Model features

The GYSMI 165 MMA inverter is a universal welding machine designed for welding with rutile-coated electrodes, as well as the ability to weld with a tungsten electrode in an inert gas environment. The welding current range allows the use of electrodes with a diameter of up to 4 mm. Built-in thermal protection prevents device failure in case of overheating.

Convenient setup The touch panel with a digital display of the GYSMI 165 MMA inverter allows you to quickly and accurately set the required welding current parameter. Quick connection Special connectors for quick connection eliminate current loss and heating at contact points. Efficient cooling Openings in the housing promote natural ventilation and remove warm air from the working elements.

- Reduced current when the electrode sticks (Anti-sticking);

- Easy arc ignition (Hot-Start);

- Arc stabilization system (Arc-Force);

- Built-in thermal protection against overheating;

- Protection class IP 23;

- Possibility of welding using TIG-LIFT method, tungsten electrode;

- Protection against short-term network surges.

Welding inverter GYS Gysmi 165

Welding inverter Gysmi 165

designed for manual arc (MMA) welding with a consumable electrode and argon arc (TIG) welding with a non-consumable electrode using direct current (DC).

In argon arc (TIG) welding mode, the arc is ignited by touching the electrode with the workpiece and then lifting it (LIFT ARC), while the microcontroller ensures a smooth increase in current and easy ignition of the arc. At the end of welding, it provides an automatic transition to crater filling with a simple movement of the torch.

Distinctive Features

- Small dimensions and weight

- The ANTISTICKING function prevents the electrode from sticking to the product when the arc is ignited, i.e. the electrode does not stick to the product and does not turn red as in conventional devices

- The HOT START function facilitates the ignition of the arc; at the moment the electrode touches the product, a current pulse is applied.

- The ARC FORCE function stabilizes the arc burning process, prevents sticking during welding, increases the penetration depth and facilitates cutting with electrodes

- Remains operational when the network voltage fluctuates from 160V to 260V

- The digital display on the front panel of the device displays the variable characteristics of the welding process

- Built-in fan, thermal overload protection

Equipment

- Welding inverter

- plastic case

- network cable 3×1.5mm², 2m long with Euro plug

- welding cable 16mm², 2m long with electrode holder and insert SKR-25

- welding cable 16mm², 2m long with grounding clamp and insert SKR-25

- shoulder strap

- passport and warranty card

- gift wrap.

Manuals and instructions

Specifications

| Characteristic | Meaning |

| Supply voltage, V | 220±15% |

| Supply frequency, Hz | 50/60 |

| Range of regulation of MMA welding current, A | 10-160 |

| TIG welding current control range, A | 10-160 |

| PT in MMA mode, % | 19 |

| PV in TIG mode, % | 24 |

| Open circuit voltage, V | 72 |

| Electrode diameter, mm | 1,6-4,0 |

| Degree of protection | IP23 |

| Overall dimensions, mm | 125x280x200 |

| Weight, kg | 4,6 |

| Manufacturer | GYS, France |

- Question: What are the maximum and minimum operating temperatures for the Gysmi 165?

Answer: The operating temperature of this inverter is from -5Co to +40Co.

- Question: What additional equipment do I need to purchase for TIG welding with the Gysmi 165?

- Question: What is the power consumption of this device model?

Answer: The maximum consumption of the inverter will be 4-4.5 kW.

- Question: Which torch for argon arc welding can be connected to this machine?

Functionality

Gysmi welding inverters are in the middle price category, and here you can find a considerable number of models with a large power reserve, which makes them closer to the professional field of operation. The main functional capabilities of the technology include:

- hot start – ensures easy ignition of the arc during the start of welding work;

- arc forcing – maintains stable parameters and does not allow the arc to die out even when the electrode is separated from the metal;

- anti-sticking – turns off when the electrode sticks and a short circuit occurs.

Unlike other brands, where these functions are also present, here you can adjust their intensity and parameter values, even turning them off completely.

Model range and technical characteristics

The welding machine (inverter) Gysmi 161 is a compact device that has excellent protection against power surges. According to the nominal data, it can withstand a surge of up to 400 V. There is also protection for connecting from generators, since in this case the power supply becomes unstable. The device has all the necessary additional functions that greatly facilitate the work of novice welders. The relatively low power allows you to cook with 4 mm electrodes, which is quite enough for home work.

Welding machine Gysmi 161

| Options | Values |

| Voltage, V | 230 |

| Open circuit voltage, V | 72 |

| Maximum current, A | 160 |

| Adjustment range, A | 10…160 |

| PV, % | 14 |

| Diameter of consumables, mm | 1,6-4 |

| Degree of protection | IP21 |

| Weight, kg | 4,1 |

| Dimensions, mm | 120 x 255 x 150 |

| Guarantee | 12 months |

The Gysmi 165 welding machine can be used for welding structural and stainless steels, cast iron, copper and other metals. One of the features is the ability to cook with infusible electrodes in a protective gas environment. On average, it can withstand about 15% energy fluctuations. All other functions have additional parameter adjustments. The voltage can be increased to a maximum of 60% during a hot start.

Welding machine Gysmi 165

| Options | Values |

| Voltage, V | 230 |

| Open circuit voltage, V | 72 |

| Maximum current, A | 160 |

| Adjustment range, A | 10…160 |

| PV, % | 10 |

| Diameter of consumables, mm | 1,6-4 |

| Degree of protection | IP21 |

| Weight, kg | 4,6 |

| Dimensions, mm | 125 x 280 x 200 |

| Guarantee | 12 months |

The Gysmi 80p welding machine has microprocessor control. It has unique arc characteristics. This is one of the first devices in the line of this brand. It is relatively low-power and can work with electrodes with a diameter of 2.5 mm. The weight of the device is small, so with equipment weighing only 2.5 kg you can move around without problems, work at heights, etc. Compactness is the main advantage of the model, since all other parameters are somewhat inferior to larger-scale analogues. Relatively low power of 3 kW ensures economical operation. The model contains all additional functions.

| Options | Values |

| Voltage, V | 220 |

| Open circuit voltage, V | 85 |

| Maximum current, A | 160 |

| Adjustment range, A | 0…160 |

| PV, % | 60 |

| Diameter of consumables, mm | 1,6-4 |

| Degree of protection | IP21 |

| Weight, kg | 2,5 |

| Dimensions, mm | 100 x 140 x 230 |

| Guarantee | 12 months |

Welding machine Gusmi 200 is a productive model. This is a microprocessor technology in which all parameters for welding with various metals are balanced. The model can be considered universal both in terms of the variety of materials with which it can work normally, and in terms of a wide range of parameters. In addition to manual arc welding, the inverter can be used for argon welding. To do this, you need to connect a burner to it. The weight is higher than that of younger models, but it is quite suitable for carrying by hand. The functional arsenal contains all the necessary functions to facilitate the work of the master.

Welding machine Gusmi 200

| Options | Values |

| Voltage, V | 230 |

| Open circuit voltage, V | 72 |

| Maximum current, A | 200 |

| Adjustment range, A | 10…200 |

| PV, % | 20 |

| Diameter of consumables, mm | 1,6-5 |

| Degree of protection | IP21 |

| Weight, kg | 5 |

| Dimensions, mm | 140 x 180 x 270 |

| Guarantee | 12 months |

User manual

There are no differences in the use of these inverters. The only thing is that in addition to setting parameters for certain welding operations, you also need to set the adjustment of additional functions that will affect the quality of the welding process. Simpler analogs have only the “on/off” position, whereas here you need to select a digital value.

Important!

If the inverter will be connected as a power source for welding using gas, you need to purchase reliable components that ensure safe operation, since they are simply not available in the original packaging.

Characteristics of the Gysmi 165 inverter

The Gysmi 165 welding inverter, popular in our country, which is now available in a new modification (E 160), has the following feature: its electrical circuit is supplemented with a microprocessor that allows welding using both TIG and MMA technology. As befits a modern welding machine, the Gysmi 165 model inverter has all the innovative options that make working with it much easier and allow you to obtain high-quality and reliable welded joints.

Welding inverter Gysmi 165 complete with storage case

Another notable feature of the inverter of this model is that the parameters of the option known as “Hot Start” can be adjusted at your discretion. The device in question, which has received many positive reviews from experts, has the following technical characteristics.

- The strength of the welding current, regardless of the operating mode used, can be adjusted in the range of 10–160 A.

- The inverter can operate on voltage in the range of 190–260 V.

- Open circuit voltage – 72 V.

- The current strength on the primary winding of the device when welding using manual arc technology is 33.5 A, when welding in a protective argon environment is 23.6 A.

- The dimensions of the device are 12.5x28x20 cm.

- Inverter weight – 4.6 kg.

Purpose of controls and displays

The presence of a digital display on its front panel greatly facilitates the work on such a machine: you can not only quickly set the required welding process modes, but also control them. How convenient such an inverter is to use is evidenced not only by the reviews of professional welders, but also by the impressions of those who are just learning the basics of this profession.

Advantages and disadvantages

When it entered the market, the Gusmi welding machine had several advantages that attracted the attention of users. Among all the general positive aspects, it is worth highlighting the following:

- for production, IMS technology, innovative at that time, was used, which made it possible to obtain equipment of higher quality;

- original design, different from ordinary models of welding machines from other manufacturers;

- well-thought-out and well-functioning cooling system;

- a reliable housing that protects the internal part of the equipment from impacts and other mechanical damage;

- convenient adjustment of parameters;

- Some models included plastic cases for storing accessories.

Subsequently, some craftsmen began to notice that the welding inverter has serious negative aspects. These include:

- complexity and high cost of repairs;

- the fastening system of some components leads to the fact that they are poorly resistant to shock, despite the protected housing;

- the price does not always correspond to the quality.

Important!

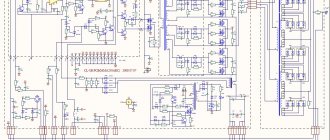

The unique production system possessed by the Gys welding inverter involves the arrangement of all components of the device on one board. The same board is connected only to the case, which saves space and maintains high performance.