Home / Consumables

Back

Reading time: 2 min

0

1508

Welding using argon is very popular among professional workers. With this type of welding work, the quality of the seams is many times higher, they are beautiful and durable.

To carry out such work you need to have a special material called filler metal wire.

Here you will find detailed information about what argon welding is and how to properly use filler wire, how many types and what they are.

- Basic data

- Selection of filler material

- Exploitation

- Let's summarize

Basic data

Filler wire is a special material with a small cross-section, which can consist of both different metals and artificial polymers.

The additive is very long, so it can be found in stores in the form of a coil. It is measured in kilograms. The type of filler material depends on the metal or polymer from which it is made.

Wire for welding work with metal products in an argon environment is a separate type. It is used when working on an automatic or semi-automatic machine.

Not only can an additive be made from this material; sometimes it is used to create electrodes.

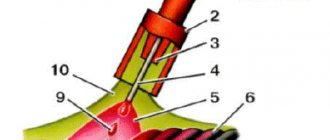

The use of filler wire for welding with argon facilitates the replacement of electrodes and creates smooth seams. The filler wire acts as a conductor between the welding current and the arc; it ignites the latter and maintains constant combustion.

Over time, the material is melted and mixed with the main workpiece. When mixing the workpiece and wire, the chemical and physical characteristics of the seams are improved.

The composition of the filler wire can contain any metal, since during operation it must be of the same metal as the workpiece itself.

Accordingly, if you are working with aluminum parts, the filler wire material should also be aluminum. Sometimes such wire is called filler rods for argon-arc work with aluminum and its alloys.

If you need to weld stainless material, then the composition of the wire should be based on anti-corrosion steel. These examples are highly generalized; we will cover all the details below.

Selecting an electrode for TIG welding

Tungsten was not chosen as an electrode by chance.

The metal is famous for its special refractoriness, for which it simply has no competitors. A tungsten electrode for argon arc welding can be identified by the “W” marking. Other symbols and even color indicate the type of alloying additives. They are necessary to improve the performance and increase the service life of consumables.

Electrodes can be either universal or special - for welding only with direct or only with alternating current.

As in the case of gas, let’s highlight the most popular type of electrode:

- WP (green electrodes) - tungsten electrodes without special additives for welding with alternating current

- Tungsten electrodes alloyed with lanthanum oxide WL-20 (blue color) and WL-15 (gold color) - universal electrodes for welding on direct and alternating currents

There are also tig electrodes with other additives - zirconium, cerium, yttrium oxide - there are quite a lot of them.

Table. Tungsten electrodes - composition and properties

| Electrode | Color/Composition | Properties |

| WP (green) | Tungsten electrodes without special additives. Tungsten is at least 99.5%, the rest is impurities. | Provide arc stability when welding with alternating current. Ideal for welding aluminum parts. |

| WL-20 (blue) WL-15 (gold) | Tungsten electrodes doped with lanthanum oxide 1.8-2.2 La2O3 | Provide easy ignition of the welding arc and its high stability, quick re-ignition. |

| WZ-8 (white) | Tungsten electrodes doped with zirconium oxide 0.7-0.9% ZrO2 | For welding on alternating current. Creates a stable, high-power arc. Withstand significant current loads. |

| WC (gray) | Tungsten electrodes doped with cerium oxide 1.8-2.2% CeO2 | For welding with any type of current, they maintain a stable arc even at low current values. |

| WY-20* (dark blue) | Tungsten electrodes doped with yttrium oxide 1.8-2.2% Y2O3 | Used for welding particularly critical joints. |

In addition to composition and properties, important parameters are diameter and length. The leading position in demand is occupied by electrodes for tig welding with a length of 175 mm. However, in addition to them, there are options of 50, 75 and 150 mm.

With diameter, everything is much more complicated, because it must be selected depending on the thickness of the metal being welded and the type of welding current. The table below will help you with this question. Here are recommendations for the most common WP and WL electrodes:

| TYPE OF CURRENT | Metal thickness, mm | Electrode diameter, mm |

| CONSTANT | 0,8 – 1,5 | 1 — 1,6 |

| 2 — 3 | 2 | |

| 4 — 6 | 3 – 3,2 | |

| 7 — 10 | 4 | |

| VARIABLE | 2 | 1,6 — 2,4 |

| 3 — 5 | 3 — 3,2 | |

| 6 — 10 | 4 |

And the last thing is sharpening the tungsten electrode. Proper sharpening will have a positive effect on arc ignition, combustion stability and the width of the weld. In most cases, the ideal option is a cone-shaped sharpening (for alternating current, a rounded tip is made).

The sharpening length should exceed the electrode diameter by 2-2.5 times. Long and thin grinding of the electrode is especially important when welding thin materials; this gives good focusing of the welding arc.

Selection of filler material

Since the range is quite extensive, novice welders may encounter some difficulties. Materials differ in manufacturers, brands, and diameters. What choice to make from all this?

The first step is to find out the type of work. Will you be producing or welding metals? Or work with soldering plastic parts? Having found the answer to this question, you will already move forward.

For example, you are going to carry out argon welding of metals. Find out what kind of metal you are going to weld. In this case, you need not just a type of metal, but a specific brand.

Once you determine that you have a steel billet, you may be faced with a dozen more different types of steel.

Once the brand becomes known to you, you can begin choosing materials.

The diameter of the additive must correspond to the thickness of the workpiece. The thicker the part, the larger the diameter. Often the values of wire diameter and metal thickness coincide.

It doesn't matter who the manufacturer is. The main thing is what were the conditions during storage and transportation of the additive to the store. Most likely, you will not be able to find out this information one hundred percent.

Therefore, it is better to purchase from a trusted store, and if possible, then go to an official representative. Representatives usually follow all storage rules and you don’t have to worry about this.

Physicochemical characteristics

Filler wire for argon welding often contains alloying elements that increase corrosion resistance. This is very convenient both during welding and during storage. A special composition helps to create a plastic material that tolerates deformation well, and this applies to the state before welding, as well as after it. In most cases, except carbon wire, the material has a low carbon content, which counters its brittleness. Thanks to this, the impact strength of the seam can be increased. Some brands are able to reduce the thermal conductivity of the metal so that deformation does not occur during welding

Filler wire for argon welding

Technical characteristics of popular brands

Using the example of the SV08G2S brand, we can consider the technical characteristics. Tensile strength can reach from 882 to 1370 MPa. Moreover, the smaller the diameter of the filler material, the higher this indicator.

Filler wire grade SV08G2S

In OK 15.66 wire, the tensile strength is only 500 MPa, since this is a grade for welding cast iron, so it has a fairly high fragility.

OK 15.66 filler wire

The characteristics of the 06X15 brand are as follows. The melting point is from 1453 degrees Celsius, the relative elongation is up to 35%, and the hardness is 90 HB.

Exploitation

The choice of filler material is not the most important element when working with argon media. You also need to understand welding technology and what its standards are. The technology itself is based on the use of argon gas to form seams.

For this type of welding, filler wire and electrodes are used. Electrodes may or may not be consumable. We will consider the use of non-consumable electrodes, since this method is more popular.

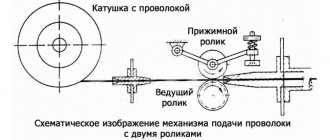

For welding in argon, automatic and semi-automatic machines are used. The additive is filled into the feed mechanism, then the desired mode is set and it passes into the welding zone.

Step-by-step semi-automatic welding process in argon

First of all, it is important to make sure that the equipment is ready, namely, set the operating mode of the semi-automatic machine, set the current strength, voltage, and wire feed speed. If aluminum wire is used for semi-automatic argon welding, it is better to choose a pull-type feed mechanism. While the pushing one is more suitable for steel wire. When the thickness of the product material is up to 3 mm, the current strength is set in the range of 120–145 A, and the wire speed is 900 m/h.

Another important nuance is polarity. Most often, direct current with reverse polarity is used for such work. That is, “-” is applied to the product, and “+” is applied to the burner with wire.

During the preparation process, it is necessary to clean the surfaces of the products. The edges of aluminum blanks are wiped with acetone and then treated with a wire brush. This is necessary to get rid of the surface film that complicates welding work.

Let's summarize

This is all the basic information that will help you work with argon gas. When selecting filler materials, consider what metal you are going to work with.

The additive can be used to mix with the workpiece and to form a joint using only the additive material.

Do you have experience with welding in an argon environment? What filler material did you choose? Have you had any problems during welding work?

Leave your comments and share your experience. Maybe your story will help beginners avoid serious mistakes. Productivity at work!