Stainless steel is an alloy of iron and chromium. Its anti-corrosion properties are manifested due to the presence of a chromium oxide layer on the metal surface. This protective layer is very stable and even after mechanical or chemical damage it quickly regains its previous appearance, and the anti-corrosion qualities of the metal remain unchanged.

What do we know about stainless steel?

Corrosion-resistant steel or stainless steel is an alloy consisting of iron and carbon, additionally enriched with special elements that give it high resistance to negative environmental factors. The main one of these elements is chromium. Stainless steel contains at least 10.5% of it. Chromium, in addition to anti-corrosion properties, gives such alloys a number of positive characteristics:

- good processability by cold forming;

- exceptional strength;

- ability to obtain reliable connections by welding;

- possibility of long-term operation without loss of its characteristics;

- attractive appearance.

Chromium, contained in stainless steel in sufficiently large quantities, promotes the formation of a surface oxide film. It is this that protects the metal from corrosion.

Stainless steel sheet

Various grades (types) of stainless steel, and more than 250 of them have been created to date, contain in their chemical composition both chromium and a number of other alloying additives, the most common of which are nickel, titanium, molybdenum, niobium and cobalt. Naturally, steels with different proportions of alloying elements in their composition have different characteristics and areas of application.

As with any other type of alloy, carbon is an essential element in stainless steel. It is this element that gives the resulting metal alloy hardness and strength.

Today, it is impossible to imagine almost any industry without the use of stainless steel. Grades of this alloy, all of which are distinguished by the ability to successfully operate even in the most aggressive environments, are used for the production of cutlery and medical instruments, containers for food liquids and products, pipes for transporting aggressive media, household appliances, and much more.

Stainless steel rods

Stainless steel concept

Let's give a definition: stainless steel is a complex alloy steel that is resistant to rust in atmospheric conditions and corrosion in aggressive environments.1

Its resistance to corrosion differs from conventional carbon steels and therefore is widely used in the food industry, oil and gas and chemical industries for operation with highly aggressive environments and food products, since during storage, oxides and other substances do not form upon contact of the liquid and the surface of the container, which may affect the properties of the stored product.

What is stainless steel from a chemical point of view? — This is an alloy with a minimum mass fraction of chromium of 10.5% and a maximum mass fraction of carbon of 1.2%.2

In simple terms, stainless steel is made by adding alloying substances to iron in different proportions to obtain the required characteristics.

Thus, the main alloying element is chromium Cr. The alloys also additionally contain carbon C, nickel Ni, silicon Si, manganese Mn, titanium Ti, niobium Nb, cobalt Co, molybdenum Mo, vanadium V, sulfur S, phosphorus P, tungsten W, aluminum Al, copper Cu, cobalt Co.

What is included in stainless steel?

chemical composition of stainless steel

A few words about the “ingredients” used in the “cooking” of stainless steel. Or more precisely about alloying elements and their properties. By the way, steel is divided according to the degree of alloying. Austenitic corrosion-resistant steels are classified as high-alloy steels, since the total mass fraction of alloying elements is at least 10%, and the iron content is more than 45%. Let's continue the story about austenitic high-alloy chromium-nickel stainless steel 08Х18Н10, also known as AISI 304, which has alloying elements totaling approximately 28% (18% chromium and 10% nickel). This stainless steel is an alloy in which chromium (Cr) with nickel (Ni) and several other elements are added to iron (Fe) and carbon (C) during smelting. Carbon is responsible for hardness and strength, reducing toughness and ductility. A high carbon content will begin to reduce the cold brittleness threshold and can lead to difficulty welding the metal. Directly in imported stainless steel AISI 304, in contrast to its domestic counterpart, the percentage of carbon is much lower. Chromium in the alloy plays the role of the main “defender” in the fight against corrosion caused by exposure to aggressive environments and various temperatures. Since, thanks to chromium interacting with oxygen, a thin passive film of chromium (III) oxide Cr2O3 is formed due to the adsorption of oxygen occurring on the surface without destroying the crystal lattice of the original metal. This passive film, uniform in composition and evenly distributed over the entire surface of the metal, contributes to the appearance of stainless properties. Chromium, interacting with nickel, provides a stable austenitic structure, which contributes to high ductility, hardenability, good stampability and weldability of products. Nickel increases corrosion properties and prevents metal grain growth when heated. Chromium also increases the heat resistance of nickel, which, in turn, lowers the threshold of cold brittleness, which allows the use of stainless steel 08Х18Н10 in the temperature range from cryogenic -196 °C to high 800 °C. At temperatures above this value, metal oxidation occurs, accompanied by scaling and decarburization of the steel with complete volatilization of the protective passive film.

Speaking about the contact of AISI 304 stainless steel with food, I would like to note the influence of chromium and nickel. The combination of these two components in the alloy increases the corrosion properties and allows the use of products in aggressive environments. Although each product on store shelves has its own acidity levels, the acidic environment formed during the cooking process when interacting with stainless steel, even under the influence of temperatures during heat treatment of products, becomes insufficiently aggressive to affect or damage the integrity of the protective passive film layer , with which the steel is coated. And this, in turn, prevents the release of any harmful impurities from the metal that can interact with products. Therefore, steel can come into contact with food without any consequences.

Designations of stainless steel grades adopted in fasteners

The fasteners use stainless steel of the austenitic chromium-nickel group, which contains nickel in the composition from 5 to 25% and chromium from 15 to 26%, which gives it high corrosion resistance, and it also has no magnetism (does not magnetize). Steel of the austenitic group is marked with the letter A, followed by a number that determines its composition.

— Steel A2 The closest analogues are AISI 304, GOST 08Х18Н10 - weakly magnetic, corrosion-resistant and non-toxic steel, does not heat up. Easy to weld without brittleness. Begins to magnetize after processing. Fasteners are made from A2 steel for fastening ventilation facades (ventilated facades), stained-glass windows made of aluminum, fences, pumps, in shipbuilding. Temperature range from minus 200 C to 425 C.

- Steel A4 The closest analogues are AISI316, GOST 10Х17Н13М2 - unlike A2, it has 2 - 3% more molybdenum, due to which it better resists the effects of corrosion and acids. It is more antimagnetic compared to A2, 100% non-magnetic. Most often used in the shipbuilding industry, as well as in devices that no longer work correctly with magnetic fasteners. It is acid-resistant stainless steel and is also not afraid of sea salt and bleach. Temperature range from minus 60 C to 450 C.

Physical properties of stainless steel

A patent for stainless steel was issued in 1913 in Great Britain. Its creator was metallurgist Harry Brearley. The invention gave a huge impetus to the development of steel and other industries.

Stainless steel gained its popularity due to its wide variety of physical properties, including anti-corrosion. New steels are made with the addition of various types of impurities to the main component. The physical properties of stainless steel depend on the type and volume of additives.

During long-term use, a number of grades of stainless steel can succumb to corrosion. This is influenced by the impurities of various metals included in its composition. However, such alloys also have a number of advantages, due to which the likelihood of oxidation is no longer so serious.

The main physical properties of stainless steel, which distinguish it from some other metals, are:

- Strength. This quality of steel allows us to produce products that compare favorably with analogues. Resistance to physical stress prevents the product from deforming, maintaining its original appearance for a long time. The reliability of high-quality stainless steel lasts up to 10 years.

- Resistance to aggressive environments. External conditions have virtually no effect on the material, which makes it possible to use it for a long time while maintaining all its properties.

- Heat resistance. All products made from this metal are highly resistant to temperature effects, including direct heating by fire. They do not change their size, shape, or properties in the event of large temperature changes.

- Environmental Safety. The anti-corrosion properties of the material prevent it from oxidizing. The metal does not contain components harmful to health, which makes it possible to use it in the food industry.

- Anti-corrosion properties. They are basic for stainless steel and prevent rust from appearing on the metal. Moreover, even alkalis and acids cannot affect the occurrence of corrosion.

- Appearance of products. It is very different from products made from other metals. The surface of the products continues to remain shiny and clean for a long time.

- Compliance. Processing stainless steel is quite simple. It is easy to make a product of the required shape from this metal.

Before choosing a metal with given physical properties, you should determine the purposes for which it is needed. Scientists have developed many different components and impurities that help make a metal with desired characteristics.

Advantages of stainless steels

With the development of economic, scientific and technological progress, the requirements for the quality of materials used in areas of the national economy are growing.

Advantages of alloy metals:

- High level of anti-corrosion properties.

- Compliance with the standards stipulated by fire safety regulations.

- Reliability, long service life without changing technical characteristics.

- Ideal combination with any building materials.

- Variety of surfaces: polished, polished, matte, decorative.

- Wide selection of rolled metal products.

- Ease of processing, molding, and assembly of parts made from this type of steel.

- A wide range of brands with unique properties.

- Environmental safety, hygiene.

Application of stainless steel

The main applications of stainless steel include:

- Mechanical engineering.

- Chemical industry.

- Energy.

- Pulp and paper industry.

- Food industry.

- Medicine.

- Aerospace sector.

- Construction.

Due to its practicality and pleasant appearance, stainless steel has become widespread. The advantages also include a variety of stainless steel grades and surface types (ground, polished, matte, glossy and even colored surfaces). The appearance of stainless steel elements does not change for decades. Stainless steel also has higher heat-resistant properties than other steels.

In construction, stainless steel is used primarily as a material for the manufacture of finishing elements: railings, window and door openings, fire doors. It is also a good decorative material for equipping restaurants, offices, pubs, discos and metro stations. In everyday life, stainless steel in combination with glass or wood is found in furniture elements.

Special food grade steel is produced for the food industry. Such alloys are distinguished by a low amount of chemical additives and have the following markings: AISI 304, AISI 304L, AISI 316, AISI 316L, AISI 316Ti, AISI 321, AISI 430.

Medical stainless steel is needed for the manufacture of instruments, utensils and other devices. It is marked 12Х18Н10Т, and is distinguished by its high corrosion properties, absence of harmful substances, hardness and practicality.

There is a misconception that stainless steel is an expensive material. In fact, if you take into account the huge period of operation, the funds invested in it are fully recouped.

Why do you need to know the decoding of steel grades?

Anyone whose work is related to metals has had to deal with the concept of “steel grade”. Decoding the markings allows you to find out the chemical composition and physical properties of the alloy. Although at first glance the marking may seem quite complex, it is easy to understand. To do this, you need to understand the principle of its composition.

For such a brief description of the alloy, letters and numbers are used to indicate the chemical elements and their quantities. This means that for competent work with steels, it is important to know the abbreviations themselves and how each element changes the properties of the finished alloy. Then it will be possible to determine with utmost precision what technical characteristics a certain grade of steel has.

Having received an order for a product, designers develop a design and also select the most suitable steel grades for a particular case, based on decoding their properties. The device being created must function under certain conditions, so it is examined during movement - this is how it is possible to understand which parts will experience increased loads.

To establish requirements for the strength of elements, calculations are made. At the next stage, the metal is selected in accordance with steel grades according to GOST, which can withstand repeated loading and friction. The greater the load the product experiences, the more limited the designer is in choosing the material. Next, a prototype of the device is made from the selected metal and tested in accordance with the methods used in a particular area. At this stage, the steel grade can be changed. Let us note that most often steel is used for the manufacture of machines, devices and complex mechanisms.

Regardless of the specific area, working with metals requires an understanding of their grades, purposes and other characteristics displayed in the index. Thanks to the numbers and letters used in the code, it is possible to quickly understand the characteristics of the metal without requiring additional clarification. This article outlines the fundamental principle of classification, as well as a simple way to read the markings of the steels most common in production.

Steel marking - the meaning of digital and letter indices

Knowing the designation of letter indices and the semantic meaning of the numbers used in steel marking, one can draw conclusions about the need for the proposed grade for a specific purpose, without even looking in the reference book. Overpay for the titanium contained in the alloy if you do not need the high fire-resistant properties acquired by alloying with this expensive metal.

Some letter indices can change the designating element, depending on its location in the marking. Consider the correspondence of letter indices:

- A (at the beginning of the marking) – S

- A (in the middle of the marking) – N

- B – Nb

- B – W

- G – Mn

- D – Cu

- E–Se

- K – Co

- M – Mo

- N – Ni

- P–P

- P–B

- C – Si

- T – Ti

- F – V

- X – Cr

- C – Zr

- Yu – Al

- h – REM

The amount of each of them in the alloy is determined by the numerical value following the letter indicating the element. Expressed as a percentage. In cases where an individual element is small, less than 1%, the number is not placed after the letter index. Carbon, as an important element, is located in front of the marking, but is expressed in hundredths of a percent.

FeNi and Ni alloys are marked only with letter indices. The exception is the number after nickel (mass fraction) and carbon (FeNi only).

If the steel was produced using special smelting methods or remelting methods, this is indicated with a hyphen after the marking. Such special methods and methods include various methods of vacuum remelting, electron beam melting, treatment with slags of synthetic origin, and others. The total number of specific methods for obtaining the required grade of alloy is specified in the standard: 24.

Let's look at examples of deciphering the markings of stainless steels 05Х12Н2М and 04Х14Т3Р1Ф-ВД. 05Х12Н2М contains 0.05% carbon, 12% chromium, 2% nickel, and up to 1% molybdenum content. 04Х14Т3Р1Ф-ВД stands for: carbon 0.04, 14% chromium, 3% titanium, 1% boron, vanadium less than 1% percent, obtained by vacuum arc remelting.

Decoding steel markings

Alloy steels are those into which special chemical elements are introduced: nickel, chromium, cobalt, titanium, tungsten. Their addition to the steel composition serves to influence the structure of the metal and obtain improved properties. The marking of steels depends on the chemical composition. At the beginning, numbers are indicated indicating the carbon content in hundredths of a percent (GOST 4543-2016). Next are the letters that indicate alloying elements. In the names of steel and alloy grades, chemical elements are designated by the following letters:

- A (at the beginning of the mark) - sulfur;

- A (in the middle of the mark) - nitrogen;

- B - niobium;

- B - tungsten;

- G - manganese;

- D - copper;

- E - selenium;

- K - cobalt;

- M - molybdenum;

- N - nickel;

- P - phosphorus;

- P - boron;

- C—silicon;

- T - titanium;

- F - vanadium;

- X - chromium;

- C—zirconium;

- Yu - aluminum;

- h - REM (rare earth metals: lanthanum, praseodymium, cerium, etc.).

If the letter A is at the end of the marking, this indicates that the steel is high quality. The letter Ш is placed at the end of the marking for especially high-quality steels.

After the letter there are sometimes numbers indicating the content of the alloying element as a percentage. If there is no number, the content of the element is no more than 1%.

At the beginning of the marking of tool alloy steels, the first place is occupied by a number indicating the average carbon content in average fractions of a percent (GOST 5950-2000). If it is not indicated, then the percentage is 1% or more. Further, the designation of stainless steel coincides with structural steels.

Special-purpose stainless steel grades are marked differently. At the beginning there is a letter indicating the purpose of the steel:

- A – automatic;

- E – electrical;

- Ш – ball bearing;

- R – high-speed.

After that come numbers indicating the average number of the main alloying element.

AISI stainless steel marking

AISI marking is increasingly appearing not only on steel products from overseas, but also on Chinese, Russian, European and other products. This classification system takes its name from its birthplace, the American Iron and Steel Institute. The classifier was liked by consumers, manufacturers, and traders.

Classification

The grade of carbon and alloy steel is presented as a four-digit expression. The first digit in it indicates the main alloying component. The second digit identifies the secondary alloying element. The third from fourth digits indicate the carbon content.

- 1ZZZ–C

- 2ZZZ –Ni

- 3ZZZ –Cr+Ni

- 4ZZZ –Mo

- 5ZZZ–Cr

- 6ZZZ - Cr+V

- 7ZZZ –W

- 8ZZZ –Ni+Cr+Mo

- 9ZZZ –Si+Mn

The letter L at the end of the marking indicates reduced carbon content. The same letter in the middle of the marking indicates alloying of the alloy with lead to improve the mechanical properties of steel processed on machines. N at the end of the marking means nitrogen treatment to increase tensile strength, all other things being equal. The letter B in the middle of the marking is boron doping.

Modern industry identifies at least 150 brands by AISI. Let's look at the key, popular steel grades and where they are used.

300 series (family of chromium-nickel alloys)

- 301 - suitable for products with high ductility, characterized by rapid hardening under mechanical influence. Wear-resistant, increased fatigue strength

- 304 is the most widely used grade, which has found application in almost all industries

- 310 – heat-resistant, with the ability to work in aggressive environments at high temperatures (1000 degrees Celsius in oxidative, up to 10,000 in reducing). 310S is suitable for furnace elements in contact with high temperature gases and condensate

- 316 is a steel that holds second place after 304 in terms of application. A favorite brand for the production of equipment for food processing, for surgical instruments, units, modules operating in salt water. Resistance to pitting corrosion

- 321 - for the needs of chemists, the oil industry, welding equipment requiring use at temperatures up to 800 degrees

400 series (ferritic and martensitic steels)

- 405 Ferrite Matrix Welded Products

- 408-heat resistant

- 409 is the most affordable grade of stainless steel, used for car exhaust systems

- 416 - Easily processed on automatic machines due to the additional sulfur

- 420 - the main purpose of making cutlery, excellent polishing

- 430-ferritic matrix, can be processed by pressure, is resistant to corrosion, used in automotive finishing

- 440 - used for high-quality cutlery, a higher amount of carbon allows knives made from this steel to remain sharp longer, with proper heat treatment

Episode 500

- The 500 series contains chromite heat-resistant steel grades.

Episode 600

600 series - was originally created for patented steel grades that do not fall under classification. Today the subsection looks like this:

- 601-604 – martensitic low-alloy

- 610-613 – martensitic secondary hardening

- 614-619 – martensitic with chromium

- 630-635 – half-austenitic with compacted martensite. Used for pipes, pumps, valves. Corrosion resistance is close to 304

- 650-653 – austenitic steels operating under large temperature differences

- 660-665 – austenitic heat-resistant.

The information presented on this page will help you select the required grade of stainless steel in accordance with its characteristics and capabilities. Steel grades are classified according to two main classifiers GOST5632-2014, AISI. Examples explain the marking of stainless steels and alloys. The areas of application of key and popular brands in manufacturing industries are given.

Stainless steel grades and their characteristics

In the modern world there are more than two hundred and fifty types of stainless steel. They differ in their series or brands and in their properties. The most popular grades of stainless steel currently are those types that belong to the 300 and 400 series. They have a high level of resistance to corrosion. In addition, their layer of protective film is quite durable due to the optimally selected proportionality of the elements used in production. Stainless steel of these series has high strength and ductility. It is actively used for the production of various items in modern industry. Soon, these series may be competed by the 200 series of steel, which, according to consumers, has the optimal combination of cost and quality.

Characteristics of AISI stainless steels

In the modern market, stainless steel of the 300 series is in great demand. It is divided into several types depending on the chemical composition:

- austenitic,

- austenitic-ferritic,

- austenitic-martensitic.

These types of steel contain different amounts of nickel and chromium. carbon.

AISI stainless steel grades:

AISI 304 stainless steel

aisi 304 (08Х18Н10) is widely used in the food industry. It is excellent for welding and to resist rust.

AISI 316 stainless steel

aisi 316 (10Х17Н13М2) is formed if an element such as molybdenum is added to aisi 304 (08Х18Н10) steel. This grade of stainless steel is widely used in the shipbuilding, oil and gas and chemical industries. It is resistant to aggressive environments.

AISI 316T stainless steel

aisi 316T (10Х17Н13М2Т) has a high level of strength due to the fact that it contains more titanium than previous brands. It has found wide application in the creation of equipment for the chemical and food industries.

AISI 321 stainless steel

aisi 321 (12-08Х18Н10Т) has the largest amount of titanium among all brands of the three hundredth series. Able to withstand heating temperatures up to 800 degrees Celsius.

AISI 430 stainless steel

Among the brands of the four hundredth series, the most widely used brand is aisi 430 (12X17). In general, the entire series is characterized by the fact that it includes stainless steel grades that are created with a high chromium content. The characteristic feature of the aisi 430 brand is that the material bends well and is subject to welding. This steel can be used for places with high temperature changes. Most often it is used for decoration of buildings and in the oil and gas industry.

Stainless steel AISI 201

The 200 series of stainless steel also has worthy brands that you should pay attention to.

Among them, the most prominent steel is AISI 201 (12X15G9ND). It differs from more expensive brands from other series in that it uses a mixture of elements such as nitrogen and manganese instead of nickel. Due to its chemical and physical properties, it is widely used in the food and medical industries. It is also suitable for the production of various types of fences and pipes. Table of stainless steel grades and their compliance with chemical composition

| Stainless steel standards | Content of alloying elements, % | |||||||||

| * | DIN | AISI | GOST | C | Mn | Si | Cr | Ni | Mo | Ti |

| C1 | 1.4021 | 420 | 20Х13 | 0,20 | 1,5 | 1,0 | 12,0-14,0 | |||

| F1 | 1.4016 | 430 | 12Х17 | 0,08 | 1,0 | 1,0 | 16,0-18,0 | |||

| A2 | 1.4301 | 304 | 12Х18Н9 | 0,07 | 2,0 | 0,75 | 18,0-19,0 | 8,0-10,0 | ||

| 1.4948 | 304H | 08Х18Н10 | 0,08 | 2,0 | 0,75 | 18,0-20,0 | 8,0-10,5 | |||

| 1.4306 | 304L | 03Х18Н11 | 0,03 | 2,0 | 1,0 | 18,0-20,0 | 10,0-12,0 | |||

| A3 | 1.4541 | 321 | 08Х18Н10Т | 0,08 | 2,0 | 1,0 | 17,0-19,0 | 9,0-12,0 | 5xS-0.7 | |

| A4 | 1.4401 | 316 | 03Х17Н14М2 | 0,08 | 2,0 | 1,0 | 16,0-18,0 | 10,0-14,0 | 2,0-2,5 | |

| 1.4435 | 316S | 03Х17Н14М3 | 0,08 | 2,0 | 1,0 | 16,0-18,0 | 12,0-14,0 | 2,5-3,0 | ||

| 1.4404 | 316L | 03Х17Н14М3 | 0,03 | 2,0 | 1,0 | 17,0-19,0 | 10,0-14,0 | 2,0-3,0 | ||

| A5 | 1.4571 | 316Ti | 08Х17Н13М2Т | 0,08 | 2,0 | 0,75 | 16,0-18,0 | 11,0-12,5 | 2,0-3,0 | 5xS-0.8 |

| 1.4845 | 310S | 20Х23Н18 | 0,08 | 2,0 | 0,75 | 24,0-26,0 | 19,0-21,0 | |||

Classification

Based on their chemical composition, stainless steels are divided into:

There are austenitic stainless steels, which are prone to intergranular corrosion, and stabilized ones - with Ti and Nb additives. A significant reduction in the susceptibility of stainless steel to intergranular corrosion is achieved by reducing the carbon content (up to 0.03%).

Stainless steels that are prone to intergranular corrosion are usually subjected to heat treatment after welding.

Alloys of iron and nickel are widely used, in which, due to nickel, the austenitic structure of iron is stabilized, and the alloy turns into a weakly magnetic material.

Martensitic and martensitic-ferritic steels

Martensitic and martensitic-ferritic steels have good corrosion resistance in atmospheric conditions, in slightly aggressive environments (in weak solutions of salts, acids) and have high mechanical properties. They are mainly used for products subject to wear, as cutting tools, in particular knives, for elastic elements and structures in the food and chemical industries that are in contact with slightly aggressive environments. This type includes steel types 30Х13, 40Х13, etc.

Ferritic steels

These steels are used for the manufacture of products operating in oxidizing environments (for example, in nitric acid solutions), for household appliances, in the food industry, light industry and for heat exchange equipment in power engineering.

Ferritic chromium steels have high corrosion resistance in nitric acid, aqueous solutions of ammonia, ammonium nitrate, a mixture of nitric, phosphoric and hydrofluoric acids, as well as in other aggressive environments. This type includes steels of the 400 series.

Austenitic steels

The main advantage of austenitic steels is their high performance characteristics (strength, ductility, corrosion resistance in most working environments) and good manufacturability. Therefore, austenitic corrosion-resistant steels have found wide application as a structural material in various branches of mechanical engineering. Theoretically, products made from austenitic stainless steels are non-magnetic under normal conditions, but after cold deformation (any mechanical treatment) they can exhibit some magnetic properties (part of the austenite turns into ferrite).

Austenitic-ferritic and austenitic-martensitic steels

Austenitic-ferritic steels

The advantage of steels in this group is an increased yield strength compared to austenitic single-phase steels, a lack of tendency for grain growth while maintaining a two-phase structure, a lower content of highly deficient nickel and good weldability.

Austenitic-ferritic steels are widely used in various branches of modern technology, especially in chemical engineering, shipbuilding, and aviation. This type includes steel types 08Х22Н6Т, 08Х21Н6М2Т, 08Х18Г8Н2Т.

Austenitic-martensitic steels

The needs of modern technology for corrosion-resistant steels with increased strength and manufacturability have led to the development of martensitic (transitional) class steels. These are steel types 07Х16Н6, 09Х15Н9У, 08Х17Н5М3.

Iron-nickel and nickel-based alloys

In the manufacture of chemical equipment, especially for work in sulfuric and hydrochloric acids, it is necessary to use alloys with higher corrosion resistance than austenitic steels. For these purposes, alloys based on iron-nickel base type 04ХН40МДТУ and alloys based on nickel-molybdenum base N70MF, chromium-nickel base KHN58V and chromium-nickel-molybdenum base KHN65MV, KHN60MB are used.

Types and classification of stainless steel

Grades (types) of stainless steel are divided into several categories. Each of them is characterized by a certain chemical composition and internal structure of the material. Each of these categories of steel is distinguished by certain technical and operational characteristics, which determine the areas of their use. In modern industry, corrosion-resistant steels of the following categories are used.

Chromium steels with ferritic internal structure

Such alloys, which contain a fairly large amount of chromium (about 20%), are mainly used in heavy industry and for the production of elements of heating systems. They are distinguished not only by exceptional corrosion resistance, but also by good magnetization ability. In terms of demand, these steels are comparable to alloys with an austenitic structure, but at the same time they are much cheaper.

Stainless steel grades with austenitic internal structure

Such alloys, which contain up to 33% chromium and nickel, are the most used types of stainless steels worldwide (70%). They are distinguished by both exceptional corrosion resistance and high strength properties.

Stainless steels with martensitic and ferritic-martensitic structure

They are characterized by a needle-like carbon structure, which makes them the strongest of all types of stainless alloys. In addition, stainless steels in this category are very wear-resistant and can be operated at high temperatures. Their composition, which is also important, contains a minimum amount of harmful impurities.

Stainless steel grades with a combined structure

Such steels, which can have an austenitic-ferritic or austenitic-martensitic structure, are the product of innovative technologies and optimally combine all the advantages of other types of alloys.

Knowing the structure of a certain grade of stainless steel, which forms its main characteristics, is important in order to optimally select it to solve the required problems.

Stainless steel cookware

Food grade stainless steel according to GOST

There is no official concept of food grade or technical stainless steel. This is the name given to any brand that is suitable for making cookware. Requirements for products intended for contact with products are set out in GOST 27002-86.

The list of possible alloys includes grades with an amount of carbon of at least 12%, chromium of at least 13%, possible presence of nickel in an amount of 5-13%, and molybdenum of about 2%.

Their selection is influenced by the following criteria:

- will the cookware be used for cooking?

- how long the contact is expected to last.

Also, there are no alloys that are used only for the manufacture of dishes, cutlery, etc. Dishes, pipes and tools can be made from the same grade. In this case, the final thermomechanical treatment can be applied in the same way.

Preferably, 12X13 stainless steel is used to make utensils that do not come into contact with food for a long time and are not subject to shock or heat.

Grade 12Х18Н10Т is a classic version of food-grade stainless steel, and since it is used in the mass production of not only tableware, its second name is medical steel.

Steel grades for food supplies

The classification of brands is carried out according to series, which indicate the internal structure after the final thermomechanical processing of the product.

There are 3 series that determine the properties of stainless steel:

Episode 400

— martensitic-ferritic stainless steel. They are distinguished by high manufacturability, i.e., good workability by pressure (rolling, stamping), and weldability. These grades contain 8-40% (on average 12%) carbon, and the main and only alloying element is chromium, contained in an amount of 13% (not less).

Stainless steel with a chromium content of 13-17% has a number of disadvantages: they are classified as weakly rusty, since with prolonged contact with water or mildly aggressive acids, pitting corrosion may appear on the surface.

This entire series cannot be used for products exposed to low temperatures (below -40 ºС) and shock loads.

Affordability and high machinability make these brands in demand for the manufacture of technical parts, structural elements, and pipelines. Cutlery (forks, spoons), coasters, dishes, and candlesticks are no exception.

| Russian classification | European equivalent |

| 08Х13 | AISI 409 |

| 12Х13 | AISI 410 |

| 20X13, 40X13 | AISI 420 |

12X17AISI 430 - used for the manufacture of dishes, cutlery, etc., limitedly used for contact with food and not intended for heat treatment.

Episode 300

— austenitic, austenitic-ferritic and austenitic-martensitic stainless steel. All grades in this series have increased corrosion resistance at temperatures up to 600 ºС (with the addition of alloying elements the temperature limit rises to 800-1100 ºС), and strength.

Nickel is added as the second alloying element in an amount of 5-13%, which contributes to obtaining an austenitic structure, and up to 2% molybdenum and/or 1% titanium are added to increase strength.

The series begins with a universal stainless steel, which is known in all spheres of human activity:

- 08Х18Н10 - chromium-nickel. The most commonly used steel is in the food industry.

Due to its complete inertness to water and mildly aggressive acids, it received the name “food grade”; if the carbon content in this alloy is increased to 12%, the name will sound like “medical steel”.

Intensively used in the chemical and medical industries.

- 10Х17Н13М2 - chromium-nickel-molybdenum alloy.

The additive of 2% molybdenum makes it durable and wear-resistant. It is also used for products in contact with food, but at high temperatures and pressure. These can be steam boilers, pipe systems for transporting liquid media. For industry, gas turbines are made from this alloy.

- 10Х17Н13М2Т - the previous alloy with the addition of titanium.

Titanium increases the operating temperature to 800-1100 ºС and the ability to work in aggressive environments with chlorine. Used in critical systems for the production of seamless pipes, as well as shut-off and connecting fittings for them.

| Russian classification | European equivalent |

| 10Х17Н13М2 | AISI 316 |

| 10Х17Н13М2T | AISI 316 T |

| 12-08Х1810Т | AISI 321 |

Episode 200

- with a predominance of only the austenite structure. Its properties are similar to both previous series, but the cost is much cheaper than the 300 series.

12X15G9ND - in this brand (it is the only one so far) nickel and molybdenum are replaced by two elements balanced in relation to each other: manganese and copper. High technology and low cost (relative to chromium-nickel brands) make this series stand out.

| Russian classification | European equivalent |

| 12X15G9ND | AISI 201 |

Useful

Designation of alloying elements in stainless steels The influence of the main alloying elements on the properties of stainless steels Compliance of foreign standards with Russian GOST Why is one brand of stainless steel magnetic and another not? What is “Food Stainless Steel”? The most common types of surface of stainless steel sheets

Designation of alloying elements in stainless steels

- In the initial part of the stamp there are numbers (two or one) showing the carbon content.

- Two numbers indicate its average content in the alloy in hundredths of a percent, and one – in tenths. There are also steels that do not have numbers at the beginning of the brand name. This means that the carbon content in these alloys is within 1%.

- The letters that can be seen behind the first digits of the brand name indicate what the alloy is made of.

- The letters that give information about a particular element in its composition may or may not have numbers. If there is a number, then it determines (in whole percentages) the average content of the element indicated by the letter in the composition of the alloy, and if there is no number, then this element is contained in the range from 1 to 1.5%.

X - chromium N - nickel K - cobalt M - molybdenum B tungsten T - titanium D - copper G - manganese C - silicon F - vanadium P - boron A - nitrogen B niobium E - selenium C - zirconium U - aluminum

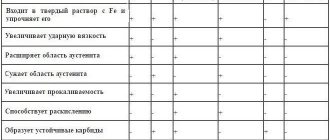

The influence of the main alloying elements on the properties of stainless steels

Chromium (Cr):

- is the main element of steel, determining its resistance to oxidation (corrosion). Chromium sharply increases the corrosion resistance of steel when it increases in the alloy above 12.5%, starting from this concentration a dense oxide film of Cr2O3 is formed on the surface (chromium actually makes steel stainless, for example, steels 20Х13, 30Х13, 40Х13, etc.) ;

- when the chromium content in steel is 12-14%, the thermal conductivity of steel is 2 times less than pure iron, and the electrical resistance increases 3 times;

- provides increased strength at elevated temperatures, the addition of chromium increases the hardness and strength of steel without reducing its ductility;

- reduces the impact strength of steel.

Nickel (Ni):

- The main function of nickel is to stabilize the austenitic structure of steel; such a structure is especially strong and elastic. The minimum amount of nickel capable of stabilizing the austenitic structure is 8% (this is exactly how much nickel is found in the most common imported steel AISI 304);

- the presence of 8-10% nickel in steel provides it with good ductility and good forming properties;

- improves the weldability of steel and further increases the resistance of steel to oxidation (corrosion) in the weld area;

- nickel increases the heat resistance of steel (especially in relation to resistance to deformation);

- Thanks to nickel, stainless steel polishes better and is more scratch resistant than conventional steels (brushed and mirrored surfaces).

Molybdenum (Mo):

- increases the resistance of steel to oxidation (corrosion) at high temperatures, reduces the resistance of steels to pitting corrosion;

- increases red resistance, elasticity, tensile strength;

- provides additional thermal strengthening.

Titanium (Ti):

- increases the strength of steel;

- Titanium is added to stainless steels to prevent intergranular corrosion.

Carbon (C):

- with an increase in carbon to 0.8%, the hardness and strength of the steel increases, but leads to an increase in the threshold of cold brittleness (for example, steels 40Х13 and 95Х18 are used for the production of knives);

- the more carbon there is in the steel, the more difficult it is to process by cutting, the worse it deforms and the worse it welds (for example, the most common commercially available imported steels of the 300 series AISI304/321/316 have 0.8% carbon in their composition, which gives them a wide range of applications compared to domestic steel 12x18n10t).

Compliance of foreign standards with Russian GOST.

Currently, almost all stainless steel products supplied to our country are marked according to AISI, DIN, or EN standards. Let's consider the compliance of these standards with Russian GOST.

AISI (American Iron and Steel Institute), American Institute of Iron and Steel

The designation of standard stainless steels according to AISI includes three numbers followed by one, two or more letters in some cases. The first digit of the designation determines the steel class. Thus, the designations of austenitic stainless steels begin with the numbers 2XX and 3XX. While ferritic and martensitic steels are defined in class 4XX. Moreover, the last two digits, unlike carbon and alloy steels, are in no way related to the chemical composition, but simply determine the serial number of the steel in the group.

The additional letters and numbers following the numbers used to designate AISI stainless steels mean:

xxxL – Low carbon content < 0.03% xxxS – Normal carbon content < 0.08% xxxN – Nitrogen added xxxLN – Low carbon content < 0.03% + nitrogen added xxxF – Increased sulfur and phosphorus content xxxSe – Selenium added xxxB – Silicon added xxxH – Extended range carbon content xxxCu – Copper added

For example:

Steel 304 belongs to the austenitic class, its carbon content is <0.08%. At the same time, in steel 304L carbon is only <0.03%, and in steel 304H carbon is determined in the range of 0.04 – 0.10%. The specified steel, in addition, can be alloyed with nitrogen (then its name will be 304 N) or copper (304 Cu).

In steel 410, which belongs to the martensitic-ferritic class, the carbon content is <0.15%, and in 410S steel the carbon content is <0.08%. In contrast to 430 steel, 430F steel has a higher content of sulfur and phosphorus, and selenium is also added to 430F Se steel.

DIN (Deutsches Institut für Normung) – German Institute for Standardization.

In the DIN marking system, unlike the Russian one, all chemical elements included in the composition are first listed, and then their mass contents are indicated. At the beginning of the designation the letter X is followed by a number corresponding to the carbon content multiplied by 100, then by the chemical symbols of the most important alloying elements, then by a number reflecting the average content of the most important alloying elements.

For example:

Х12Cr-Ni17 7 – high-alloy chromium-nickel steel containing <0.15% C, 16-18% Cr; 7-8% Ni; <2% Mn; <1% Si. X5Cr-Ni-Mo18 10 – high-alloy chromium-nickel-molybdenum steel containing 0.07% C; 16.5-18.5% Cr; 10.5-12.5% Ni; 2-2.5% Mo.

EN (European Norm) - European standards - >standards adopted by the European Committee for Standardization (CEN) In them, the steel grade is presented as 1.XXXX, where:

- 1. determines that this material belongs to steel;

- The next two digits after 1 determine the number of the steel group, and the last two – the serial number of the steel in the group.

By the group number you can unambiguously determine what type a particular steel belongs to.

1.40ХХ – 1.45ХХ – stainless steels 1.46ХХ – 1.49ХХ – heat-resistant and acid-resistant steels

For example:

1.4016 - AISI 430 (12Х17) 1.4301 - AISI 304 (03Х18Н10) 1.4541 - AISI 321 (08х18Н10Т) 1.4842 - AISI 410S (10Х23Н18)

Table of correspondence between GOST steel grades and standards of other countries.

| GOST | Euronorms (EN) | AISI |

| 12X15G9ND | ______ | AISI 201 |

| 12X17G9AN4 | 1.4373 | AISI 202 |

| 15Х17Н7 | 1.4310 | AISI 301 |

| 12Х18Н9 | ———- | AISI 302 |

| 08Х18Н10 | 1.4301 | AISI 304 |

| 03Х18Н11 | 1.4306 | AISI 304L |

| 03X18AN11 | 1.4311 | AISI 304LN |

| 12Х18Н12 | 1.3955 | AISI 305 |

| 06Х18Н11 | 1.4303 | AISI 305L |

| 08Х20Н11 | 1.4331 | AISI 308 |

| 20Х23Н13 | 1.4833 | AISI 309 |

| 03Х24Н13Г2С | 1.4332 | AISI 309L |

| 20Х23Н18 | 1.4843 | AISI 310 |

| 10Х23Н18 | 1.4842 | AISI 310S |

| 20Х25Н20С2 | 1.4841 | AISI 314 |

| 08Х17Н13М2 | 1.4436 | AISI 316 |

| 03Х17Н13М2 | 1.4404 | AISI 316L |

| 03Х17Н14М3 | 1.4435 | AISI 316S |

| 03X17N13AM3 | 1.4429 | AISI 316LN |

| 1Х16Н13М2Б | 1.4580 | AISI 316Сd |

| 08Х17Н13М2Т | 1.4571 | AISI 316Ti |

| 08Х19Н13М3 | 1.4449 | AISI 317 |

| 03Х19Н13М3 | 1.4438 | AISI 317L |

| 08Х18Н14М2Б | 1.4583 | AISI 318 |

| 08Х18Н10Т | 1.4541 | AISI 321 |

| 12Х18Н10Т | 1.4878 | _________ |

| 08Х25Н4М2 | 1.4462 | AISI 329 |

| 15Х12 | _____ | AISI 403 |

| 08Х12Т1 | 1.4512 | AISI 409 |

| 10Х13 | 1.40006 | AISI 410 |

| 08Х13 | 1.4000 | AISI 410S |

| 15Х13Н2 | _______ | AISI 414 |

| 20Х13 | 1.4021 | AISI 420 |

| 12Х15 | 1.4001 | AISI 429 |

| 12Х17 | 1.4016 | AISI 430 |

| 08Х17Т | 1.4510 | AISI 430Ti |

| 20Х17Н2 | 1.4057 | AISI 431 |

| 12Х17М | 1.4113 | AISI 434 |

| 12Х17Б | 1.4522 | AISI 436 |

| 15Х5М | 1.7362 | AISI 501 |

| 15Х9М | 1.7386 | AISI 504 |

| 09Х17Н17У | 1.4503 | AISI 631 |

| 06ХН28МДТ | 1.4503 | AISI 904L |

Why is one brand of stainless steel magnetic and another is not?

A little theory: A magnetic field with a certain level of its intensity acts on bodies placed in it in such a way that it magnetizes them.

Ferromagnets are substances that, in particular, include iron, cobalt and nickel, which are capable of actively magnetizing, even when placed in weak magnetic fields. We are used to identifying stainless steel using a magnet. It is believed that “real stainless steel” should not be magnetic, but in practice this diagnostic method does not always allow obtaining a reliable result. Why is this happening?

The term “stainless steel” refers to various materials, the composition of which may contain ferrite, martensite or austenite, as well as their various combinations. The characteristics of stainless steel depend on the phase components and their ratio. So, which stainless steel is magnetic and which is not?

Stainless steels that are magnetic.

Martensites and ferrites are strong ferromagnets. Such materials are not afraid of corrosion, but at the same time the magnet affects them, just like ordinary carbon steel. The presented group of stainless steels includes chromium or chromium-nickel steels of the following groups:

- Martensitic – is a ferromagnet in its pure form. These are mainly nickel-free steels 20Х13, 30Х13, 40Х13, as well as some steels alloyed with nickel, for example steel 14Х17Н2;

- Ferritic – A common magnetic steel of the ferritic type, which, due to the low carbon content in its chemical composition, is softer than martensitic alloys, is 08Х13 and its imported analogue AISI 410;

- Martensitic-ferritic – A popular brand of magnetic stainless steel, the internal structure of which consists of martensite and free ferrite, is 12X13 and its relative imported analogue AISI430.

Stainless steels that are not magnetic.

Most often, chromium-nickel or chromium-manganese-nickel alloy is used to produce stainless steel. These materials are non-magnetic.

- Austenitic – The most popular brand of stainless steels, which occupy a leading place among non-magnetic steel alloys, is 08Х18Н10Т, as well as steels of this type 08Х18Н10, 12Х18Н10Т, 10Х17Н13М2Т and their foreign analogs of the 300th series AISI 304/321/316 and others;

- Austenitic-ferritic - These materials are based on chromium and nickel, and manganese can be used as additional alloying elements.

When more than 9% manganese is added to an alloy, it becomes non-magnetic.

An example is the imported steels AISI 201 (12Х15Г9НД) and AISI 202 (12Х17Г9АН4).

What is “Food Stainless Steel”?

We often hear the term “food grade stainless steel”. Let's figure out what lies behind this. We will not find such a term anywhere in Russian GOST, since this name was invented in everyday life. “Food grade stainless steel” is something we encounter every day in our kitchens (edging the surface of many kitchen stoves, range hoods, microwave oven chambers, etc.), in the bathroom (washing machine drum), in shopping centers (stair railings) ) etc. and so on.

In general, “food grade stainless steel” is a universal product for many areas of activity where certain corrosion resistance, acid resistance, heat resistance and heat resistance are required. Here are some of the most common and in demand brands of food grade stainless steel today and their areas of application:

- 08Х18Н10/08Х18Н10Т (AISI304/AISI321) is perhaps the most common grade of “food grade stainless steel” used in the food industry, and has a composition that excellently resists intergranular corrosion, has a high level of weldability and versatility for many types of production. — 08Х13 (AISI 409) — used for the manufacture of kitchenware and cutlery. It is used to make microwave oven chambers, kitchen hoods, and edging for kitchen stoves;

- 12X13 (AISI 410) – used for the production of equipment elements used in the field of winemaking and food waste processing, for the production of alcohol and drinks from it. This steel has high heat resistance in mildly aggressive environments, excellent resistance to corrosion;

- 20Х13–40Х13 (AISI 420) – often used for the manufacture of all types of sinks (both household and industrial), utensils for heating, as well as for hygienic processing of food products. These alloys perfectly resist high-temperature rusting, they have good ductility and wear resistance;

- 08Х17 (AISI 430). They are indispensable in cases where it is necessary to make dishes in which food will be subjected to heat treatment. In environments containing sulfur, it demonstrates a high level of anti-corrosion resistance, is characterized by good deformability and strength, and has an increased thermal conductivity coefficient;

- 08Х17Т (AISI 439), from which sinks and other sanitary fixtures, clothes washing machines, and refrigeration units are produced. But in general, this alloy is considered quite universal and suitable for use in different operating conditions.

The most common types of surface of stainless steel sheets

- 1 D or M2B-M4B (matte) - the usual version for further processing, the surface of the sheets is less smooth than 2B and 2D, hot-smoked, with annealing and etching;

- 2B or M2A-M4A (matte, smooth) – very smooth surface, cold-rolled, with annealing and etching;

- 1 G / 2 G or 4 N / 5 N (polished) - unidirectional texture, slightly reflective. The surface of the metal is very smooth (roughness Ra = 1.20 - 1.50 µm), which does not reflect, but shimmers with the colors of the rainbow, c/c, additional processing by wet or dry grinding with fine-grained belt sandpaper or matte polishing (wet grinding using cooling oil). Standard types of surface finish (grit) 180, 240, 320;

- 2 R or VA (mirror) – the metal surface is very smooth (roughness Ra = 0.05 μm), reflects, but the reflection is not clear, smoother and brighter than 2B, cold-cotton, fired in a vertical oven using caustic ammonia ( finishing rolling on a temper mill is possible);

- 1M or Tear Piate (corrugated) – hot rolling with knurling of a pattern (“lentil”, “quintet”, etc.);

- 2M or DECO (decorated) - textured stainless steel, has a clearly defined pattern

Heat resistant stainless steel

The category of heat-resistant materials includes alloys that are capable of maintaining their structure and not changing their quality characteristics when exposed to temperatures above 550º C. The chemical composition and marking of this type is regulated by GOST 5632 - 2014. According to the production method, such stainless steel can be cast or deformable.

Metals vary in their ability to withstand certain loads at high temperatures. In accordance with these indicators, three types of stainless steel are distinguished.

- Heat resistant stainless steel. Does not corrode at 600°C.

- Heat resistant. Shows inertness to aggressive media at temperatures above 550°C.

- Heat resistant. Resists mechanical loads at 400 - 850°C.

In terms of composition, materials with increased heat resistance are:

- Martensitic. Brands produced using perlite additives. The mixture of metals is hardened at 950 - 1100 ºС. The resulting alloys contain more than 0.15% carbon, 11-17% chromium and small amounts of nickel, tungsten, molybdenum, and vanadium. They do not react with alkalis and acids. Prolonged exposure to a humid environment does not affect their technical characteristics.

- Austenitic. Steels have a homogeneous or heterogeneous structure. The homogeneous composition, which is not subjected to hardening, contains an increased amount of carbon and a maximum of alloying elements: Ni, Cr, Mn, Mo, V, Nb. Such alloys are resistant to temperatures up to 500°C. This class includes: 06Х14Н6Б, 08Х18Н12Т, 20Х23Н18, 07XI6H9M2. Heterogeneous grades undergo hardening and aging during the production process. This is necessary for the formation of carbide, carbide-nitride and intermetallic compounds. They strengthen the boundaries of the matrix and impart the necessary heat resistance to the alloy at temperatures from 700 to 750°C. Representatives of this type are steels: 08Х17Н13М2Т, 20Х25Н20С2, 45Х14Н14В2М.

- Nickel and cobalt. These are some of the best heat-resistant materials, capable of maintaining all technical parameters unchanged at temperatures up to 900°C. These grades are divided into homogeneous and heterogeneous alloys. These include: KHN77TYU, KHN55VMTFKYU, KHN70MVTYUB.

Application

The listed advantages contribute to maintaining a leading position in the rolled metal market. Anti-corrosion alloys are an indispensable material in heavy engineering, energy, oil and gas and agricultural sectors.

The material is in demand in the following areas of the national economy:

- Construction, architecture;

- production of equipment and medical instruments;

- pulp and paper production;

- food industry;

- transport engineering;

- chemical industry;

- electrical power and electronics;

- production of household appliances and household items.

The decorative qualities of stainless metals and the high level of anti-corrosion properties make it possible to use parts and elements made from them for facades, advertising installations, shop windows, and fountains. Railings, doors, stairs, and elevators are made from alloyed material.

Application of heat-resistant steels

Alloy metals, resistant to high thermal loads, are used for the production of pipes, parts, components of machines, units, and industrial equipment. This list includes:

- parts of thermal furnaces;

- parts of conveyor belts for furnace conveyors;

- heat treatment units;

- fuel combustion chambers;

- motors, gas turbines;

- methane conversion devices;

- furnace screens;

- exhaust systems; heating elements.

Heat-resistant stainless metal is the best material for the production of parts and mechanisms that will be used in aggressive environments at elevated temperatures.

Sources

- https://met-all.org/stal/marki-nerzhaveyushhej-stali.html

- https://generalsteel.ru/marki-nerzhaveyushchih-stalej/

- https://vt-metall.ru/articles/447-svojstva-nerzhaveyushhej-stali

- https://martensit.ru/stal/nerzhaveyushhaya-stal/

- https://tk-metal.ru/stal/marki-nerzhaveyushchei-stali-klassifikatsiya-rasshifrovka.html

- https://solidiron.ru/steel/marki-nerzhaveyushhejj-stali-i-ikh-kharakteristiki.html

- https://intehstroy-spb.ru/spravochnik/nerzhaveyuschaya-stal-marki-vidy-i-harakteristiki.html

- https://prompriem.ru/stal/pishhevaya-stal-marki.html