It is impossible to achieve the desired welding quality without the correct choice of electrodes. A clear understanding of the market will help you avoid mistakes. It is necessary to know about the types of products from different manufacturers, recommendations regarding the use of a specific brand, and the principles of marking electrodes.

- Consumable and non-consumable electrodes

Explanation of the designations of the electrodes used for welding.

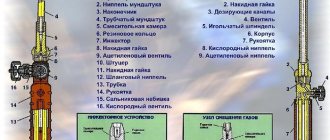

The markings on the electrode pack are very important. This determines whether the selected welding materials are suitable. Let's look at the decoding of the notation. Designations are applied in accordance with GOST 9466. The marking has the form of a simple fraction, with a numerator and denominator.

E50A - This is a type of electrodes used for manual arc welding. It is determined depending on the material that needs to be boiled. For ordinary ferrous, heat-resistant and structural steels, the type is taken from GOST 9467. The number in the index that follows “E” indicates the temporary resistance ( σпч ). For a weld seam welded with E50 type electrodes, the temporary resistance is 50 kgf/mm2 . Next comes the stamp - “UONII 13/55” . The brand carries information about the metal from which the electrode core is made. The brand is selected based on the metal being welded. You can familiarize yourself with the list of main brands and their areas of application.

Let's go back to the labeling. After the mark comes the diameter of the electrode, indicated in millimeters - “4.0”. After the diameter comes the letter “U” - this place indicates the purpose of the selected electrodes.

What is the purpose of electrodes?

Differences in the coating and core material of the electrodes are determined by their purpose. Some are used for welding carbon, low-carbon, and low-alloy steels whose tensile strength does not exceed 600 MPa. This group is conventionally designated by the letter - U.

The second group are materials used for medium-alloy steels whose tensile strength exceeds 600 MPa. Symbol – L.

The third group includes welding materials used for welding work with high-alloy steels. The properties of which are aimed at solving certain problems. They are designated V.

The next group is used when welding heat-resistant alloy steels. Denoted by T.

And the group closes, which also includes highly specialized welding materials, namely those used for surfacing metal products with special characteristics. Designated - N.

The last designation is “D”.

The thickness of the coating is indicated here. They come in 4 types:

- “M” – with thin.

- “C” - with average.

- “D” – with thick.

- “G” – especially thick.

Each type includes electrodes in which the ratio of the diameters of the rod and coating corresponds to the following conditions:

- For thin – D/d ≤1.2

- For medium D/d ≤1.45

- For thick D/d ≤1.8

- For particularly thick D/d ≥1.8

Now let's go down. We see “E 43 2(5)” - this is the index of the weld metal (welded metal). Most often it is taken from GOST 9467, 10051 or 10052. According to the index in GOST, you can see what minimum properties the seam will have. Next we see the letter “B”. It indicates the type of electrode coating.

Types of coverage: how to determine which one to choose?

Coating of electrodes is possible in the following options:

- Acid coating – A

- Basic coating – B

- Rutile coating – R

- Cellulose coating – C

In this regard, it is impossible to say which one is better and which one is worse: they are all designed for different types of work, as well as conditions of use. Therefore, it is impossible to unambiguously answer the question which electrodes for welding will be better. As a rule, it is necessary to use them to form a strong weld seam in critical structures.

Next we see the number “1”.

This is a designation for the positions in which you can cook.

«1» – for any provisions;

«2» -for any, with the exception of top-down;

«3» – vertical from top to bottom, horizontal, bottom;

«4» – lower position and boat position.

And the number “0” ends.

This is the type of current and polarity. This figure is taken from the table below. Indicates “0” that welding must be performed on direct current with reverse polarity connected. Having analyzed the transcript, we will dwell in more detail on each point.

What are welding electrodes coated with? What is this coating?

Coating is a special coating that is designed to protect molten metal from the negative effects of oxygen. It creates a gas shell while the core melts.

Coatings are divided according to the functions they perform: gas-forming and slag-forming

functions.

Gas-forming

components create protective gases and an ionizing atmosphere.

Slag-forming

include elements that promote deoxidation, refining, alloying of the seam and the base metal, increasing the bonding and plastic properties of the seam. During welding, a layer of slag is formed in the weld pool for protection.

Types of coverage: how to determine which one to choose?

There are 4 main types of electrode coatings used in manual arc welding. Let's deal with each of them one by one.

Let's talk about the main component. Rutile

- a natural mineral that, by forming a protective gas shell, creates a weld pool. Welding with materials such as rutile is characterized by high stability.

Ignition of the arc occurs without problems even for beginners. That is why they are often used in installation. The seam is obtained with small scales, with a uniform casting structure over the cross-section.

The following advantages of working with this coating can be highlighted:

- It is permissible to use both alternating current (AC) and direct current (DC);

- Easy to ignite using both new and secondary arc ignition;

- Not demanding on the cleanliness of the product surface. Can be used on rust, undried edges of the product, scale and even paint;

- The metal practically does not splash.

The disadvantages include:

- There is not a large range of materials that can be used with;

- In the weld pool there is active mixing of slag and metal, which makes it difficult to distinguish where the slag is and where the metal is. This leads to slag inclusions;

- The presence of moisture in the coating leads to a defect in the form of pores. This is an important point that is worth paying attention to. Proper storage and calcination before welding is necessary.

Acid coating: application features

Good to use, but in an open space, otherwise it will not be safe for the welder. The advantage is definitely that the slag is easily separated.

Acid coating requires low idle voltage. Currently they are rarely used.

Basic coating

They have become very widespread, one might even say ubiquitous, due to their versatility. Their coating contains fluorine and calcium. During welding, the coating elements evaporate, protecting the molten metal. The bath's gas shield actually consists of carbon dioxide.

They are used when using direct current; as a rule, the polarity is reversed.

When melted, the coating removes harmful impurities from the weld such as sulfur (S), phosphorus (P) into the slag. This helps to increase strength, increase ductility, and reduce fragility. As a result, there are no cracks.

Arc ignition is worse than that of rutile ones, but their range of application is wider. The arc burns less stably compared to rutile. This is due to the content of fluoride compounds that reduce ionization.

Welding should be carried out only on a well-prepared surface. There should be no moisture or dirt. Otherwise, we will get a large number of pores in the weld metal. Another reason for pores is an increase in the length of the arc. The protection dissipates and gas from the atmosphere enters the weld pool.

Cellulose coated electrodes

The use of welding materials with this type of protection is less and less. This is due to the fact that welding with them hydrogenates the weld seam. The strength of the connection decreases and pores appear.

More than half of the coating consists of organic substances and during welding provides strong gas formation. They cook in all positions; it is even possible to carry out the process from top to bottom.

The surfaces may not be well prepared; this will not actually affect the quality of welding. This has something in common with rutile coating.

Labeling rules

A specific scheme is used to mark all types of existing electrodes. According to its construction, the first digit determines the type of electrode, the next position informs about the brand of the product, and it is followed by the diameter designation.

The fourth in this scheme is the code that determines the purpose, and the fifth is the thickness of the coating. The sixth is a code that characterizes the welding seam or metal deposit. Below you can read information about the coating of the rod. The eighth position provides information about the spatial location of the electrode during welding, and the ninth - about the voltage and type of current.

For a better understanding, it is worth considering a specific example:

The first four characters “E46A” carry information about the type of electrode rod. It deciphers like this:

- E – intended for electric arc welding;

- 46 – unit of arc rupture resistance according to GOST 9467-75 standards;

- A – improved rod class.

The next index “U” in the marking means that the electrode can be used in work with alloy and low-carbon steel. “D2” is assigned to the second group of products based on coating thickness.

The marking in the denominator 432(5) is a parameter of the weld joint that forms the weld. “B” is the main type of electrode coating. The position of the electrode during work corresponds to the value “1”. Current mode “0” is the reverse polarity of direct current.

Below is a table about the meaning of metal rod coating markings:

| Coverage type | Marking according to GOST 9466-75 | International ISO marking | Marking according to the old GOST 9467-60 |

| sour | A | A | P (acid ore) |

| basic | B | B | F (calcium fluoride) |

| rutile | R | R | T (rutile (titanium)) |

| cellulose | C | C | O (organic) |

| mixed types of coating | |||

| acid rutile | AR | AR | |

| rutile-basic | RB | R.C. | |

| mixed other | P | S | |

| rutile with iron powder | RJ | R.R. | |

What should you keep in mind when you are about to start welding?

Before you begin, you should carefully inspect your home welding electrodes and determine:

Is there any mechanical damage? If they exist, then this is an obstacle to further actions, the welding arc will not be stable, and the protection of the molten metal of the bath will not be of high quality.

Humidity: Should be minimal. The electrodes will only be dry if they have been stored correctly. Don’t worry if this point has become an obstacle to further action – it can still be fixed. To do this, you need to dry them in a special oven or, if you are at home, in a regular oven.

Another option , which will require more time, is to leave them in a warm, not humid place. So, dry welding materials will provide you with a strong weld and reduce the risk of such a defect as gas pores.

The shelf life of electrodes used for manual arc welding is determined by the manufacturer, but as a rule it is without restrictions. The main thing is the storage conditions, which are also given by the manufacturer. In a closed package sealed in plastic film, the electrodes will be nothing even after 10 years.

Packing

The following can be used as packaging containers:

- plastic boxes;

- boxes made of metal alloys with a sealing function;

- carton boxes; to preserve the rods, this type of container is packaged in polyethylene or shrink film;

- boxes or packs of cardboard are also wrapped in packaging or sack moisture-resistant paper;

- For increased tightness, it is possible to pack materials in bundles wrapped in paper and then packed in polyethylene.

Packs and boxes have the following packaging forms: 1 kg; 5 kg. several packaging options for them

- boxes made of container or corrugated cardboard;

- fiberboard boxes;

- wooden boxes;

- reusable closed-type metal box pallets;

- large wooden boxes.

Each parameter of consumables affects the size of the package and its capacity. Also, all this also depends on the manufacturer, who independently shapes the container.

Important! When purchasing welding electrodes, it is necessary to accurately calculate the number of rods that will be needed to carry out a certain amount of work. If the required value is significantly exceeded, a certain number of electrodes will remain unclaimed. They will have to be stored for a long time and may absorb moisture. Then you will have to carry out calcination procedures; the number of calcinations is limited. Shelf life depends on storage conditions.

[ads-pc-4][ads-mob-4]

Types of electrodes and how to choose them for welding at first?

Among the most popular and available for welding are the following brands of electrodes:

- OK-46

- MR-3

- SSSI 13/55

- TsL-11

Let's consider each type in detail.

TsL-11

Electrodes of this brand are used for stainless steel, the so-called stainless steel. They are used in products that will operate at temperatures not exceeding 250 °C.

In everyday situations, they help the welder to achieve a seam with fine flakes, and to obtain a transition without fractures between the edges of the product and the seam. The slag itself has a small volume, so it will not be difficult to remove it. Please note that they have basic coverage.

Rutile MP-3 and OK -46

These electrode brands are rutile. It should be chosen if you work with carbon and low-alloy steels. The undoubted advantage of the chosen model is that it can be used with both direct and alternating current. The most widely used welding electrodes are the MP-3 brand, especially in everyday life. At the dacha or in the garage, they are best used for welding.

The arc is stable despite the quality of preparation of the product and the cleanliness of the metal surface. Another plus is that the metal practically does not splash. They have absorbed all the advantages of their coverage while at the same time reducing the negative factors.

UANNI 13/55

This is an extremely commonly used and very popular electrode. Unlike the previous type, the main coating is used. They are used in the same way as the previous grades for low-carbon, low-alloy steels. This option is also good because it is used for elements of critical products and structures. This is due to the characteristics of the weld seam formed:

- It is distinguished by its special plasticity;

- The seam is durable and can withstand heavy loads;

- When applied, it is not afraid of cold;

- Voltage drops are not critical.

When working with UONII 13/55, special rules must be observed

These rules apply to the preliminary preparation of materials: they must be clean from rust, soil, oily contaminants, and moisture. If the workpiece has oil, water, rust stains or drops, pores will appear.

And now more about polarity

If work is carried out on direct current (which most often happens), then the question may arise: what polarity should be connected - reverse or direct? How to do it?

We partially paid attention to the first question when we considered the types of coatings and types of electrodes. So be sure to check this when you get started.

Direct polarity connection diagram: ground is connected to the “plus” of the inverter, and the electrode holder is connected to the “minus”.

When the connection is made according to the reverse polarity scheme, as you understand, everything is the other way around: the ground cable is connected to the “minus” of the device, the “plus” is connected to the holder.

The question arises, what is the difference between these two connection schemes?

The difference when connecting is that with reverse polarity, more heat goes into the electrode metal. This reduces the heat input into the base metal and the structure is less deformed. When using direct polarity, on the contrary, heat input increases in the metal of the product.

It is often used for welding thick metal or TIG welding. You can read more in this article.

Rutile coating

Rutile is titanium dioxide. In addition to it, the coating contains silicon and oxygen.

Rutile coating is characterized by the following properties:

- formation of a high-quality seam at any spatial position of the electrode;

- stable arc burning;

- minimal splashing of melt and coating;

- possibility of welding on both direct and alternating currents;

- possibility of welding rusty and dirty parts;

- quick and easy ignition of the electrode;

- easy removal of slag.

What electrode diameter should I choose?

This is another question you may encounter. Everything here is quite simple: the diameter will be selected according to the thickness of your welded metal.

Moreover, if the metal is very thin (less than one and a half millimeters), then manual welding (RMW) is most often unacceptable (here we use tungsten electrode welding, semi-automatic or automatic).

In other situations, you can select an electrode. You can see the ratio in the following table:

Coating thickness coefficient

E42A-UONI-13/45-3.0-U D

———————————— E432(5)-B 1 0

Coating is necessary to protect the liquid metal of the weld pool from interaction with the external environment. The coating melts as the arc burns and the rod melts. The thicker the coating, the more protective gas is released. The coating thickness level is indicated in the electrode marking with the letter:

- M - thin.

- C - average.

- G - very thick (maximum possible).

- D - thick.

How to determine the current value?

This is another important question you may have. In general, it should be noted that the current value is always given approximately, in a fairly wide range. This is due to the fact that with different spatial positions, different thicknesses of the product, and the number of passes, it will vary. And it is determined by the welder himself (we can say that this comes with experience).

The main thing is that you feel confident, focus on the controllability of the bathroom and adjust the current so that it is convenient for you to control the welding seam. Indicative figures are shown in the table below:

Read about how to properly adjust the current strength here.

Now you have become acquainted with the main aspects that a beginner should take into account when starting to work on welding seams. Read more information on our information portal mrmetall.ru.

Basic coating

It is known that it contains calcium salts - carbonate and fluoride. Its advantage is considered to be a low hydrogen content. Typical representatives of electrodes with basic coating are UONI products. Their coating ensures a high-quality seam, both in appearance and in technical indicators: ductility, strength, impact strength.

The electrodes do not form crystalline cracks inside the seam, therefore they are recommended by specialists for critical welding operations and for products operated in harsh climatic conditions. They can be used when welding in any position except vertical.