A force measuring device, or dynamometer, is a device with which the magnitude of a force or moment of force is measured. Invented more than 200 years ago, it was gradually improved over time, becoming more compact, convenient and accurate. What this device is, what it consists of, how it works, what types there are, will be discussed in this article.

Modern dynamometer

What is a dynamometer?

The device determines the relative power of available or required effort to perform any physical action.

Industrial, medical and consumer devices differ:

- dimensions;

- principle of operation;

- calculation method;

- scale type;

- technical parameters and other characteristics.

A dynamometer is used to measure the strength of a person, unit, machine, etc. The designs and types of such devices vary over a wide technical range. In the International System of Units, force is measured in newtons. Dynamometers, depending on their purpose, are equipped with different scales. Some devices measure the force applied in kilograms. It is common European practice to define force in newtons.

It reflects the amount required for 1 second. change the speed of movement of a solid object weighing 1 kg. This indicator is calculated by the computational link of the dynamometer. Most models for household, industrial and medical purposes use decanewtons or kilograms, which is necessary to unify the obtained values. Newtons are used only in some laboratory and educational dynamometers.

Force and its measurement

Force in mechanics is a measure of the interaction of bodies. Force expresses the degree of mechanical action of one body on another, and it is force that causes changes in the movement (acceleration) of bodies. Outside the action of forces, any body is either at rest or moves rectilinearly and uniformly.

Like most physical characteristics, forces have magnitudes, which allows them to be compared with each other. And, since the action of force is expressed in the message of acceleration to the body, the unit of measurement of force is based on this property.

The SI unit of force is the force that imparts an acceleration of 1 meter per second per second to a mass of 1 kilogram. This unit is called "newton".

Purpose

Compact devices and stationary equipment have different areas of application. Regardless of the technical modification, dimensions and design of the measuring element, all such devices are designed to determine the applied force.

In construction, a dynamometer is used to measure the degree of pressure on the holding frame:

- vertically suspended load;

- concrete slabs;

- various floors;

- external elements of buildings;

- balconies;

- flights of stairs.

Such large-sized equipment is used in the mining industry to determine the force required to destroy rock using a non-explosive method. In industrial production, stationary dynamometers are used to calculate the strength of materials and structures.

Electronic devices that are used in medicine to determine the physiological parameters of muscle fibers are highly accurate. Such devices measure the power indicators of critical components, mechanisms and assemblies.

Industrial Application

In the metalworking industry, similar equipment is used to determine the functional characteristics of press dies. Dynamometers make it possible to determine with relative accuracy the cutting, bending and deformation forces of metal workpieces and products.

One of the purposes of industrial-type devices is to measure the traction capacity of production plants and torque, which are indicated in the technical data sheet of vehicles, engines and other units.

Dynamometers of different types are used in the manufacture of:

- robotic mechanisms;

- space technology;

- military vehicles and installations;

- prostheses;

- implants;

- heat and electric locomotives;

- electronic and analog scales;

- control and measuring equipment for various purposes;

- power units;

- turbines;

- lifting and rigging devices.

Such devices are used in the production of torque wrenches designed for tightening threaded fasteners with a given force. Dynamometers are needed in the production of agricultural and municipal machinery, mining dump trucks and heavy installation equipment.

In construction

Devices and equipment for measuring force are used in the construction of residential complexes and administrative buildings. They are necessary when designing overpasses and transport interchanges.

Dynamometers are designed to measure the load-bearing capacity of building structures, beams and architectural fragments. Such equipment is used in the construction of dams and other hydraulic structures. They have found application in bridge construction, design of Ferris wheels and amusement rides.

In medicine

Any physiological and anatomical parameter of the human body can be accurately assessed in digital terms. For this purpose, specialized medical devices are used.

The dynamometer is used to measure muscle strength and muscle contractions. Devices for medical purposes have a wrist or postural design. There are optical dynamometers that are used to determine the strength of the muscle fibers that support the eye lens.

The use of such monitoring and measuring equipment for medical purposes allows you to accurately:

- Establish the patient's physical condition.

- Determine the speed of recovery after exhaustion, serious illness or injury.

- Assess the dynamics of postoperative rehabilitation.

- Calculate muscle functionality.

- To find out the degree of muscle development in patients with birth defects and genetic pathologies.

Indicators of muscle strength provided by a medical dynamometer vary within a certain range depending on the degree of fatigue of the subject, his age, and gender. Using a dynamometer, the strength of the handshake is determined, which, according to recent scientific data, can be used to determine the functional state of the heart apparatus and predict the risk of an acute cardiac crisis.

An important medical purpose of the device is to assess children's health. Scientists from Baylor University (Texas, USA) found that the functional state of a child’s body can be determined by the strength of the hand’s grip. There is evidence of a relationship between muscle weakness and life expectancy. To determine this parameter, such a measuring device is used.

What force is measured with a dynamometer?

With this device you can measure various forces. The main ones include the following:

- Elastic force;

- Friction force;

- Gravity.

These are the most popular options used by customers.

There are types of dynamometers such as:

- Mercury;

- Medical;

- Manual;

- Traction;

- Electronic.

Each of them has its own special features in use. Let's talk about this in more detail.

A hand dynamometer, some know it as a strength meter, is used to measure the muscular strength of the arm. This device should be placed in the palm of your hand and the hand should be clenched into a fist.

A medical device is used to measure the strength of muscle groups.

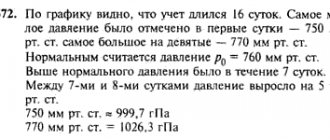

The electronic version of the dynamometer can be used by stretching and compressing. It consists of a strain gauge, which is connected by a cable to a special remote control. This sensor will change due to different loads.

The traction dynamometer is most used to measure large loads: tractors, sea tugs, locomotives, and other types of heavy weights. It is with this model that forces up to several tens of thousands of newtons can be measured.

Types of dynamometers

In accordance with the design of the power unit and the implemented operating principle, electronic, hydraulic and mechanical devices are distinguished. The latter are further divided into spring and lever. There are combined models that combine several operating principles to ensure high accuracy of measurements for various purposes. A special category of dynamometers are diagnostic devices that have their own classification.

Some models are intended exclusively for use in medical institutions, hospitals and physiotherapy offices. There are compact household dynamometers.

The range of such devices is varied and includes dozens of manual options. There are specific devices for single use, called disposable sensors.

They are used to determine the strength of destructive loads - powerful explosions, extreme dynamic pressure, colossal impacts. Before losing integrity and failing, they manage to transmit a signal to a receiving unit located at a safe distance about the characteristics of the destructive impact.

Mechanical models

The simplest and most unpretentious products to use. In a spring-type mechanical dynamometer, the applied force is transferred to a spirally twisted steel wire. Depending on the design features and purpose of the device, the working element is subjected to tension or compression. The recorded indicator of elastic deformation is recorded by the arrow of the measuring scale. The result is considered proportional to the mechanical force.

Dynamometers with a lever instead of a spring are no less common. It is attached to the needle of the measuring scale. The acting force deflects the lever rod or plate by a certain number of units. The recorded value is considered to be indicative of the applied mechanical pressure. Such dynamometers cannot be called very precise measuring instruments.

The simplest and well-known stretching instrument is the cantar or steelyard. This is a manual scale with a spring design. A common example of a lever tool for household use is a torque wrench for cars.

Hydraulic modifications

Devices of this type measure the force of an external influence by moving (pushing) a liquid contained in a special flask. The displaced substance moves through the pipe onto a scale that records its level. A dynamometer is used to measure torque in turboprop engines. Hydraulic models are installed in aircraft equipment for automated feathering of the propeller in the event of a power plant failure.

Such devices are much more accurate than their mechanical counterparts, but have a more complex design. Depressurization of the cylinder with liquid instantly leads to loss of functionality of the device.

Errors in dosage when filling a hydraulic dynamometer have a significant impact on the performance of the device and the accuracy of calculations. In aviation technology, devices are used that are made in the form of several cylinders from a high-strength and heat-resistant composite or metal alloy.

Electronic dynamometers

The design contains a pair of sensors for different purposes. One, considered the main one, converts deformation energy into an electrical impulse. An auxiliary sensor is needed to amplify the signal and record it in RAM.

The electronic unit is:

- inductive;

- piezoelectric;

- vibration-frequency;

- capacitor;

- strain gauge.

Such devices are extremely accurate and maintain synchronization with additional equipment - mechanisms for determining cutting force or wire devices that are used to evaluate resistance. Electronic dynamometers are equipped with a small display and a touch or keypad control panel. The calculated result is displayed as a numerical value and in the form of an oscillogram.

Reference models

This category includes electronic devices with particularly precise calibration. They are used in laboratory practice, for setting up other dynamometers, and on test benches. Reference devices are designed for testing critical components, assemblies and mechanisms. This dynamometer has a force sensor connected to a digital measuring unit. The performance of exemplary models is not affected by environmental conditions.

They are equipped with an integrated self-diagnosis mechanism. Such devices have the function of automatically compensating for lateral loads, preventing them from distorting the value displayed on the display. The dynamometer, which is given the name reference, is used to measure strength indicators with maximum accuracy. Such devices have compact dimensions, resistance to external factors and durability.

They have a user interface, a variety of digital indicators and a port for connecting to a computer. Reference models are compatible with other types of control and measuring equipment, which allows for a comprehensive assessment of the operating parameters of the tested mechanisms and products.

Medical dynamometers

Highly specialized devices designed to test the physiological parameters of the body, performance and endurance of people. Such dynamometers are used in clinical practice and sports medicine. Existing models are wrist and backbone. The former are diagnostic devices for determining the compressive capacity of the upper limbs.

Devices of this class are used to assess the condition or monitor professional suitability in:

- physiotherapy practice;

- sports;

- Ministry of Emergency Situations;

- military units;

- law enforcement agencies;

- companies providing forwarding services;

- transport enterprises.

A separate group consists of children's hand dynamometers. The most common domestic model in this category is DMER-30-0.5. Milling devices have great functionality. They are intended to test the strength of different muscle groups responsible for straightening the body, maintaining balance and stabilizing the spinal column. The most popular model of deadlift dynamometers is DS-500.

Differences between a deadlift and a wrist dynamometer

Every athlete should know the differences between a wrist dynamometer and a deadlift dynamometer. The most important difference lies in its intended use. Let's take a closer look at this further.

First, let's talk about the deadlift dynamometer. This material is a floor equipment located on a support foot whose size will be 300 by 200 mm.

- It will contain two handles, which are located in the upper part. They move to the sides.

- This product allows you to fix the upper limbs.

- Now let's talk about the wrist dynamometer. This model has an oblong handle.

- It needs to be completely wrapped around your fingers, and it should completely fit in your palm when you start squeezing it.

- At the top of this device there is a dial on which you can see the result.

The procedure must be performed first on the right hand and then on the left. This must be followed according to the testing instructions, otherwise the result will be incorrect.

Why is it necessary to know strength indicators?

Such devices have virtually unlimited applications. Manufacturers of various equipment indicate the results obtained with their help in technical documentation. Measuring power and load capabilities allows you to predict the service life and determine the operational life of a machine, component or unit. On this basis, rules for the use of products and their service are established.

The data obtained using dynamometers is used in engineering calculations and design work. Such information is of key importance during the construction of buildings and bridges, hydraulic engineering and other structures. Using established strength indicators and load capacities, they ensure the safety of road traffic, manned flights, operation of mechanisms and equipment, and park attractions.

In medicine, data obtained using such devices is necessary for choosing therapeutic tactics, methods and means of rehabilitation. For professional athletes, dynamometer analysis allows them to evaluate the effectiveness of training and make the necessary adjustments to accelerate progress.

How is muscle strength of the hands measured?

Small-sized hand dynamometers are products made of a steel spring, scale and pointer. Such a device determines the force of impact in kilograms. When measuring, a person holds the device with the dial facing inward and straightens his arm to the side at shoulder level. Holding his arm straight, the subject squeezes the device to the maximum, like an expander. On the right and left hands, the measurement is performed 3 times, and the highest value is selected as the result. According to statistics, the average strength of the right hand in women is 25-33 kg, in men - 35-50 kg. The left hand is weaker, and its indicators, as a rule, differ downwards by 5-10 kg.

In addition to the muscle strength of the hand, back strength is also subject to study. When determining it, a person stands on the platform with both feet, bends down, grabs the dynamometer lever with his hands and, applying a certain force, straightens until the handle of the device is at knee level. To obtain an optimal result, the study is also carried out three times in a row and the best result is recorded.

So why are dynamometers needed, and what medical discoveries have found their place in the scientific world with their help?

An international team of researchers has found that the strength of your handshake can determine your risk of heart disease. To do this, over several years, experts observed 140 thousand volunteers in 14 different countries. Throughout the study, scientists regularly assessed the heart condition of the volunteers and recorded data from a dynamometer, which determines the strength of the hand grip. It turned out that the risk of cardiovascular disease was higher in those volunteers who had lower finger grip strength. Thus, according to experts, reducing the strength of a handshake by 5 kg increases the risk of early death by 16%, heart attack by 17%, and stroke by 9%. Scientists cannot yet explain what causes this connection. But there is a high probability that muscle weakening may be caused by a decrease in the elasticity of the arteries due to disturbances in the functioning of the heart.

Factors that influence strength performance

Electronic devices are considered the most accurate. Their measurements are virtually unaffected by environmental factors. The results of medical examinations are influenced by the time of day and the patient’s physical fitness. The lowest muscle strength is recorded in the morning and evening hours. At midday, this physiological indicator reaches its peak value.

The amount of muscle strength is affected by the psycho-emotional state at the time of the test. Sleep disorder, nutrient deficiency in the body, vitamin and oxygen starvation reduce muscle activity and reduce the indicators obtained by measuring with such a device. Mechanical dynamometers are considered the least accurate.

The level of error in calculations of such devices is influenced by a large number of external and design factors:

- ambient temperature;

- air humidity and density;

- degree of wear of parts;

- backlashes;

- build quality;

- power block manufacturing material;

- spring properties of steel, which change during operation.

A dynamometer is used to measure the strength capabilities of a mechanism, building structure or human body. In the latter case, the obtained values decrease with insufficient physical activity and muscular dystrophy.

Muscle weakness and early death

Scientists from the University of Michigan have concluded that muscle weakness and life expectancy are interrelated. Low muscle strength can increase the likelihood of early death by almost 50%. The study used data obtained from a survey of 8,326 volunteers aged 65 years and older who took part in a nine-year health assessment program. Muscle weakness was observed in 46% of people. A low strength indicator for men was less than 39 kg, for women - up to 22 kg.

Experts are confident that measuring hand grip strength should become a mandatory part of preventive examinations for both elderly and middle-aged people. After all, muscle weakness is a pressing problem that needs to be combated. And, if a person did not take care of his muscles in his youth, it’s okay, because it’s never too late to do this in middle and even old age.

Leave your email to always receive important information and services to maintain your health

Dynamometry is a technique for measuring the strength of an individual muscle or group of muscles using special devices - dynamometers.

Operating principle of a dynamometer

Mechanical models are considered the simplest in design and operating principle. In spring modifications, a force to be measured is applied to the elastic part. It causes deformation changes - stretching or compression. This activates a pointer attached to the spring, which moves along the scale, recording the amount of force applied. Lever and hydraulic dynamometers have a similar operating principle.

In the latter, the role of a deformable element and, at the same time, a recording device is played by a liquid pushed out by the applied force. In lever models, a moving part changes position under external pressure. The lever moves the arrow attached to it by a certain number of scale divisions. Due to their accuracy and versatility, strain gauge devices have become widespread.

Such devices are capable of recording dynamic and static loads. Its design includes a measuring element of increased elasticity and several strain gauge grids. The applied force causes deformation changes, which lead to an imbalance of the resistance bridge currents. As a result, an electrical impulse is generated, captured by a special sensor and displayed on the display as a digital value.

Induction models, designed for testing power units with power up to 966 hp, are distinguished by a fundamentally different mechanism of action and low inertia. The design of such devices includes a polished metal disk that is influenced by electromagnetic forces. It turns around at a set speed, generating current vortices, the magnitude of which is recorded by a tensor sensor.

The dynamometer is used to measure static load indicators. For this purpose, devices with a piezoelectric operating principle are used. The structural structure of such devices includes a special plate.

It is based on quartz with defect-free areas. The mineral has a direct or inverse piezoelectric effect. A charge is formed by mechanical action on a quartz plate. The type of electrical reaction is determined by the position of the cut relative to the axial lines of the crystals. A special converter transforms the charge into voltage. Devices of this class are used to assess the impact power.

To measure pressure during grinding, milling and other types of metalworking, control tools with a wire indicator are used. Their design includes a square plate made of a durable and elastic alloy. It is attached to the inner surface of the case with spring links made of a special grade of steel. The device allows you to measure horizontal and radial force with high accuracy.

The pressure exerted on the plate is recorded by the reading unit, which displays it on the display. The sensor accurately captures the vibration pattern of the part on the elastic fasteners and converts them into digital values.

Electric dynamometer with wire sensors - the secret of operation

A dynamometer with resistance wire sensors is also used in industry. The B.I. dynamometer was especially widely used. Mukhina. The basis of the device is the so-called “boat”. This is a square plate that is mounted inside the device body on links. The links (supports) are elastic, consist of hardened steel and have the shape of hollow tubes. They have the following feature: they have low rigidity relative to the vector perpendicular to the axis, and high rigidity relative to the vector parallel to the axis.

A dynamometer (from the ancient Greek denbmyt - “force” and mEfseshch - “I measure”) is a device for measuring force or moment of force, consists of a force link (elastic element) and a reading device. In the power link, the measured force causes deformation, which is communicated directly or through transmission to the measuring device. Existing dynamometers can measure forces from fractions of newtons (N, fractions of kgf) to 20 Mn (2000 tf). According to the principle of operation, dynamometers are distinguished between mechanical (spring or lever), hydraulic and electronic. Sometimes two principles are used in one dynamometer.

Specifications

They depend on the type, functionality and scope of application of the device. The most common domestic models of dynamometers are the DK series.

These simple, but accurate and reliable mechanical devices have the following technical characteristics:

| Parameter | Meaning |

| Calculation range | 3-140 decanewtons (daN) |

| Level of error | 0.75-4 daN |

| Scale pitch | 0.5-2 daN |

| Weight | 170-250 g |

Electronic copies are more diverse and functional. They have an extended range of measured indicators - 2-120 decanewtons. The discreteness (level of error) for most of these devices does not exceed 0.5 daN. Electronic dynamometers automatically turn off after a time specified in the settings if there is no user activity. They can withstand temperatures of +10...+35°C without errors in calculations.

Medical diagnostic equipment of the stand type has a maximum value of up to 500 decanewtons. Such devices are equipped with a large scale with a division value of 2-5 daN. Such devices make it possible to diagnose early manifestations of scoliosis and postural disorders in children.

Dynamometer in everyday life

With a steelyard you can quickly measure the weight of hand luggage, household items and food products. Despite the advent of high-precision electronic scales, cheap and convenient pocket dynamometers are still actively used in everyday life.

More structurally complex devices in everyday life are used to measure the force of closing elevator doors and passenger transport:

- buses;

- trolleybuses;

- trams;

- subway cars.

There are home instruments designed to assess the degree of ripeness of fruits. The operation of the tonometer is based on the dynamometer principle. Such a device will be needed if it is necessary to find out the weight of substances in different states - liquid, bulk, dry.

Dynamometers are useful when performing installation and construction work and apartment renovation. They are used to evaluate the lifting force of car windows. Mechanical devices are used in everyday life to measure the closing force of hatches and sliding garage doors.