Home / Articles / Miter saw for wood: choosing, setting up, making from a grinder and a circular saw

18 Feb 2018

Category: Articles

No comments

Miter saws are widely used for large volumes of work with boards, bars and other lumber made of wood or wood-based composite materials. They are electrically driven devices mounted on a flat, horizontal bed for cross-cutting long lumber. Despite the presence of a frame, such equipment is not stationary, since it can be installed anywhere, transported or moved to where cutting needs to be done.

Types of miter saws for wood

The modern market for power tools can offer a large selection of different models of miter saws, which may differ from each other in the following parameters and design features:

- engine type and power, as well as its location;

- the type of gearbox that transmits torque from the engine shaft to the saw blade;

- the presence of an electronic system, which is needed to maintain the speed of rotation of the disk when cutting it into the thickness of the workpiece material;

- the presence of a broaching system that allows you to give the saw blade a horizontal stroke, which ensures cutting wide workpieces;

The broach allows the pendulum with the disk to move horizontally along the slot, ensuring trimming of wide lumber - the standard size of the disks used.

Miter saws are equipped with three types of engines:

- asynchronous;

- collector;

- valve

Asynchronous electric motors are reliable, economical and operate without creating much noise. Their disadvantage is their heavy weight (up to 20 kg) and low power, which does not allow them to reach speeds of more than 2800 rpm. For these reasons, such motors are rarely used in pendulum saws.

Brushed motors are more compact in size and lighter in weight. They can reach speeds of up to 5–10 thousand revolutions per minute, but when the commutator brushes operate, they create a certain level of noise. Such a motor requires periodic maintenance, consisting of replacing the brushes, but despite this, it is used in most models of miter saws.

Electric motors of the third type, valve-type, are the most modern and advanced device, taking all the best qualities of asynchronous and commutator motors. Instead of a brush assembly, they have an electronic unit that allows them to achieve high rotation speeds of the motor shaft. But such motors are quite expensive and are used only on high-quality miter saws in the highest price segment.

Depending on the type of gearbox used, pendulum saws can be belt or gear driven. Of course, gears provide more reliable traction and better torque transmission. But they create additional noise during operation, and when the gearbox fails. This will require complicated repairs at a specialized service center. At the same time, the belt can be easily replaced independently, and it operates almost silently. In addition, the belt drive dampens disc vibrations and extends the life of the bearings.

To obtain a high-quality cut, especially hard wood and viscous composite materials, it is very important to stabilize the speed of the saw blade under load. It is for this purpose that most modern miter saws have a special electronic unit. Electronics are also widely used to create more comfortable working conditions with this tool, namely:

- to ensure a smooth engine start;

- to slow it down when the engine is turned off;

- for various safety interlocks that ensure safe operation of cutting power tools.

The presence of electronics in different models gives them additional advantages, but also leads to an increase in the cost of the miter saw. The more functions this tool has, the more convenient it is to work with.

Miter saws with broaching have become increasingly popular recently. Two rods on which the pendulum with the cutting head is attached allow you to move the saw blade to produce a high-quality, even cut of wide material.

Pendulum saws also differ in size and type of saw blades used. The main parameters of the saw cutting element are:

- landing diameter;

- outside diameter;

- number of teeth - the larger it is, the better the quality of the cut;

- disc thickness;

- maximum rotation speed.

All these parameters are printed on the disk itself, in a certain place. To cut thinner workpieces (for example, laminate), you will need a blade with a larger number of teeth.

For specific models of miter saws, you can only use a certain size blade for which the tool is designed

First of all, a good disc

If you are still using the standard blade installed on the saw from the moment you purchased it, which, as a rule, is only suitable for cutting rough boards on a construction site, it’s time to buy a better one, suitable for carpentry work. It is better to choose a blade with a negative rake angle, which prevents the workpiece from lifting during cutting. Look for a 250mm disc with 60-80 teeth, while a 300mm disc should have 80-100 teeth. Such discs leave almost no chips during transverse and oblique cuts.

How to choose a benchtop instrument for your home

To choose the right miter saw, you need to have a good idea of what kind of work you are going to use it for. What matters here is the sawing material, its density, and thickness. It depends on what parameters the tool will suit you best. What criteria should you first of all pay attention to when choosing a miter saw?

Motor power and disc size

Both of these parameters are interrelated. For an engine of a certain power, only specific disc sizes should be used. Today on the market you can find miter saws with power ranging from 800 to 2500 watts. The most in demand are tools with engines of 1.6–1.8 kW, because such saw power will be enough for both a home workshop and for running a small business related to woodworking. More powerful saws already belong to the category of professional saws, and will be quite appropriate for large volumes of sawing timber.

The greater the power of the tool, the larger the diameter of the disk that can be used, naturally matching the diameter of the mounting hole. For home purposes, if you do not plan a large volume of sawing work, the best option would be a saw blade with a diameter of 200–215 mm; for professional use, you need to buy a tool designed for disks with a diameter of 250 mm or more.

Wood cutting parameters

The main indicator characterizing the cut is its width, which directly depends on the thickness of the disc. For valuable timber, it is better to choose thinner discs so as not to waste expensive wood on sawdust. Such discs wear out faster than thick ones, which have a significantly longer service life.

The cleanliness of the cut is influenced by the number of teeth on the disk; it can range from 8–10 to 80–90. The more teeth there are on the disk, the cleaner and higher quality the cut is.

Speed

An important parameter characterizing the operation of a miter saw is the number of revolutions of the saw blade. Modern miter saws are produced with cutting tool rotation speeds from 3200 to 6 thousand rpm. Only by working at high speeds of rotation of the disk can a clean, smooth cut be ensured without splitting off fibers or chipping the lumber. Therefore, in expensive professional models of the most famous brands, this figure is never less than 4–5 thousand rpm.

engine's type

The most practical and affordable option is a miter saw with a commutator motor. Such a motor will provide a sufficient number of disk revolutions per minute without weighing down the entire tool. Indeed, in most cases, miter saws should be able to be transported closer to the place where construction or finishing work is carried out. A pendulum saw with an asynchronous motor can be useful for a home workshop. It has large dimensions, and it is best to install it permanently on a specially made workbench.

It has larger dimensions and heavier weight due to the weight and size of the engine itself

Type of transmission

To avoid the hassle of having to frequently lubricate the gears of the gearbox and monitor the condition of the bearings, it is best to purchase a sawing tool with a belt drive. It will operate more silently, and if it fails (the belt breaks or stretches), it will be enough to simply remove the gearbox cover and replace the belt.

The belt drive is covered under a special removable casing

Rotary device design

One of the determining criteria that should be taken into account when choosing miter saws is the ability to cut workpieces at different angles. For this purpose, the design of the tool has a rotary table, which ensures setting the required inclination of the cut in the vertical plane, as well as a mechanism for rotating the cutting head of the tool to give the required inclination to the saw blade in the horizontal plane. Saws of various designs of rotating system are available for sale:

- without turning the saw blade;

- with a turn to the right at an angle of 45–50o;

- with the disk turning left and right.

The ability to ensure rotation of the cutting head depends on the location of the electric motor on the tool's pendulum. By purchasing a miter saw with the ability to adjust both vertical and horizontal cutting angles, you are purchasing a more functional device that can always come in handy for any woodworking work.

Security systems and additional features

When choosing a miter saw, you should pay attention to some of the nuances of its design that ensure the safety and convenience of sawing work, namely the presence of such elements and components as:

- electronic soft start and braking system, as well as a system that ensures stabilization of the disk rotation speed under load;

- protective transparent casing;

- tool cutting head broaching mechanism;

- table extension, with special supports that slide out along guides for more reliable fastening of the workpiece;

- illumination of the work area, if cutting is intended to be done in rooms with poor lighting;

- laser guidance to ensure precise cutting along the intended line.

Reviews

According to reviews from buyers of miter saws, you should pay attention to such details as:

- possibility of sawing boards with maximum dimensions of 50x200 mm;

- as compact dimensions and lighter weight as possible so that the tool can fit in the trunk of a car;

- acceptable price

Main selection criteria

There are certain criteria based on which you can choose tools for cross-cutting work.

Firstly, before purchasing, you should decide in advance how often the trimmer will be used. The minimum functional set that a very specific model should have will depend on this.

In cases where it is intended to be used rarely at home, you can opt for a device with a minimum set of functions. And, on the contrary, when you plan to use this mechanism frequently, it is better to buy a professional model with a wide range of options.

Secondly, the device you purchase must be safe. Thus, the presence of a protective casing on the circular saw that covers the disk during end cutting will ensure safe working conditions.

You should estimate the total weight of the wood trim and its dimensions. If these indicators are too high, it will be difficult for the user to work with such a tool.

How to use the tool

Any newly purchased saw, regardless of the model and manufacturer, requires adjustments, as well as a tool that has already been in use, if the cutting accuracy is impaired. This procedure is performed as a type of maintenance on a complex tool designed to perform precise work operations. Setup operations include:

- adjusting the fit of the side stop to the surface of the turntable; it may have burrs, burrs, or an uneven surface that need to be cleaned and the bottom surface of the stop needs to be ground in with sandpaper;

- aligning and securing the stop on the frame strictly perpendicular to the cutting line using the small play provided in the mounting holes of this element;

- elimination of play of the turntable in the place where it is fixed by the rod;

- adjustment of the perpendicularity of the vertical cut, as well as the cut at an angle of 45o;

- adjusting the tension of the return spring so that when lowering the pendulum by the handle, you do not use excessive force, leading to deformation of the tool structure and disruption of the cutting accuracy.

The procedure for performing work on setting up a miter saw is presented very clearly and in detail in the following videos.

Setting up a miter saw - video

How to adjust the degree of inclination of the cutting head - video

Things you'll need

- Scrap a piece of wood

- Phillips screwdriver

Mark a straight line on a piece of wood with a pencil. Place the wood on the cutting table under the saw blade.

Lower the miter saw handle until the blade is to the left of the line. Move the piece of wood from side to side as necessary to align the blade with the line.

Turn on the laser on the saw handle. Notice where the laser beam hits the tree. The beam must be on line. Locate the adjustment screw on the top of the laser unit next to the thumbscrew.

Loosen the screw 1/8 turn using a Phillips screwdriver. Turn the thumbscrew in any direction with your fingers to align the laser beam with the line on the wood. Tighten the adjustment screw when the beam is aligned with the line on the wood.

Locate the adjustment screw at the front of the laser if the beam is at an angle to a straight line. Turn the screw 1/8 turn left or right using a Phillips screwdriver until the beam is parallel to the line on the wood.

Source

If the saw does not turn on - typical malfunctions and repairs

A miter saw, like any mechanism operating under large dynamic loads, is susceptible to defects and malfunctions. Among the most common breakdowns of this tool are the following:

- combustion of the motor (rotor or stator), the cause of which may be the incorrect choice of cutting speed and saw blade feed, or the use of an unsuitable blade for cutting a certain material - all this leads to overload of the electric motor and its combustion;

- wear of the electric motor rotor gear or gear wheels;

- wear of brushes of an asynchronous motor;

- loose or broken drive belt.

It is better to entrust all malfunctions related to the electric motor to professionals, since repairs will require both special equipment and knowledge of the structure and operating principle of electric motors. You can independently replace the worn commutator brushes of an asynchronous motor or change the gear belt.

Now get to the corners

Make sure your new blade is positioned exactly at right angles to the machine table. Using a proven square, place it on the saw table and move the ruler to the plane of the disk without touching the teeth (photo at the beginning). The machine manual explains how to adjust the stops. Perform these operations, ensuring that there is not even the slightest gap between the square and the disk. After this, set the pointer to the zero division of the inclination scale. Repeat this procedure to fine-tune the 45° tilt (Photo A).

Trimming from a grinder

Technical characteristics of a cross-cutting machine with a broach, assembled by yourself:

- disk revolutions - 4500;

- cutting length - 350 mm (much higher than that of a middle-class factory tool).

Types of miter saws

There are several types of miter saws (popularly called “miter saws”). Let's get acquainted with these varieties.

With broach

This device is considered the most universal, since the saw can be moved not only around the axis, but also along the cut along the straight line of the mowing line.

Checking the result of the adjustment

The surest way to test the accuracy of a miter saw is to make a 45° bevel on each end of four scraps of the same section and length, and then dry assemble the square frame by tightening the corners with a band clamp. A loose joint at any of the corners means you will need to recheck each step of the setup and readjust the machine again if necessary. Remember that whiskers attract attention. With careful settings, you can make others admire your work.

Characteristic versions of the mechanism

The principle of mobility of cutting units in single-saw machines is implemented by the following types of structures:

- Straightforward. The block moves on a rigid horizontal console, the height of which can be adjusted;

- Pendulum (PME). The location of the disk assembly on the suspensions allows it to move in an arc, lowering and rising;

- Balanced. The saw is located under the table, the knife is raised by pressing the pedal. Number of lifts 10 – 12 per minute;

- Stationary. The workpiece is fed to a fixed rotating wood knife.

Multi-saw installations include trimmers and slashers. On double-sided cross-cutting machines, the side and top sides of a wooden part are processed in one pass.

Pendulum type

Industrial CME (pendulum cross-cutting machine) has the following characteristic features:

- manual or pneumatic feed of the cutting unit;

- mechanized supply of parts;

- adjusting the length of the workpiece by installing stops;

- pneumatic clamp;

- electrodynamic braking.

The design of the manual feed of the DME disk works by ensuring a return to its original position under the influence of a counterweight.

The large radius of the CME installation increases the possible width of sawn timber trimming.

The suspended type of fastening makes it convenient to use the TsME machine in cutting production.

Straight stroke

Serial production of parts of a given size is carried out by a cross-cutting machine with several saw units. The distance between the disks on the wood corresponds to the required size. The lumber is pushed along a bed with rollers onto saws that cut it to size. In one shift, machines of this type process several dozen cubes of wood.

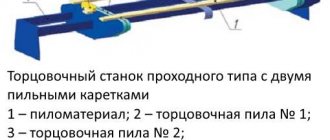

Cross-cutting machine with two saw carriages

Productivity and the accuracy of the angle between the edges of the timber are increased on double-sided equipment for trimming wood.