Reducer for carbon dioxide cylinder

To carry out work with carbon dioxide, you need equipment that lowers and stabilizes the pressure of carbon dioxide that comes from a cylinder or pipeline. Such equipment is called carbon dioxide reducers and regulators.

Carbon dioxide reducer design

Structurally, a typical cylinder carbon dioxide reducer is a device that includes:

- Inlet fitting with a filter element, through which the reducer is connected to the valve of the carbon dioxide cylinder. All non-flammable gases use a right-handed G3/4″ thread. Small volume cylinders have a Sp21.8″ thread. When selecting a cylinder-reducer pair, make sure that the threads match; if the thread diameters do not match, it is recommended to use adapters.

- A working chamber, the volume of which is regulated by a spring-loaded membrane made of oil- and petrol-resistant rubber. For balloon reducers, the typical design is a single-chamber design, but ramp and network devices can be manufactured in a two-chamber design with a sequential pressure reduction.

- An adjusting screw with a pusher and a pressure disk, designed to position the membrane inside the working chamber.

- A reducing unit that ensures gas flow through the gap between the valve and the seat into the low pressure chamber.

- Pressure gauges calibrated in MPa (kPa). As a rule, there are two of them: one shows the pressure at the inlet of the gearbox, and the second shows the operating pressure at its outlet. In a design with one pressure gauge, only the operating pressure indication gauge remains.

- Outlet fitting with nipple. To prevent the flow of carbon dioxide back into the reducer, a check valve is usually installed in front of the outlet fitting.

- A safety valve that is triggered when there is a sharp increase in the flow of carbon dioxide from the cylinder. It has a suction ring, which is used to periodically purge the valve.

- Sealing elements (gaskets).

- Housing elements made of brass or aluminum alloy.

Principle of operation

The principle of operation of the carbon dioxide reducer is based on the fact that the gas pressure at the inlet presses the spring of the reducing unit, as a result of which the gas enters the working chamber. The cross-sectional area of the chamber is larger than the cross-section of the inlet fitting, so the gas expands and the pressure decreases in accordance with the ratio of the cross-sectional areas of the chamber and the fitting. This ratio can be changed using an adjusting screw, which positions the membrane inside the working chamber and thus changes its geometric parameters.

The reducer maintains a constant operating pressure at the outlet due to the fact that when the inlet pressure changes, the membrane moves inside the working chamber, and the pressure (working) spring is compressed or weakened. This leads to a change in the geometry of the working chamber, which affects the degree of reduction in such a way that the change in pressure at the reducer inlet is compensated by a change in the ratio of the cross-sectional area of the chamber and the inlet fitting.

Gearbox selection

When choosing a gearbox for semi-automatic or any other welding, several parameters must be taken into account. And it’s worth starting with the working conditions. What exactly are you going to cook? And how often?

For home welders who use gas for rare work and short-term welding, any reducer that has the same thread as the cylinder can be suitable. Technical characteristics and cost are no longer important here.

If you perform simple welding work (assembling a barbecue or minor repairs), then a regular carbon dioxide reducer will do the job, even if it is installed on an oxygen cylinder. But keep in mind that this is a one-time solution and after welding you will have to throw away the device.

Speaking about models, we note the extremely popular and well-proven gearbox UR 6-6. It is designed for welding with carbon dioxide. It is inexpensive and has two full-fledged pressure gauges on board. One pressure gauge is designed to monitor pressure readings, and the second is designed to show gas flow. The AR-40-2 model is well suited for argon. This is a simple domestic gearbox. It works properly and does the job well.

Professionals assure that an argon reducer can be used with an oxygen cylinder, and vice versa. If you do home welding, you can check this statement. But our experience has shown that when using an oxygen reducer with an argon cylinder, the pressure can drop to a critical point. So use the devices as intended.

If you need a universal reducer for several types of gas, then take a closer look at the AR-40/U-30 model. It is designed for argon and carbon dioxide. Withstands temperature and pressure changes without problems.

These are relatively budget models. If finances allow, then pay attention to models not with pressure gauges, but with a rotameter. This device very accurately shows gas consumption without delays and with minimal errors. But this is a choice for a professional.

Carbon dioxide flow regulators

A carbon dioxide regulator is a device very similar to a gearbox (with a similar purpose and similar design), but it performs another important function - ensuring a stable flow of working gas.

Pressure is a static quantity. The pressure gauge will show the operating pressure no matter what the gas flow rate is. When calculating the need for carbon dioxide to perform a certain amount of work, when developing a welding process, or when making economic calculations, a parameter such as carbon dioxide consumption is much more useful. And here we need a carbon dioxide reducer-regulator - a device that reduces the inlet pressure to working pressure and ensures stable flow of working gas.

Unlike a gearbox, the main parameter characterizing the performance of a regulator is its maximum throughput. The value of this indicator is usually indicated on the labeling of the device in l/min. For example, U-30 means “carbon dioxide regulator with a maximum capacity of 30 l/min.” The pressure gauge of the reducer-regulator is calibrated in flow units (l/min or cubic m/hour). Flow stability is ensured by installing a nozzle or throttling valve with a calibrated hole at the outlet. Otherwise, the designs of the gearbox and regulator are identical.

general information

In general terms, a reducer is a device that reduces the pressure in a gas cylinder. It is installed directly on the cylinder and is necessary every time you use a semiautomatic welding machine, if you generally weld in a protective or inert gas environment. Often two cylinders are used, each of which must have its own reducer installed.

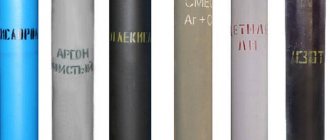

Each type of gas has its own reducer. For your convenience, the device is marked with a specific color, which indicates the purpose of the gearbox. If the reducer is marked in black with a yellow inscription, it means it is intended for carbon dioxide (aka CO2 reducer). If the background is blue and the inscription is black, it means for oxygen. White markings and red signature - acetylene. And black markings with blue or white inscription are intended for acetylene or argon, respectively.

Another way to recognize the reducer you need is to remember the color of the cylinder. After all, it is also marked using color. For example, a black cylinder is often used for argon, a blue cylinder for oxygen. And so on by analogy with other colors.

Means for combating gearbox freezing

Carbon dioxide freezes into “dry ice” at just -78°. Since compressed carbon dioxide actively takes away heat during expansion, with intensive extraction the gearbox cools to this temperature quite quickly, especially when working outside at low outside temperatures. In addition, carbon dioxide contains water in small quantities, the freezing point of which, as is known, is 0°. In this regard, when working with compressed carbon dioxide, a serious problem is freezing of the gearbox, leading to disruption of its functioning.

To combat this phenomenon, electric heaters are used. The Centrogaz company offers both flow-through heaters designed to heat the gas passing through them, and heaters mounted on the regulator body and heating the device body itself to a temperature that prevents the formation of water and carbon dioxide ice in the gearbox (regulator).

Regulator (reducer)

Designed to reduce the gas pressure coming from the cylinder and automatically maintain a constant operating flow rate (pressure).

Attaches to the cylinder valve using a union nut.

Gas pressure and flow are controlled by rotating the handwheel. Gas is withdrawn through a nipple to which a hose is attached.

The U-30P-2 carbon dioxide flow regulator is equipped with an electric heater, which is installed on the housing shank (supply voltage 36 V, power consumption 200 W)

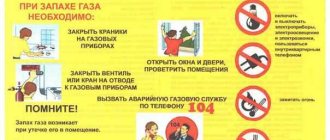

Rules for safe work with carbon dioxide gearbox

When working with compressed carbon dioxide under pressure, safety measures must be observed in accordance with the requirements of the “Inter-industry rules on labor protection” for the relevant field of activity and GOST 12.2.008.

Before starting work it is necessary!

- make sure that the pressure gauges are in good working order and that the filter element is present at the inlet fitting;

- check the tightness of all threaded connections;

- make sure that the connecting elements of the gearbox are clean and free of mechanical damage;

- Before opening the cylinder valve, make sure that the flywheel of the gearbox screw is turned out until the spring is completely released

Prohibited!

- tighten the threads, carry out any repair work on the gearbox under pressure;

- mount the reducer on a gas cylinder lying on its side or tilted;

- quickly open the cylinder valve before starting work.

The Centrogaz company provides refilling of carbon dioxide for welding and food grade carbon dioxide with preliminary cleaning of the cylinder. In our online store you can buy carbon dioxide reducers for carbon dioxide cylinders for technical and food purposes. You can receive the equipment by ordering delivery or picking up your order at any of our warehouses in Moscow.

Is interchangeability possible?

Some types of welding gears are interchangeable, but not all. So, instead of a specialized CO2 reducer for welding, it is permissible to use an oxygen one, but a reverse replacement is absolutely forbidden.

Oxygen is a chemically active substance, a strong oxidizing agent, so special metals and alloys are used to work with them. In addition, oxygen is pumped into gas cylinders under pressure that exceeds the same parameter for carbon dioxide by more than 2 times.

A welding reducer for carbon dioxide screwed onto an oxygen cylinder can last, depending on its quality, from several hours to a couple of weeks. But the sealing membranes, the main structural element, will inevitably be completely destroyed, as a result of which the device will begin to etch.

To avoid erroneous actions by the welder, different threads are made on gearboxes for flammable and non-flammable gases. For flammable - left, for non-flammable, respectively, right.

Similar threads are found in cylinders for cutting and welding. In this case, the oxygen reducer has a right-hand thread. Oxygen does not burn on its own, but supports combustion. It is explosive under certain conditions.

The oxygen reducer used during welding with a carbon dioxide cylinder faces another threat. Carbon dioxide causes parts in contact with it to freeze to -60 °C. Since the pressure regulator designed for oxygen is not supposed to withstand this operating mode, it will also begin to deteriorate.

Delivery of carbon dioxide reducers

Delivery cost in Moscow and the Moscow region: by courier - 500 rubles. (restrictions on courier delivery - no more than 50 kg and no further than 20 km from the Moscow Ring Road towards the region).

Delivery to other regions is carried out by transport companies. How to choose a transport company is described on our website in the Delivery in Russia section.

Contact number for receiving orders for delivery: +7 (495) 921-34-24 (accepted on weekdays from 9.00 to 17.00, on Saturdays from 10.00 to 14.00, and on the website - around the clock).

Dehumidifier

The dehumidifier absorbs moisture from carbon dioxide. Available in two modifications: high and low pressure. A high pressure dryer is installed before the regulator (reducer), and a low pressure dryer after it. The desiccant agent is silica gel or aluminum glycol. By calcination at 250-300°C, these substances can be restored.

1 – Bushing; 2 – Union nut; 3 – Spring; 4 – Grid; 5 – Filter; 6 – Drying material; 7 – Mesh washer; 8 – Housing; 9 – Fitting.

Explain about CO2 flow regulators for a semi-automatic machine

1 Why do some have one pressure gauge, and others have two?

It's a mess in the country. There should be 1 pressure gauge at a high level - show the residual pressure in the cylinder. It is necessary in order not to release the gas completely, otherwise there will be problems with refueling. And there is also such a thing as a change in pressure (flow) when the upper pressure changes. Each gearbox is different in this regard. 2 the pressure gauge must be calibrated as a flow meter to set the required gas flow. Therefore both are needed. This is specifically for welding gearboxes, and there is also one for beer and water.

2 Is the flow rate set using the same knob as the pressure? Is there a dependence of flow on pressure?

Naturally. The operating principle of a gearbox with a pressure gauge and a flow meter (except for the rotameter, see above) is the same. It's just a matter of scale graduation. At a constant bore diameter (nozzle), the relationship between flow and pressure is more or less linear.

3 Is a heated regulator necessary or is it unnecessary?

It may be needed either at high flow rates, or when working in the cold, or when using gas with high humidity. Without a heater, ice may freeze and individual parts of the gearbox may jam or the passage hole may become clogged. IMHO not needed for a personal garage.

4 With heating there is only one pressure gauge, a second one is not needed? Or can you install it yourself? There seems to be a plug there.

See above, the country is a mess. You can install it if you are sure that this is a plug and not a safety valve. True, I would not buy such products. H.z. what else did you save on?

5 Is heating always NOT ON 220V?

There is also 220, see https://www.energoportal.ru/unit68606.htm or others.

6 What is the fundamental difference between regulators and reducers for CO2?

If the color is black, then it is CO2, there are indeed ones designed for carbonating all kinds of water and other drinks. There is not a flow meter, but a gearbox. In general, they are not intended for welding, but people use them at low cost. Oxygen reducers such as BKO and argon are also used, only propane ones are not allowed. Their blood pressure is lower.

7 Finally, recommend a device for working with a low-power semi-automatic machine, with a 5-10 liter cylinder, the most optimal, convenient, and informative.

Almost anyone can. You quickly get used to the scales (flow or pressure) and features. You need to look at the construct. How the pressure screw is made, is it possible to unscrew the seat of the reducing valve (helps with repairs. How the surfaces of the parts are processed. This speaks about the production culture. From the manufacturers BAMZ and Donmet. These are more or less stable companies. You can count on warranty repairs if something happens.