wedding The brightness of turquoise symbolizes the end of all difficult and crisis situations, which tormented families in the second decade of its existence. On this anniversary, turquoise jewelry is given as a gift. — 20 years — Porcelain wedding On a new family anniversary, the festive table is served with new porcelain dishes, which show the increased (compared to a earthenware wedding) family wealth. Porcelain is also given as a gift on this day. — 21 years — Opal wedding (practically not celebrated) — 22 years — Bronze wedding (practically not celebrated) — 23 years — Beryl wedding (practically not celebrated) — 24 years — Satin wedding (practically not celebrated) — 25 years — Silver wedding Having lived together for a quarter of a century is already a lot! Silver as a noble metal is a symbol of a beautiful and strong family union. It is customary to celebrate a silver wedding with all relatives and friends. The couple exchange silver rings and subsequently wear them along with their wedding rings throughout the anniversary year. Guests bring gifts of silver dishes and cutlery. The husband wears a dark suit, the wife wears a silver-gray outfit. — 26 years — Jade wedding (practically not celebrated) — 27 years — Mahogany wedding (practically not celebrated) — 29 years — Velvet wedding (practically not celebrated) — 30 years — Pearl wedding Pearls are a symbol of impeccable family relationships, since real pearls never fades. And 30 years are like 30 pearls, strung on a thread of time. On this day, the husband presents his wife with a pearl necklace. This gift is a kind of reminder of the tears that were shed by the wife during family troubles; the husband seems to be asking for forgiveness for his unfortunate words and actions. - 31 years old - Dark wedding (practically not celebrated) - 34 years old - Amber wedding Amber is a magical stone, it must lie for several centuries to become what it is. So the family becomes exemplary for this anniversary. Almost perfect. Anniversary gifts can include amber jewelry. — 35 years — Linen wedding or Linen wedding or Coral wedding The symbol of this anniversary is a linen tablecloth, representing peace, prosperity and home comfort. This anniversary is a glorification of the mistress of the house, who managed to maintain the warmth of the hearth all these years. Linen tablecloths, napkins, bedspreads, towels and sheets are presented as gifts. And also, since the anniversary has another name, they give products made from corals. - 37 years - Muslin wedding (practically not celebrated) - 38 years - Mercury wedding (practically not celebrated) - 39 years - Crepe wedding (practically not celebrated) - 40 years - Ruby wedding Ruby is a symbol of fiery love. It is intended to remind spouses of the feelings that they experienced when they decided to become one family. In addition, this anniversary suggests that the intimacy of the spouses has become blood, since the color of the ruby is so similar to blood. On this day, a wonderful gift for a wife would be a ruby ring from a loving husband. - 42 years - Mother of pearl wedding (practically not celebrated) - 43 years - Flannel wedding (practically not celebrated) - 44 years - Topaz wedding (practically not celebrated) - 45 years - Sapphire wedding The symbol of this anniversary is the fidelity stone - sapphire. It is believed that this stone not only relieves heavy thoughts, but also refreshes feelings and gives strength to fight adversity and illness. On this day, spouses are given jewelry with sapphire. In addition, this anniversary is celebrated with friends who have been with their spouses all these years. — 46 years old — Lavender wedding Lavender is a mountain plant that can withstand even the most difficult natural disasters. Usually they give a bouquet of lavender, whose delicate and strong scent will last for a very, very long time. - 47 years - Cashmere wedding, or Wool wedding Give the spouses clothes made of wool or cashmere, cozy, warm and reliable, like their love. — 48 years — Amethyst wedding The husband gives his wife an amethyst jewelry as a sign of marital fidelity. This stone symbolizes honesty and clarity of intentions, which over 48 years of marriage should have been finally determined. — 49 years — Cedar wedding This tree is as strong, reliable and warm as your relationship. It is customary to give fans made of wood, as well as various carved boxes. — 50 years — Golden Wedding It falls to the chosen few to live to see this anniversary, and therefore this anniversary is celebrated solemnly and magnificently. Relatives and friends are invited, always children, grandchildren, great-grandchildren, friends and colleagues. The main gift for a golden wedding is new wedding rings to replace those given 50 years ago. After all, gold could wear out over the years, so old rings are passed on as family treasures to unmarried grandchildren and great-grandchildren. On the day of the 50th wedding anniversary, you can arrange a second wedding ceremony. — 55 years — Emerald wedding May the brightness of feelings not be lost over the years! A bright green emerald stone should confirm that the spouses still have strong emotions for each other. On this anniversary it is customary' /> wedding

carried out by a connected laboratory. Its industrial base and strict quality control throughout entire production periods satisfy all the requirements of product consumers and GOST. All products undergo strict heat treatment. Metal cutting Pipe making Mohs hardness Weather and folk signs Works of the children of our employees Periodic table of Dmitry Ivanovich Write us a letter Moscow “Monolith” ® ™ tel. fax + 7 (499) 902 - 17 - 62; federal mob. tel. + 7 ( 916 ) 697 — 57 — 14 E — mail : [email protected]

Molybdenum is an intense carbide-forming element and inhibits graphitization. The strength and hardness of cast iron increases with increasing molybdenum content. With increasing molybdenum content, the strength of cast iron increases linearly : 1% Mo increases the strength by approximately 1 kg/mm 2 at any degree of eutecticity from 0.8 to 1.0. The impact strength does not increase, and even increases slightly. Molybdenum increases the strength of cast iron at elevated temperatures. Maximum strength is achieved at a content of 1.9% Mo, then a drop in properties occurs due to the formation of ledeburite. The increase in hardness due to increased homogeneity is not accompanied by a deterioration in machinability. Molybdenum also increases the wear resistance of cast iron and its growth stability.

The chemical composition and properties of high-strength cast iron are regulated by GOST 7293 - 85 and are marked with the letters “B” - high-strength, “H” - cast iron and a quantity indicating the ordinary value of the tensile strength of cast iron. For example, HF 100 is high-strength cast iron, the tensile strength limit is 1000 MPa (or 100 kg/mm 2).