You can buy disc straightening stands produced by well-known manufacturers. The price of disk drives varies within optimal limits. We offer a wide range of stands that are distinguished by excellent performance characteristics.

Various wheel straightening machines are indispensable assistants for tire fitting specialists. With their help, disc defects that may occur as a result of the vehicle falling into a hole or rut are eliminated. With the help of such stands, high-quality repairs are made. The discs are secured to a special faceplate of the disc rolling equipment and then straightened.

Using wheel straightening machines, steel elements, forged and cast wheels are restored. The machine helps correct both mild and complex deformities. Wheel straightening machines are used in car repair shops, tire shops and service stations.

Purpose of equipment for editing disks

During the repair and straightening process, the curved disk is returned to its correct, original shape. Depending on the material, the leveling process can be done in the garage yourself. Using a sledgehammer, specialists successfully restore stamped steel wheels. Existing noticeable defects are removed and the surface is sanded. In this case, there is no guarantee that you have recreated the original wheel geometry. You should not skimp: entrust the straightening to professionals; they will carry out the restoration efficiently and quickly.

Restoring aluminum cast wheels is more difficult. A negative feature of the alloy is heating, during which the quality of the metal is completely lost. Competent repairs must be carried out exclusively by cold rolling, using spot heating for severely damaged disk elements. The procedure can only be carried out on a special cold rolling machine. The machine has a hydraulic drive and a set of straightening attachments .

Universal and specialized disc straightening machines

Even the most careful driver is not immune to holes in the asphalt. A hole more than 10 cm deep can cause serious damage to wheel rims. Violation of the wheel geometry leads to uneven abrasion of the rubber, damage to the suspension and steering rod.

Purpose of equipment for editing disks

cast wheel straightening machine

During the repair process, the disk is returned to its original shape. In some cases, this process can be done by yourself. The technology depends on the material.

Stamped steel wheels can actually be repaired by hand using a sledgehammer. The surface is straightened, all noticeable defects are removed. However, there is no guarantee that the original geometry has been returned. Therefore, it is advisable not to skimp and entrust the repair to professionals who carry out the restoration quickly and efficiently.

Restoring cast aluminum wheels is more complex. The characteristics of the alloys are such that when heated, their original qualities are completely lost. Competent repairs are carried out exclusively by cold rolling with spot heating of especially damaged elements. The procedure is only possible on a rolling machine with a set of attachments and a hydraulic drive.

Types of disk straightening machines

Choosing a wheel for a modern car is not an easy task. Discs are made from various alloys and materials, and they also have different designs and patterns. Therefore, you need to choose a disc straightening machine wisely. There are such types of fossil machines:

- For straightening discs made of steel alloys;

- For straightening light alloy wheels;

- For discs made of non-ferrous metals;

- For repairing the "eight";

- Stands for repairing truck wheels.

According to the principle of operation, machines are divided into mechanical and hydraulic. Mechanical, in turn, are used to eliminate such damage:

- Runouts along the radius and axis;

- Ellipticity;

- Shallow dents;

- Correcting the rubber seat.

Features of disc straightening machines

A disc straightening machine is a special stand that has its own characteristics. The machine consists of a shaft on which the disk is mounted, as well as a power hydraulic cylinder with various attachments. Some machines for cast wheels are equipped with a turning module, which is used to rework the disc after the deformation has been eliminated.

The straightening machine has many advantages. Among them:

- Operational payback. Prices for machines used to edit various disks vary within reasonable limits, so they pay for themselves in about one month.

- Increasing the prestige of a tire workshop. If the service station has a straightening machine for steel or alloy wheels, you will solve any problems of car enthusiasts that have arisen due to wheel malfunctions. This, in turn, will increase your customer base.

- High reliability, strength and durability. Machines for rolling cast and steel discs have optimal performance characteristics.

The use of disc straightening stands allows you to speed up the repair process and makes the repair better.

Using different types of machines

Using a hydraulic stand, a technician can restore almost any dent or defect. There are times when it is necessary to use hydraulic and mechanical equipment .

For steel wheels

During the straightening process of steel disks, the damaged part is rolled through pressure rollers. The disc is placed on the shaft, and rollers act on the distorted areas at the required angle for alignment.

The universal flange is attached to the tip of the shaft, then the wheel is put on and secured with a nut. If the wheel has several holes, then each hole must be put on the flange. Deformed fastening holes are centered using conical nuts. The electric motor is located in the lower part of the frame, connected to a gearbox and V-belt drive. The tension of the V-belt drive is also controlled by a nut. On such a stand it is possible to roll deformed wheels with sizes from 10 to 15 inches.

For alloy wheels

Now alloy wheels are very popular both among young people and among S-class cars. These discs look very impressive, they are light and durable. They can be insidious and cast .

Cast ones are restored very simply: pressure is applied to the damaged area using a hydraulic booster. Forged rims have better characteristics than cast ones. There are a large number of methods for repairing forged rims using nozzles through which pressure is applied to the part.

The damaged rim is installed on the faceplate on its own. The working surface, in turn, is equipped with grooves designed for attaching any type of rim. The average force required to restore shape ranges from 3 to 3-5 tons. This pressure is created using a hydraulic drive , which, in turn, is controlled by a hydraulic distributor with a pressure adjustment function and a pressure reduction valve.

The working fluid (technical oil) pushes the cylinder out under pressure. The pressure is provided by a pump located near the engine at the bottom of the machine. The efficiency of rolling directly depends on the performance of the pump. The pump communicates with the electric motor through a coupling. On the reverse side there is a runout indicator - a metal guide with a pointed end. The runout indicator serves to directly select the straightening point and is an important factor at the final stage of restoration.

The casting straightening machine is equipped with working attachments and rods for smoother straightening. The machine design includes a drawer for storing tools and spare parts. Models of hydraulic devices with a hand pump are less common, however, they are less productive.

To edit figure eight

Hydraulic figure eight straightening equipment will help correct radial deformation of the rim. When using such equipment, the disc is placed on a horizontal bed and pressed with a leveling hydraulic press.

Universal disk drives

The universal repair stand is a combined approach to restoration using hydraulics and mechanics. Such devices work with diameters from 10 to 25 inches. They eliminate radial and axial runout, restore the rubber seat and correct ellipse. Repairs with such devices are carried out in two ways:

- Double-sided rolling of internal and external surfaces with stationary and mobile rollers.

- Straightening using a hydraulic cylinder. In this case, control is carried out by a hydraulic distributor.

The power of such machines is 380 volts, they are equipped with a three-phase electric motor. Universal machines are equipped with a cutter for cleaning solder after welding. There are varieties of machines with scissors for trimming edges .

Disc straightening machines, disc rims in Moscow - buy at a low price

Due to the poor condition of many road surfaces, many cars fall into holes and potholes, resulting in discs that bend or break. This in turn leads to failure of the suspension and steering rack (column).

Straightening a disc on your own is a rather complex and time-consuming process, so drivers are forced to turn to car services.

Specialized workshops use disc straightening machines for this purpose, returning them to their previous condition, which allows car owners to save money, since the process of restoring products is much cheaper than buying new ones.

How do disk drives work?

The machine for rolling discs can be of different modifications. But the principle of operation is the same for everyone. The disk is secured to the shaft using a faceplate, then rotates. Damaged areas are exposed to pressure provided by support and pressure rollers. The result of this process is ideal wheel rim geometry and a satisfied customer. Our company offers to buy machines for straightening discs on favorable terms.

Types of disk drives

All disc straighteners are divided into types, which depend on the type of disc for editing. Machines are also divided by engine type:

- electromechanical. The equipment is capable of eliminating deformations on stamped models by rolling them through special rollers;

- electrohydraulic. The discs are straightened by applying a power hydraulic press to the damaged surface. As a result, even the most complex deformations are eliminated. This equipment is used for light alloy and cast products.

If you want to buy machines for straightening disks, then you need to consider the following nuances:

- width and diameter. You need to decide what disc parameters your auto repair shop will service;

- voltage. Typically, large car services choose high-voltage equipment that is connected to a three-phase network. For small workshops, machines operating from a single phase are suitable;

- fold adapters. Their presence allows you to service disks with different numbers of holes;

- power. It can be from 0.5 to 1.1 kW.

When choosing a machine for straightening cast disks, you should also pay attention to the manufacturer, the presence of functional features, dimensions, how many disks it can service in one working day, and cost.

We have the best disk drives only

The most popular and in demand are machines from such brands as “Sibek”, Comec, AE&T; such products have an ideal price/quality combination.

In automotive production, stamped wheels are often used. Their main advantage is that they can be restored by rolling. The product is placed between two rollers, the flanges of which rotate freely. In this case, the wheel is installed on the spindle and secured through standard holes. The installation allows you to straighten products with different seat sizes.

The operation of the machines is based on the use of a built-in electric motor, which in turn is driven through a gearbox or V-belt drive. Such equipment easily restores the shape of the disc and even copes with ellipse.

What characteristics do good disc drives have?

The technical characteristics of the stands depend on certain factors: power supply parameters, required engine power, weight and linear dimensions of the equipment, thickness of the material that will serve the machine at the straightening site.

To evaluate the efficiency of using equipment for rolling stamped wheels, it is necessary to determine the possible productivity. In other words, the car service technician must take into account the number of rims or wheels with an average level of damage that will be mounted within one hour.

Knowing this parameter, you can purchase equipment with the required performance, with which the car service can serve a large number of customers.

Equipment advantages

Stamped wheels are mainly used for cars and trucks. They are easily deformed during use, but can be restored. Therefore, car services that straighten discs will always have a huge number of visitors.

The main advantages of the machines:

- restoration of the geometry of disks and wheels of any size;

- technological processes have a high level of automation. A tire specialist installs the wheel on the machine, all other manipulations are automated;

- affordable prices. The cost of the equipment is quite affordable, so most service stations can purchase it.

All stand models are easy to use and maintain. If you lubricate the bearings in a timely manner, monitor the general condition of the electric motor, and regularly assess the condition of the machine, then the disk drive will serve you for a long time. When choosing a machine, maintain a balance between price, functionality, and quality.

Source: https://www.VseDlyaServisa.ru/catalog/legkovoj-shinomontazh/stanki-dlya-pravki-diskov/

Review and comparison of machines

Suppose you are the owner of a tire shop and decide to add straightening of alloy wheels to your range of services. The decision is the right one, which will help you make money in the off-season. Most car enthusiasts straighten and straighten their wheels when changing shoes. So repairing disks is a good income at any time of the year. It’s worth noting right away: if you can save money when equipping a tire workshop, then you should not save money when purchasing disc straightening equipment, as well as an argon apparatus. You need to buy everything according to the list: no less, no more.

So, you need a disk drive like this:

- Radius disk installation up to 24 inches;

- Device with double-sided hydraulic cylinder;

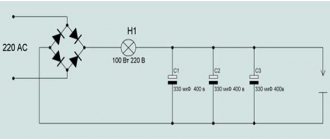

- 380 volt hydroelectric station;

- The device is equipped with electric spindle rotation.

It may happen that in your city there are not even cars that use wheels with a 22-inch radius. And you will never have such a client. Remember that a large frame will make it much easier to work with wheels and rims of any radius. And also do not forget that if the service turns out to be unclaimed, then it is easier to sell the R24 machine.

You must understand what a double-sided hydraulic cylinder is. If the hydraulic cylinder rod moves automatically in both directions and is equipped with a switch core control handle, then it is a two-way cylinder. There are machines with a one-way hydraulic cylinder . When using such a machine, you will have to pump the valve screw by hand to secure the parts to the frame.

The price of disc straightening equipment is unreasonably high, so you need to choose the right sample correctly. Hydraulic drives exist at 380 volts and at 220. An electric motor with a power of 220v is low-power and is unlikely to cope with the task of rolling serious deformations. There are cases when the power supply of the workshop does not allow purchasing a machine with a power of 380 volts, then you will have to purchase a low-power device.

By electric rotation of the spindle we mean the rotation of the axial mounting of the disk on universal stocks with a roller spacer or turning group. Manual rotation will slow down the work several dozen times.

How to choose a disk straightening machine

To choose a straightening machine, you need to pay attention to what disks you plan to work with, as well as the purpose of the equipment and the availability of additional functions. We offer machines for straightening cast wheels of various types at competitive prices, among which you can easily choose the option that suits your needs. To place an order for a disk drive, as well as find out any information you are interested in, call our managers or leave a request in a special online form on the website.

Disc drives on our market

- Favorite or Junior. Similar to each other, low-functional, inexpensive machines. Copes with mild deformities. The power of such machines is 220 volts, and they are perfect for entry-level restoration. When customer traffic increases, you yourself will understand that it’s time to change the machine to a more serious one. The price of the unit is 75−95 thousand rubles.

- Favorit-P. The machine for straightening cast wheels is equipped with a mobile turning group; the working spindle rotates using an electric motor. The disadvantage is the presence of a start button, which must be held constantly, which is completely inconvenient to use. The device is suitable for straightening minor damage and chips. Experts say that the machine has more shortcomings than required: an unstable small table, an inconvenient start button, a poorly designed hydraulic switch. The only advantage is the price of the unit, which ranges from 50 to 60 thousand rubles.

- Titan 5700 and KÖNIG 24″. Many auto mechanics and specialists recommend only this machine. The Titan 5700 is a well-proven and running machine. According to online stores, it is the most popular model. At a low price, they have a complex turning group, well-established straightening stops and a gear drive for spindle rotation. Many car enthusiasts complain about severe overheating of the disc. To correct this problem, use a turning group to turn the inner flange. The spindle rotates using a gearbox and has several directions of displacement. The price of such a machine is from 70 to 80 thousand rubles.

- Titan 5800 Konig 15T00/56T 00. The machine is completely similar to the Titan 5700, however, it is not equipped with electric shaft rotation and a turning group. Well suited for independent modification. On the Internet you can find many videos on upgrading such a device. If you have the opportunity to machine a pulley and install an electric motor on it, you will save a good amount. When purchasing such a machine, be careful, because there are right-handed and left-handed stands. Copies of models (ALU-22) are also sold in Russia. Better quality and price.

- KraftWell KRWRPL 24. A well-proven disc straightening machine manufactured in Turkey. Now there are many Chinese fakes. The units are equipped with a belt drive for spindle rotation. Rotation speed is more than 200 rpm. Unlike gear machines, this type is much simpler and suits many private car mechanics at a price. They are not available for sale, but can be found on the Internet upon order.

There are now a huge number of disc stands. They are “sculpted” by all and sundry, which is why there are low-quality and poorly-functioning devices. The quality of restoration for a device directly depends on the configuration. To begin with, you can purchase a simple machine at a price of 70 thousand rubles. With an increase in customer traffic, you can purchase a more modern machine, the price of which is 170–380 thousand rubles. It all depends on the “coolness” and pathos of your service.

Many car service centers have several machines; the main thing is to choose efficient models with adjustable control of hydraulic cylinders. Using this machine you can restore the rim of any foreign car. Purchase hydraulic oil along with the machine.

The price of foreign machines is twice as high , domestic equipment for tire fitting is not cheaper and, moreover, is hardly of better quality. For this reason, most car services have outdated devices. So you have to find an experienced specialist in the restoration of alloy wheels or teach a new master the craft.

It is important to remember that working on disk equipment without special training and experience is strictly prohibited. If improperly restored or welded, the wheels may simply collapse, not to mention the health hazard if used incorrectly.

Disc straightening machines: features

The wheel straightening machine is designed to work with cast, steel and light alloy wheels. To correct defects in steel disks, there are machines that correct the flanges and flanges of the disk rim, correcting deformations, such as “figure eight”

According to their purpose, disk drives are:

- For rolling. Rollers are used.

- For straightening. There are cutters for trimming edges.

- Universal. They repair and straighten any discs.

A machine for straightening cast wheels is also on sale.

The Tech Auto company sells advanced service equipment. We work only with trusted partners. Our products have a manufacturer's warranty and quality certificates. You can buy a machine for straightening discs in Moscow in our store at the best price. With us you will receive detailed advice, the best service and delivery within the agreed time frame.