Bulky transformers for welding work are confidently being replaced by more compact and mobile inverters. Light weight and economical energy consumption allow the devices to be used in everyday life at home or on a summer cottage. However, not every user is able to navigate the abundance of characteristics of modern welding machines. The modern electronics market offers a huge selection of different types of models.

We have compiled a universal rating for you, which examines in detail the best representatives of this market segment. How to choose a universal model for your home or garden? Which company's inverter should I choose? What should you pay attention to first? Based on customer reviews, we have selected several universal models of construction equipment.

Design and principle of operation of a welding inverter

Externally, the inverter consists of a power source, ground cables and a holder, and a power cord. Welding is possible due to the conversion of current into direct voltage with a decrease in volts and an increase in amperes, and the closure of an arc with a temperature of up to 5000 degrees on the product, which melts the edges of the metal and the electrode. Protection from the effects of the atmosphere on the liquid metal is achieved by covering the electrode, which forms an insulating gas cloud.

The inverter housing is equipped with an indication of sensor operation, a current and voltage regulator, sockets for connecting cables, a belt and a transport handle. Perforations for ventilation are required. Visual control of current strength is available using the scale and switch position or digital display.

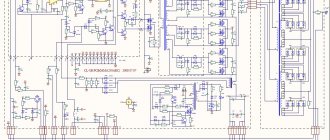

Inside, the welding inverter consists of the following parts:

1. Filter capacitors. 2. Pulse width modulator. 3. Regulator.

4. Network indicator and overheat indicator. 5. Cooling cooler. 6. Transistor cooling radiators

7. Step-down transformer. 8. Output rectifier radiator. 9. Output connectors.

In addition, not indicated on the diagram, but each inverter uses:

- interference filters;

- soft start relay;

- current sensors;

- control circuit with keys;

- integral stabilizer;

- diode bridge;

- network rectifier.

The operating principle of the inverter is to receive alternating current from a 220 V/50 Hz network and convert it to direct current. Then it changes back to alternating, but with a frequency of 50-85 kHz. The resulting voltage is reduced at the transformer to 30-90 V, and the current, on the contrary, increases to 20-500 A. At the output, the voltage is rectified again and welding is carried out at direct current with multi-thousandth pulsation.

This scheme made it possible to reduce the size of the transformer and significantly reduce the weight of the device. The arc has become much more stable, softer, and the molten metal is easier to form and form into a seam. Many welders note a pleasant rustling sound when the arc burns, indicating the correct operation of the inverter.

Other advantages of inverters include:

- Economical voltage consumption, reducing the cost of manufacturing structures or home use.

- Low load on wiring, because the power of most devices is in the range of 4-7 kW.

- Supports a wide amperage range for welding thin and thick metals.

- Duration of operating cycle with efficiency up to 95%.

- The ability to weld not only carbon steel, but also alloy metals, as well as copper and aluminum.

- Reduced spatter during welding.

But devices with inverter technology are much more expensive than transformers. Due to their complex electronic circuitry, they require more careful handling and are sensitive to negative temperatures. They are more complex and expensive to repair.

Classification by number of phases

Inverters used in hybrid systems are classified by the number of phases and can be single or three phase. Single-phase devices are typically used in systems with solar panels with a standard voltage of 220 volts. Through them, power is supplied to household appliances and other equipment. The output voltage connected to one phase can fluctuate in the range from 210 to 240 V, the output frequency changes are 47-55 Hz, and the power fluctuations are from 300 W to 5 kW.

Modifications of single-phase inverters work with different battery voltages - 12, 24 and 48 volts. It is undesirable for the converter to operate in critical conditions, at the limit of its capabilities, so its power is coordinated with the voltage of the battery or solar panels.

How to decide on the right type of welding inverter

To understand how to choose a welding inverter for your home and garden, you need to see what technological problems it can solve. It depends on the type of device. There are three categories of welding inverters.

MMA

These are simple models that only support manual welding with coated electrodes (MCW). They are best suited for everyday tasks in a private home: welding a canopy on a gate, building a barbecue, fixing a leak in a pipe, making a greenhouse.

MMA welding inverter.

MIG/MAG

This is a more advanced category of welding inverters, which, in addition to an electronic unit for converting current, also has a mechanical unit for feeding wire from a reel. Instead of short electrodes that burn out and require frequent replacement with new ones, the wire is continuously fed into the weld pool through the torch. This ensures long and even seams.

MIG/MAG welding inverter.

Such devices are chosen for critical connections where productivity and accuracy are important (manufacture of metal doors and gates, tanks and containers, car body repairs). They cost much more, so they are justified only in the case of small home production. To protect the weld pool, they use inert gas (carbon dioxide or argon), supplied along the torch hose from a cylinder with a reducer.

MMA/TIG

In addition to welding with a consumable electrode, such models have a connector for connecting a torch with gas and a non-consumable rod (tungsten). This allows you to weld very thin metals (from 0.8 mm) with neat seams and even without the use of filler wire (only due to the molten edges).

MMA/TIG welding inverter.

The main advantage of TIG is the ability to weld stainless steel, aluminum and copper. This is practical when making heated towel rails, repairing radiators, or welding a crack in an engine block or gearbox. Such models also need to be equipped with a cylinder and a reducer.

Varieties

Before choosing which welding inverter is best, you should understand what types they have:

Standard inverter-type welding machines for manual arc welding are one of the most common and sought-after products in this area. These are compact and powerful models suitable for all basic welding procedures. The presence of automatic settings allows you to simplify basic operations that are complicated by work circumstances. Externally, the device of the welding inverter resembles an ordinary transformer, since it does not contain additional tools, like other varieties. It contains microprocessor equipment that allows you to bypass all particularly difficult aspects when welding thin metals or difficult-to-weld alloys.

What parameters should you pay attention to when choosing a welding inverter?

Before choosing an inverter welding machine, you need to take into account the location of operation (permanent or changing), network parameters, upcoming work (metal thickness, number of connections, type of steel, spatial position). All this will help to more accurately understand what characteristics the device must have in order to cope with the assigned tasks.

Here are the key technical data and how it relates to workmanship and performance capabilities.

Operating voltage

Inverters come with an operating voltage of 220 or 380 V. There are models of a combined type that can switch. For home and garden use, it is better to choose 220 V devices, as this simplifies the connection through a household outlet. They can easily be brought to the work site by attaching a carrier.

380 V inverters are professional equipment for connection in enterprises. This allows you to obtain increased power and melt thick metal from 20 mm. If you often come across such products at work and there is a three-phase input in the garage, then it is advisable to choose just such a device.

Combined type models are practical for moving activities, when you can cook from 380 V in the workshop, and connect to a household outlet when traveling.

In addition to the standard operating voltage parameters, you need to select an inverter based on the input current range. When 220-230 V is stably present in the house, then a model with exactly these characteristics is suitable. But if the voltage often drops at the dacha, then the equipment will not be able to produce the required current strength, and sometimes even carry out welding. Here the choice is made in favor of inverters capable of cooking with an input voltage of 130-190 V.

Welding current adjustment range

The range of adjustment of the welding current affects the thickness of the metal that the machine can handle. The upper and lower bounds are important here. For example, to weld a barbecue made of 4 mm thick steel, a current of 120-160 A is sufficient. You can weld a canopy to a gate with a current of 100-140 A. This is also enough for making a greenhouse or laying a water pipeline. An inverter with a maximum current of 160-190 A is suitable here.

But when the priority is welding thick parts (channels, rails), or when the inverter is used for cutting in hard-to-reach places, then choose a current strength of 250-400 A. There are industrial devices with an indicator of up to 500 A.

The lower current limit is important when welding thin metals. For example, to make a tank from steel 1.5 mm thick, you need to lower the current to 45-70 A. When you need to patch up the car body, you use an even lower current of 15-30 A. For this, choose an inverter capable of lowering the amperes to these values.

Another important thing is the form of current regulation, which can be smooth or stepped. The first changes readings in 1A steps, and the second switches at intervals of 10-20 A, depending on the model. When you have to weld the same metals according to the type of steel and thickness, then stepwise adjustment with large increments is enough, because the settings will rarely be accessed. But if the thickness and types of materials often change, then better quality seams will be obtained using a finely adjustable machine that allows you to adapt to a new task.

Duration of switching on (DS)

For each inverter, its on-time duration is indicated, indicated as a percentage, which implies the operating time at maximum current. This figure varies from 30% to 100%. In practice, this means that a model with a maximum current of 200 A and a duty cycle of 30% will be able to work for 3 minutes out of 10, and then turn off for cooling.

If you need an inverter for small household tasks, then a duty cycle of 30-50% is sufficient. In this case, such work will not be performed at the maximum current, which actually increases the welding duration to 5-6 minutes. Since there is no rush here, there is no point in overpaying for more productive models.

But when the priority is high speed of work performed (for example, when making a tank or doors for sale, where after tack welding you can continuously carry out full welding), then it is better to choose an inverter with an on-time of 60-80%. Moreover, the higher the maximum current value, the longer it will be possible to work at lower values. For frequent metal cutting, a PV value of 100% is desirable.

Open circuit voltage

Thanks to the inverter transformer, the voltage in it drops to 12V during welding, making it safe for the welder who comes into contact with metal parts. When the arc is not ignited, the device maintains an open circuit voltage varying from 30 to 90 V. When the electrode is brought to the product and the arc is excited, it automatically decreases.

This indicator affects the ease of ignition of the electrode. The higher the open-circuit voltage, the faster the passage of electricity and initiation of the arc. This is especially practical when welding rusty metals, which eliminates the need to protect the joint until it shines before applying the seam.

If an inverter is rarely needed and it is not difficult to clean the welding area, then an open circuit voltage of 30-50 V is sufficient. For an experienced welder, this will be the best option. It will be much more difficult for a beginner to ignite the electrode, and if the metal is also rusty or contains traces of paint, then it is better to choose a device with an idle speed of 70 V or more.

Power consumption

This indicator is measured in kW and can be from 4 to 27 units. It implies what load the device will put on the network when operating at maximum current. For your home, it is better to choose low-power models in the range of 4-6 kW, which will not burn out the wiring. If a powerful line is laid in the garage and there is a 16-25 A machine at the entrance, then a more powerful 7-9 kW model is suitable, allowing you to weld thicker metal or carry out cutting. For 10 kW equipment, a connection to a panel board and three-phase network will be required, which is not applicable everywhere.

The power consumption parameter is also relevant in the case of mobile use of the inverter. For this, a gas generator is used, but its output current must cover the needs of the welding machine. Often the capabilities of generators reach 5 kW, so you need to choose an inverter within these power limits.

Protection from dust and moisture

The protection of the case from dust and moisture penetration is indicated by the international IP system with numbers from 21 to 23. The first number means that large objects with a diameter of 12.5 mm or more will not get into the case. This is a standard that protects internal elements from being struck by tools or protruding metal structures. In view of this, you should not work near the inverter with a grinder or drill, because small particles can easily penetrate inside the housing and short-circuit the contacts.

The second digit means:

- 1 - the inverter is protected from vertical raindrops.

- 2 - the housing will not allow falling drops to pass through at an angle of up to 15 degrees.

- 3 - falling splashes at an angle of up to 60 degrees will not cause harm.

Since welding work cannot be carried out in the rain, the degree of protection has a greater influence on whether it will be possible to save the device if there is an unexpected downpour and welding was carried out in the open air. If you plan to work in a garage, IP21 is enough, but for frequent use in the yard or even in the field with a generator, IP23 is useful.

Ventilation system

To prevent the transformer and diode bridges from overheating, a ventilation system is built into the inverter housing. Its simplest design consists of a fan and perforations on the case for air in and out. Due to this design, the internal components are often covered with a layer of dust, which slows down the heat transfer process and requires disassembling the housing and cleaning. But for household needs using 1-3 hours a day, this is quite enough.

The second type of ventilation system includes a cooler and radiators, with the key components of the inverter built inside the radiators. This helps to absorb heat more efficiently and remove it outside, but such models are more expensive. The choice of an inverter with a radiator is justified in case of frequent use of the device at maximum current (welding of thick metals, cutting).

Inverter cooling system with powerful fan and radiators.

Does operating temperature range matter?

Thermal indicators of PV are calculated based on a temperature of +25 degrees. Therefore, in cooler climates (+10…+15), the devices will be able to work longer. Some reputable manufacturers include a working value of +40 degrees in their products. Problems rarely arise with positive temperatures if you choose the right PV and current strength.

But when working in cold weather, electronics may malfunction. For a home or cottage, this will not be a problem if welding is carried out in a barn or garage. Any inverter cooks perfectly at an outside temperature of +5 degrees. But when you have to apply seams directly in the cold (installing a fence, gates, welding trusses to mortgages), then you need to check with the manufacturer on the official website (via the contact form) for the acceptable parameters, because this is not indicated in the characteristics.

Weight and dimensions are important

Despite their much compact dimensions compared to transformers, inverters still have differences in size and weight, which is related to their power and functionality. Small devices are produced with dimensions of 150x200x300 mm, which is well suited for mobile use. They can be easily delivered to the work site in a special case.

Most models have a shoulder strap, which is convenient for working at height. In this case, their weight varies from 3 to 4.5 kg. But the maximum current rarely exceeds 200 A, so they will not be able to connect steel that is too thick.

When using an inverter to solve more serious welding problems (assembling a garage frame, cutting), they use powerful models. Their dimensions can reach 500x200x450 mm, and weight up to 25 kg. To operate such equipment, you will need to allocate a permanent location and long cables to reach the corners of a large structure. Otherwise, you will still have to purchase a cart for transportation if you don’t want to carry it in your hands.

Professional inverter welding machine.

Review of manufacturers

The leaders in the production of high-quality inverter welding machines can be considered:

- France;

- Germany;

- Italy;

- China;

- Russia.

Inverters from the French company GYS have become popular. Its inverters are being improved depending on the availability of new components. They are reliable and provide long operating time.

German-made Fubag inverters remain unsurpassed in quality. The latest models are equipped with the Protec 400 protection system.

The Italian company Telwin produces excellent devices for everyday life and for professionals. The company's products do not require advertising. All additional functions are included without fail. The devices operate smoothly. The seam lays beautifully and without splashing.

This review could include many more inverter welding machines, but it is impossible to keep up with the process of their modernization.

Useful additional features

The most inexpensive inverters can only change the current strength and show an indication of the network and overheating. Most often, the automation turns off the power when the temperature rises. But to make work more comfortable or easier, there are several additional functions.

Anti Stick function

To get an even seam, it is necessary to maintain a clear distance between the end of the electrode and the parts to be welded within 3-5 mm (depending on the current strength). Beginners have difficulty doing this (the hand is not yet used to it), so the electrode often sticks to the surface. The function instantly turns off the voltage and resumes it as soon as contact with the product is broken.

Otherwise, the user must use physical force to tear off the end of the filler material, which results in crumbling of the coating.

Hot Start function

Practical for welding rusty metals or critical joints. The function operates by supplying increased voltage (V) at the start of welding, which ensures easy ignition and eliminates the need to repeatedly knock the end of the electrode on the surface. If this is the front side of the part, then the arc will leave fewer marks, which will then have to be processed mechanically.

Arc Force function

Optimal for beginners whose electrode often sticks. A device with this function “feels” the distance between the contacts and when the arc is about to go out, it briefly adds current (A) to prevent this. This action is also useful when welding thin metals (1.0-1.2 mm), since small values are initially set there (20-40 A), which provokes sticking.

It is better to choose an inverter with a digital display, since this way you can always see the current voltage and current. The drawn scale is usually small and already difficult to distinguish from 3-4 meters.

Inverter with electronic display.

If the machine is equipped with a connector for TIG welding, then the arc decay function is useful, providing a smooth decrease in amperes when the welder releases the button. This will prevent the formation of fistulas at the end of the seam and allow the weld pool to crystallize systematically.

When an inverter machine with argon is used for welding large stainless steel containers or repairing motor housings and gearboxes, the function of remotely adjusting the current strength is practical. It is made in the form of a second button on the burner and allows you to adjust the amperes without approaching the inverter each time.

Household or professional class - decide on the tasks

To choose equipment, you need to decide on its tasks and loads. Its class depends on this, which can be as follows:

- household - these devices are designed to perform welding work in a small volume. After 5-10 minutes of work, they require a mandatory break to cool down. The maximum current that devices of this class are capable of delivering usually does not exceed 120–200 A;

- professional - these devices are used in the manufacture of metal structures, laying communications, etc. They are distinguished by the possibility of long-term operation without interruption, in addition, their inverters are capable of generating a current of 200–300 A.

- industrial - capable of working for days on end with virtually no breaks and generating a current of 250–500 A.

If you purchase a device for ordinary household needs, i.e. To use it from time to time, you don’t need a professional device, as it is bulky and very expensive. But if you plan to earn money by welding, the household device will quickly become unusable under constant load. As for industrial devices, they are usually used only in production, so we will not consider them further.

Operating principle

When it is necessary to change the AC voltage, one converter with initial and repeated winding is sufficient. With continuous electricity, everything is not so easy - the car enthusiast needs a more complex electrical circuit with semiconductor components.

In the case under consideration, it is necessary to increase the voltage and transform its type. For this purpose, a mixed circuit is used, in which both converter and semiconductor devices are used.

The basis of pulse-width modulation is the operating principle of the inverter. The main generator supplies impulses, the frequency of which ranges from 10 kHz to 20 MHz, to a power switch connected to the winding of the induction converter - alternating current is removed from its output.

The width of the shocks is determined by the connected load, and therefore the circuit uses a feedback structure. The smallest signal duty cycle is equal to the minimum power, and as the output current increases, the push width reaches 1:1 (the limit value).

The difficulty is that the type of output signal that is obtained in this case is not a plastic decrease/increase in voltage (graph), but a square wave with an abrupt change in potential.

This means that the measured voltage cannot be applied to various electronic devices. To convert a square wave into a sine wave, the inverter circuit is supplemented with filters from capacitors and coils.

Protection

Inverters are equipped with various types of protection, which, when critical values are reached, turn off the device or sound an alarm in the following situations:

- Input voltage is too high or too low.

- Short circuit.

- Overheat.

- Exceeding the permissible load.

- Incorrect connection.

The higher the cost of the device, the more attention is paid to protective measures.

What is the current waveform of your electric inverter?

PureModified