Application area

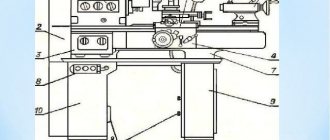

The buyers of the 1M63 screw cutting machine were often machine-building plants with fairly large production volumes. This is due to the fact that the model’s lead screw allows processing of workpieces with a length of 750-10000 mm, depending on the RMC. However, today this screw-cutting lathe is significantly inferior to modern screw-cutting models in terms of productivity and processing accuracy. Purpose: you can sharpen cylindrical and cone-shaped parts, cut threads.

The 1M63 model lathe can be used to work with complex shapes and rounded types of workpieces. An additional purpose is cutting various standard threads. The equipment drawing assumes a very convenient design of the main spindle and the cutter itself; in addition, the following tools can be installed for operation: countersinks, drills, taps and dies. The workpiece itself for subsequent processing can be fixed directly in the chuck or supported by fasteners in the centers.

The main advantages of the machine are attributed to:

- ease of performing any operation;

- uncomplicated design of the machine's key elements;

- the bed of the 1M63 lathe is characterized by sufficient rigidity, and the standards of temperature stability and processing accuracy have also been increased;

- the characteristics of the installation’s engines have high power ratings, which facilitates metal processing;

- the wear resistance of each individual component unit is high;

- thread cutting speed is very high;

- the kinematic diagram is characterized by a certain rigidity, which has a positive effect on the overall performance of the installation;

- The 1M63 package includes electrical and standard mechanical interlocks, which provide maximum safety when performing any operation.

see also

What can be made from rubber bands on a machine?- 3B642 universal sharpening machine

- Rotary lathes

Which frequency converter is better for a lathe?- Vertical boring machine 2e78p

- What is a jointing machine?

- How to weave from rubber bands on a loom

- Maintenance of metalworking machines

- Machine arabesque oriole

- T-shaped shaving machines for men rating

- Lathe 1m63 electrical diagram

| © 2015, All-Stanki.ru - equipment for the production of PVC windows and double-glazed windows | Contents, site map. |

Design Features

The 1M63 has several qualities that distinguish it from other lathes:

- The 1M63 tool holder is designed so that tools made of special alloys and high-speed steel can be used. The tool holder is designed in such a way that it can be adjusted to fit the cutting tool and rotated to the desired angle.

- The 1M63 metal lathe belongs to the class of screw-cutting machines, which are responsible for the ability to carry out work on cutting threads. To do this, a guitar of interchangeable gears is installed. In addition, the gearbox has replaceable gears. By selecting gears, you can change the thread pitch.

- In order for the part to be turned at high speed and at high feed rates, the rigidity of the lower part of the support and the bed was increased.

- The 1M63 screw-cutting lathe is equipped with a special motor and feed box, which make it possible to speed up the movement of the support while turning the workpiece. The feed box also has hardened steel gears.

- When creating the upper part of 1M63, the possibility of movement was also provided. That is why, when installing a standard tool holder, it is possible to turn conical surfaces.

Guitar lathe 1M63

The passport of the 1M63 screw-cutting lathe indicates that the weight varies from 4200-13200 depending on the RMC indicator. Let's also review the main characteristics.

Download the passport (operating instructions) of the 1M63 screw-cutting lathe

A wide range of work performed on turning equipment of this model is ensured by individual design upgrades. Any operation of turning, creating cones and cutting threads is carried out quite easily, without fine scrupulous adjustments. Additional design features of the 1M63 installation are:

- the diameter of the workpieces has been increased to 700 mm;

- the permissible diameter of parts above the caliper is 350 mm;

- the permissible weight of workpieces has been increased, now you can work with parts up to 3.5 tons;

- the diameter of the cylindrical hole in the main spindle is 105 mm;

- there is a function of cross-shaped displacement of the calipers in the longitudinal plane – 5.2, in the transverse plane up to 2 m/minute;

- the power of the power unit was increased to 15 kW;

- The weight of the model is 5750 kg.

Lathe support 1M63

Large dimensions and increased functionality allow the 1M63 model to be installed in large workshops, where the emphasis is on the quantity of products produced. At the same time, the accuracy and efficiency of the machine also remains at a sufficient level.

Lathe 1m63 - Buy 1m63 on Alibaba.com

0 0 Largest diameter of the workpiece above the layer, mm ///0 mm

| Basic technical data of the machine | |

| Accuracy class according to GOST 8-82 | |

| The largest diameter of the workpiece above the layer, mm | |

| The largest diameter of the workpiece is set above the layer, mm | |

| The largest diameter of the workpiece is installed above the recess mm | |

| Maximum length of installed parts RMC mm | |

| Maximum workpiece weight, kg | |

| Forward frequency/spindle revolution, rpm | |

| Number of forward/reverse spindle speeds | |

| Maximum shift of a composite slider, mm | |

| Number of feeds of longitudinal / transverse / compound sliding | |

| Feed limits of longitudinal / transverse / compound sliding (1st row) | 0,064… 1,025 0,026 … 0,38 |

| Limits / number of metric thread pitches, mm | |

| Limits/number of pitches inch threads, threads/inches | |

| Limits/number of modular groove module steps | |

| Limits / number of thread pitch steps, diametric pitch | |

| fast longitudinal / transverse, m / min | |

| dial for longitudinal / transverse diameter on the move, mm | |

| Shift to rotate dial for longitudinal/lateral movement, mm | |

| End element when moving a composite slider, mm | |

| Displacement to rotate the scale when moving the composite slide, mm | |

| Maximum needle movement, mm | |

| Number of electric motors on the machine | |

| Motor main movement, kW/rpm 9999 | |

| High speed motor, kW/rpm | |

| Coolant pump motor, kW |

, Caterpillar repair manual, download service manual

Caterpillar logo

Caterpillar PDF instructions free download

| Heading | file size | Download link |

| Cat 72H PIPELAYER Operation and Maintenance Manual.pdf | 6.8Mb | Download |

| Cat Th460B Telehandler Operation and Maintenance Manual.PDF | 11.8Mb | Download |

| Cat Track Adjustment PDF manual.pdf | 2.5Mb | Download |

| Caterpillar 226B Operators Manual.pdf | 5.7 MB | Download |

| Caterpillar 246C, 256C, 262C, 272C, 277C, 287C, 297C Service Training PDF.pdf | 2.1Mb | Download |

| Caterpillar 247, 257, 267, 277 and 287 MultiTerrain Loaders Service Manual PDF | 6.8Mb | Download |

| Caterpillar 320D L.pdf | 2.5Mb | Download |

| Caterpillar 325D.pdf | 787.5kb | Download |

| Caterpillar 3516C Genset Specifications.pdf | 614.7kb | Download |

| Caterpillar 426 Operation and Maintenance Manual.pdf | 13.4Mb | Download |

| Caterpillar 6D16 Diesel Engine Service Manual.pdf | 4.6Mb | Download |

| Caterpillar 914G.pdf | 2.5Mb | Download |

| Caterpillar 950F Service Manual.pdf | 1.2Mb | Download |

| Caterpillar 980H Wheel Loader.pdf | 1Mb | Download |

| Caterpillar 988H Manual PDF.PDF | 1.8Mb | Download |

| Caterpillar AD55B Articulated Dump Truck.pdf | 1.3Mb | Download |

| Caterpillar C18 Maintenance PDF Manual.pdf | 521.2kb | Download |

| Caterpillar CCM Pc Manual.pdf | 3.3Mb | Download |

| Caterpillar Custom Track Service Manual.PDF | 4.7Mb | Download |

| Caterpillar D10T Service Manual.pdf | 5.1Mb | Download |

| Caterpillar D3K, D4K and D5K Crawler Tractors Bulldozer Operator's Manual.pdf | 3.9Mb | Download |

| Caterpillar Digital Voltage Regulator - Service Manual.pdf | 43Mb | Download |

| Caterpillar Engine Tools Cat 3512 Overhaul Prueba.PDF | 11.9Mb | Download |

| Crawler Excavator 390D Specification.pdf | 106.9kb | Download |

| Additional Caterpillar Excavator for 3066 Engine.pdf | 23.6Mb | Download |

| Caterpillar Forklift GP35N IC Pneumatic Trucks Electronic Sales Guide.pdf | 10.7Mb | Download |

| Caterpillar TM 5-3805-261-10 CAT 130G MIL Operating Manual.PDF | 5.7 MB | Download |

| Caterpillar Troubleshooting 3516B and 3516B Large Displacement Engines for Caterpillar Machines.pdf | 1.7 MB | Download |

| Caterpillar_Marfa_10 February 2010 Operating manual ICL LDH 1250.pdf | 3Mb | Download |

| DLMS Training.ppt | 16.2Mb | Download |

| Caterpillar 772 dump truck.PDF | 1.6Mb | Download |

| Manual de Et Caterpillar.pdf | 1.6Mb | Download |

| Tools 3500 caterpillar.pdf | 1.1Mb | Download |

| Cat 3406 Engine Parts Manual.pdf | 3.1Mb | Download |

Caterpillar Shematics Wiring Diagram PDF Free Download

| Heading | file size | Download link |

| C15 Motor Wiring Diagram Cat.GIF | 39.1kb | Download |

| Cat 3126 EWD Electrical Diagrams.pdf | 6.6Mb | Download |

| Caterpillar 246C Shematics Wiring Diagram.pdf | 926.2kb | Download |

| Caterpillar 3176B and 3406E Wiring.pdf | 263.4kb | Download |

| Caterpillar 3176b, c-10, c-12.3406e Electrical System.pdf | 159.6kb | Download |

| Caterpillar 3412E Industrial Engine Shematics Wiring Diagram .pdf | 1.7 MB | Download |

| Caterpillar 3508B Electrical Wiring Diagram.pdf | 582.9kb | Download |

| Caterpillar 416E Blackhoe Loader Shematic Hydraulic System.pdf | 494kb | Download |

| Caterpillar 422E Blackhoe Loader Shematic Hydraulic System.PDF | 494kb | Download |

| Caterpillar 422E Shematics Electrical Diagram .pdf | 977.1kb | Download |

| Caterpillar 428E Blackhoe Loader Shematic Hydraulic System.pdf | 494kb | Download |

| Caterpillar 428E Shematics Electrical Diagram .pdf | 977.1kb | Download |

| Caterpillar 432E Blackhoe Loader Shematic Hydraulic System.PDF | 719.6kb | Download |

| Caterpillar 432E Blackhoe Loader Shematics Wiring Diagram.pdf | 544.1kb | Download |

| Caterpillar 434E Blackhoe Loader Shematic Hydraulic System.pdf | 719.6kb | Download |

| Caterpillar 434E Blackhoe Loader Shematics Wiring Diagram.pdf | 544.1kb | Download |

| Caterpillar 442E Blackhoe Loader Shematic Hydraulic System.PDF | 719.6kb | Download |

| Caterpillar 442E Blackhoe Loader Shematics Wiring Diagram.pdf | 544.1kb | Download |

| Caterpillar 444E Blackhoe Loader Shematic Hydraulic System.pdf | 719.6kb | Download |

| Caterpillar 444E Blackhoe Loader Shematics Wiring Diagram.pdf | 544.1kb | Download |

| Wiring Diagram Caterpillar 950F Shematics.PDF | 255.4kb | Download |

| Caterpillar 950G Shematic Hydraulic System.pdf | 473.5kb | Download |

| Caterpillar C10 -C12, 3176B, 3406E Engine Wiring Diagram -Schematic, Laminated.jpg | 37kb | Download |

| Caterpillar ELECTRICIDAD APLICADA A EQUIPOS CAT.pdf | 8.2 MB | Download |

| Caterpillar Hydraulic Systems Handbook.PDF | 6.3Mb | Download |

| Caterpillar RENR2237 Shematics Electrical Diagram .pdf | 560.3kb | Download |

| Engine Wiring, Caterpillar.pdf | 603.2kb | Download |

| T-630 CAT Engine Wiring.pdf | 5.1Mb | Download |

Caterpillar Engines PDF service manual free download

Caterpillar G3516 Generator Service Manual .PDF

| Heading | file size | Download link |

| Application Recommendations for Cat 3600 and C280 Diesel Engines.PDF | 891.4kb | Download |

| CAT Truck Engine Programming Manual PDF.pdf | 5.5Mb | Download |

| Caterpillar - Troubleshooting C175-16 and C175-20 Engines for Caterpillar Machines.pdf | 3.6 MB | Download |

| Caterpillar 3176B Engine ESTMG.pdf | 540.6 KB | Download |

| Caterpillar 3208 Diesel Engine SM Manual Copy One.PDF | 150.7Mb | Download |

| Caterpillar 3208 Engine Maintenance Interval .pdf | 927.6kb | Download |

| Caterpillar 3406e, C-10, C-12, C-15, C-16 and C-18 Truck Engine Troubleshooting.pdf | 25.8Mb | Download |

| Caterpillar 3408C and 3412C Marine Generator Sets Service Manual.pdf | 488.2kb | Download |

| Gas generator set Caterpillar 3516 PDF Manual.PDF | 89.3kb | Download |

| Caterpillar Air Intake System.pdf | 473.2kb | Download |

| Caterpillar C11 and C13 Industrial Engine Service Manual.pdf | 1006.4kb | Download |

| Caterpillar C11, C13, C15 and C18 Industrial Engine Troubleshooting Guide PDF.pdf | 2Mb | Download |

| Caterpillar C175-16 Generator Engine Engine PDF.PDF | 60.6Mb | Download |

| Troubleshooting C27 and C32 generator set engines.pdf | 2.2Mb | Download |

| Caterpillar C27 and C32 Generator Set Engine Maintenance Manual.pdf | 20.6Mb | Download |

| Caterpillar Diesel Engine Control Systems.pdf | 587.1kb | Download |

| 1.3Mb | Download | |

| Caterpillar Gas Engine 351B PDF Service Manual .pdf | 4.2Mb | Download |

| Caterpillar Marine Controls Installation Guide.pdf | 6.8Mb | Download |

| Diesel generator set Caterpillar Model D100-6S PDF manual.pdf | 3Mb | Download |

| Caterpillar Sr4 Hv Generators User Manual.PDF | 1Mb | Download |

| Caterpillar SR4B Generators Operation and Maintenance Manual PDF.pdf | 1.3Mb | Download |

| Caterpillar Fuel System Troubleshooting 3116.docx | 289.8kb | Download |

Caterpillar Parts Manual Catalog PDF

Instructions for use

| Heading | file size | Download link |

| Cat C15 Engine Parts.PDF | 2.5Mb | Download |

| Cat D6R TRACTOR Parts Manual.pdf | 16.2Mb | Download |

| Caterpillar 3406C Generator Set Parts Manual PDF.pdf | 7.8Mb | Download |

| Caterpillar 773d Tipper (OHT) Catalog.pdf | 2.5Mb | Download |

| Caterpillar 938G II Front Loader Parts Manual.PDF | 26.2Mb | Download |

| Caterpillar C15 Standby Generator Parts Manual .pdf | 8Mb | Download |

| Caterpillar C9 Industrial engine spare parts. Manual.pdf | 7.4Mb | Download |

| Caterpillar C9 Marine Auxiliary and Generator Engine Parts Manual PDF.pdf | 5.9Mb | Download |

| Caterpillar Catalog Pecas.PDF | 9.6Mb | Download |

| Caterpillar Diagnostic Tools - PDF Catalog.pdf | 3.4Mb | Download |

Caterpillar Inc. is an American corporation that produces the widest range of earthmoving equipment, construction equipment, diesel engines, power plants (powered by natural and associated gas) and many other products

This is one of the largest manufacturers of construction equipment, with more than 480 units located in 50 countries on five continents of the planet. Russia has its own plant in the Leningrad region, in the city of Tosno (since 2000).

CATERPILLAR Construction Equipment

Mini excavators CATERPILLAR

CATERPILLAR 301.8C

CATERPILLAR 301.8C CATERPILLAR 301.6C CATERPILLAR 301.8C CATERPILLAR 302.5C CATERPILLAR 303.5C CR CATERPILLAR 303C CR CATERPILLAR 304C CR 3049 9505 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 CATER 9495 910 CATER 305 910 CATER 9495 CATER 94900 910 CATER 305 949 CATER 305 910 CATER 9495 CATER 305 910 CATER 94900 10

CATERPILLAR backhoe loaders

CATERPILLAR 422E CATERPILLAR 428E CATERPILLAR 432E CATERPILLAR 434E CATERPILLAR 442E CATERPILLAR 444E CATERPILLAR 385C FS

CATERPILLAR straight shovel excavators

CATERPILLAR 385C FS

CATERPILLAR crawler excavators

CATERPILLAR 311D LRR CATERPILLAR 312D CATERPILLAR 312D L CATERPILLAR 314C LCR CATERPILLAR 315D L CATERPILLAR 319D L CATERPILLAR 319D LN CATERPILLAR 311D LRR CATERPILLAR 320D L CATERPILLAR 320D LRR CATERPILLAR 321D LCR CATERPILLAR 323D L CATERPILLAR 323D L CATERPILLAR 323D LN CATERPILLAR 323D SA CATERPILLAR 324D L CATERPILLAR 324D LN CATERPILLAR 325D L CATERPILLAR 325D LN CATERPILLAR 328D LCR CATERPILLAR 328D LCR CATERPILLAR 329D L CATERPILLAR 329D LN CATERPILLAR 324D L CATERPILLAR 325D CATERPILLAR 330D CATERPILLAR 345C CATERPILLAR 365C CATERP ILLAR 385C CATERPILLAR 325D LRE CATERPILLAR 336D LRE CATERPILLAR 345C LRE CATERPILLAR 385C LRE

CATERPILLAR excavators

CATERPILLAR 365C L CATERPILLAR 330D L CATERPILLAR 330D LN CATERPILLAR 336D L CATERPILLAR 336D LN CATERPILLAR 345D CATERPILLAR 345D L CATERPILLAR 365C ES CATERPILLAR 365C L CATERPILLAR 385C CATERPILLAR 385C L

CATERPILLAR wheeled excavators

CATERPILLAR M313D CATERPILLAR M315D CATERPILLAR M315D CATERPILLAR M316D CATERPILLAR M318D CATERPILLAR M322D CATERPILLAR M318D MH CATERPILLAR M322D MH CATERPILLAR M325D MH CATERPILLAR M325D LMH CATERPILLAR 797B

CATERPILLAR Dump trucks

CATERPILLAR 770 CATERPILLAR 772 CATERPILLAR 773F CATERPILLAR 775F CATERPILLAR 777F

Caterpillar 770 mining dump truck

CATERPILLAR dump trucks:

CATERPILLAR 797B CATERPILLAR 730 Ejector (4) CATERPILLAR 785D CATERPILLAR 789C CATERPILLAR 793D

CATERPILLAR Articulated Dump Trucks

CATERPILLAR 725 CATERPILLAR 730 CATERPILLAR 730 E CATERPILLAR 735 CATERPILLAR 740 E CATERPILLAR 740 CATERPILLAR 226B-2

CATERPILLAR Skid Steer Loaders

CATERPILLAR 216B-2 CATERPILLAR 226B-2 CATERPILLAR 232B-2 CATERPILLAR 236B-2 CATERPILLAR 242B-2 CATERPILLAR 246C (XPS) CATERPILLAR 256C (9495) CATERPILLAR CATERPILLAR 9CUSPRARCARPARPERPILLER 265C (9) CATERPILL AR CATERPILLAR 9CUSPRARPARPARCARPARCARPARCARPARCARCARPARCARCARCARCARCARCARCARE XPS)

Caterpillar mini loaders CATERPILLAR

CATERPILLAR 247B-2 CATERPILLAR 257B-2 CATERPILLAR 277C (XPS) CATERPILLAR 287C (XPS) Crawler 297C (XPS)

CATERPILLAR telehandlers

CATERPILLAR Th355 CATERPILLAR Th355 CATERPILLAR Th436 CATERPILLAR Th506 CATERPILLAR Th507 CATERPILLAR TH514

CATERPILLAR Track Loaders

CATERPILLAR 953D CATERPILLAR 963D CATERPILLAR 953D WH CATERPILLAR 963D WH CATERPILLAR 907H CATERPILLAR 973C WH

CATERPILLAR front loaders

CATERPILLAR 906H + CATERPILLAR 907H + CATERPILLAR 908H + CATERPILLAR 914G + CATERPILLAR IT14G + CATERPILLAR 924H + CATERPILLAR 924Hz + CATERPILLAR 928Hz + CATERPILLAR 930H + CATERPILLAR IT38H (2) + CATERPILLAR 938H + CATE RPILLAR 950H + CATERPILLAR 962H + CATERPILLAR 966H + CATERPILLAR 972H + CATERPILLAR 980H CATERPILLAR IT62H CATERPILLAR IT62H

CATERPILLAR front loaders

CATERPILLAR 992K CATERPILLAR 988H CATERPILLAR 990H CATERPILLAR 992G CATERPILLAR 992K CATERPILLAR 993K CATERPILLAR 994F

CATERPILLAR excavators

CATERPILLAR 325D MH CATERPILLAR 330D MH CATERPILLAR 541 CATERPILLAR 345C MH CATERPILLAR 365C MH CATERPILLAR 385C MH

CATERPILLAR feller bunchers

CATERPILLAR 511 CATERPILLAR 521 CATERPILLAR 522 CATERPILLAR 574 CATERPILLAR 541 CATERPILLAR 551 CATERPILLAR 552

CATERPILLAR Forestry machines

CATERPILLAR 320D FM CATERPILLAR 324D FM CATERPILLAR 325D FM CATERPILLAR 330D FM CATERPILLAR Forwarders: CATERPILLAR 574

CATERPILLAR Harvesters

CATERPILLAR 550 CATERPILLAR 550 CATERPILLAR 501 HD CATERPILLAR 511 CATERPILLAR 521 CATERPILLAR 522 CATERPILLAR 532

CATERPILLAR seals

CATERPILLAR 815F-2 CATERPILLAR 825H CATERPILLAR 816F-2 CATERPILLAR 826H CATERPILLAR 836H

CATERPILLAR Motor graders

CATERPILLAR 120K

CATERPILLAR 12M (2) CATERPILLAR 120K CATERPILLAR 12K CATERPILLAR 140K CATERPILLAR 160K CATERPILLAR 120M CATERPILLAR 12M CATERPILLAR 160K CATERPILLAR 140M CATERPILLAR 140M CATERPILLAR 160M CATERPILLAR 160M CATERPILL AR 14M CATERPILLAR 14M CATERPILLAR 16M CATERPILLAR AS4251C Tracked 24M Tracked 16M Tracked 24M

CATERPILLAR Asphalt pavers

CATERPILLAR AS3173 CATERPILLAR AS4251 CATERPILLAR AS4251C

CATERPILLAR road rollers

CATERPILLAR PF300C CATERPILLAR PF300C CATERPILLAR PF300C HW CATERPILLAR PS300C CATERPILLAR PS300C HW CATERPILLAR CB14 CATERPILLAR CB14 XW CATERPILLAR CB22 CATERPILLAR CB24 CATERPILLAR CB24 XT CATERPILLAR CB32 CATERPILLAR CC34 com bi CATERPILLAR CB34 CATERPILLAR CB34 XW CATERPILLAR CB434D CATERPILLAR CB434D XW CATERPILLAR CB534D CATERPILLAR CB534D XW CATERPILLAR CC24 Combi CATERPILLAR CC34 Combi CATERPILLAR CP433E CATERPILLAR CP533E CATERPILLAR CP54 CATERPILLAR CP56 CATERPILLAR CP64 CATERPILLAR CP74 CATERPILLAR CS533E HW CATERPILLAR CP76 CATERPILLAR CS423E CATERPILLAR CS533E CATERPILLAR CS533E HW CATERPILLAR CS54 CATERPILLAR CS54 XT CATERPILLAR CS56 CATERPILLAR CS64 CATERPILLAR CS74 CATERPILLAR CS76 CATERPILLAR AP600D CAT6

CATERPILLAR Asphalt pavers

CATERPILLAR AP655D CATERPILLAR AP755 CATERPILLAR BB621C CATERPILLAR BB651C CATERPILLAR AP300 CATERPILLAR AP600 CATERPILLAR AP600D CATERPILLAR PM102 (2) CATERPILLAR BB650 CATERPILLAR BB740 CATERPILLAR cutters: CATERPILLAR PM102 CATERPILLAR PM200

CATERPILLAR tracked tractors

CATERPILLAR D3K + CATERPILLAR D4K + CATERPILLAR D5K + CATERPILLAR D6K + CATERPILLAR D6K + CATERPILLAR D6N + CATERPILLAR D6G-2 + CATERPILLAR D6R-3 + CATERPILLAR D6T + CATERPILLAR D7G-2 + CATERPILLAR D7E + CATERPILLAR D8R + CATERPILLAR 587T + CATERPILLAR D11T + CATERPILLAR D11T CD Crawler D6T WH Crawler D7R-2 WH

CATERPILLAR Pipelayers

CATERPILLAR 561N CATERPILLAR 572R-2 CATERPILLAR 583T CATERPILLAR 814F CATERPILLAR 587T

CATERPILLAR wheeled bulldozers

CATERPILLAR 814F-2 CATERPILLAR 824H CATERPILLAR 834H CATERPILLAR 844H CATERPILLAR 854K

CATERPILLAR Wheel scrapers

CATERPILLAR 613G CATERPILLAR 623G CATERPILLAR 621G CATERPILLAR 627G CATERPILLAR 631G CATERPILLAR 631G CATERPILLAR 637G CATERPILLAR 657G

CATERPILLAR engines

CATERPILLAR C-10 CATERPILLAR C-12 CATERPILLAR 3034 NA 47 2600 CATERPILLAR 3126E CATERPILLAR C-12 CATERPILLAR C-18 CATERPILLAR C-7 CATERPILLAR C-9 94949 CAR 9P 10 CILLER 9 94949 CATER 11 CATERPILLAR C-15

CATERPILLAR C-15

,

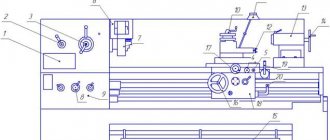

Main characteristics

The design of the clutch of the 1M63 lathe, as well as its other elements, complies with the established standards in 1982. The model belongs to accuracy class H and must meet the established standards. The technical specifications are as follows:

- 1M63 spindle bearings support rotation speeds ranging from 10 to 1,250 rpm.

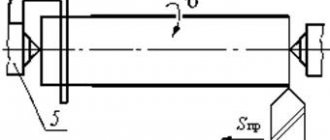

- A lathe can have a very different RMC. During operation, both fixing elements are motionless.

- The model can be used for processing long and non-rigid parts with different RMC values. For this purpose, it is possible to install a steady rest. However, it is worth considering that the steady rest is not supplied. The steady rest for the 1M63 lathe is used to limit the deformation of parts when processing.

- The tool holder is made in a classic style: the tool itself is stationary, only the support moves. The distance between the axis of the centers and the edge of the tool holder is 32 cm. In the manufacture of the tool holder, durable material is used, which eliminates the possibility of deformation of the structure. Adjusting the tool holder allows you to select optimal turning performance.

- The holes in the spindle are 65 mm. The spindle is used to install workpieces with a diameter of 630 mm. A straight rod can be installed and fed as it is turned on the 1M63 screw-cutting lathe in question.

- The tailstock is installed on the screw-cutting lathe in question, and with its power, the rear end is fixed.

- The gearbox allows you to adjust the speed in 22 ranges.

- The support has longitudinal and transverse feed in automatic mode.

- The kinematic mechanism is quite complex. There is a front and back stock. There is a gearbox in the headstock. The tailstock allows you to fix the second end of the part. The position of the tailstock can be changed. Overrunning clutches 1M63 are also used, which are responsible for maintaining the accuracy of operation.

- When considering gearboxes and feeds, we note their high strength and reliability. The maintainability of the boxes makes the 1M63 screw-cutting lathe more attractive.

- The electrical cabinet is located in the headstock, which is confirmed by the drawing of the 1M63 lathe.

- The apron of the 1M63 lathe is controlled using a special switch.

- The characteristics of the replacement wheels allow you to cut inch, metric, modular and pitch threads. The technical potential of the model is quite large. You can install replaceable wheels for turning threads of various types

You should purchase a steady rest to improve the quality of processing when you need to carry out high-precision turning of deformable workpieces. Lunettes can be made from a wide variety of materials. If you do not use a steady rest, a strong feed will lead to deformation of the workpiece. Steady rests can be installed and removed depending on the tasks assigned.

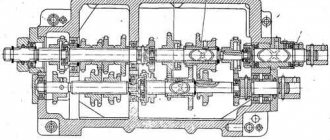

Electrical equipment and kinematic diagram

Kinematic diagram of the 1M63 machine

The 1M63 screw-cutting lathe, the electrical circuit of which has 4 electric motors, also has a detailed description of each node module in its passport. The main motor can operate from a 50 Hz or 60 Hz network. The electrical diagram indicates that the motor has a power of 13 kW.

The operating instructions provide for cooling the system. A large motor is also installed for this purpose. The kinematic diagram indicates the need to supply 22 liters of liquid per minute. Electric motor power 0.12 kW.

The kinematic mechanism is also represented by a motor, which ensures accelerated movement of the caliper. The cutter moves along with the support thanks to the installation of a motor with a power of 1.1 kW.

The kinematic diagram of the 1M63 machine also indicates the presence of four couplings. The 1M63 friction clutch is responsible for the movement of the carriage: longitudinal and transverse passage is carried out during turning, the internal mechanical element allows you to quickly bring the cutting tool. The electromagnetic type of the device allows you to quickly change the position of the carriage. There is a 1M63 direct friction clutch, which is designed to ensure smooth direct feeds in the equipment.

Electrical circuit of the machine 1M63

- everything you need to know about the connection diagram

What is a connection diagram?

An electrical diagram is a simple visual representation of the physical connections and physical layout of an electrical system or circuit. It shows how electrical wires are connected to each other and also shows where devices and components can be connected to the system.

When and how to use a wiring diagram

Use wiring diagrams to help design or manufacture a circuit or electronic device. They are also useful for making repairs.

DIY enthusiasts use wiring diagrams, but they are also common in home construction and auto repair.

For example, a home builder will want to confirm the physical location of electrical outlets and light fixtures using a wiring diagram to avoid costly mistakes and building code violations.

How to draw a circuit diagram

SmartDraw comes with ready-made electrical diagram templates. Customize hundreds of electrical symbols and quickly add them to your electrical circuit. Dedicated control knobs around each symbol allow you to quickly resize or rotate them as needed.

To draw a wire, simply click on the Draw Lines option on the left side of the drawing area. If you right-click on a line, you can change the color or thickness of the line and add or remove arrows as needed. Drag the symbol onto the line and it will insert and snap into place. Once connected, it will stay connected even if you move the wire.

If you need additional symbols, click the arrow next to a visible library to open a drop-down menu and select More. You can search for additional symbols and open any relevant libraries.

Click Set Line Transitions in SmartPanel to show or hide line transitions at intersection points. You can also change the size and shape of your hop lines. Select Show Dimensions to show the length of your wires or the size of your component.

Click here to read SmartDraw's complete tutorial on how to draw circuit diagrams and other electrical diagrams.

How does a wiring diagram differ from a diagram?

A diagram shows the layout and function for an electrical circuit, but does not show the physical layout of wires. Electrical diagrams show how wires are connected, where they should be in the actual device, as well as the physical connections between all of the components.

How does an electrical diagram differ from a graphic diagram?

Unlike a pictorial diagram, a wiring diagram uses abstract or simplified shapes and lines to show components. A pictorial diagram is often a photograph with labels or highly-detailed drawings of the physical components.

Standard Wiring Diagram Symbols

If a line touching another line has a black dot, it means the lines are connected. When unconnected lines are shown intersecting, you will see a line transition.

Most of the symbols used in an electrical diagram look like abstract versions of the real objects they represent. For example, a switch would be a break in a line with a line at an angle to the wire, like a light switch that can be turned on and off. The resistor will be represented by a series of plugs symbolizing current limitation. The antenna is a straight line with three small lines branching off at the end, much like a real antenna.

- conductive wire

- Fuse, cut off when current exceeds a certain value

- Capacitor used to store electrical charge

- Toggle switch stops current when opened

- Push-button switch, instantly passes current when the button is pressed, interrupts the current when released

- The battery accumulates electrical charge and generates constant voltage

- Current limiting resistor

- Ground wire used for protection

- Circuit breaker used to protect a circuit from overcurrent

- Inductor, a coil that generates a magnetic field

- Antenna transmits and receives radio waves

- Surge protector used to protect a circuit from surge voltage

- , generates light when current passes through

- Diode, allows current to flow in one direction, indicated by an arrow or triangle on the wire

- Microphone converts sound into an electrical signal

- Electric motor

- Transformer, changes alternating voltage from high to low or vice versa

- Headphones

- Thermostat

- Electric outlet

- Junction box

Lamp

Examples of electrical connections

The best way to understand electrical circuits is to look at some example electrical diagrams.

Click on any of these electrical diagrams included in SmartDraw and edit them:

Browse SmartDraw's entire collection of electrical wiring examples and templates

,

Repair of equipment

Working on any equipment involves both scheduled and complex repairs. Measures to restore the functionality of individual mechanisms are required for the 1M63 model quite rarely. But a gradual loss of stability and loosening of individual structural components leads to a decrease in the accuracy of operations and a decrease in processing speed.

To carry out a comprehensive repair from the manufacturer, the customer must send the following documents together with the machine: a technical passport of the installation, special reports of previous technical inspections and a statement that reflects information about the assembly node modules.