What is silumin

Silumin is a metal alloy made from aluminum. In general, various aluminum alloys are widely used in industry, just like alloys containing lead.

The formula of silumin is quite simple, the main components are aluminum and silicon, depending on the type of silumin, the silicon content in percent can be from 10 to 20. Moreover, alloys with the addition of silicon are more durable than aluminum with a lead additive.

[edit] Budget alternatives

- Metal-plastic.

The subject beats in all respects, but, unfortunately, it cannot replace it in any area. - Carbon steels.

This refers to cheap brands, where there is a lot of carbon and little actual steel. More expensive, but also more durable. Like the subject, they are quite fragile, no better than the previous point, and not universal. However, there is nothing to complain about the famous black self-tapping screws, cheap and cheerful, except perhaps for their excessive rigidity, which is why the fasteners gradually tear apart softer materials.

Alloy composition

Depending on the type, silumin has a different composition. The most common types are:

- an alloy of aluminum with silicon, with silicon containing about 10%;

- the second type of silumin has higher strength. The alloy composition contains about 20% silicon;

In addition, other aluminum alloys are often used in industry:

- an alloy of aluminum with magnesium and silicon, often used for the manufacture of automobile bodies;

- an alloy of aluminum and tin, used in the production of cast bearings;

- aluminum-magnesium alloys are used in aggressive environments, for example, in the exterior decoration of buildings.

Reviews

Irina Petrovna Usikova, 49 years old, Tula

I used a set of stainless steel pans for a month. Did not like. Food constantly burns, despite the double bottom. Water takes a long time to boil. Returned to traditional aluminum. I try not to think about the harm. It is not yet known what kind of stainless steel Chinese pans are made of.

Olga Aleksandrovna Vishnevskaya, 37 years old, Novosibirsk

I always buy thick-walled aluminum pans. There are simple ones and non-stick ones. Somehow the stainless steel didn't work. I don’t feel any harm from aluminum on my health. My grandmother used it all her life and nothing was wrong, everything was fine.

Did you find this article useful?

Tags: dishes

- Related Posts

- Taifi pink grapes - description and photo of the variety

- Fresh apple juice

- What does long-term abstinence lead to in men?

« Previous entry

Silumin production

Metallurgy is constantly developing, new technologies are emerging, and old technical processes are being improved. There are two ways to obtain the alloy - silumin:

- extract metal for starting materials from ore, but such a mixture will have a large amount of foreign impurities;

- When thermal power plants operate, ash remains as a waste, from which the desired alloy can be made.

In addition, a mixture of aluminum and silicon can sometimes be found in nature, in particular in bauxite ore, but a high-quality alloy suitable for use in production can only be made artificially.

Properties of silumin

Silumin has properties that have made it a very popular material on the modern market. It is quite durable and reliable, and the low cost and ease of manufacturing complex elements often make this material irreplaceable. Let's take a closer look at its properties.

Interesting: Types and equipment of metal slitting

Chemical properties

Silumin alloy is similar in its chemical properties to pure aluminum, it all depends only on the amount of impurities. For example, unlike duralumin, silumin is not susceptible to corrosion in conditions of high humidity, including sea water.

Physical properties

In terms of its physical properties, silumin is often compared to stainless steel, but at the same time it is much lighter. The alloy has the following physical properties:

- the strength of the material is not much inferior to its steel counterparts. It becomes possible to achieve a ratio of low weight and high strength with a lower density of the alloy compared to steel;

- in appearance, silumin is very similar to pure aluminum, the color of the products is gray, and in cross-section - silver;

- the material has high fluidity, which makes it possible to manufacture products of complex shapes from it;

- the melting point of silumin is relatively low, about 700 °C;

- Along with excellent strength, silumin has high fragility;

- silumin is not magnetic.

Mechanical properties

Mechanical properties directly depend on the chemical composition of the alloy and its manufacturing process. The main mechanical characteristics of silumin can be considered:

- fragility, the material may crumble during processing;

- high density;

- low microhardness.

Foundry properties

Aluminum-silicon alloys are excellent for making cast products. At the same time, the material has high specific strength, low weight and resistance to corrosion. An additional advantage is the low cost of the finished product.

Despite the obvious advantages, silumin also has a drawback - increased gas porosity, however, modern technological processes make it possible to eliminate this feature during the casting process.

Composite materials

Street lamps made of materials with different physical properties. Since in the previous examples we clearly saw that none of the existing materials meets all the requirements that we place on street lighting, therefore, in composite structures, as a rule, a steel base and an outer layer of inert polymer materials are used.

Advantages of composite material:

Does not rust. The structural steel base provides the necessary strength and rigidity of the structure. High quality durable coating. A thick layer of outer coating made of polymer materials provides 100% protection against corrosion and oxidation for decades. The coating is resistant to sunlight and retains the color of the product for at least 20 years.

Decorative. In the production of lamps, polymer material allows the production of complex, highly artistic parts, simulating cast iron. High protection against dust and moisture. Street and landscape lamps made of composite materials do not conduct electricity.

Application

The low cost and good characteristics of the material have made it very popular in various fields, from household appliances to aircraft construction.

Aircraft industry

Silumin is widely used in the aircraft industry due to its low weight and increased strength. The characteristics of the material allow it to be used in components and assemblies that are subject to vibrations and strong shocks. In particular, the housing of the indoor unit, brackets and other important elements can be made from it.

Auto and motorcycle industry

Reducing the weight of a car can significantly affect the overall performance; it is not surprising that the ratio of weight and strength of silumin is highly valued here too. Silumin is used for the manufacture of body elements, internal combustion engine crankcases, and in motorcycles it can even be found in piston blocks.

Weapons production

Silumin entered this industry not so long ago, but at the same time it has already become quite widespread. In particular, it is used to make pneumatic weapons, models and replicas of military weapons, airsoft equipment, etc.

Interesting: What is surface hardening of steel

Household products

In everyday life you can also find products made from silumin. Products can be very diverse, ranging from meat grinders, heat exchangers and spare parts for household appliances, to pots, pans and other kitchen utensils.

Plumbing products

Components for plumbing systems located indoors are rarely subjected to severe shock loads. Therefore, silumin is widely used in the manufacture of faucets, adapters, fittings and other plumbing parts.

Other areas

Resistance to corrosion and sea water makes it possible to use the material in shipbuilding, for sheathing various steel structures. Some brands of silumin are used in the space industry.

Rolled steel for street lighting

Durable and inexpensive material to produce (does not apply to forged products).

Advantages of steel:

Strength. The material can withstand significant loads. It doesn't have a high cost.

Disadvantages of steel:

Aesthetics. Difficulty in manufacturing decorative parts. Especially when it comes to garden or park lanterns in the “classic” style. In decorative terms, steel products are much “simpler” than lamps made of silumin and cast iron.

Corrosion. The main problem with steel lamps. Painted, non-galvanized steel corrodes within two to three seasons. This can become a big problem if such lamps are located, for example, in a park, where it is not possible to use special equipment.

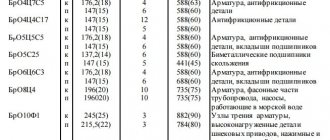

Marking

Silumin can be marked in various ways. The international ISO system imposes certain requirements on alloys. Let's look at some brands as an illustrative example:

- AK 15. The letters “A” and “K” correspond to the components: aluminum and silicon, respectively. The number in turn indicates the percentage of the second most important component in the alloy;

- AL 9. The letter “L” in this case indicates the presence of lithium in the composition.

Sometimes the percentage value of another component, which is included in large quantities in the alloy, may be added to the marking, for example:

AK 15 Ts8. “Ts8” means that the alloy contains 8% zinc.

The Aluminum Association system has been created for the international market. When using this system, a four-digit code is used, in which the first digit is “4” (indicates the alloying system), the second digit carries the serial number of the alloy modification, the third and fourth are the composition of the alloy and information about its purity. In the case of using an experimental casting, an “X” is added to the marking.

In the post-Soviet space, GOST is more often used for marking; in this case, the alloys will also be designated by a four-digit code, for example, 1319. In this case, the number “1” at the beginning indicates the main element - aluminum. The second number indicates the alloying system, and the subsequent ones indicate the grade and modification of the alloy.

Why aluminum cookware is harmful to health

The main advantage of aluminum kitchen items is that they do not harm cooked dishes. The resulting oxide film prevents the metal from reacting with food. If there is a non-stick coating, you can even cook sour dishes.

The main advantages and benefits are confirmed by the following facts:

- good thermal conductivity;

- uniform heating;

- low cost;

- light weight.

It is convenient to place aluminum kitchen items on shelves in large quantities, since due to their light weight they will not collapse.

There are many myths about the dangers of aluminum cookware for the human body, invented by people themselves. The World Medical Organization has proven that the metal used in production is not a carcinogen. Aluminum does not cause cancer. The ingestion of metal into the body is negligible, and only provided that cookware without a non-stick layer is used.

The production of aluminum cookware does not require large financial costs. Therefore, it is accessible to many. The plasticity of the metal makes it possible to manufacture products of various shapes. Other positive properties of aluminum cookware include:

- it does not rust;

- durability;

- dishes are prepared quickly, because... the dishes have high thermal conductivity;

- it is easy to care for;

- light;

- food does not burn or stick in such a saucepan.

If used incorrectly, the metal may darken, ruining the surface. The disadvantage of aluminum utensils is that not everything can be cooked in such utensils. It is also undesirable to store acidic foods. Otherwise, the oxide film is destroyed. The food will have a metallic taste. The oxide film can be restored, but it will not be as strong as it was at first.

You can eat sour foods with aluminum spoons or forks, because... During the meal, the metal does not have time to oxidize.

The list of possible dishes includes navy pasta, rice with vegetables, buckwheat porridge with mushrooms, meat broths and soups. Whether it is possible to cook jam in an aluminum pan is another question. But there is something important for housewives to know: before putting the processed berries on the fire, they are covered with sugar for 40 minutes.

If the jam is not needed for preservation and is cooked for only 5-10 minutes, there is no point in worrying. The main thing is to immediately transfer the finished product into a bowl and not worry about whether aluminum pans are good or bad. The following are especially tasty in such dishes:

- Beef with stewed cucumbers. Ingredients - meat, onions, carrots, vegetable oil, 2-3 bay leaves, cucumbers, salt and pepper to taste. In dishes without chips or cracks, food can be boiled in tomato sauce. If the aluminum pan has scratches inside, replace the last ingredient with chicken broth

- Wheat porridge with pumpkin in milk. Neither cereals nor berries are considered sour ingredients. Dairy products in aluminum containers boil 1.5 times faster than in stainless steel containers. But most importantly, they don’t burn. Only after preparing such dishes are they immediately transferred to containers made of ceramics and glass

- Boiled pasta with vegetables. After heat treatment for 25-30 minutes, up to 45% of the nutrients are retained. These include not only calcium and magnesium, but also vitamins C, A and B1

- Steamed river fish, especially useful for diseases of the gastrointestinal tract. The calories here are 4-5 times less than in smoked meats, so preparing such a dish in a 1-liter aluminum pan means taking the path of healthy eating

It is better to make jam in an aluminum pan from pears. They have less sugar than apples. This means that the volume of acid released is also less. Dishes cooked over a fire are especially tasty in 5-7 liter containers. In an aluminum pan weighing 800 ml it is convenient to cook pearl barley for fishing, and in large containers - from 15 to 20 liters - for camping soups.

What should you not cook in aluminum pans? The “black” list includes products containing alkali. These include beets, carrots, garlic, radishes and celery. The oxide film is also destroyed by parsley, cilantro, lettuce, dates and dried fruits.

So, first, let’s find out what materials aluminum cookware is made from. In food production, pure aluminum and some alloys of this metal are used to make such utensils. They change the physical properties of aluminum, affect heat resistance, as well as its ductility.

As a rule, ready-made aluminum sheets are used in production. These sheets are then stamped into kitchen utensils. Basically, the process uses the method of minting or forging. Of course, not many people, when buying such dishes, pay special attention to the issue of manufacturing. However, it should be noted that forged cookware has greater strength and thermal conductivity.

Those utensils that are made only from aluminum, without adding additional substances, are extremely popular. However, it costs comparatively more.

Myths associated with the use of aluminum cookware:

- The use of aluminum cookware can cause a variety of diseases. This myth is considered the most common and unconfirmed. Be that as it may, there are no studies that address this topic. In addition, it is impossible to know exactly the possible number of aluminum particles that penetrate the human body.

- At the same time, thanks to numerous examinations, it became known that aluminum enters the human body in 2 ways: thanks to the products that we are used to using for heartburn, and thanks to antiperspirant deodorants, which contain aluminum hydroxychloride. Many people use these cosmetics every day.

- They don't even think about what consequences this may have. The effect of this substance on the skin has been officially studied and is therefore considered negative. Therefore, it is wrong to say that aluminum cookware is the cause of a particular disease. Because our ancestors cooked in these dishes and were completely healthy.

- Aluminum cookware is short-lived. Those kitchen utensils that are made of thin metal can, of course, become deformed - this is the basis for this conclusion. To prevent the dishes from becoming deformed, it is necessary to purchase one that has thick walls. It costs much more, has thick walls, but weighs more. Plus, on the outside there is most often a ground wheel. It is very important to choose high-quality kitchen utensils and properly care for them, then they can last for many years.

Aluminum cookware

Now let's list the positive and negative aspects of aluminum cookware. Positive:

- Small price. This also applies to products that are coated with Teflon, stone, and ceramics. Due to the presence of an aluminum base, the cookware is slightly more expensive than similar analogues.

- Increased thermal conductivity. Cookware made of aluminum tends to heat up quickly and also cool down quickly. This makes it possible to save your time, which will be spent on preparing food. As a rule, such containers are used to heat porridge, milk, and boil eggs.

- Aluminum cookware does not rust. And all because it has a thin oxide film that appears on the surface of pots, plates, spoons... This film is very durable, therefore, the food does not come into contact with the metal itself.

- Modern aluminum cookware has a protective coating. It extends the life of the cookware and also reduces the risk of aluminum particles penetrating into the food. Thanks to this move, the likelihood of changes in the taste of food and its aroma is reduced, which often happened earlier when oxidation processes started.

Negative:

- The increased thermal conductivity of aluminum is often the reason why food sticks to the surface. If you don't pay attention to every moment, you can simply spoil the food.

- Although cookware does not require extensive care, removing burnt-on food requires a lot of time. And the use of aggressive detergents spoils the surface or removes its protective film.

- Also, such dishes, as mentioned above, sometimes become deformed. Even if you handle it carefully, there is no guarantee that the original appearance of the dishes will not be damaged over time.

The difference between silumin and other metals and alloys

To understand what is in front of you, silumin or steel, just remember and pay attention to a few simple things:

- color, silumin is distinguished by a gray surface color and a silvery color on the cut. Remembering this, you can easily distinguish it from copper, bronze or brass. The surface of these metals has a yellow or reddish tint;

- magnetic properties, silumin, unlike steel, is not magnetic;

- weight, silumin has less weight than similar steel products.

Interesting: What is resistance welding and its types

How to clean aluminum cookware at home

Immediately after purchasing an aluminum kitchen item, you should boil it by adding 5 tsp per 1 liter of water. salt. If the walls become dark after cooking, rinsing in water with added ammonia will help restore the shine. You can try rubbing the walls with a soft cloth and dry teeth cleaning powder.

If stains appear on aluminum cookware, remove them with an apple cut in half. Dark plaque is removed with a damp sponge soaked in vinegar. Immediately after cleaning, the aluminum object is washed with clean water. Washing with water with dissolved borax at the rate of 1 l/1 tbsp will help restore shine. l. Burnt food can only be removed by soaking for a day.

It is believed that such dishes are quite difficult to care for. Housewives are afraid of damaging the oxide film that forms on the surface. This film has a protective property and appears after a chemical reaction of the metal with oxygen. Factories use electrochemical oxidation, which creates a film with great strength.

Thanks to the oxide film, food does not interact with the metal, so the quality of food heated in an aluminum pan remains high.

The acids and alkaline agents you use when cleaning can damage the protective film. The same applies to powders, brushes, scrapers, and scourers with iron fibers. Due to the fact that conventional products are of little use when cleaning aluminum cookware, women are at a loss when it comes to removing heavy stains.

If food is burnt on an aluminum frying pan, you should simply soak it for several hours or pour water and put it on fire. Baking soda or vinegar, diluted with water, will help deal with blackened metal. Whey also helps with black spots.

It is necessary to wash such dishes carefully, using only soft sponges or flannel cloths. Porcelain or glass cleaners work best. They will help pots and pans regain their lost shine.

During the era of shortages, Soviet women used a more sophisticated cleaning method - boiling silicate glue and soda in an aqueous solution (100 grams per 4 liters of water).

A modern housewife is unlikely to use such methods to restore the original appearance of her favorite kitchen assistant, since you can now buy delicate cleaning products in the store.

Repair of silumin products

Silumin is not resistant to shock loads, therefore, it can be subject to various types of mechanical damage. After impacts or falls, silumin products may develop cracks and chips. The silumin repair technology has some features.

Welding

It will not be possible to cook silumin with conventional electrodes, because... When the temperature rises, an oxide film appears on the surface of the product, preventing the parts from joining. Therefore, welding work must be carried out using tungsten electrodes and specialized solders. Work order:

- the surface of the product is degreased and securely fixed;

- the surface of the alloy is heated to 220 °C, while the part is placed on a steel pad to remove heat;

- a weld is made.

Welding work related to silumin requires certain skills and dexterity; without experience, it will most likely not be possible to complete a weld the first time.

Soldering

Products that are not subject to stress can be repaired by soldering at home. Work can be done with a powerful soldering iron or gas torch. It is advisable to protect the surface around the work area with metal pads. At the soldering site, the alloy is heated to 600 °C. For a high-quality result, special solder (for example, ER4043) and flux (Castolin 190 Flux) are required.

Glue

Aluminum glue is commercially available today; it can be used to repair parts that are not subject to stress. The gluing process is simple:

- the glue is diluted to the desired consistency;

- the gluing area is cleaned of dirt and degreased;

- glue is applied to the parts, after which they are connected and placed under pressure for a day.

Cold welding

Cold welding for silumin is of two types:

- the components are in two tubes, the contents must be mixed according to the instructions;

- a block or rod that is somewhat reminiscent of plasticine.

Before using cold welding, the surface of the part is cleaned and degreased, and excess irregularities and roughness are removed. After preparing the surface, the crack or chip is filled by cold welding and joined with slight pressure. In this case, you should not use a press or put too much pressure on the product.

[edit] Drama

The lock cam is one of the most loaded parts of the structure.

And the weakest link. It is unique for each mortise lock model, so finding the right one on sale is problematic. The tradition of making parts from silumin for consumer goods that break at the most inopportune moment came into fashion in the late Soviet Union in the 70s, after which it was adopted by the Chinese. And when the post-endo-industrial era began, all sorts of shitty materials became top priority as the cornerstone of a consumer society, and the Celestial Empire became a global factory, riveting slag for the whole world. Among other things, silumin turned out to be in great demand.

Actually, you can understand the narrow-eyed: aluminum is expensive, silicon is cheap, due to the fact that it is produced from sand on an industrial scale. The first one slowly but surely oxidizes in air, the second one is corroded by water. If both components are soldered correctly, with careful handling, the Tru-Silumin part will serve you for many years. But why? - the Chinese will ask. It is much more profitable to sell something that will break tomorrow and ruin the manufacturers of quality items by dumping, so that the buyer has no choice and comes to you again. A textbook case of globalist monopoly collusion. That is why any silumin things break a little less often than always; fasteners - nuts, bolts, couplings - cause special hatred. The most memetic are silumin fastening washers for flexible water hoses, installed by greedy owners on the first floors. It is this weak link that is the most common reason for flooding yourself and your neighbors. Silumin is a completely unsuitable conductor, but, of course, it cannot isolate it from current leakage. In a word, Nuva vagina, nuva Rubra Cogorta

. Thus, without the support of an ambivalent element, the aluminum base quickly becomes covered with scale, and silicon, as you might guess, is inexorably washed away by the water element. The ending is a bit predictable.

In this country and in general wherever you can find hard water or an outdated water supply system designed for screw valves and connections (that is, bursting from a water hammer at once when combined with ball valves and other modern graces), the phenomenon blooms magnificently and collects huge profits.

Also, a favorite thing for manufacturers is to make the entire product from normal materials (for example, a door lock), and a small (and very important) part inside from silumin. Outwardly, this is not detected, and after a couple of years the silumin part breaks (especially if there is a load on it), which causes you a lot of problems. And when you come to the store, suddenly this very part will not be there, because (surprise) it is not produced separately. Although, if you have certain skills (and a familiar lathe/milling machine/3D printer who will make you the same part, but from normal material, for a bubble), you can make it even better than it was.