Characteristics of steel grade 40

Steel 40 is a structural carbon quality steel with limited weldability. Welding is carried out without heating and without subsequent heat treatment, methods: manual arc welding, automatic submerged arc welding and gas protection, ESW. Preheating and subsequent heat treatment are recommended. CTS without restrictions.

Not prone to flake sensitivity, no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at HB 170 and σв=530 MPa, K υ solid. spl=1.2 and Kυ b.st=1.05. Forging is carried out at temperatures from 1250 to 780 0C, with air cooling of workpieces with a cross-section of up to 400 mm. Steel 40 is used to make axles, crankshafts, pinion shafts, rods, gears, pipes, forgings, fasteners, shafts, discs, rotors, flanges, gears, bushings for long and very long service at temperatures up to 425 degrees.

Chemical composition of steel

As previously noted, the chemical composition of 40X steel is determined by markings. However, it does not reflect the entire composition. Steel grade 40X is characterized by the following features:

- The carbon concentration in the composition ranges from 0.36% to 0.44%. Note that manufacturers cannot provide a more accurate indicator due to the complexity of the metal production process.

- Chromium is the main alloying element; the metal contains 0.8-1.1%.

- The alloy production process determines that nickel, silicon and manganese are included in the metal. Their concentration is no more than 1%, but even a small amount leads to a change in performance characteristics.

- The composition contains harmful elements, for example, phosphorus and sulfur. Their concentration is strictly regulated.

- Copper is also included in the composition, but it is about 0.035%. That is why the concentration of this element does not change the basic performance characteristics.

Chemical composition of steel 40x according to GOST

Refining of the structure with various alloying elements is carried out using strong deoxidizers, after which slag is introduced, treated with silicon and carbon.

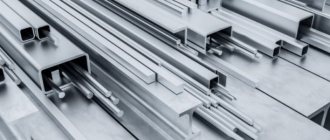

Supply steel 40

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| Metal forming. Forgings | GOST 8479-70; |

| Long and shaped rolled products | GOST 2591-2006; GOST 8319.0-75; GOST 2879-2006; GOST 9234-74; GOST 11474-76; GOST 1133-71; GOST 2590-2006; |

| Sheets and strips | GOST 82-70; GOST 14918-80; GOST 19903-74; GOST 16523-97; GOST 103-2006; |

| Ribbons | GOST 3560-73; |

| Long and shaped rolled products | GOST 8560-78; GOST 8559-75; GOST 1051-73; GOST 7417-75; GOST 10702-78; GOST 14955-77; GOST 1050-88; |

| Sheets and strips | GOST 4405-75; GOST 4041-71; GOST 1577-93; |

| Ribbons | GOST 10234-77; GOST 2284-79; |

| Steel pipes and connecting parts for them | GOST 20295-85; GOST 3262-75; GOST 24950-81; |

| Low carbon steel wire | GOST 1526-81; GOST 5663-79; GOST 792-67; |

| Medium and high carbon steel wire | GOST 17305-91; GOST 26366-84; GOST 9850-72; GOST 7372-79; GOST 3920-70; GOST 3110-74; GOST 9389-75; |

Analogues and nomenclature

If 40X GOST steel is used as the main component, the designer needs to remember that it is possible to use similar metals. There are Russian and foreign analogues.

Domestic

Russian analogues are used in production:

- 45X.

- 38HA.

- 40ХН.

- Some others.

They are used to create various critical parts: axles, gear rings, plungers and others.

Foreign

Among foreign materials there are the following metal analogues:

- G51400, H51350 - manufactured in the United States.

- 37Cr4, 41Cr4, 41CrS4 - from Germany.

- 35Cr, 38CrA, 40Cr, 40CrA - made in China.

They can be used in the manufacture of mechanisms that are planned to be used at low air temperatures.

Mechanical properties of rolled steel 40

| GOST | Forging condition | Section, mm | σв(MPa) | δ5 (δ4 ) (%) | ψ % | KCU, J/cm2 | NV, no more |

| no less | |||||||

| 1050-88 | Hot-rolled, forged, calibrated and silver steel of the 2nd category after normalization | 25 | 570 | 19 | 45 | 59 | — |

| Calibrated steel, category 5: | |||||||

| after cold hardening | |||||||

| after annealing or high tempering | Samples | 610 | 6 | 35 | — | — | |

| Steel calibrated and calibrated with special finishing after tempering and annealing | Samples | 510 | 14 | 40 | — | — | |

| 10702-78 | Heat-treated sheet of category 1-2 | — | Up to 590 | — | 40 | — | 197 |

| 4041-71(Transverse samples) | 4-14 | 510-650 | 21 | — | — | 167 | |

| Normalized and hot rolled sheets | |||||||

| 1577-93 | Annealed or high tempered sheets | 80 | 560 | 20 | — | — | — |

| Normalized or hot rolled strips | 80 | 520 | 21 | — | — | — | |

| Hot rolled sheet | 6-25 | 570 | 19 | 45 | — | — | |

| 16523-70 (Transverse samples) | Up to 2 | 510-660 | -16 | — | — | — | |

| Cold rolled sheet | 2-3,9 | -17 | — | — | — | ||

| Up to 2 | 510-660 | -17 | — | — | — | ||

| 2284-79 | Cold rolled strip: | 2-3,9 | -18 | — | — | — | |

| annealed | |||||||

| cold-worked strength class H2 | 0,1-4 | 450-700 | -14 | — | — | — | |

| 10234-77 | Annealed flattened tape | 0,1-4 | 850-1050 | — | — | — | — |

| 0,1-4 | Up to 700 | 10 | — | — | — | ||

Decoding steel 40X

In the CIS, the GOST 4543-2016 standard is used, which allows you to determine not only the chemical composition, but also the various performance qualities of the material.

Download GOST 4543-2016

Steel 40X GOST defines the following substances in its composition:

- The first number 40 is used to indicate the main element in the composition, which is carbon. As a rule, most of the composition is iron, and carbon, the concentration of which is 0.44%, determines the main performance characteristics.

- The next letter X indicates that the composition contains an alloying element represented by chromium. The absence of a number after the letter indicates that the concentration of the element is 1.1%. As previously noted, chromium increases the corrosion resistance of the structure. However, the steel grade in question, 40X, is not characterized by high anti-corrosion qualities.

- Considering 40X GOST, we note that the composition includes a fairly large amount of nickel, silicon and manganese. They determine some of the performance characteristics of the metal, but they are not noted in the markings.

Deciphering allows you to determine the chemical composition and basic performance qualities of the material. It is worth considering that foreign manufacturers use different standards when labeling materials, but the chemical composition of analogues is approximately similar.

Mechanical properties of steel 40 forgings

| Heat treatment | Section, mm | KP | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | NV, no more |

| Normalization | 300-500 | 215 | 215 | 430 | 18 | 40 | 44 | 123-167 |

| 500-800 | 16 | 35 | 39 | |||||

| 100-300 | 245 | 245 | 470 | 19 | 42 | 39 | 143-179 | |

| 300-500 | 17 | 35 | 34 | |||||

| Up to 100 | 275 | 275 | 530 | 20 | 40 | 44 | 156-197 | |

| 100-300 | 17 | 38 | 34 | |||||

| Hardening. Vacation | 300-500 | 275 | 275 | 530 | 15 | 32 | 29 | 156-197 |

| 500-800 | 13 | 30 | 29 | |||||

| 100-300 | 315 | 315 | 570 | 14 | 35 | 34 | 167-207 | |

| Up to 100 | 345 | 345 | 590 | 18 | 45 | 59 | 174-217 |

Advantages and disadvantages

The positive and negative qualities of a metal determine its properties. Among the qualities of type 40x steel, the characteristics of endurance and hardness are important. The admixture of chromium in the composition gives the components the following positive features:

Advantages

They are highly durable and rust resistant.

Withstands strong and long-term loads.

Withstands extreme temperatures from -40 to +425 °C.

The magnetic properties of the material do not affect the quality of the steel.

They can be used in various environmental conditions.

Surfaces do not need to be cleaned or treated.

They tolerate warping well.

Flaws

The negative features of the alloy include the fragility of steel and its flake sensitivity. But heat treatment makes it possible to reduce these properties to minimum values.

Interesting: What is resistance welding and its types

Mechanical properties of steel 40 at elevated temperatures

| Test temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % |

| Sample with a diameter of 6 mm and a length of 30 mm, rolled. Deformation speed 16 mm/min. Strain rate 0.009 1/s | ||||

| 700 | 99 | 140 | 48 | 85 |

| 800 | 70 | 110 | 53 | 97 |

| 900 | 54 | 71 | 55 | 100 |

| 1000 | 28 | 58 | 69 | 100 |

| 1100 | 24 | 37 | 60 | 100 |

| 1200 | 16 | 26 | 87 | 100 |

| 1300 | 12 | 18 | 56 | 100 |

Description of mechanical symbols

| Name | Description |

| Section | Section |

| sT|s0.2 | Yield strength or proportional limit with tolerance for permanent deformation - 0.2% |

| σB | Short-term strength limit |

| d5 | Elongation after break |

| d4 | Elongation after break |

| d10 | Elongation after break |

| d10 | Elongation after break |

| y | Relative narrowing |

| kJ/m2 | Impact strength |

| HRB | Rockwell hardness (steel indenter, spherical) |

Mechanical properties of steel 40 at normal temperature

| Type of rental | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Heat treated sheet, GOST 4041-71 | 4-14 | 510-660 | 21 | |||||

| Cold rolled pipes. | 580 | 320 | 17 | Normalization | ||||

| Hot rolled pipes. | 600 | 340 | 16 | |||||

| The rod is calibrated, GOST 10702-78 | 590 | 40 | Annealing | |||||

| Rolled products annealed, GOST 1050-88 | 510 | 14 | 40 | |||||

| Rolled products cold-hardened, GOST 1050-88 | 610 | 6 | 35 | |||||

| Rolled products, GOST 1050-88 | up to 80 | 570 | 335 | 19 | 45 | Normalization | ||

| Cold-worked tape, GOST 2284-79 | 690-1030 | |||||||

| Annealed tape, GOST 2284-79 | 440-690 | 14 | ||||||

| Strip, GOST 1577-93 | Jun.60 | 570 | 335 | 19 | 45 | Normalization |

Steel 40x. Its description and scope

Steel is one of the most important structural metals. It has found wide application in construction, mechanical engineering, and many other industries. This metal has many different grades, and they all differ from each other in characteristics. Steel 40x is a structural alloy grade of this material. And here we will talk about it in more detail.

In addition to the usual impurities, the 40x brand contains a certain amount of elements that are specially introduced. This ensures special properties. Here, chromium is used as an alloying element. It is because of this that the letter X is present in the steel marking.

This steel has a special feature - it is difficult to weld. In this regard, 40x steel is heated to 300°C during the welding process, and after it is subjected to heat treatment. In addition to this feature, there is a tendency to release ability, as well as flake sensitivity.

Steel 40x has the following characteristics:

– relative elongation – 13-17%;

– impact strength – up to 800 kJ/sq. meter;

– tensile strength – up to 900 MPa.

There are other features characteristic of this grade of steel:

– the endurance limit is quite high;

– the ability to carry out processing by cutting, welding or under pressure;

– resistance to warping and decarbonization during thermal exposure.

For all such materials these are the most important properties. They allow the use of 40x steel in the engineering industry.

When forging steel of this grade, the temperature at the beginning of the process is 1250 °C, and at the end - 800 °C.

Very often, this steel is used in the manufacture of improved parts that are characterized by increased strength. These are products such as plungers, spindles, axles, shafts, rings, gear shafts, crank and cam shafts, bolts, axle shafts, racks, bushings, sponge rings, mandrels and other necessary parts.

Steel 40 is widely used for the manufacture of taps, drills, and files. As you can see, these are all tools that have to be worked at low speed, and the heating temperature is no more than 2000 degrees. These products are rods with a circular cross-section. They are manufactured in accordance with GOST 5950-2000.

If you need steel that is resistant to corrosion, you need to pay attention to grade 40x13. This is stainless, corrosion-resistant steel. It becomes resistant to corrosion after hardening, because the carbide is completely dissolved. Steel 40x13 is produced in induction furnaces, as well as open arc type. The resulting material is perfectly deformed at a temperature of 850-1100 oC. To avoid cracks, heating and subsequent cooling must be carried out slowly.

Finally, it is worth giving a recommendation to buyers. It is best to buy 40x steel, as well as products made from it, from manufacturers directly. Here the cost will always be without extra charges, because you “bypass” the intermediaries. Products can also be manufactured according to the parameters you ordered. In addition, factories often offer discounts to wholesale buyers, and there is also a guarantee of product quality. And in case of marriage, you will know who to contact.

Mechanical properties of steel 40 depending on tempering temperature

| Temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | HB |

| Hardening 850 °C, oil | ||||||

| 200 | 750 | 930 | 7 | 45 | 29 | 267 |

| 300 | 710 | 860 | 8 | 51 | 69 | 247 |

| 400 | 640 | 790 | 10 | 57 | 88 | 225 |

| 500 | 550 | 730 | 12 | 62 | 127 | 208 |

| 600 | 450 | 660 | 16 | 66 | 167 | 188 |

| 700 | 380 | 620 | 17 | 71 | 206 | 170 |

Physical properties of steel 40

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| 0C | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.13 | 51.5 | 7850 | 483 | 160 | |

| 100 | 2.01 | 11.6 | 50.6 | 486 | 221 | |

| 200 | 1.98 | 12.7 | 48.1 | 497 | 296 | |

| 300 | 1.9 | 13.5 | 45.6 | 512 | 387 | |

| 400 | 1.85 | 14.5 | 41.9 | 529 | 493 | |

| 500 | 1.79 | 14.5 | 38.1 | 550 | 619 | |

| 600 | 1.67 | 14.9 | 33.5 | 574 | 766 | |

| 700 | 1.6 | 15.15 | 30 | 628 | 932 | |

| 800 | 12.5 | 24.8 | 674 | 1110 | ||

| 900 | 13.5 | 25.7 | 657 | 1150 | ||

| 1000 | 14.5 | 26.9 | 653 | 1180 | ||

| 1100 | 15.2 | 28 | 649 | 1207 | ||

| 1200 | 15.8 | 29.5 | 649 | 1230 |

C40 Carbon Steel St37 Ss400 S275

carbon steel plate 1. Steel plate details:

| Product | st37 steel plate | ||

| Thickness 000000 120 mm | |||

| Width | 1500-3600 mm | ||

| length | upon request Cold rolled or hot rolled | ||

| Surface treatment | Blasting/shot peening and spraying or as required. | ||

| Standard | ASTM, EN, GB, JIS, DIN | ||

| Material | Q215A/B, Q235, Q275A/B/C/D, SS330, SS400, SM400A, Kr. C, Cr.D, S235JR, ASTM A36 | ||

| Usage | Used in home appliance construction, mechanical engineering, container manufacturing, shipbuilding, bridges, etc. D. | ||

| Mill | Baosteel, Shougang, Xingang, Angang, Jigang, Magang, Hanggang, Wugang. | ||

| Package | Standard export sea packing | ||

| Terms of payment | L/C or T/T | Delivery detail | Within 3-15 days after receiving deposit or L/C |

2.Chemical composition of different grades

9000 9000

with chemical composition of various grades with chemical composition

| Si | S | R | ||||

| Not more than | ||||||

| Q195 | 0.06 ~ 0.12 | 0.25 ~ 0.50 | 0,3 | 0,05 | 0,045 | |

| 000 | 0,09 ~ 0,15 | 0,25 ~ 0,55 | 0,3 | 0,05 | 0.045 | |

| 9000 | ||||||

| Q235 | A | 0,14 ~ 0,22 | 0.30 ~ 0,65 | 0,3 | 0.30 ~ 0.70 | 0.045 |

| 00018 | 0.35 ~ 0.80 | 0.04 | 0.04 | |||

| 000 ≤0,17 | 0,035 | 0.035 | ||||

| Q255 | 0,18 ~ 0,28 | 0,40 ~ 0,70 | 0,3 | 0,05 | 0,045 | |

| IN | 0.045 | |||||

| Q275 | 0,28 ~ 0,38 | 0,50 ~ 0,80 | 0,35 | 0,05 | 0,045 | |

3.Applicant of various classes

1>.Q195, Q215

Due to low strength, good ductility and toughness, easy to process, so widely used in construction, construction, motorcycle body steel nails, rivets, bolts and iron wire, etc.

2>.Q255, Q275

high strength, but ductility, weldability and toughness are not very good, they are not easy to weld and cold bending process, so they are widely used for rolling reinforcing bars or bolts, but more in mechanical parts and tools, etc. d.

3>.Q235

Widely used in construction. The carbon content is 0.14%~0.22%, with high strength, good ductility, toughness and weldability, good overall performance, social meets the general steel structure and reinforced concrete requirements, and low cost.

reinforcing steel frame or building frame, high voltage pole, bridges, vehicles, boiler, containers, ship, etc.

Similar images:

Export packing of steel sheet

9000 9000 9000 9000

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 900 0 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 and other thousands in our products, please feel free to contact us for more

9000 2

information.We welcome all customers all over the world. Thank you!

2

,

stainless steel | Types and Facts Stainless steel , any of a family of alloy steels typically containing 10 to 30 percent chromium. Combined with low carbon content, chromium provides remarkable resistance to corrosion and heat. Other elements such as nickel, molybdenum, titanium, aluminum, niobium, copper, nitrogen, sulfur, phosphorus or selenium can be added to improve corrosion resistance in certain environments, improve oxidation resistance and impart special characteristics.

Stainless steel equipment Stainless steel equipment in the dairy industry. © Mark Yuill / Shutterstock.com

steel: stainless steel

This outstanding group derives its stainless steel characteristics from an invisible, self-healing chromium oxide film that forms when...

Most stainless steels are first melted in electric arc or oxygen furnaces and then refined in another steelmaking vessel, mainly to reduce the carbon content. In the argon-oxygen decarburization process, a mixture of liquid oxygen and argon gas is injected into the liquid steel. By changing the ratio of oxygen to argon, carbon can be removed to controlled levels, oxidizing it to carbon monoxide without oxidizing or losing expensive chromium. Thus, cheaper raw materials such as high-carbon ferrochrome can be used in the initial smelting operation.

There are more than 100 grades of stainless steel.

Most are classified into five main groups within the stainless steel family: austenitic, ferritic, martensitic, duplex and precipitation hardening. Austenitic steels, which contain 16 to 26 percent chromium and up to 35 percent nickel, generally have the highest corrosion resistance. They are not heat cured and are not magnetic. The most common type is 18/8 or 304 grade, which contains 18 percent chromium and 8 percent nickel. Typical applications: aviation, dairy and food industry. Standard ferritic steels contain 10.5 to 27 percent chromium and no nickel; Because of their low carbon content (less than 0.2 percent), they are not heat-cured and have less critical anti-corrosion applications such as architectural and automatic trimming. Martensitic steels typically contain 11.5 to 18 percent chromium and up to 1.2 percent carbon, with nickel added. They are heat-hardened, have moderate corrosion resistance, and are used in cutlery, surgical instruments, wrenches, and turbines. Duplex stainless steels are a combination of austenitic and ferritic stainless steels in equal amounts; they contain 21 to 27 percent chromium, 1.35 to 8 percent nickel, 0.05 to 3 percent copper, and 0.05 to 5 percent molybdenum. Duplex stainless steels are stronger and more corrosion resistant than austenitic and ferritic stainless steels, making them useful for tank construction, chemical processing, and chemical shipping containers. Precipitation-hardened stainless steel is characterized by its strength, which is due to the addition of aluminum, copper and niobium to the alloy in amounts of less than 0.5 percent of the total alloy weight. Its corrosion resistance is comparable to austenitic stainless steel and contains from 15 to 17. 5% chromium, 3 to 5% nickel and 3 to 5% copper. Precipitation-hardening stainless steel is used in the construction of long shafts. stainless steel Nickel and chromium content in various types of stainless steel.

Encyclopædia Britannica, Inc. . DIN structural steel St37-2-Product ID :: 605105305-russian.alibaba.com Din structural steel ST37-2

St37 series are German brands, but this is a general variety, there are several small brands. Such as: St37-2 St37-3U St37-3n RST-2 UST37-2 type. ST37-2 is a grade of carbon steel in the Din standard. This material is equivalent to Q235B carbon structural steel (old number: A3-B) Other: Since it is also similar to our quality carbon structural steel and 20 steel, 20 steel is also a useful substitute.

Chemical component of structural steel Din ST37-2

| C | S | P | N | |

| ST37-2 | 0,21 ~ 0,20 | ≤ 0,065 | ≤ 0,065 | ≤ 0,009 |

Mechanical properties of structural steel Din ST37-2

Strength

≥

Tensile strength : 340~470 Impact: +20℃ 27J

Photos of Din ST37-2 structural steel

Packaging : usually bare and loose. If necessary, in bundles

Shipment : by container or bulk vessel depending on quantity, size and destination port.

Our services

EXW, FOB, CFR, CIF according to your requirements

Third party inspection (SGS, BV ect) is acceptable,

FAQ

1.What is the MOQ?

MOQ depending on material and size.

Small MOQ is acceptable, but the cost will be high compared to large quantity.

2. How long does the price last? ?

Because the price of steel products is according to the market, the price is not stable.

So the price validity period is usually 3~7 days.

3. What is the total delivery time?

Small quantity from stock, about 25~30 days

Production time is about 45 days.

4. What payment term can our company make?

T/T, usually 30% deposit, 70% balance before shipment.

Some products (further process) require an advance payment of 40% or more to 100%.

Any other questions, feel free to contact us.

Tel: + 86-20-81362610

Fax: + 86-20-81367319

About our company

Our company was founded in 2002, and mainly operates Wusteel, Ansteel, Xinsteel, Xiangsteel Wuhansteel, Anshansteel Tiansteel Nansteel, XingCheng steel and many high-quality products from famous domestic manufacturers. Our products mainly contain low alloy and high strength steel sheets, carbon steel sheets, alloy steel structure steel sheets, thicker and thicker wall steel sheets, bridge slabs, steel structure sheets, shipbuilding and oil platform steel sheets, steel pipe sheets, high Steel and strong steel plates, steel molds, corrosion-resistant plates, composite steel plates, etc. We deal with 12 main series, more than 300 brands and more than 40 types have filled out the internal form, more than 80 varieties have successfully replaced imports, and more than 30 varieties are exported to the United States, Japan, Germany and other developed countries and regions. Specification: width: 1500-4020, thickness: 8-700 mm, length: 3000-27000 mm. Delivery Terms: According to customer's requirements, we can deliver the goods under several conditions, such as hot rolling, normalizing, tempering,

. , Strenx® - High Performance Structural Steel Strenx® - High Performance Structural Steel - SSAB 180 This site uses cookies to improve your experience. By continuing to use this site, you agree to our Cookie Policy. Brands and Products Steel Selector Download Center Help Desk Services Contact Us Company News Department

Quick links

Extranet Select site Search

Subscribe to SSAB

Brands

Strenx Hardox Docol GreenCoat Toolox Armox SSAB Boron SSAB Domex Form SSAB SSAB Laser SSAB Weathering SSAB Multisteel COR-TEN

Products

Industry Solutions Workshop Steel Categories Strenx 1300 Strenx 1100 Strenx 960 Strenx 900 Strenx 700 Strenx 650 Strenx 600 Strenx 100-110 Strenx Tube Strenx Sections Hardox Overview Product Program and Data Sheets Products Customer Cases Download

In focus

Hardox in my body

Contact Hardox

Sales Technical support

Subscribe Hardox

Hardox In My Body

Martensitic Complex Phase High Plasticity Double Phase High Formability Double Phase Ferritic Bainite Press Quenching Steel High Strength Low Alloy Pipe Coatings, Miscellaneous

Add a comment Cancel reply

Hardness of steel grade 40

| Hardness steel 40, heat-treated sheet GOST 4041-71 | HB 10 -1 = 167 MPa |

| Hardness steel 40 Rolled calibrated cold-worked GOST 1050-88 | HB 10 -1 = 241 MPa |

| Hardness steel 40 Hot rolled products GOST 1050-88 | HB 10 -1 = 217 MPa |

| Hardness steel 40 Rolled calibrated annealed GOST 1050-88 | HB 10 -1 = 197 MPa |

| Hardness steel 40 Hot-rolled annealed products GOST 1050-88 | HB 10 -1 = 187 MPa |

Endurance limit steel 40

| σ-1, MPA | Steel condition |

| 231 | Annealing 850 °C, σ0.2 =275 MPa, σв =520 MPa Quenching 845 °C, water. Tempering 550 °C, σ0.2 =600 MPa, σv =710 MPa, HB 209 Quenching 845 °C, oil. Vacation 430 °C, σ0.2 =415 MPa, σв =630 MPa |

| 393 | |

| 230 | |

| σ4001/100000 = 100 MPa, σ4501/100000= 50 MPa, σ5001/100000 = 30 MPa, σ4001/10000= 260 MPa, σ5001/10000= 70 MPa, σ4001/100000 = 190 MPa, σ5001/100000 = 44 MPa | |

Foreign analogues steel 40

| USA | 1040, 1042, G10400, G10420 |

| Germany | 1.0511, 1.1186, C40, C40E, C40R, C42D, Ck35, Ck40, Cm40 |

| Japan | S40C, S43C, SWRCH38K, SWRCH40K |

| France | 2C40, C40E, FR38, XC3841, XC38H1, XC42, XC42H1, XP42HI |

| England | 060A40, 080A40, 080M40, C40, C40E, CS40 |

| European Union | 1.1186, C35, C40, C40E |

| Italy | C40, C40E, C40R |

| Belgium | C40-2 |

| Spain | C40E |

| China | 40, ML40 |

| Sweden | 1555, 1650 |

| Bulgaria | 40, C40E |

| Hungary | C40E |

| Poland | 40, 40A, 40rs, D40, P40 |

| Romania | OLC40, OLC40X |

| Czech | 12041 |

| Australia | 1040, M1040 |

| South Korea | SM40C |

- Structural steel

- Tool steel