After assembling the veranda frame and installing the rafters, I realized that the impact tool is very convenient in frame house construction (video).

Previously, I only worked as a screwdriver. Now there is an opportunity to purchase an impact wrench. After testing, I was convinced that the impact wrench and attachments make it easier to work with large fasteners. I bought the network version, but there are also battery-powered models - they have the same principle, only the difference is in price.

To work with a wrench you need to buy a set of adapters, otherwise you will only be able to work with hex fasteners

⇒ You can discuss the post on VKontakte or Facebook

Any comments or suggestions? Write / Call ⇒ my Contacts

Need help building a frame house? See ⇒ my Services

Tags: #Screwdriver #Wrench #Impact #Wood #Review #What to Tighten #Comparison #ScrewdriverWrench #ImpactWrenchWrench #Which is Better ScrewdriverOrWrench #Power Tools #InWood #Twisting #Adapters #ImpactWrench #ScrewdriverWithImpactMechanism #ScrewdriverAndScrewdriverDifference

quote: Originally posted by alexei2011june:

How to use a wrench without overtightening the screw? Can the tightening force be controlled by rotation? Can they assemble furniture?

I’m using a set of Shurik and impact wrench Milwaukee 18 volt lithium, I’m happy as hell, Makita sucks next to each other both in performance and in price (Shurik Makita cost as much as a set of Milwaukee in a suitcase and still went through repairs twice, collecting dust). A drummer with a “cartridge” for a bat, i.e. at the end there is a 6-sided hole. It pulls just any screw, twisted it without drilling and 150*6 with a cross under Pozidrive N 3. Smoothly pressing the button gives a low speed, no adjustments, as the tightening force increases, it finishes off by itself with a torque, when tightened all the way, it locks itself without tightening. I tightened hundreds of screws and the head broke off a couple of times. Full charge is 30 minutes, there is a charge indicator in the battery. Sucks the battery dry without losing power.

Forget about assembling furniture with such a drummer, he’ll screw right through. For furniture, I took a Makitov electric screwdriver, it folds from a straight state to an L-shaped one, I took a blue “Proff” while I was alive, but I quickly charge 7-volt batteries, in half an hour of work, but the replacement one also charges in half an hour at most.

| hunter1957 | posted 4-9-2011 22:30 The only thing to take into account is that lithium-ion batteries are not suitable for operation and storage at subzero temperatures. |

| ehpebitor | posted 4-9-2011 22:45 |

quote: Originally posted by Mower_man:

I charge 7-volt batteries quickly, in half an hour of work, but the replacement battery also charges in half an hour at most.

A small announcement: The Skil company is starting to produce a new corded two-speed drill/driver model - 6222 Energy - which will go on sale in September 2009. If it were not for the 6-meter power cord (220 V), it would be very difficult to distinguish it from its battery-powered counterpart. The model is planned for delivery to several dozen European countries, including Russia.

0.45 Amp. Rotation speed (idle): continuously adjustable in two ranges - 0-300 and 0-850 rpm. Diameter of screws to be driven (max.): 6 mm. Quick-release chuck, diameter 1.0-10 mm. Drilling diameter (max.): in steel - up to 8 mm, in wood - 10 mm. 19 stages of torque adjustment + drilling mode. Reverse. Weight: 1.2 kg. https://www.holodilnik.ru/domestic/drills_and_screwdrivers/skil/6222ab/

| Mower_man | posted 4-9-2011 22:50 |

quote: Originally posted by ehpebitor:

If it were not for the 6-meter power cord (220 V), then

Everything corded is “manual” in the firebox, the cords actually get stuck, I carry a lot in my hip bag or by the hook on my work belt. With larger units, of course, the situation is different.

| ehpebitor | posted 4-9-2011 22:57 |

quote: Originally posted by Mower_man:

the cords really get stuck

| Mower_man | posted 4-9-2011 23:08 |

quote: Originally posted by ehpebitor:

If in production, then to some extent I agree, but for the home once a year, unscrewing, tightening and drilling is an irreplaceable thing.

It depends on what kind of house and at what stage of finishing/construction, dozens of thousands of screws were screwed in. I only have about 30 door panels, tomorrow I will install permanent doors, 6 and 7 in a row.

| alexei2011june | posted 4-9-2011 23:19 A frivolous remark. Li-ion has no disadvantages, no worse in terms of temperatures nimh. I don’t know what they put in the instrument, the best cans are Panasonic NCR-18650 LiNiCoO2 - operating range -20 to 60 degrees. I have one in the 18650 assembly, protected, with a record capacity of 11Wh. In severe frost -40 we switch to lithium batteries. It’s a pity that tool manufacturers don’t use standard RC123 batteries (like in cameras) and their li-ion 18650 counterparts. More about autonomous power supply. There is a useful thing: 12/220 inverters. For an instrument, a clean sine wave is desirable - no overheating, soft start. Experience inverter 600W 2.5kg. An ordinary Soviet drill 420W - no problem. A small grinder 800W works, but does not cut at full power. The cable problem has been resolved. Wherever I can’t stretch the cable, I take a car battery and a converter box. I liked the Bosch impact wrench more for use on the farm. Some things in an old car cannot be carefully unscrewed without something like this. It's a shame he might have problems with screws. |

The difference between a wrench and a screwdriver

An electric screwdriver covers a wide range of jobs. It is used both for tightening (screws, screws, self-tapping screws) and for drilling low-density materials. The tool has a speed control and can be equipped with different types of chucks (quick-clamp or jaw). Suitable for home and industrial use. With a wrench, things are different. This tool is widely used in production for fast and high-quality fastening of parts, but it is increasingly beginning to appear in the home kits of car enthusiasts. May have a hex chuck or a square with a friction ring. Impact wrenches are considered the most effective, although impulse-type models are also very common. The main difference between a wrench and a screwdriver is the increased power of the former. The impact wrench can tighten self-tapping screws, but it requires a fair amount of skill to do this, since with too much effort it can tear off the caps or drive the fasteners deep into the board. The main household use of a wrench is unscrewing car wheels and fastening large threaded structures. It is ideal for this task.

Read also: How to make a birdhouse correctly

The next difference is the cartridge. Unlike the clamping mechanism of a screwdriver, you will need adapters to use drills or bits on a wrench.

Device and purpose

A screwdriver is used for various construction and repair work, but its main function is to quickly screw in and tighten fasteners: self-tapping screws, screws, bolts, screws.

It helps to cope with a large volume of tasks in significantly less time than using a screwdriver.

Budget screwdrivers of low and medium power are used in the assembly, installation and dismantling of furniture, equipment, construction of frame structures (partitions, walls, suspended ceilings) and other objects. A powerful tool with an impact mechanism copes with drilling holes.

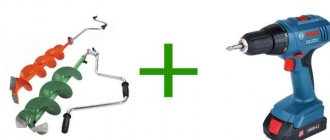

In addition to the standard operations listed in the instructions for the screwdriver, it can also be used for other tasks. Use a mixer attachment to mix thin solutions. Using a special adapter, the device is connected to an ice auger to quickly make holes.

The body of most screwdrivers is made of plastic, which reduces the overall weight of the tool. Inside the case are located:

- engine. Depending on the type of device, it can be electric or pneumatic. The former operate from a network or battery, the latter from a compressed air tank or compressor.

- Gearbox. A gear mechanism that transmits rotational motion from the motor to the spindle.

- Clutch-regulator. Connected to the gearbox, it is used to adjust the screwing depth and torque.

- Start capacitor. He starts the engine.

- Chuck. Bits, drills, and socket heads are inserted into it. The most common are quick-clamping three- or four-jaw ones.

- Power source (battery) and/or power cord.

The body houses a control panel with a power button and a speed switch. To operate in unscrewing mode, reverse is used. Additionally, the screwdriver can have a backlight and a fuse.

The difference between a wrench and a screwdriver

An electric screwdriver covers a wide range of jobs. It is used both for tightening (screws, screws, self-tapping screws) and for drilling low-density materials. The tool has a speed control and can be equipped with different types of chucks (quick-clamp or jaw). Suitable for home and industrial use.

With a wrench, things are different. This tool is widely used in production for fast and high-quality fastening of parts, but it is increasingly beginning to appear in the home kits of car enthusiasts. May have a hex chuck or a square with a friction ring. Impact wrenches are considered the most effective, although impulse-type models are also very common. The main difference between a wrench and a screwdriver is the increased power of the former. The impact wrench can tighten self-tapping screws, but it requires a fair amount of skill to do this, since with too much effort it can tear off the caps or drive the fasteners deep into the board. The main household use of a wrench is unscrewing car wheels and fastening large threaded structures. It is ideal for this task.

Read also: Sails for small MK ships

The next difference is the cartridge. Unlike the clamping mechanism of a screwdriver, you will need adapters to use drills or bits on a wrench.

Additional functions of screwdrivers

Modern equipment has a number of additional functions that significantly simplify its operation. These functions include:

The rotation speed is very important for the operation of a screwdriver, since the more revolutions per minute the tool performs, the less the load on the engine.

- The impact mechanism is a rather useful feature that allows you to drill holes in stone and brick.

- A pulsed increase in torque is useful for easier sinking of fasteners into the material when unscrewing a stuck screw or drill.

- Backlighting is a useful addition when working in hard-to-reach places or in places with poor lighting. The most successful option is to place the light source above the battery pack.

- An important function of the device is the ability to regulate the rotation speed. Almost all modern models are equipped with this function. With its help, you can independently set the required drill rotation speed, which allows you to perform your tasks more efficiently.

What is the difference between the tools

An impact wrench is generally considered a tool for professionals, while a screwdriver is mainly used for smaller household jobs. The main differences between a wrench and a screwdriver are their following characteristics.

- An impact wrench is more bulky than a screwdriver and does not have a chuck. At the end there is a special rod on which a nut head is attached.

- The power of a wrench applied to an object is many times greater than the power of a screwdriver. Using the first one, you can solve any “problems”.

- There is a significant difference in the weight and size of these mechanisms. Impact wrenches are usually larger and heavier.

- Screwdrivers have several operating modes that can be adjusted. Unlike them, no other special tools have this capability.

Thus, impact wrenches are used more often for heavy mechanical work, while its competitor is more often used for simpler household repairs. In addition, for simple tasks, you can try to make a wrench yourself using ordinary attachments.

Features of service. Prices

Like other types of tools, a manual meat grinder requires careful handling for long and successful operation. In addition, the use of any mechanical device must meet certain safety requirements. There should be no sharp edges, chips or cracks on the body and elements of the multiplier (handle, heads). Excessive work loads are also unacceptable. The socket head and handle must be fitted tightly and have no play. Heads that are worn out or have a broken hexagon cannot be used. Before use, make sure that the head is fully seated on the fastener until it stops.

How to make a wrench with your own hands?

An impact wrench is a modern metalworking equipment with an electric, gasoline, and pneumatic base for unscrewing/tightening nuts and bolts, as well as screws in metal and wood. In demand in all industries where these hardware are used. Not a single car service station (STO) or private car repairers can do without them.

Impact wrench, screwdriver, screwdriver, drill-driver... which is better

When looking at models of screwdrivers, you are sure to come across impact wrenches, screwdrivers and drill-drivers. How they differ and which is better to choose are two questions that many people have. The main difference is in the purpose of the tool:

- Screwdrivers - for tightening/unscrewing self-tapping screws into bases of different densities.

- Drills and screwdrivers. They can both drill holes and twist screws.

- Screwdriver (nut driver). A powerful tool designed for tightening large screws and nuts. Usually has a shock function - for reliable fixation of nuts. Usually used in car repair services. Too powerful for domestic use. Screwdrivers and impact wrenches are characterized by increased power - for tightening powerful fasteners

As is clear from the description, for construction or household work there is a choice between a screwdriver and a drill-driver. The second modification is a universal tool that has two modes of operation - drilling and tightening screws. It's good for occasional use.

Cordless or corded screwdriver?

Screwdrivers can be powered either from an alternating current source (stationary network) or from a rechargeable battery. The 1st type tool has 2 disadvantages: it is heavy and has a limited area of use. Battery-powered equipment has less weight and significantly greater mobility. They are convenient to work both outdoors and in buildings. There is no wire in such a tool that would constantly interfere with work.

If a screwdriver is needed for daily work, then your choice should be a professional tool.

There are several types of batteries, so choosing a good cordless screwdriver is not so easy. Batteries for mobile screwdrivers are divided into 3 types:

- lithium-ion (Li-Ion);

- nickel-cadmium (Ni-Cd);

- nickel metal hydride (Ni-MH).

Each type has its own strengths and weaknesses. The batteries of the last 2 types are somewhat similar to each other. On average, they can withstand about 1000 and 500 charge-discharge cycles, respectively. They are not afraid of low temperatures, but have a memory effect when the battery capacity decreases due to the fact that it was not fully discharged or charged. Therefore, they must be completely discharged before charging.

Lithium-ion batteries do not have this drawback, and they are also considered more environmentally friendly. But it is prohibited to operate them in low temperature conditions, as this will lead to their failure. When choosing a screwdriver, you should pay attention to the availability of a replaceable battery.

Choosing a device with 2 batteries is a good and correct decision, since an additional battery eliminates downtime.

If you understand the advantages and disadvantages of each type of screwdriver and it is difficult for you to make a choice in favor of one option or another, then you can purchase a combined type that can operate both from the mains and from a battery.

A few words about the impact wrench

An industrial or homemade impact wrench is used to install and remove bolts and nuts. Some may accidentally confuse it with a drill, but experienced craftsmen will immediately point out the special attachment in the holder that a regular drill does not have. You definitely won’t be able to do without it if you need to unscrew an old nut that is so rusty that you simply can’t unscrew it with your hands or a wrench. The tool is available in the following versions:

- pneumatic;

- gasoline;

- hydraulic;

- powered by electricity.

The impact wrench is widely used in repair shops and for various assembly work. More powerful tools are used in mechanical engineering.

Useful tips

Quite often there is a need to unscrew heavily rusted fasteners.

What to do in situations when a standard household tool cannot cope with the task? What to do in this situation, because household tools do not cope well with this task. A good solution for this is to use an impact screwdriver. Thanks to it, unscrewing rusted parts will not be difficult. It is enough to wet the fasteners with brake fluid so that when dismantling the part can be unscrewed as easily as possible. However, in some situations this does not help. There's no need to panic. Try lubricating the bolt with brake fluid again and leaving it for a while. The liquid will corrode the stagnant texture and you can do everything without significant effort using a percussion tool.

Advantages and disadvantages of impact wrenches

Significantly greater power and the presence of an impact mechanism in impact wrenches make it possible to work with threaded fasteners of a much larger diameter than when using screwdrivers. If for most screwdrivers the diameter of the fasteners that can be used is limited to 6 mm, then for electric impact wrenches it is 60 mm, and for impact wrenches with other types of drives it is even larger.

The use of a tangential impact makes it possible to unscrew heavily tightened, rusty/sticky nuts and tighten them securely, which is important, for example, when repairing vehicles.

The disadvantages of impact wrenches include much less versatility compared to screwdrivers. Square socket impact wrenches are only suitable for working with bolts and nuts, as well as plumbing bolts and anchor screws.

Impact wrench with a combined socket - square + hexagon.

Hex socket impact wrenches, also called screwdrivers, allow the use of a variety of bits (e.g. screws/screws) and chuck adapters, including for drilling. Using impact wrenches, you can successfully tighten self-tapping screws of various lengths/diameters into solid materials without pre-drilling. However, such manipulations carry the risk of damaging the bit or screwed elements due to the high torque and the absence of a release clutch.

The inconsistent torque inherent in impact wrenches also makes them difficult to use as multipurpose tools like screwdrivers. Another feature of most electric impact wrenches is the lack of torque adjustment. Most models of this type of device do not have any adjustments other than switching the direction of rotation (reverse). Some models have 2-3 speeds, through which you can adjust the tightening force.

A few advanced models of electric impact wrenches have up to 12 speeds, as well as an electronic rotation control system. Some models of pneumatic impact wrenches are equipped with adjustable torque.

Manual impact wrench “meat grinder” for trucks

In a truck driver's toolkit, a torque wrench or “meat grinder” is very popular. Such a tool can greatly facilitate the unscrewing of wheels, stepladders, springs and other bolted connections, even those that are “stuck” and under heavy load. Far from civilization, a compact impact wrench can be of enormous benefit, saving the driver time and effort.

Motorists who have not encountered a hand wrench often ask the question “How to unscrew a nut on a wheel.” This process is extremely simple, but has certain features that must be taken into account when using the tool. The first thing to remember is that a manual mechanical impact wrench turns in the opposite direction (if you turn the handle clockwise, the bit and nut will go in the opposite direction). It is also necessary to monitor the location of the stop (to unscrew/tighten the left and right wheels, its position changes). The exact information is given in the table below.

How to use a wrench as a screwdriver

To use a wrench for small jobs, such as tightening screws, you need to have considerable skill. Because the dimensions of the tool are not particularly suitable for this work. In addition, you will need to purchase some kind of adapter that allows you to clamp bits for screws. Even if you have it, you should be careful during the work itself. Electric impact wrenches are very powerful, so there are often cases when a self-tapping screw is screwed into the surface by several millimeters or the head is cut off. In other words, we advise using any tool strictly for its intended purpose. If this is not done, then either the tool itself will quickly wear out, or the work it performs will be of very poor quality.

Tool ergonomics

An important point when choosing a hand tool is the shape, location of the handle and controls. The most common are screwdrivers with pistol-type handles. In this case, it is very important to determine the center of gravity. Therefore, before buying, you need to pick up the instrument and understand how quickly the feeling of fatigue occurs. If after a few minutes you feel discomfort, it is better to choose another model.

There are models with 2 handles. They are more convenient when you need to drill a hole. Many hardware stores have special test benches. If you have them, you can take several types of tools you like and perform test drilling, which will help you choose the best option for you.

How to make a wrench from a screwdriver

For various reasons, in everyday life you may need to unscrew a couple of dozen nuts. Buying a wrench for such a fleeting need is quite expensive, but you don’t want to turn it by hand when you have a good old screwdriver at your disposal. It performs the main rotational function; all that remains is to convert it to loosen the nuts. Everything here is extremely simple. To make a wrench from a screwdriver, you will need a special adapter for the bits and the attachments themselves, the size of your nuts. Adapters cost around 300 rubles and are sold in most hardware stores. When all the components are at hand, we clamp the adapter shank in the chuck, put on the required attachment and use a homemade impact wrench from a screwdriver. Due to the low power of the screwdriver, you will have to loosen and tighten the nuts manually, but the time for unwinding will be reduced tenfold. Of course, you can go further, get into the electronic components of the tool and increase the rotation force. We do not recommend engaging in such manipulations, as they will most likely lead to damage to your instrument. Do not neglect the manufacturer's recommendations. Save this page on your social media. network and return to it at a convenient time.

Instrument care rules

The screwdriver requires minimal maintenance. In order for the tool to work properly, you must adhere to the recommendations specified by the manufacturer, do not use it for tasks that are not specified in the technical data sheet, and do not overload it too often. Periodically, the inside of the chuck and rotating parts must be lubricated with machine oil.

The instrument should be stored in a dry place, away from sources of heat, dampness and sunlight. After each use, wipe the housing with a clean, dry cloth to remove construction dust. If drops of mortar get on the screwdriver, you can clean it with a well-wrung out soapy cloth.

Read also: Transistor stepper motor control circuit

If you follow the operating rules and do not use the tool for tasks exceeding its capabilities, you can significantly simplify repair and construction work. In order for a screwdriver to work for a long time and not break down at the wrong time, you need to take care of it promptly, monitor the condition of the parts and recharge it before use.

Nowadays, there are many tools for tightening fasteners, and one of the most popular representatives of this class is a screwdriver. Almost any housework will be easier if you have this wonderful assistant in your arsenal. But despite all its versatility, the screwdriver has a very similar competitor. The impact wrench has a narrower focus, but is much better suited for certain jobs. Let's figure out how these tools differ and how you can make a wrench from a screwdriver with your own hands.

Carrying out installation work

The first piles are screwed into the corners of the foundation. After marking the land plot for development, places for their installation are determined.

Small holes are first dug by immersing the tip, which has a helical blade, into the ground. The tightening of screw piles begins with the products located at the corners of the foundation. Then all the others are aligned in height.

If it is impossible to level them horizontally during installation due to the fact that some can no longer be screwed into the ground, they are cut to the required height. Please keep in mind:

- installation must be carried out strictly vertically. To do this, it is necessary to periodically check the installation process using a magnetic or water level;

- You cannot screw another one in place of the one that has been unscrewed.

A nut from an old spanner

The idea of this homemade product belongs to the author of the YouTube channel Mr. Deswal.

Required parts:

- box wrench;

- extended nut;

- steel round timber;

- long bolt.

First of all, you need to cut off one of the heads from the ring wrench. We cut out a small part in it so that it can be put on the extended nut.

Next, we prepare the parts for welding. We clamp the elongated nut in a bench vice, put the head of a spanner on it (as shown in the photo below), and scald it. We clean the weld seam.

We cut the workpiece to the required length from a round steel bar.

We cut one of the ends of the round timber on both sides at an angle, and then finish it on a grinder or using a grinder.

We insert the steel round timber with its sharp side into the elongated nut, and then screw in a long bolt, which, when tightened, will rest against the end of the round timber and put pressure on it.

The homemade nut hammer is ready. Now you can test it in action.

In a vice we clamp the bolt with the stuck nut. We put the device on it, fix it with pliers or other available tools, and tighten the bolt.

As it is tightened, the end of the bolt will push the round rod forward, which, in turn, with its pointed part will “bite” into the nut, gradually splitting it.

Then we remove the nut splitter to the side, and remove the split nut from the bolt using pliers.

Details on how to make a simple nut with your own hands are shown in the author's video. We recommend you watch it.

HOMEMADE TOOL FOR RUSTED NUT

To make the device comfortable to hold in your hands, it makes sense to weld a handle made of a round or square rod to one of the sides of the elongated nut (or a piece of tube can be used).

Lubricant for air impact wrench

The service life of any mechanical tool largely depends on the quality of lubrication of its parts. The easier the mechanism operates, the less wear will occur. If you want your impact wrench to serve you faithfully for many years, follow the basic rules for maintaining the tool. To add oil to the impact wrench mechanism, you do not need to disassemble it. It is enough to add about 8-10 drops of lubricant to the nozzle of the tool where the air hose is installed, then start it and let it idle for 30 seconds so that the oil is quickly distributed among the parts. This procedure should be repeated every 3-4 hours during continuous operation, and also before storing the instrument.

Pros and cons of a wrench

A significant advantage of the impact wrench lies in its ability to tighten fasteners with increased force and unscrew rusted connections. This tool becomes an excellent assistant when working with large equipment. Unfortunately, the increased power of the tool makes its operation noisier. If you can work quietly with a screwdriver after lights out, then the impact wrench will quickly make itself felt.

To twist small elements with a wrench, you need to have a certain skill, otherwise there is a high risk of damage to the material. With a screwdriver, in this regard, everything is much more convenient, although it takes longer. The adjusted ratcheting mechanism will not allow you to twist the self-tapping screw, installing its head exactly on the surface of the material.

To summarize, we can say that a wrench is a powerful and noisy tool designed for tightening large fasteners. Suitable for household needs, but not everyone needs it. The screwdriver works at a lower speed. At the same time, it is very easy to use and does not require special skills or adapters.

Conclusion:

The impact wrench is needed by those who know exactly where they will use it. A screwdriver is suitable for most household jobs.

Professional or household tool?

Before choosing a good screwdriver, you need to decide on the amount of work that it will perform. For small and short-term work, the household option is perfect, as it will have less power and, accordingly, less cost than its professional counterparts. A household screwdriver is well suited for simple construction and repair operations:

- removing and screwing fasteners;

- screwing in dowels and anchors;

- drilling wood, metal and other surfaces.

Professional models are used for capacitive and complex construction and repair work. They are designed for long-term and continuous use, have relatively high power, and only high-quality materials are used in their manufacture. Therefore, the price of such equipment will be much higher.

In everyday life, screwdrivers with a torque of 10-15 Nm perform well. A professional tool is equipped with a torque of up to 120-130 Nm. In this case, the rotation speed can reach 1200-1300 rpm, while in household appliances 350-450 rpm is quite sufficient. If you need to carry out small-scale and complex work, then a home screwdriver is quite suitable.

Chuck type

There are two types of screwdrivers: keyed and quick-release chucks. The second option is more convenient, since the bits are released and clamped by turning the chuck, without additional devices. In this case, the tool is held with the left hand and the chuck is rotated with the right. Keyless chucks come in two types - with one or two couplings. The second coupling serves to lock the shaft so that the nozzle can be changed. If there is only one clutch, there is a button on the housing to lock the shaft, with which the shaft is locked. In this case, before starting to replace the nozzle, press the shaft lock button, hold it, and replace it. Release the button, you can work.

There are two types of quick-release chucks - single-clutch and double-clutch

An additional advantage of the quick-release chuck is that you can install a nozzle with a shank of any diameter into it. The main thing is that it fits into the holder. Therefore, when choosing a screwdriver, we pay attention to such a parameter as the diameter of the chuck. It determines the maximum diameter of the nozzle that can be installed.

Key cartridges require a special key. It is inserted into the hole in the chuck, turning in one direction or the other, and the bit or drill is released or clamped. This tool costs a little less, since its design is a little simpler.

Main characteristics of screwdrivers

If the work with a screwdriver will be carried out at a stationary workplace, then it is better to purchase an electric tool, since it does not require recharging and its power is higher than that of a cordless screwdriver.

If you contact a consultant in a hardware store with the words “help me choose a screwdriver,” then you should understand that they are more interested in selling a more expensive product than in helping the buyer. If you are not knowledgeable about screwdrivers, be prepared to pay a lot of money for such a purchase.

To prevent this situation from happening, you first need to decide for what work you are using this equipment:

- for removing and tightening screws, self-tapping screws and other fasteners;

- for drilling soft or hard wood;

- for drilling or cutting threads in metal;

- for tightening or removing dowels and anchors during installation work.

Having decided on the purpose, you can proceed. In this case, its main parameters should be taken into account:

- maximum torque;

- number of revolutions;

- operating modes;

- cartridge type.

Maximum torque is one of the main characteristics of any screwdriver. It determines the maximum diameter of a screw that can be screwed into wood, metal and other building materials.

If you are engaged, for example, in assembling furniture, then in this case it is better to buy a cordless screwdriver.

In most cases, 10-12 Nm of torque is sufficient for home use. With this power, you can easily tighten most self-tapping screws with a diameter of up to 4 mm to a depth of up to 90 mm for both wood and metal. With this tool you can also drill holes in wood with a diameter of about 12 mm, and in metal - up to 8 mm.

If the screwdriver is used to cover the roof of your house, then in this case it will be necessary to work with roofing screws, for which it is advisable to use a tool with a power of at least 20 Nm.

The maximum number of revolutions determines the quality of work. For example, for screwing in screws, 500 rpm is quite enough, but for drilling, this value should be increased to 1200 rpm.

Different operating modes of the tool allow it to perform different functions. Very often a screwdriver is used as a drill. To do this, it must be able to operate in simple or impact drilling mode. To carry out chiselling work, the device must be equipped with a perforation function. Home screwdrivers can have up to 5 operating modes, while professional ones have more than 20.

There are 2 types of chucks for screwdrivers: quick-release and key. For the 2nd option you need a special gear wrench. If a quick-release mechanism is used, then in this case everything is much simpler: you can easily insert a drill into it and a bit holder.

The key chuck can have 1 or 2 couplings. In the first case, the product is additionally equipped with a shaft locking mechanism when replacing one attachment with another. If there are 2 clutches, then instead of blocking the cartridge holds 1 clutch, and the 2nd clamps it.

Where and what power is needed

For truck tire fitting, the required tool parameter is from 2400 Nm onwards. The axle should be longer than usual, because many dual wheels have recessed studs or nuts.

Weight is important: from 6-7.5 kg (good models) to 16-20 (fake cheap ones). For tire mounting of passenger wheels, a maximum Nm of 700 to 1000.

Operating principle of a meat grinder

The design of this tool is quite simple and is a planetary gearbox assembled in a metal case. Active rotation of the handle is transmitted to the output shaft, while the tool head rotates much more slowly than the handle rotates, but the force transmitted to the bolt or nut increases many times. By increasing the torque, a manual meat grinder can cope with fasteners that are almost impossible to unscrew by hand. For trucks, buses, tractors, and other large equipment, having such a device can be very useful.