A belt conveyor is a transporting device based on the principle of continuous operation, and the working body is a belt. These types of transporting devices have proven themselves well in various fields of production, agriculture and construction; they can transport various cargoes: piece and bulk.

Belt Conveyor

Transportation of quicklime, slaking waste and fluff is carried out by belt, scraper, bucket, screw conveyors and chamber pneumatic pumps. Lime suspensions (sludge, milk) and water are pumped with centrifugal and plunger pumps.

Belt conveyor device

One of the main reasons for the popularity of belt conveyors is their simple and straightforward design, ease of maintenance and ease of assembly. Let us examine in detail the structure of the belt conveyor according to Fig. 1, which shows a standard general purpose belt conveyor.

Figure 1. Belt conveyor structure

Let's consider all the units in order:

- Tension drum - serves to adjust the tension of the belt; tension is carried out by securing the ram in the required position of the frame;

- The belt is the main working body, which performs two main functions: load-bearing and traction;

- Drive drum - drives the entire structure, the rotating motion is transmitted by a gearbox from an electric motor through a mechanical (gear) or belt drive;

- 5. 6. 7. 8. 9. Roller supports - serve as support for the belt, preventing it from sagging when transporting heavy loads; roller supports also center the belt and prevent it from flying off the drums.

We examined the design of the main components of a standard belt conveyor. Depending on the tasks performed, the structure of the belt conveyor can be simplified or supplemented with third-party units. For example, when transporting over several meters, metal or wood flooring can be used instead of roller supports.

Belt conveyors are often equipped with a loading funnel or similar equipment that facilitates the process of loading various (mostly bulk) cargo onto the belt.

Operating principle and main components of a scraper conveyor

The scraper conveyor is a reliable device designed for the continuous movement of powdery, lump and granular bulk cargo.

Among its advantages are:

- possibility of unloading at different points using several outlet valves;

- smaller (in comparison with a belt conveyor) area required for its installation;

- closed design, which makes it dust-, gas- and waterproof.

Such conveyors are used by enterprises of the agro-industrial complex, metallurgical industry, coal industry, etc.

Operating principle of a scraper conveyor

During the product transport process, only one part of the constantly rotating chain is always involved. Along its entire length, at equal distances from each other, scrapers are placed. They push the load towards the tension station, move it along the bottom of the chute and push it out to the place where the material is unloaded. The web then returns to the top through the drive station.

If the scraper conveyor is horizontal, the product layer may exceed the height of the scrapers. This will not prevent the lower and upper layers from forming a single flow, the maximum possible height of which depends on the factors listed below.

- Product density. If the density is high, then the friction between the layers of material will be insignificant and transportation will be faster.

- External friction. This factor depends not only on the properties of the load, but also on the quality of the walls of the gutter.

- Internal friction. The smaller the product particles, the lower this figure.

Consequently, the speed of movement of the material will be lower near the walls of the trench (due to additional contact with them) and higher in the center of the flow. If a vertical scraper conveyor or elevator is used, the weight of the product must also be taken into account.

Main components of a scraper conveyor

The main components of the structure include: a chute, a drive station, a tension station, a complex of scrapers, a stand, and traction chains.

The gutter consists of a bottom, a cover and two side walls. The chain moves in the upper part, and the load moves in the lower part. As a rule, in vertical or inclined conveyor models, a partition is installed between the chain webs. It prevents the downward part from sagging under the pressure of the mass of the contents. The drive station consists of a sprocket (it sets the blade in motion) and two shafts with bearings. The tension station also has a sprocket and rotates due to the movement of the reverse branch of the web. The tensioning device may consist of automatic compression springs or a lead screw. In the first case, a travel switch is additionally used. The scrapers are mounted on traction chains. They immerse the material and move it at a speed of approximately 1 m/s, located at an equal distance from each other. The stave is connected to the tension and drive sections. It is an intermediate sector with a closed traction mechanism located inside. The traction chains of the horizontal conveyor apply pressure only to the lower part of the structure

Therefore, it is important that the links have flat scrapers and move the contents ahead of them along the entire length of the structure. The speed of transportation and its quality depend on this. LLC "MHM Ukraine" (g

Odessa) is the official representative of 3BHungaria in Ukraine. At your service: individual selection of equipment, delivery, installation supervision, warranty and post-warranty service

MHM Ukraine LLC (Odessa) is the official representative of 3BHungaria in Ukraine. At your service: individual selection of equipment, delivery, installation supervision, warranty and post-warranty service.

Belt Conveyor Operation

The working body of a belt conveyor is a conveying belt. It is driven by a drive drum using friction.

Loading of the transported material occurs on the tension drum (often called the end drum), and unloading occurs in the area of the drive drum. Depending on the type of material being transported, various loading and unloading devices are used that help automate the transportation process.

Rotating brushes or scrapers are installed on belt conveyors intended for transporting bulk cargo.

Types of belt conveyors

Belt conveyors are widely used in various industries, this in turn has led to various modifications, which can now be divided into several groups.

Types of belt conveyors are usually reduced to 4 groups:

- by type of traction organ;

- by type of load-carrying organ;

- by type of cargo transported;

- by type of application.

In this article we will examine in detail two types of belt conveyors, which differ in their scope of application.

According to application, belt conveyors are divided into stationary and mobile .

Properties

This material is subject to high mechanical loads and abrasive effects. And it, in turn, depends on the scope of use. Despite all of the above, tapes are actively used in the food industry, manufacturing, metallurgy, mining, and at the airport. All areas require different tapes.

The first conveyor belts were simple in design and were used to move sacks of grain over short distances. And the covering of the tape was wooden.

The structure of the conveyor belt includes several layers, which we presented in the table.

| № | Layer and description |

| 1. | Working rubber lining. Surface over which cargo is transported |

| 2. | Fabric pad. It is an important element of the tape, which determines its strength and flexibility. |

| 3. | Rubber gasket. It is able to connect the layers of the frame |

| 4. | Non-working rubber lining |

Stationary Belt Conveyor

The stationary conveyor (Fig. 3, a, b) consists of a belt 2, lower 4 and upper working 3 (carrying material) roller bearings, a drive mechanism, a tensioning device 1, a frame, drums 6 and 9, a loading device 7. Rubberized ones are usually used tapes that are produced in widths from 300 to 800 mm. Standard tapes are designed to operate at temperatures from - 25 to + 50 ° C. By special order, tapes are manufactured that are designed to operate at temperatures up to 100 ° C.

Figure 3. Stationary belt conveyors (a, b), roller supports (c, d), tensioning mechanism (e), ejectors (f, g):

a - with unloading through the head drum, b - with an unloading cart, c - grooved, d - straight, f - one-sided, g - two-sided; 1 - tension device, 2 - belt, 3, 4 - upper and lower roller supports, 5 - tension drum, 6, 8 - head and tail drums, 7 - loading device (funnel), 9 unloading cart.

Production of conveyors and components for them

Thanks to new technologies and modern production methods, it was possible to achieve the highest possible performance of conveyors and long service life. Thus, a special tape for transportation may differ in its characteristics and properties. For example, the tape can be made from fabric, cables, rubber, or especially durable raw materials with protection against cuts. The material of the tape, in turn, has its own special characteristics - fire resistance, frost resistance, resistance to chemical acids, and dirt-repellent properties. Such a wide variety of materials and installations makes it possible to expand production tasks and take into account all the capabilities and goals of a particular enterprise.

Mobile Belt Conveyor

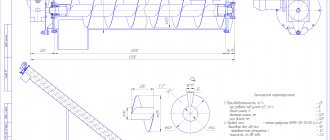

Mobile conveyors (Fig. 4) are used to move quicklime lump lime over a distance of 5-15 m. The conveyor consists of a welded steel truss 4, on which roller supports 3, drive 6 and tension 1 stations, a flexible rubberized belt 5 and a support chassis 7 are installed. , 9 with running wheels 8.

The drive station 6 consists of an electric motor, a gearbox and a drive drum. Tension station 1 includes a tension drum and a tension device in the form of two screws, when the nuts rotate, the drum moves, providing the required belt tension.

Figure 4. Mobile belt conveyor:

- 1, 6 — tension and drive stations;

- 2 — loading funnel;

- 3 - roller support;

- 4 - farm;

- 5 - tape;

- 7, 9 - movable and fixed supports;

- 8 — running wheels;

- 10 - winch.

The working body of the conveyor is belt 5, which goes around the drive and tension drums. The upper branch of the belt 5 is supported by grooved roller supports 3, and the lower branch is supported by flat ones.

The movable support 7 is attached at its upper end to two carriages moving along the guides of the farm. The carriages are moved using a hand winch 10 and a pulley. When the movable support moves along the guides, the height of the discharge end of the conveyor changes.

The mobile conveyor has a design capacity of 90 t/h with a material density of 1 t/m3, a belt width of 400 mm, a belt speed of 1.6 m/s, and a maximum unloading height of 3.8 m.

Equipment Features

We list the most common types of belt conveyors:

- straight. The design is based on a flexible tape supported by roller supports. Capacity can reach 25 thousand t/h, length - 10 km. Used in warehouses, sorting shops, etc.;

- grooved. The base of the belt is a grooved roller support made of steel or aluminum. Such conveyors are widely used in mechanical engineering, energy, woodworking industry, construction, coal mining and waste processing enterprises;

- inclined. The main difference between such conveyors and straight ones is their orientation at an angle to the horizontal. The equipment is used when it is necessary to transport goods up and down. Inclined conveyors are used in various industries, in warehouses and logistics complexes;

- mixed type. One part of such a conveyor is straight, the other is inclined. There are L-shaped and Z-shaped tapes of mixed type. Most often used in confined spaces;

- rotary. The belt of such a conveyor moves along sliders divided into segments. The equipment includes a torque transmission system. The rotary conveyor is used in many industries; it is most widespread in confectionery enterprises;

- telescopic. This conveyor allows you to adjust the length and angle of inclination during operation. To make changes, you do not need to turn off the equipment and free it from loads. A conveyor of this type is relevant for transporting bulk materials in quarries, on river and sea vessels, etc.