Cable and rope play the role of a very strong and durable rope that can be used for various purposes, most often in construction. The ability of these materials to withstand very heavy loads makes it possible to widely use them in various fields.

A wide selection is provided by the company TechService, whose steel products are particularly successful and popular. The products of this company are distinguished by their durability and excellent functional characteristics.

Slings, ropes, cables

Slings are devices designed for lifting and moving loads.

Slings are simply irreplaceable when carrying out loading and unloading operations. They are cables, chains or ropes combined with hooks or loops at their ends. Slings, depending on the materials used in their manufacture, can be divided into rope, chain and textile. The choice of a specific type of sling directly depends on the characteristics of the cargo being moved, as well as the conditions under which loading or unloading is expected.

Textile slings are very compact and lightweight. It is for this reason that they are very convenient to use when working with fragile loads - because such slings practically cannot damage them. Textile slings are resistant to sudden temperature changes and direct sunlight. In addition, direct contact with water or oil will not harm them at all. Working with textile slings is the safest for workers.

Rope and chain slings are excellent for working with fairly heavy and large loads. They are highly reliable and in most cases are equipped with special gripping loops. Rope slings are heavier than other types of slings. They can consist of several ropes - branches. Chain slings are a little safer to work with than rope slings.

A cable (steel rope) is a wire product. Today, many types of cables are produced, differing from each other in design and type. Moreover, for different types of cables, the core and wire may have different physical and chemical properties.

First of all, steel ropes must be distinguished from each other by the structural type of lay. This can be a single lay, double or even triple. We also note that there are also several ways to lay steel rope strands. In general, there are actually a lot of nuances and subtleties in this matter. When storing steel ropes, despite the peculiarities of their design and manufacture, it is still better to prevent exposure to natural precipitation on them. During long-term storage, steel ropes must be inspected at least once every six months and lubricated with a special rope lubricant.

Each type of rope has certain advantages and disadvantages that must be taken into account when choosing them depending on specific operating conditions. So, for example, single lay ropes have increased rigidity. For this reason, they are widely used in cases where the rope is subject to almost only tensile loads. Triple lay ropes are used when the main operational requirements are maximum elasticity and flexibility of the rope. In addition, ropes should be selected taking into account a certain safety margin, which will completely eliminate the possibility that the rope will simply break.

In addition to steel ropes, you can also find their plant and synthetic counterparts. Plant ropes are made from specially processed, strong and fairly long fibers of certain plants. On naval vessels, sisal and hemp plant ropes are most widely used. Hemp ropes are made from hemp fibers. Their really significant drawback is their high hygroscopicity and susceptibility to rotting. In order to prevent rotting, the rope strands are twisted from tarred heels. Such ropes are called tarred, and ropes made from non-tarred heels are called white ropes. Sisal ropes are made from fibers from the leaves of the agave plant.

All synthetic ropes can be divided depending on the types of polymers used in their manufacture. Today, the most widely used are polyamide (nylon, nylon, etc.), polypropylene, and polysteel ropes.

If you need to carry out loading and unloading operations using slings, cables or ropes, then it would be quite logical not to purchase these products, but to hire a specialized company that provides services in this area . It should be understood that loading and unloading operations must be carried out as safely as possible, and this depends to a large extent on the professionalism of the specialists involved, and on the correct choice of the same slings, and on the good condition of the lifting equipment. In order to avoid all possible unforeseen situations, when carrying out this type of work you should absolutely not chase the cheapest. If you contact an organization that has already proven itself on the positive side in the market for these services, then you will no longer have to think about whether the lifting equipment and slings have passed all the necessary periodic inspections and checks, whether the slingers are certified and whether they are sober at all, and also, in the end, whether your cargo will be damaged during loading or not. Ensuring complete safety of the work, as well as your personal peace of mind, I assure you, costs much more than the not very significant difference in the cost of providing services by professionals and those simply wanting to earn extra money. So contact the professionals in this matter and they will select the optimal type of slings, cables or ropes in your case!

Which steel ropes are best for construction machinery? on the Nedvio website

- Real estate

- Construction

- Repair

- Plot and Garden

- About country life

- Questions and Answers Interactive cadastral map

- About the Nedvio project

- Advertising on Nedvio.com

Question from a reader of our portal: Which steel ropes are best for construction machinery?

Answer: It is necessary to understand the range of steel cables and ropes, if only because many models of special equipment, loaders, cranes and lifting devices cannot work without them in principle.

Steel ropes, like many other technical products, come in different types and different applications. The choice of cable type depends, first of all, on the design of the device and the conditions in which it will operate.

Let's now look at which steel rope is best to choose for construction mechanisms and equipment, and by what criteria this should be done.

What is a cable?

The concept of braid in modern everyday life is used for products of various types, mainly of textile origin. Often, various tapes are also classified as braid , depending on the purpose of their use. The braid can be finishing, hemming, bag, edging, patterned, decorative, cinching, trouser, curtain, corsage

(by appointment).

Braid

distinguished by the material from which it is made -

braid

can be

satin, nylon, grosgrain, silk, cambric, velvet.

The name

braid

has its roots in the Tatar language.

Braid

is a woven or woven product in the form of a ribbon of various widths, used mainly for fastening elements of products, tying them together, as well as for decoration and design.

Considering the main purpose of the braid

, its main characteristics are primarily strength, density and resistance to deformation. Read more.

Leg-split

The name twine has its roots in the German language, which, in turn, borrowed it from Italian (German Spagat, from Italian spaghetto - twine).

Twine is a twisted or woven thread, a garter rope, which is currently used for tying, packaging, stitching goods, materials, and raw materials. Twine is widely used - in industry, construction, and agriculture. The most illustrative examples of the use of twine are tying boxes, crates, and packaging.

Twine is distinguished by its thickness, which ranges from 800-8500 tex, by the material from which it is made, structure and type of finish. Read more.

Rope

Rope evokes different associations for different people. The rope, like the wheel, is an invaluable invention of man. However, not even of man, but of nature. In nature, rope is found at every step and it would be difficult to imagine the world around us if rope were not present in it.

The first rope that helped the monkey get down to the ground was a liana. The primeval forest was literally entangled with these natural ropes, and they were the main means of transportation of the first primates. Thanks to this rope, the hand of the great ape was largely formed. capable of grasping and firmly holding oblong objects. This means that it was the rope that became the first link that led to the transformation of a simple monkey into an ape. Read more.

Convectors - an alternative or main source of heat

Convectors are firmly established in our daily lives. Convector,

one of the types of heating devices for central heating systems, in which most of the heat is transferred from the coolant to the heated room by convection. This is traditionally considered. However, now convectors are devices that have nothing to do with convection, although they perform heating functions.

Particular attention should be paid to electric convectors. Modern technologies make it possible, with economical energy consumption, to obtain a sufficient amount of heat to heat fairly large rooms, which can sometimes make an electric convector a quite decent alternative to the main source of heating. Read more.

Hemp rope

Hemp rope is made from hemp stems, or more precisely from coarse bast fibers.

Hemp rope has an attractive aesthetic appearance and good strength. Hemp rope is made only from environmentally friendly raw materials; it does not accumulate moisture, does not stretch or electrify, and is also resistant to solar and thermal radiation. The quality and price of hemp rope are optimally related to each other. In addition, it is made from industrial hemp, which does not contain narcotic substances. Hemp rope has a wide range of applications: from lifting loads (heavy physical activity) to decoration.

Areas of application for hemp rope:

Construction. Used in the construction of wooden houses.

It is used as a material for finishing crown joints, fastenings and decorative works.

This rope is also often used to seal logs in a bathhouse or sauna.

Furniture industry. It is used in the manufacture of various furniture, in particular sofas.

Fishing industry. Used for packaging and various fastenings.

Agriculture. Applies depending on business needs.

Hemp rope perfectly harmonizes in structure and color with any tree. This rope is used for assembled, finished, wooden houses. This finishing does not require any special skills. Any home after such finishing becomes more solid, comfortable and attractive. The rope protects the seam because even when exposed to water, it retains its qualities and properties. Hemp rope is very resistant to physical stress and has good elasticity, which allows finishing robots both inside and outside the house. You need to select a hemp rope depending on the width of the gap, and then use a caulk to push it there like euroflax.

Cable. Types and device. Application and material. Peculiarities

Cable - a twisted or twisted rope made of steel wire, synthetic or mixed strands. Unlike rope, it has higher mechanical stability and strength characteristics. Widely used for lifting heavy loads or as a part of machinery that transmits traction force.

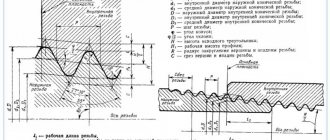

Cable device

Cables are characterized by complex, dense weaving. It consists of many steel wires or synthetic fibers. They can be woven with fabric fibers to increase flexibility and thickness. The wires are woven or twisted into strands. A certain number of strands are then in turn woven into a cable, also often called steel rope. The strands can be laid around the inner core. This allows you to improve the performance of the product, simplifying its production and increasing strength. The core can be made of thicker steel wire than the strands are woven, or it can be a rope made of synthetic, organic, non-rotting materials.

The fibers of other materials present in the strands reduce friction between the wires, which has a positive effect on the service life of the cable. Without them, the rope is constantly subject to internal friction due to uneven stretching during loading or twisting.

Also, the surface of the cable may have a protective sheath made of synthetic materials. As a rule, this is PVC insulation or similar substances. The sheath prevents corrosion of the wire, and it also prevents injury from it when grasping the surface of the cable with an unprotected hand.

Scope of application

The scope of use of cables is extremely wide. This is due to the huge variety of products in terms of strength, diameter, length and fracture resistance.

The cable is used to perform many works:

- Rigging.

- Towing.

- Lifting.

The flexibility and strength of the cables allow them to withstand repeated twisting, winding on drums, and coiling. The thin wire of the cables is made of steel with a high number of bends before breaking. Thanks to this, multi-ton loads are tied together with cables during transportation. They are used as guy wires for towers and boiler room pipes. Cables are used to lift loads with cranes. They are the ones holding the elevators.

Equipment is towed using cables. They are used in bicycles, motorcycles and other equipment to transmit force from the lever to the clutch, brakes and other mechanisms. Cables hold up suspension bridges and are used in hundreds of applications in everyday life and industry.

Cable structures

The way the cable is laid affects its performance, in particular flexibility. In this regard, when choosing a rope, design is an important parameter.

According to the laying method, the cables are:

- Single.

- Double.

- Triples.

A single lay has a core around which one strand is wound. It can wrap up to four layers in a spiral. This laying method makes the finished rope very susceptible to unauthorized unwinding if its ends are not secured. They gradually become frayed and unravel into many protruding sharp wires.

Double is an order of magnitude more difficult. It consists of a core around which two or more strands are wound in several layers in a spiral. This weaving makes the finished product less susceptible to unraveling into individual wires at the edges. The strands surround the core and are additionally intertwined.

Triple braiding consists of several double lay cables. That is, the strands are intertwined around the core, forming even thicker strands. Those, in turn, similarly curl in a spiral above the main core. These are thick, very strong cables for working with multi-ton loads.

In addition to the lay design, its method is also an important parameter. It depends on how the cable behaves without load. According to this criterion, they are divided into 2 types:

- Unwinding.

- Non-unwinding.

The first ones consist of wire, which, after weaving, has internal tension. As a result, without load, such strands strive to return to their normal position. This is accompanied by their unwinding after removing the bandages from the ends of the cable. The rope has a memory effect, so if you lay it flat and then release it, it will try to curl up in rings.

The latter do not maintain internal tension in the wire. This is achieved by straightening and preliminary deformation. As a result, after the cable is ready, the release of its ends is not accompanied by the unraveling of the strands into many thin wires. Such products are more flexible than previous ones. They are resistant to metal fatigue, meaning they retain their performance characteristics longer. When unwinding such a cable, it is more likely not to curl up in rings, but will lie straight as it was stretched.

Are cable and rope the same thing or not? What is the difference?

The rope is made of metal (steel) wires, the rope is made of hemp threads (modern ones are probably made of polypropylene).

The cable is quite rigid, and the rope is soft. Well, the cross-section of the rope is usually much larger than that of the cable. The difference is small, but it is there. However, at present there is no clear boundary. Cable is a twisted or twisted product made of steel fibers, similar to a rope. Rope (sometimes synonymous with cable) is a rope made of synthetic or natural fibers that must be at least 13 inches in diameter. The purpose is also different: cables belong to load mechanisms that are widely used in many types of equipment in the engineering, transport and mining industries; ropes (meaning mainly made from natural materials) are very durable and moisture-resistant, used as suspended fastenings with loads in environments with high humidity, for re-stretching objects and decoration, as well as sports equipment.

All products twisted from individual strands are called a cable, but cables are divided into several types according to their circumference. With a circumference of 35 to 100 millimeters, the name of the product coincides with the general term and is called a cable, and a cable with a circumference of more than 350 millimeters is called a rope. This classification is determined by the standards of many countries around the world and Russia. But in the navy, the anchor chain is also called a rope, but this is a tribute to tradition.

Different names are used for different areas of use. In general, it is generally accepted that cable is a product made of metal, while rope is made of synthetic or other non-metallic substances. But according to modern standards, in relation to lifting mechanisms, the word rope instead of the word cable . Sometimes with clarification - “steel rope”. So there's not much difference.

Unexpectedly, two answers to such a question turned out to be two very different. I am still inclined to believe that the answer to the question about spinning fibers for ropes and ropes should be “JUTE” - it is more often found in various kinds of crossword puzzles.

Most likely to overcome life's difficulties.

Are you most likely from Mother Volga?

Because it is there that the mooring ropes are called “chalkas” (from the word berth or moor, i.e. tie the ship to the “roar”, shore, pier, etc.)..

Each mooring rope has at its “end” a braided light for mooring and throwing it onto bollards (not so important, coastal or ship).

I think that in your question the word “stunned” has exactly this meaning.

A simple ship's rope (in coils and wound - just a rope).

It will become “stunned” if it is cut and the ends are braided into fires.

It is then that it will become suitable for mooring a ship and will differ from ordinary rope.

One autumn evening, daddy hedgehog was returning home from a gloomy forest, he was carrying apples on his needles for his children, he was very tired because he had to go very far into the thicket of the forest to get apples, for some reason daddy hedgehog called this part of the forest “work " And now there was very little left to the mink when daddy the hedgehog saw a small ravine that was not there before. “Damn!” the hedgehog swore. “I got lost from fatigue,” the hedgehog thought. But it was no longer safe to return; predators had already begun to hunt. And so daddy the hedgehog thought, thought, and with the last of his strength he wove a birch rope and, like Tarzan, flew to the other side of the ravine. And on the other side his beloved hedgehog wife was waiting for him, she was very worried and went to meet the hedgehog dad. Seeing such a crazy and heroic act, she shouted “Bravo” and everything ended well.

A beautiful question and a beautiful task that shows how the human imagination gives in to the comparison of big and small. But the most interesting thing about this problem is that in fact, it doesn’t matter what the length of the original circle was and what its radius was, if this length changes by 1 meter, the radius of any circle will increase by 16 centimeters. And it’s easy to prove it. Let us have a circle of length l which we will increase by 1 meter. Then we have that the radius of the new circle will be equal to: R=(l+1)/2п = l/2п + 1/2п

In this equation, the left term is nothing more than the radius of the initial circle, which depends on its length, and on the right, the increment of this radius, which no longer depends on the length of the initial circle and is a constant. That is, it doesn’t matter whether the circumference is 40 thousand kilometers, or a million kilometers, or even 1 meter, but if it is increased by another 1 meter, then the radius of any circle will increase by 16 centimeters. Into which not only a mouse can fit, but also a cat chasing it.

First, it’s worth understanding the terminology:

- Climbing rope is a special rope with special dynamic and strength properties, used in mountaineering, rock climbing and speleology.

- Twine (string) is a thin, strong thread for packaging, stitching, etc., made by twisting paper, bast fibers, chemical fibers or threads, as well as their combinations.

- Cord (German: Schnur) is a fairly thin cord, wire or rope.

- A tench is a thin ship's cable. In the days of the sailing fleet, it was made from hemp.

- Rope is a thick, strong rope made of intertwined plant, synthetic or metal fibers.

- Cable is a twisted or twisted rope product.

- A halyard is a tackle designed for raising and lowering sails (mainsail, staysail and others), individual parts of the spar (for example, yards, topmasts, gaffs), flags, pennants, etc. The halyards used on ships and vessels are classified as running rigging.

It turns out that these are the names of ropes and cords for various fields of activity and application, practically indistinguishable functionally. That is, a climbing rope, for example, is quite suitable as a rope for tying luggage, or for hanging laundry.

The materials from which ropes are made are divided into 2 main classes: vegetable and synthetic.

Synthetic:

- Polyamide - RA, amidplast (nylon-66, perlon, encalon, brinylon, anthrone, selon, rilsan). The strength of nylon cables is approximately three times greater than that of premium manila cables and approximately 10 times that of coconut cables, despite the fact that they weigh less. Nylon ropes do not absorb water. Nylon does not rot or rot. Dirt is easily washed off; there is no need to wipe it before packing. The melting point of nylon 66 is 265 °C, nylon 6 is 215 °C, but damage can occur at lower temperatures. They also produce elastic nylon gear that stretches up to 30% of the length and returns to its original size after the load is removed. Nylon silk cables are very slippery, so knots must be made with extreme care. The most difficult thing to handle is thin fishing lines, which are a continuous elongated thread.

- Polyester - PETP, linear ethylene glycoltere-phthalate plastic. Thermoplastic, melting point 260 °C. Trade names: terylene (England, Italy, Finland), diolene/trevar (Germany), polyester (Netherlands), tetoron (Japan), dacron (USA and Turkey), tergal (France and Spain), tesil (Czech Republic). Like nylon, polyester is produced both as a short-wave multifilament yarn with a soft surface and as a thin continuous polyester fiber. Polyester is inferior to nylon in elasticity, but wears out relatively little. Polyester gear is currently the most common in sailing.

- Polyethene - HDPE, ethenplast, HD, polyethylene. Thermoplastic, melting point approx. 180 °C. The fiber is produced only as monofilament. They are durable, the breaking force of these cables is 1.5 times greater than the Manila ones.

- Polypropene - PP, propenplast, polypropylene, meraclon. The melting point of polypropene is about 165 °C. Multi-strand continuous fiber rope is almost twice as strong as manila rope. Three-strand or braided cables are low cost and are widely used. Polypropene film cables with flat fibers made of thin film are also widely used. The breaking force of such materials is higher. Film polypropene does not sink. A wet cable retains its strength and flexibility. However, film polypropene wears out quickly, so it is recommended to first inspect cleats, bollards, winches and remove sharp ribs and protrusions on them.

- Kevlar is an aramid. It is stronger than steel cables. Main disadvantages: high price, low resistance to moisture and short service life (up to 5 years, some manufacturers provide a 10-year warranty). A wet rope has much lower strength than a dry one. Recently, Kevlar cables have appeared, in which the latter shortcomings have been partially eliminated.

Types of cables[edit | edit code]

Wire ropes and cables[edit | edit code]

Cable work cables[edit | edit code]

When making wire ropes (classical laying), the constituent fibers are twisted 3 times. First, the fibers are spun into bobbins (yarn), then the bobbins are spun into strands, and the strands into cable. Cables come in steep and flat lay depending on their purpose. Flat lay cables can withstand great forces, but steeply twisted cables wear out less and are more durable.

Vegetable rope of cable work. Structure

Cable work cables[edit | edit code]

Cable work ropes are distinguished by the fact that the fibers are woven 4 times. Cable-working cables are denser and therefore wear out less and retain less moisture compared to cable-working cables. Cable work cables are more expensive and weaker compared to cable work cables of the same diameter.

Cable work rope. Structure

In the literature, cable-type ropes are also called ropes with braided braiding (for example, climbing ropes).

Number of strands in the cable[edit | edit code]

Cables can be three-strand, four-strand, multi-strand (8 or 16 strands). As an exception, there are five-strand coarse cable cables. Steel cables are usually six-strand with a core.

Three-strand cables are more common, but four-strand cables are also common. In the middle of such a four-strand cable, if its thickness is 50 mm or more, there is a fifth thinner strand (core), which fills the empty space remaining between the four strands. Three-strand cables are much stronger than four-strand cables of the same thickness in sizes up to 125 mm. For sizes exceeding 150 mm, four-strand cables are stronger than the corresponding three-strand ones. Three-strand cables, the strands of which are thicker, wear out faster than four-strand cables of the same size.

Among medium-sized cables, four-strand ones are softer than three-strand ones. Four-strand cables also have the advantage that they are more round in cross-section than three-strand cables.

Cables made from synthetic materials are either made according to the same principle as those made from plant fibers (but the number of strands is usually greater: 8 or 16), or consist of a braided braid and a core with straight fibers. In such cables, the core occupies 2/3 of the cable thickness.

Right and left lay cables[edit | edit code]

Depending on the direction of lay, the cables are of right lay (direct descent) and left lay (reverse descent). Almost all plant cables are right-hand lay cables and, most often, three-strand. There are also reverse descent (left lay) cables. When making right-hand lay cables, the strands are twisted in the direction of the sun (clockwise), these cables have the same spiral direction as a screw with a right-hand thread.

Square cables[edit | edit code]

In the 1950s, the so-called “square cables” appeared - the cable is woven from eight strands, alternating them in pairs, with one pair in the cable going clockwise and the other counterclockwise (see illustration). Such cables are soft, without twists. They retain these properties even after getting wet.

Types of synthetic cables[edit | edit code]

If synthetic raw materials are drawn into thin smooth threads, the length of which is equal to the length of the entire cable, then such cables are called “monofilament” (“monofilament”). They are more durable, but slippery and do not hold the knot well. Monofilament cables are woven from elongated continuous threads with a diameter of more than 0.1 mm - more rigid with a hard and shiny surface.

If the cable is twisted from relatively short threads, then such cables are called “multi-strand” (“filament”). [source not specified 4372 days] The surface of such a cable is slightly fleecy. This material has less strength, but such cables are soft and flexible, and it is convenient to tie knots on such cables. Multifilament cables are woven from yarn consisting of thin threads, the diameter of which does not exceed 0.1 mm. In the trade, nylon filament material is referred to as “wool-like nylon.”

There are also multi-film cables; they are woven from thin film threads-strips.

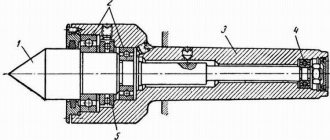

Remote control cables[edit | edit code]

They consist of a durable steel braided cable (core), coated with lubricant and placed in a flexible casing with a polyurethane sheath. At the ends of the cable, fittings (tips) are fixed, fixing the position of the outer casing, but allowing independent movements of the core inside it.

Application of ropes and ropes:

- In everyday life - a household rope, for example, to hang laundry; cable for towing a car; cord for tying cucumbers in greenhouses; linking various things; stretching an awning, tent; rope for horizontal bar and swing; creating a fence; such as a dynamic off-road rope (snatch rope), etc.

- In mountaineering - as main and safety ropes of standard mountaineering diameters, rap cord; establishing crossings; static and super-static ropes, rope for rappelling from helicopters and stands.

- In yachting - as running and standing rigging, mooring halyard, anchor halyard, clew halyard.

- In production - rope and cord for tightening furniture, rope for felling trees, as cargo ropes during loading and unloading operations, for lifting and moving cargo, for installing fences, as load-bearing and submersible ropes for nets, for towing barges and ships, as a transmission element on the lines of the timber processing complex.

Application area

Used in a variety of areas. The main direction is production. Galvanized metal cable is used on winches and cranes, in the manufacture of overhead roads and on drilling units, excavators and lifts. They are needed for guying masts on ships, fishing structures and trolleybuses.

A safety rope will ensure safety when performing high-altitude work in industry, and it will also become insurance against falls in mountaineering.

Synthetic products are actively used in the installation of urban structures, for example, traffic lights, advertising or warning signs. Plant products are used in the manufacture of mooring lines and tugs, slings and lashings, and for other purposes.

Properly manufactured cables can solve many different problems, which has influenced their distribution.

Ropes, strings, threads: similarities, differences and features

Ropes, cords and threads form three main groups of twisted products. Twisted products are products made by twisting two or more strands. Different types of twisted products differ in the material of manufacture, design and direction of twist.

Ropes Ropes are twisted products of complex design with a large diameter of 4 mm. The ropes are characterized by increased breaking load and pronounced wear resistance. Recommended for those applications where a high degree of product reliability is required.

To produce high-quality ropes, a multi-stage twisting process is used, consisting of three or more twisting stages depending on the diameter of the product. At the first stages, the threads are twisted into heels. Thicker strands are then formed from the heels. At the final stage, the finished rope is twisted from the strands. At each new stage of torsion, the direction of twist changes to ensure a balanced rope. Moreover, the greater the number of heels in the rope structure, the more reliable and durable the product. Depending on the number of twisted strands, ropes can be 3 or 4 strands. Depending on the direction of twist, ropes are either right-handed (Z-twist) or left-handed (S-twisted). Twisted ropes are widely used in the industrial and construction industries, and in commercial fishing. Read more about how not to make a mistake when choosing a suitable rope in our material “Twisted rope: subtleties of choice.”

Ropes The second group of twisted products is ropes. These are relatively thin products, with a diameter of 2.5 to 5 mm. They are characterized by greater flexibility than ropes, but less wear resistance. They tie well into knots. Ropes made of polyamide demonstrate good shock-absorbing properties and are used in belay and rescue work and in mountaineering.

Ropes are similar in design to ropes, but differ in fewer heels in one strand and less dense twist. Rope products are in demand for the construction of fishing gear, in agriculture and for packaging work.

Threads Threads are a group of thinner twisted products with a diameter of up to 2 mm, obtained by twisting yarn on special equipment. Technical threads are made from modern synthetic materials - polyamide, polyester, aramid fibers and high-modulus polyethylene. Fishing threads are made mainly from polyester - Polytex threads and polyamide - Extra threads. According to their structure, fishing threads have two or more twists. The thickness of a thread directly depends on its linear density, measured by tex or denier. The higher this indicator, the thicker the thread.

For reference:

Denier is equal to the linear density of a thread weighing 1 gram and length 9 kilometers. Tex is the linear density of a thread weighing 1 gram and length 1 kilometer.

Thus, 1 tex is equal to 9 denier. Depending on the intended purpose, twisted threads can be coated with special chemical compounds that improve the consumer qualities of the threads (wear resistance, smoothness, ultraviolet resistance). High-quality synthetic threads are widely used in fishing, in the clothing and footwear industries, in medicine and surgery, and in construction.

Materials: Modern synthetic fibers used to produce twisted and woven products make it possible to produce products with exceptionally high consumer characteristics.

Polyester (PES). Products made from polyester are characterized by increased strength, resistance to ultraviolet radiation, low hygroscopicity and negative buoyancy. Polyester does not shrink when in contact with water and has negative buoyancy. Twisted polyester products include Polytex ropes and Polytex threads.

Polyamide (PA). The strength of the material is not inferior to polyester, while being distinguished by significant elasticity and high tensile strength. Used in the manufacture of fishing tackle, ropes and threads. A special feature of the material is that it shrinks up to 15% when wet. Twisted polyamide products – ropes and ropes Extra, high-strength threads Extra.

Polistil (Danline). A synthesized material that consists of 65% polypropylene and 35% low-density polyethylene. Polysteel is characterized by increased strength and wear resistance, low elongation. Used to make high-strength Danline ropes for industrial fishing, shipping, construction and towing applications

Miscellaneous[edit | edit code]

Cable sizes[edit | edit code]

The size of cables is determined in two ways: either by circumference in English inches or by diameter in millimeters. Currently, the latter method is more common.

How to distinguish synthetic cables using improvised means[edit | edit code]

Synthetic fibers are easily distinguished by the following characteristics:

- If the sample does not sink in water, then it is made of polyethylene; if it sinks, then it is either polyamide or polyester.

- Samples are exposed to open fire. If during combustion there is dark smoke and the sample melts, then it is polyester; if it melts without changing color, then it is polyamide, polypropene or polyethylene.

- If the sample is moistened with 90% phenol or 85% formic acid (a few drops on a piece of glass) and the fiber dissolves, then it is polyamide; if the sample does not dissolve, it is polyester; if it does not dissolve and remains flexible - polypropene or polyethylene.

- Undyed nylon rope has a light color between the strands; polyester silk rope has a high metallic sheen.

Rope breaking strength (RPT)[edit | edit code]

RPT is the load at which the cable breaks

, Where:

f is the safety factor for a given cable (from the reference book),

c is the radius of the cable circle.