Modern chainsaws are rather capricious devices, although their creators use the same technologies in their production. The problem is the materials used. According to independent sources, a tool for cutting wood in the average price category lasts 500-1200 hours, professional devices - up to 2000, and sometimes longer. At the same time, it is important to follow the manufacturer’s recommendations: maintain the equipment in a timely manner, observe a certain operating mode, fill with high-quality fuel and oil.

Chinese and new chainsaw does not start, what could it be?

The popularity of Chinese chainsaws knows no bounds.

This is due to their main advantage - affordable cost. At the same time, owners of Chinese chainsaws often have questions about problems starting the engine of the tool. Before you find out why a Chinese chainsaw won’t start, you should note one feature - the design of these tools is no different from Russian, German and other manufacturers. That is why the reason why the chainsaw does not start can be detected based on the algorithm described above. Chinese chainsaws are very sensitive to fuel quality, so checking the fuel quality comes first in the diagnostic algorithm. The use of low-quality fuel leads to the fact that the tool does not work at full capacity, its service life is reduced, and there are also difficulties with starting

The instructions for the tool indicate the recommended type of gasoline and oil, which are important to use in order for the Chinese chainsaw to work for a long time and at full power

https://youtube.com/watch?v=kUz7KXtDhOs%3F

If you bought a new chainsaw and it does not start, then troubleshooting should begin by returning the tool to the store. Make sure that you start the engine of the tool correctly, and if you cannot achieve a positive result, then you need to return the tool to the store under warranty. Attempting to troubleshoot the problem yourself will leave traces and may void the warranty.

It is recommended to double-check that the fuel mixture is prepared correctly. If everything is done correctly, but the engine of a gasoline tool does not start, then there is a high probability of a manufacturing defect. There can be a defect with any part, but this should already be determined in the store’s service center.

Consequences of operating on a rich and lean mixture

- Due to the operation of the engine on an excessively rich mixture, a layer of leading carbon is formed on the insulator of the central electrode, which can cause interruptions in sparking.

- White or gray color of the center electrode insulator indicates a high combustion temperature in a low-fat mixture. Both options negatively affect the traction performance and durability of the power drive.

- Installing the carburetor on a lean mixture can cause a phenomenon where the chainsaw does not start hot; in another version it grabs, but does not start.

READ Crosscutting With Or Without Broaching

Confirmation of the normal quality of the air-fuel mixture is the brown color of the insulator and the absence of carbon deposits.

How to remove and replace the drive sprocket

The chain moves along the bus by a drive sprocket, which is connected to the gearbox. It is an assembly unit that rotates due to a bearing. At the end of the tire there is a driven sprocket with the same pitch relative to the drive one. Therefore, when carrying out repair work, all factors are taken into account: the alignment of the splines, the presence of bearings, and the kinematics of the tool.

When the spline wears out, the drive sprocket is replaced, otherwise traction with the chain will not occur.

In order to change a part, you must perform the following steps:

- unscrew the nuts of the tire cover and remove the headset using working tools;

- remove the air filter;

- unscrew the saw spark plug;

- ;

- inspect the drum and check the crown;

- ;

- if necessary, replace the broken part with a new one;

- Reassemble all parts in reverse order.

If the process of replacing a sprocket on a Husqvarna chainsaw is difficult, use the services of a specialist.

Fake? It's worth knowing in advance!

Experts say that before purchasing, it is extremely important not only to check the spark on the chainsaw. Well-known and high-quality devices like Calm are rated by serial number. The subtleties of this procedure are clearly visible in the photograph. The fact is that this type of equipment is very expensive. That's why even in a store you can often find a fake.

How to determine before buying an original chainsaw chainsaw? The easiest way to do this is with a serial number. You can find it right under the muffler. This is a tool. Sometimes the manufacturer indicates this information on the clove. It is located somewhat further from the muffler. The same part of the original product will feature not only digital information, but also the company logo.

Another criterion that indicates that this is a real Chainsaw Chain is the presence of a branded sticker. It must be present on the body itself or under the serial designation. The tag has a barcode.

Spark plug problem

A problem with spark plugs is one of the most common causes of chainsaw breakdowns!

This is one of the most common reasons why the engine stalls when cold. As a rule, its electrodes are covered with a layer of corrosion and carbon deposits, as a result of which the distance between their ends decreases - and there is ultimately no room for a spark to jump through.

Expert opinion

Samoilov Vladimir Alekseevich

Experienced gardener and specialist in gardening equipment

Ask a Question

Each manufacturer has its own distance between the electrodes, so before inspecting the spark plug you must carefully study the operating instructions and technical specifications of the tool.

The cause of corrosion and carbon deposits on the electrodes is uneven fuel supply, which is already a problem with the carburetor, which can be solved separately. There doesn’t have to be soot on the spark plug - there may be no spark because the fuel completely fills it when it’s hot, which also indicates problems with the carburetor.

The spark plug itself must be removed, dried and checked to see how the spark passes through it:

- First, remove the wire and unscrew the spark plug.

- Return the wire end to its original position.

- Place the spark plug on the cylinder with the skirt.

- Check for a spark by starting with the starter.

If there was a spark in this way, then you need to immediately move on to the problem with the carburetor. If not, then the spark plug must either be cleaned of rust and carbon deposits, or replaced. It is also possible that adjusting the distance between the electrode contacts will help.

Other reasons for the lack of spark include:

Generator unit malfunction. If this is the reason, then the problem can only be solved by completely replacing it.

Poor or broken contact between the spark plug tip and the electrically conductive high voltage cradle. There can be a simple adjustment using a tester.

The final check for problems with the spark plugs can be completed with a number of simple procedures, after which the chainsaw should start:

- Unscrew the spark plug and give it a full inspection.

- Clean it from rust and deposits, dry it

- Place the ends of the electrodes at the correct distance.

- Drain all excess fuel from the engine of the tool so that the ignition compartment does not flood.

- Place the spark plug back and try lighting again.

If these procedures helped and the saw began to work and the chain began to move, then you can work like this for about 5-30 minutes until the spark plug floods again

It is important to understand that this solution is temporary and just indicative. The main problem lies in the carburetor.

The question with him is ambiguous: in any case, it is necessary to adjust the fuel supply, but how to do this - yourself or with the help of a mechanic - is up to you.

When setting up the carburetor, be sure to use a tachometer, which will allow you to find out the number of engine revolutions with greater accuracy.

Based on them, you can already adjust its operating mode by adjusting the tightness of the screws on the carburetor block in several scenarios:

Setting for continuous operation at low speeds.

Arranging the correct fuel supply at maximum speed.

Setting up idle speed.

Expert opinion

Samoilov Vladimir Alekseevich

Experienced gardener and specialist in gardening equipment

Ask a Question

It is possible that the carburetor is sucking in a lot of air from the outside, which is why the saw begins to behave strangely at idle speed, and the amount of revolutions changes on its own. This can be solved by using ordinary gaskets on the carburetor, with the help of which it is necessary to ensure its tightness.

A complete inspection of the carburetor is necessary if it was not possible to determine a specific problem, but there is confidence that the jamming of the saw is associated with this particular part.

The audit is carried out as follows:

- It is necessary to remove all communications (wires and hoses) from the device;

- Carry out cleaning and purging. It is better to do this without removing the carburetor;

- Remove the product and clean it a second time so that no traces of fuel or oil remain inside;

- Gradually disassemble the device, guided by the drawing in the documentation or drawing up a diagram yourself;

- All channels must be blown out with compressed air, and parts must be washed in an industrial solvent;

- Give the parts at least 2 hours to dry;

- Reassemble the carburetor, strictly following the instructions in the documents and diagram;

- Connect back.

Benzopilapilit to the side

When cutting, you may notice that the result is an uneven cut. Why does benzopylapilit crookedly? There are several reasons:

- Incorrect chain sharpening. The teeth are sharpened at the wrong angle or only in one direction. Proper sharpening is required.

- Incorrectly selected chain. At very high speeds, a difference of even 0.2-0.3 mm between the width of the groove or the width of the seat will be visible, which is why chainsaws cut to the side. An appropriate circuit must be installed.

- Uneven tire wear. Over time, the tire wears out on one side and then the chain pulls to the side. Rotate the tire regularly to ensure even wear on both sides. If the wear is excessive, replace the tire.

READ What oil can be used for a chainsaw chain

Why does the chainsaw stall?

If the chainsaw starts and stalls, the reasons may be different. An external inspection should be carried out before attempting to repair the instrument.

If the saw stalls during operation, you should check the presence of a mixture of oil and gasoline in the tank. If the fuel mixture runs out, the device will not work. In situations where there is still gasoline left, you should evaluate the quality of the tool before turning it off. The appearance of extraneous sounds and the subsequent sudden stop should alert you.

The formation of carbon deposits on the electrodes can also cause difficulties in the operation of the tool. You should carefully inspect the device and clean it if necessary.

When you press the gas

In cases where the chainsaw stalls when you press the gas, you should check the muffler and fuel filter. A possible cause of the problem is a leak in the fuel hoses. In some cases, adding speed helps.

Sometimes checking all the details does not give results, the tool suffocates, chokes when gas is added. If the device stalls when a person presses the gas, it is possible that the fuel supply is insufficient for normal operation. This phenomenon occurs due to a clogged carburetor or filter.

Damage can also occur due to the air filter becoming clogged with dust. When you give gas, the device stops working. You should not fix the problem yourself, since each model has individual characteristics.

The problem may be caused by insufficient or lack of lubrication on the chainsaw chain. If the chain is dry, you should clean the channels through which oil is supplied to the device bus. If the oil leaks, there are cracks and defects in the pipes, they need to be treated with sealant.

Under load

In situations where the device stalls under load, the problem may be with the gas tank or filters. Check the fuel quality and change the filter.

Often the saw does not gain speed due to the fact that the mixture poured into the gas tank has a low octane number. There is not enough power, sufficient heating is not possible, the chainsaw stalls under load.

Often, malfunctions of components lead to the device stalling under load. Hoses, seals, and gaskets should be checked for leaks. If parts are faulty, you can try to repair or replace them.

In cases where the chainsaw starts and immediately stalls, there is not enough fuel, the device does not heat up. The device must be recharged

It is important to use the correct mixture. Different types of fuel are better suited for different models. It is necessary to read the instructions, recommendations, reviews of people for whom the device works normally

It is necessary to read the instructions, recommendations, reviews of people for whom the device works normally.

Idling

In situations where the chainsaw stalls at idle, you need to inspect the condition of the muffler. If the part is dirty, exhaust gases are poorly removed, the engine cannot continue to work and stops.

The saw stalls at idle and in cases where the carburetor is not configured correctly. For beginners, it is better to entrust the repair to specialists, since there is a possibility of incorrect settings, due to which the tool will not be able to work. A tachometer is required to adjust the carburetor.

At high speeds

If the device stalls at high speeds, pay attention to the condition of the gasoline and air filters, the serviceability of the fuel hoses

A dirty air filter can be washed under warm running water.

It is important to thoroughly dry the part before installing it so that water does not damage the serviceability of the tool.

If fluid stops flowing through the fuel hose, it is clogged. You can clean the part or replace it with a new one.

In cases where the saw stalls at high speeds, but the liquid completely flows through the hose, and the air filter is clean and in good working order, look for the cause of the breakdown in the fuel filter. Replace it with a new one or clean it.

In some cases, the problem is hidden in the gasoline pump. When a component wears out, fuel begins to leak through the walls. If this phenomenon is observed, a new pump should be installed.

When tilted

If the saw does not develop speed when tilting, turns off, or stops working, you need to check the fuel level in the tank. If it is not too high, the device in an inclined position is not supplied with sufficient fuel, since the fuel pipe is above the mixture level.

External condition is an important criterion

When a chainsaw is stored in a store for a long time, it is necessary to check the functionality of the device before purchasing. Don't try to run the tool

First of all, it is important to evaluate the appearance of the device and check whether the case contains:

- kinks;

- dents;

- cracks.

Read:

Particular attention should be paid to the pipes. If these parts are deformed, they should be replaced immediately

If the device has been stored for a long time, it is necessary to completely drain all available fuel. Oil and gasoline mixed with each other form sediment over a long period. It can ruin the condition of the carburetor.

Troubleshooting Tips

Fuel transfusion and filling of a chainsaw spark plug can be one-time and accidental. For example, “over-pumping” with a pump cap (primer): the engine does not start immediately, the operator presses his finger on the cap again and again, tries to start it, then pumps it up again.

In this case, the reason is not at all in the carburetor. You need to unscrew the spark plug and ventilate the combustion chamber by pulling the starter cord several times, as when starting. The candle is wiped, dried on the flame of a gas burner or burner, or another one is used. They check the spark, put the spark plug in place. They try to start it first without choke.

If it does not start after 3-4 jerks, press the pump cap 2-3 times. They try again. That is, after an overflow, it is better not to pump up the fuel first, but to pump it up incrementally. Until the engine starts.

Candles sometimes require their own maintenance and care.

- Inside, around the insulator, there should absolutely be no soot or dirt.

- The contact between the electrode and the plate from the spark plug body is cleaned with “zero” sandpaper. Carefully, without rounding the end of the electrode.

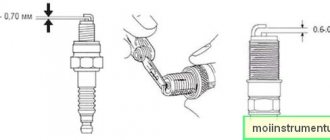

- You need to know the recommended spark plug gap indicated in the instructions for each chainsaw model (from 0.5 to 0.65 mm or more).

- To accurately adjust the spark plug gap, special feelers are used - a fan-shaped set of plates of different calibrated thicknesses, which fold into a handle like a folding knife. Sold in auto tool and spare parts stores.

- When working in winter, it is better to store the chainsaw at low temperatures. When taken out of the heat and into the cold, a sharp temperature change can cause condensation to form everywhere, including in the ignition system, and this is harmful.

One of the reasons for the lack of spark in a chainsaw is described in the following video, where they also talk about how to fix the breakdown:

Modern chainsaw ignition systems are quite compact and reliable. You just need to protect them from direct moisture, shock, and exposure to extreme temperatures. And then there will be no problems with the lack of spark during startup. Also, 1-2 spare spark plugs that are known to work will not be superfluous.

Every year the technology becomes more perfect and smarter, more complex in design and easier to operate. Manufacturers of chain saws cannot help but keep up with the times: special vibration suppression systems, easy starting, automatic chain lubrication, tool-free chain tensioning... But no matter what additional functions the model is endowed with, it is not immune from malfunctions. For a chainsaw of any price range, the vast majority of breakdowns can be avoided with proper care and use of the equipment.

Visual assessment

What do I pay close attention to? Since a chainsaw is a very complex device, its mechanism is also a bizarre system. It is incorrect to assume that the device was necessarily configured at the factory or in the store. When purchasing a tool, first of all, you should evaluate:

- correct idle speed setting;

- degree of chain tension;

- general setting.

After all, most models were not pre-trained. That's why, if the buyer does not know the intricacies of using a chainsaw, it is worth contacting an expert. This will help check not only its configuration, but also its overall working condition. It is very important to make a visual assessment of the device.

What to do when a candle on a chainsaw fills

Before heading to the service center, it would be a good idea to try to fix the current malfunction of the spark plug on your chainsaw yourself. Of course, this is only relevant if you have “direct” hands, since, otherwise, there is a high probability of increasing the cost of repair work.

Poor quality fuel

The chemical composition of low-octane gasoline includes various alcohol components. Their complete combustion requires more time than when using high-quality fuel, and accordingly this becomes the main reason for the failure of the chainsaw spark plug.

Unfortunately, many citizens naively believe that fuel containing alcohol has a positive effect on gasoline consumption and purchase fuel substitutes. In some cases, efficiency does occur, but such fuel has a negative effect on the chainsaw engine, shortening its service life.

Incorrect start

As a rule, during the first start of a chainsaw, inexperienced men miss a “pop” when the air damper is closed and continue to pull the starter. Because of this, a large amount of fuel accumulates in the combustion chamber, but there is a critical lack of air. The spark plug is filled with excess gasoline and there is no longer any spark to speak of.

Clogged filter

Due to severe contamination of the paper filter of the chainsaw, a sufficient amount of oxygen does not enter the fuel chamber. The fuel mixture does not have time to ignite and gasoline floods the spark plug. If the filter has already exhausted its service life (this will be noticeable by its appearance), then it must be replaced. If you don’t have a new filter at hand, but you still need to work, you can try blowing the filter with a reverse air flow.

Chainsaws from different manufacturers and model ranges differ from each other. To clean or change the filter, it is a good idea to first look at the instruction manual. Well, or look there if you can’t remove the filter without prompting.

Ignition system failure

Perhaps this is one of the most difficult problems that will need to be overcome in order to continue using the chainsaw. There may also be several reasons for the malfunction here.

Incorrect clearance

For the most part, the gap on the chainsaw's spark plug should be within 0.5 - 1.2 millimeters (more accurate data should be reflected in the user manual). In order to check if this is so, you need to do the following:

- Using a screwdriver or special keys, unscrew the bolts securing the chainsaw cover.

- Having gained access to the flywheel and magnetic core, the clearance level is checked.

- If it does not correspond to the characteristics declared by the manufacturers, then using a special gasket or improvised means (an ordinary A4 sheet folded several times is perfect) the required distance is set.

Ignition coil problem

To make sure that the ignition coil is working properly, you need to be able to use a multimeter. This device allows you to measure the degree of resistance of the coil. A good coil will have resistance. In a burnt out one there is a break or a short circuit.

If the coil is working properly, then the gap between the coil and the flywheel may be broken. To set it up, you need to perform a number of simple steps:

- Dismantling the saw body and loosening the bolts that secure the ignition system. The magnet (magneto) of the flywheel must be connected to the coil itself.

- The adjusting plate is inserted between the flywheel magneto and the coil itself. The gap should be within 0.2 mm.

- After tightening the bolts, the adjustment plate is removed.

- It is imperative to rotate the flywheel completely and several times (2-3 will be enough). However, it should not cling to the coil.

- The final stage is assembling the chainsaw body.

Carburetor adjustment failure

Often the spark plug on a chainsaw is flooded due to improper operation of the carburetor. For greater clarity, we recommend watching this video

If this is your first time setting up a carburetor yourself, pay attention to the following factors:

- The presence of built-in compensators and other automatic control elements makes adjustment impossible without special equipment. In this regard, you will have to contact a specialized service center.

- If there is no proper effect from adjusting the carburetor, the cause of flooding of the spark plug will be a stuck float or a lack of tightness of the valve.

Replacement of wear parts

Support our channel in any way you can, this will encourage us to make new videos for you that will help you, we will

If you do not replace wearing parts in a timely manner, their excessive wear will negatively affect the remaining components of the chainsaw. In particular, if the tire and drive sprocket are not changed in time, increased vibration will negatively affect the crankshaft bearings. 2 how to check the magneto ignition module.

Chainsaw ignition module. The maximum working depth of the sprocket teeth should be 0.5 mm. In practice, sprockets are often operated to a wear depth of one mm or more. unaware that this leads to increased load on the crankshaft bearings and accelerated failure. When 3-4 chains wear out, it is necessary to change the tire itself; by this time its wear reaches its maximum values.

The chainsaw bar wears especially hard in the area where cutting is done most frequently, usually. this is the underside of the guide bar. To ensure uniform wear, each time the chain is replaced, the bar must be turned 180° relative to the horizontal axis.

When installing a new chain, a new drive sprocket must be installed. Since under normal load the service life of the drive sprocket is twice as long as the service life of the chain, it is advisable to use one sprocket for alternate operation of two chains. Thanks to this, the sprocket and chains wear out almost simultaneously.

Read:

Problematic situations when operating a chainsaw engine that arise due to a faulty spark plug, and how.

This video discusses the breakdown of the ignition coil, its replacement and starting the chainsaw. And also look at mine.

If you do not replace wearing parts in a timely manner, their excessive wear will negatively affect the remaining components of the chainsaw. In particular, if the tire and drive sprocket are not changed in time, increased vibration will negatively affect the crankshaft bearings. The maximum working depth of the sprocket teeth should be 0.5 mm.

In practice, sprockets are often operated to a wear depth of one mm or more. unaware that this leads to increased load on the crankshaft bearings and accelerated failure. When 3-4 chains wear out, it is necessary to change the tire itself; by this time its wear reaches its maximum values.

In this video, the ignition coil fails, it is replaced and the chainsaw is started. And also look at mine.

The chainsaw bar wears especially hard in the area where cutting is done most frequently, usually. this is the underside of the guide bar. Spare parts for Chinese chainsaws allow a weak spark to spark in the conditions. To ensure uniform wear, each time the chain is replaced, the bar must be turned 180° relative to the horizontal axis.

Read:

Video: Spark Lost on Chainsaw

Identifying the problem is quite simple. Disconnect the fuel supply hose from the carburetor and see what happens to the gasoline. If it flows smoothly with a good trickle, then breathing is fine. If it is not there or it flows weakly and intermittently, the cause is revealed. The airways are clogged with dirt. You can solve the problem by cleaning the air hole with a regular needle or a strong stream of compressed air.

Checking the chainsaw output.

One of the reasons for poor operation of a chainsaw may be a clogged exhaust duct or its muffler. A drop in power is observed during sawing of lumber and logs. This most often occurs due to tar deposits on the spark plug or muffler, which is formed when a bad mixture of gasoline and oil is burned, which interferes with the exhaust gases.

A clogged resonator can lead to poor starting of the chainsaw.

To eliminate the cause of poor starting of the chainsaw, in this case you can remove the accumulated combustion products. To do this, perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling panel and gasket;

- Remove the spark arrester;

- Disassemble the resonator body;

- Wash all elements from carbon deposits with detergent;

- Let them dry completely;

- Reassemble everything in reverse order;

How filters work

The next most popular cause of saw malfunction is clogged filters. The cutting tool consists of two filters - air and fuel. These parts are responsible for different processes, but equally contribute to cleansing and trap foreign particles.

Fuel filter

Checking the operation of the fuel filter is carried out as follows:

- The fuel supply channel is disconnected from the carburetor.

- Gasoline is being pumped.

- The supply of fuel is monitored.

- If gasoline flows under low pressure (or does not flow at all), then the conclusion is made that the fuel filter is clogged.

- All gasoline is removed from the tank.

- The filter element is detached using a hook.

- The replacement cartridge is being cleaned. If desired, you can skip this step and replace the clogged filter with a new one.

- The saw is going back.

Filters tend to become dirty over time. Therefore, experienced chainsaw owners clean filters as a preventative measure. The frequency of this procedure depends on the conditions in which the master works. If there is a lot of dust in the workshop, the cartridges become dirty faster.

Air filter

As a result of a clogged air filter, the saw engine begins to operate unstably. In practice, this factor leads to periodic switching off of the saw or difficulties with starting. The absorbent material accumulates dust and dirt, a large volume of which leads to complete obstruction of the membrane. When air stops flowing into the system, the gasoline becomes too rich.

The air filter is cleaned according to a similar scheme:

- The chainsaw is opened and the air filter is removed.

- Removing the filter prevents dust particles from entering the carburetor.

- The cartridge is disconnected and cleaned of accumulated dirt.

- The surface of the filter is treated with washing liquid.

- The element is thoroughly dried.

- The saw is going back.

Breather

What to do if the spark plug is flooded on the chainsaw

If you suspect a flooded spark plug, you need to inspect it. Using a spark plug wrench, it is unscrewed and carefully examined. If the spark plug is wet, but there is a spark, then it has definitely been flooded.

Many experienced owners are able to determine with a high degree of probability the current condition of a candle by its color. It is recommended to carry out this procedure regularly.

- Light brown soot is exactly what all owners want to see. In this case, the functionality of the chainsaw is not impaired.

- Black carbon deposits indicate an unbalanced mixture, namely a lack of oxygen in the fuel chamber. If the situation does not improve, there is a high probability that the chainsaw spark plug will flood again.

- If corrosion is detected on the fork or the distance between the electrodes is too large, then most likely a lean fuel mixture is used.

Structural components

All two-stroke gasoline engines have a similar operating principle, and therefore the ignition system in them has a standard structure and design.

Chainsaw ignition device:

- Magneto: a device that converts mechanical energy into electrical energy and provides a pulse of current to the chainsaw's spark plug;

- Spark plug: designed to ignite the fuel-air mixture through a discharge that occurs between the electrodes;

Magneto Spark Plug

- Electrical cable;

- Engine shutdown button.

Plugs come in spark, arc, glow and catalytic types. Chainsaws use spark plugs for 2-stroke engines. The schematic diagram of the chainsaw ignition is shown in the image.

Chainsaw ignition circuit

Main causes of malfunctions and ways to eliminate them

The main element of any chainsaw is the engine.

Each engine, no matter which one, “Husqvarna”, “Stihl”), has its own engine life. The limit of this resource depends on the quality of operation and storage conditions

Sometimes a saw can fail before its expected lifespan due to the poor quality of the fuel and oil used. After the motor limit has expired or intensive work with the saw, unpleasant consequences arise when the chainsaw:

- Doesn't start.

- It starts, but immediately stalls.

- It works, but there are interruptions in engine operation.

- The engine does not develop full power and stalls when you press the gas.

The consequences are very diverse, as are the reasons for their occurrence:

- problems with fuel and oil, their ratio is violated or other brands of fuel and oil were selected that were not recommended by the manufacturer;

- the fuel system is clogged;

- problems with the ignition system;

- carburetor settings are lost;

- vibration has loosened the fastenings of engine components.

Each problem can be either independent or complex. Sometimes these problems can overlap. It is necessary to consider them in more detail.

Chainsaw won't start

There was a need to do some work. The chainsaw won’t start, what are the reasons and solutions? Modern saws have the same operating principle and design. Therefore, let’s look at a specific example: what are the reasons why the Stihl 180 saw does not start?

It is necessary to check the condition of the spark plug. Due to carbon deposits or incorrect gaps between the diodes, the spark does not pass through. This prevents detonation of the combustible mixture. We clean the deposits, adjust the gap, check for the presence of a spark. To do this, put the tip with the wire on the spark plug, lean it against the cylinder (or any other metal surface), and pull the starter. If there is a spark, screw in the spark plug and start the engine. Along with manipulating the spark plug, it is necessary to clean and rinse the air filter.

If the start does not occur, then it is necessary to adjust the carburetor. We carry out the settings according to the instructions for the specific chainsaw. These actions are usually enough to start the engine. These recommendations can also be used in case of malfunctions on other Shtil models (ms142, 240, 250, 350) and even on models from other manufacturers.

The saw starts up and stalls

Usually the reason why a chainsaw starts and stalls is poor fuel quality and a violation of the composition of the combustible mixture. There are other possible reasons, such as: clogged fuel system, incorrect carburetor adjustment.

If the fuel filters are cleaned and the quality of the gasoline is good, then simply adding a turn of the “L” screw usually helps; it is responsible for idle speed.

Chainsaw stalls under load

The engine started, it idles quite smoothly, but the chainsaw stalls when you press the gas. The reasons in this case are: clogged air filter, clogged fuel channel, poor quality of the fuel mixture, incorrect carburetor adjustment, problems with the ignition system.

It is necessary to drain the contents of the gas tank and fill it with good fuel, with the correct ratio of gasoline and oil. Check the fuel hose and its integrity, and if necessary, rinse the tank and hose. Make additional adjustments to the carburetor.

Problems that arise can be easily resolved with your own hands. They do not require large expenses, you just need to periodically perform preventive maintenance to clean the chainsaw from dirt. Fill with good fuel and use the oil specified by the manufacturer. It is recommended to mix fuel and oil immediately before operating the chainsaw.

There is no need to keep the finished mixture, as resinous fractions are formed. These compounds negatively affect the piston group. At the beginning of work, you need to let the chainsaw warm up a little, and apply the load gradually. Compliance with technological requirements will allow your chainsaw to serve you for a long time.

Diagnostic stages

When a chainsaw refuses to start, it is necessary to diagnose all components. The correct sequence of checks is the key to timely elimination of the problem.

Quality and correct fuel supply

If gasoline is at the bottom of the tank, check whether the fuel drive is lowered into it. On some models, the “disease” is the disconnection of the supply hose, so check it first.

The quality of the fuel is of no small importance. Manufacturers recommend using AI-92 gasoline and special two-stroke oil

It is contraindicated to pour into engine oil or waste.

The manufacturer indicates the ratio of oil and gasoline in the instructions. Violation of proportions reduces the service life and prematurely disables the chainsaw.

The gasoline-oil mixture for refueling tools can be stored for no more than 15 days. Then the oil precipitates and the channels and jets become clogged.

Spark on the candle

Ignition of the fuel is impossible without supplying a high-quality spark, so the second stage of startup diagnostics is checking the ignition.

Components that have exhausted their service life produce a weak spark, so the saw does not start well. The procedure for checking a node:

- The candle is unscrewed, placed on the cylinder and connected to the candlestick.

- Turn on the ignition and pull the starter.

- If the spark is continuous, the spark plug is working.

- If the cutting is intermittent or absent at all, the part must be replaced.

At the same time, check the gap between the contacts. Its value should be from 0.5 - 1 mm. In this case, the specific size of the gap is indicated in the instructions.

Basic information about the condition of the candle is obtained from its appearance:

- Black carbon deposits – incorrect carburetor adjustment. The reason is a lack of air and an excess of fuel in the cylinders.

- The spark plug is wet - the entire ignition system is faulty or too much fuel is entering the cylinder.

- Red soot – there is an excess of additives in gasoline.

Filter status

Clean filters are the key to long service life for your chainsaw.

A common problem with chainsaw operation is a clogged air filter. Manufacturers recommend cleaning this unit regularly using a compressor. A clogged filter prevents air from flowing into the carburetor. As a result, excess fuel causes the spark plug to become flooded and stop producing a spark.

The fuel filter in the gas tank may also become clogged. If damaged, it must be replaced. The service life of a fuel filter depends on many factors. But the main thing is the quality of fuel and oil.

How does breather affect the saw plant?

One of the important parts of the chainsaw is the pressure regulator in the fuel tank - the breather. It is a valve that allows air to pass in one direction. When the outlet of a part becomes clogged, air does not enter the tank and the pressure inside increases.

Diagnosis of the breather is carried out in the following sequence:

- Unscrew the gas tank cap. If air escapes, the pressure regulator is faulty.

- Screw on the lid and start the saw. If the engine starts and immediately stalls, the breather needs to be cleaned.

One of the options for checking the operation of the unit is to monitor the flow of fuel from a disconnected hose. If gasoline flows out continuously, it means the part is working properly. A weak, intermittent stream indicates a blockage.

A small blockage can be removed with a needle without dismantling. If the breather is clogged thoroughly, you will have to remove it and carry out a thorough cleaning.

Muffler or exhaust duct clogged

Carbon deposits are systematically deposited on these components. It needs to be cleaned regularly, but most owners forget to do this. As a result, while the tool is operating, combustion products have nowhere to go, and the engine does not start or suddenly stalls.

The following factors contribute to increased carbon deposits:

- Poor quality fuel.

- Violation of the proportions of oil and gasoline.

Long-term operation of the tool without maintenance.

If a newly purchased saw does not start when using high-quality fuel, the tool should be returned to the seller immediately. Most likely, there is a manufacturing defect in the saw, and self-diagnosis will lead to loss of warranty.