Home / Devices

Back

Reading time: 2 min

0

650

In the past century, manual arc welding was popular. At that time, there was no offer on the market for a more convenient method of joining metals. However, science does not stand still.

Quite quickly, a new welding method arose, which was given the name “plasma”. Engineers realized that with the participation of plasma it is possible not only to perform welding, but also to cut metal.

Most of the craftsmen highly appreciated their potential, and the developers launched mass production. As of today, the most popular of them is the Gorynych plasma welding machine.

It is relatively cheap, multifunctional and will appeal to both professionals and beginners. In our article we will tell you about the device and the need to purchase it.

Installation of plasma cutting and welding Gorynych is a universal device designed for home and professional use. There are 2 versions of the device: model GP37-10 and GP37-12. Their difference lies in the range of adjustment of the welding current.

The first model has a range from 2 to 10 Amps, and the second - from 3 to 12 Amps. Apart from this there are no other differences. Both models are delivered in a branded bag for comfortable transportation.

- Peculiarities

- Device design and potential

- To buy or not?

- Summarize

Peculiarities

The Gorynych plasma welding device is compact and small in size. When fully equipped, the weight of the power supply and burner is no more than 6 kg, which is convenient for repeated trips or when working in hard-to-reach places.

Due to the peculiarities of the method, you do not need to take gas cylinders, compressors, filler wire and everything that is needed when using other technologies.

You can easily put all the equipment in a small bag and carry out field work.

For plasma welding you will need non-consumable electrodes and working fluid. As a working fluid, you can use water, a solution of ethyl alcohol 45% or ammonia 3%.

However, water is used most often. It must be distilled.

The device consumes up to 200 ml/hour of working fluid. These figures are quite parsimonious. It quickly pays for itself and consumes electricity economically. For its operation, you need standard 220 Volts, which are available in every household outlet.

The device can be connected to a low-power fuel generator, since its operation requires no more than 2.5 kW.

Device technical parameters

Main technical parameters of the Gorynych device:

- Welding arc current - from 3 to 10 A.

- Electrical voltage is 220 V.

- Operating voltage - 100 - 200 V.

- Efficiency - 80%.

- The duration of operation on one filling at the nominal operating mode is 20 minutes.

- Torch temperature is not less than 6000 C.

- Burner dimensions: 60x190x190 mm.

- The price for the Gorynych welding device depends on the configuration and averages from 27 tr. up to 35 tr.

The design features of the device have certain nuances. For example, the burner is equipped with a special rotating lever, thanks to which it does not heat up and lies comfortably in the hand. The part adjacent to the nozzle is protected by a metal shield that prevents the plastic burner from melting.

The start button is located conveniently under the working finger and has a soft and smooth stroke. Reaching operating power requires about 3 minutes. The power of the device does not depend on the position of the burner in space. It is possible to refuel the device during operation.

More on this topic on our website:

- How much does a Chameleon welding mask cost - price and reviews from welders? It should immediately be noted that there is a positive factor that will be useful for a welder using a Chameleon welding mask. During welding work, constant raising and lowering will not be required...

- Kempi welding machine - price and characteristics of the inverter Kempi welding equipment has been known to Russians since 1979 - it was then that the first models of welding machines from this legendary Finnish manufacturer began to be sold in the USSR. Today the equipment...

- Semi-automatic welding machine - which one to choose for welding at home Welding is the most reliable and practical way of attaching metal elements to each other. If we are talking about welding not by a professional, but by an amateur, then you need a high-quality...

- Aurora welding machine - choosing a semi-automatic welding machine Welding is an integral component in the construction of buildings, in the manufacturing industry, and in household use. Several decades ago, welding transformers were mainly used for welding - heavy and...

Share a link to this material with your friends on social networks (click on the icons):

Device design and potential

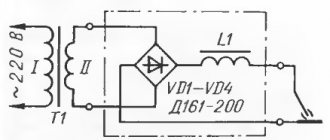

Plasma welding consists of two components: a power supply (which has a built-in control unit) and a plasma generator, with the participation of which cutting or welding is performed.

The kit includes a plasma torch that does the crucial job of creating the seam. The device does not have complex electrical circuits.

Despite such a simple structure, the device can perform a large number of jobs. He is capable of welding, cutting and soldering all types of metals, including non-ferrous ones.

There will be no problems when working with cast iron or stainless steel. It can be used to harden steel.

The Gorynych plasma complex can also work with artificial polymers. This can be PP, PVC, HDPE, PET and a number of others.

The device can perform surface heat treatment of materials and metals such as glass, ceramics, granite and others. Materials can be either organic or inorganic.

What else can you do with Gorynych welding? For example, removing oxidation from metal coatings, cutting fiberglass, applying glazes, melting concrete, and even extinguishing minor fires using water vapor after extinguishing the arc. This unit can replace a lot of tools like a grinder, jigsaw, cutter, and soldering iron.

Don't forget about the most important feature - welding capability.

Plasma processing technology

The main components of a plasma welding machine are a power source and a specially designed torch called a plasma torch.

The plasma torch has a fluoroplastic housing placed in a casing, inside which an electrode assembly is installed. The working (plasma-forming) mixture, protective gas and cooling medium are supplied to the torch, unless air cooling is used.

Principle of operation

The following can be used as a plasma-forming mixture:

- Argon in its pure form;

- Argon mixed with hydrogen;

- Argon-helium mixture;

- Air;

- Hydrogen;

- Nitrogen;

- A mixture of water and alcohol (this technology appeared relatively recently).

Under the influence of an electric discharge, the working medium turns into plasma, which is an ionized gas. The plasma temperature can reach 30 thousand degrees. In this case, the plasma arc is compressed into a very thin beam, due to which its specific power per 1 sq. mm cross-section increases many times over. This makes it possible to use plasma to solve problems that an electric discharge arc with its temperature limit of 5 thousand degrees cannot effectively cope with.

Let's watch the video, a little about this device:

But high temperature is only one of the advantages that a plasma welding machine has. The advantages of these devices also include:

- High efficiency;

- Low consumption of protective gases;

- A small heating area of the material and, as a result, small shrinkage of the seam and an almost complete absence of deformation;

- The possibility of using this equipment for welding non-metallic materials with metal ones.

Summarize

Plasma devices from Gorynych are very successful. Starting from private specialists in the repair and installation of heating systems, and ending with country experts and garage welders.

Their popularity is due to their affordable prices and ease of use. The price for the GP37-10 and GP37-12 complex is more than affordable, which means that any master will be able to afford its purchase.

Gorynych plasma machines are a good choice for both beginners and skilled welders. And its most important advantage is not the price or ease of use, but the quality of the seams.

The connections are attractive and strong, even when welding metals with an oxide film on the surface (stainless steel, aluminum and others). We definitely recommend Gorynych plasma complexes to you.

Popular manufacturers

For those who have not yet bought a plasma welding machine, but are planning to do so and are painfully choosing a manufacturer, we can recommend several companies whose products have managed to win the trust of users.

TM Gorynych

In the case of the Gorynych plasma welding machine, the price is not significant, since this device makes plasma processing of various materials more profitable and affordable than ever. The fact is that devices from TM Gorynych use water or a water-alcohol solution as a plasma-forming medium, and water vapor plays the role of protection. As a result, a film of oxides forms on the surface of the seam, which prevents the development of corrosion processes.

Let's watch a video about this model:

An important advantage of the equipment produced by this brand is its mobility: the Gorynych welding machine can be easily carried like a bag, since it does not require any transformers, as well as gas cylinders and compressor equipment. In this case, the power source can be either a regular 220 V network or an autonomous generator.

To carry out work, ventilation is not necessary, since the air is not only not poisoned by substances harmful to the human body, but is also saturated with oxygen released during the partial decomposition of water vapor.

The temperature of the water-plasma arc reaches 6000 degrees. Depending on the strength of the current used, the device can work with workpieces with a thickness of 0.5 to 8 mm.

Model Gorynych

Cost of plasma devices Gorynych:

- A device with a current of up to 8 A: about 29 thousand rubles;

- A device with a current of up to 10 A: 30 thousand rubles;

- Device with current up to 12 A (2.5 kW): 33 thousand rubles.

Prices for consumables:

- Welding nozzle (2.1 mm): RUB 200;

- Cutting nozzle (1.2 mm): RUB 200;

- Cathode: 200 rub.

Multiplaz

The operation of a plasma welding machine from the Multiplaz company is also based on the use of water and aqueous-alcohol solutions. Due to this, it was possible to reduce the size of the device, while abandoning transformer and compressor equipment. Devices from the Multiplaz company are placed in a small container-bag and weigh very little: the power supply has a mass of about 5 kg, a plasma torch in the form of a pistol weighs about 1 kg.

Let's watch the video, a little about the operation of the device:

A feature of water plasma devices is their environmental friendliness. Heat treatment of metals can be carried out even in closed spaces that are not equipped with ventilation, since the formation of plasma from water is not accompanied by the release of substances hazardous to health, but on the contrary, it enriches the air with oxygen.

Model Multiplaz

Plasma is generated as follows. First, an electric discharge arc occurs between the cathode and the nozzle, which acts as an anode. Under its influence, distilled water turns into steam, which then ionizes and turns into a plasma state. The steam’s own pressure ejects it from the burner in the form of a jet, which acts on the workpiece material.

Cost of the Multiplaz 3500 model (power - 3.5 kW): 90 thousand rubles.

Plazarium

One of the most popular is the model of plasma welding machine Plazarium SP3. Compact and reliable device with excellent characteristics. An inverter circuit is used, which makes it possible to obtain a stable current regardless of voltage fluctuations in the supply network.

Model Plazarium

The device is equipped with temperature sensors that allow you to control the process and avoid accidents due to equipment overheating.

Cost of the Plazarium SP3 model (power - 2.64 kW): about 39 thousand rubles. The price level for plasma welding machines depends on the power (the higher it is, the more expensive the unit) and on the “name” of the manufacturer.