The need to make a vibrator from a hammer drill appears during the pouring of the screed, foundation, and leveling of the concrete surface. The device is in demand for small-scale production or the creation of reinforced concrete structures at home. Instead of buying a ready-made vibrator for a hammer drill, it is easier and cheaper to make it yourself from materials found in a garage or scrap metal collection point.

Description of the vibrator for the hammer drill

A vibrator is a specific device used during construction work using cement mortars. It improves the quality of the pour: it compacts the structure of the future structure, eliminates air gaps in it, removes excess moisture, and slightly speeds up the construction of buildings. This means it reduces construction costs.

When pouring concrete, the mixture is saturated with air, especially if there is not enough liquid in it. A mass of air-filled voids is formed inside the composition, which reduces the strength and other characteristics of the material and its service life.

If a vibrator was not found at a construction site a decade or two ago, it was replaced by the manual bayonet method. Workers used improvised means, such as fittings and pipes, to bayonet the solution. This approach is very costly and ineffective. It is more advisable to use electric traction. At any construction site there is a hammer drill from which you can make a vibrator for concrete in ten minutes.

The vibrating tip is represented by an attachment for a hammer drill:

- The deep concrete vibrating tip is attached to the motor of a rotary hammer or drill through a flexible shaft and vibrates at high frequency and low amplitude, spreading vibration through the concrete.

- The surface vibrator for concrete is inserted into the chuck like a drill. The hammer drill operates in impact mode - it transmits mechanical vibrations from the impact mechanism to the formwork with concrete.

The principle of operation is to destroy the bonds between the molecules of the concrete solution, as a result of which air bubbles filling the voids are removed. Excess moisture, being lighter than the other components of the mixture, rises to the top.

The device gives concrete the required degree of density and fluidity, improves its mechanical and operational properties, and promotes uniform filling of voids with the mixture.

Methods (methods) for compacting concrete

Concrete can be compacted using three methods: vibrating, bayoneting and compaction.

Concrete compaction using the vibration is carried out for plastic concrete using an electric vibrator. At the same time, the quality of concrete is much higher than that of uncompacted or manually compacted concrete.

Concrete compaction by tamping is carried out for heavy concrete using machine or manual tampers in unreinforced or lightly reinforced structures. Compaction is carried out layer by layer, the thickness of fully compacted concrete should not exceed 15 cm.

We used manual concrete compaction using the bayonet (GOST 10180-90 Concrete). To do this, you can use a metal rod (for example, a piece of reinforcement or pipe) weighing 2-4 kg, preferably with a rounded end. The reinforcement needs to be immersed in the concrete with frequent pushing movements with a small amplitude (as if to “pierce” the concrete) and then begin to swing frequently from side to side. Then the piece of reinforcement must be slowly pulled out of the concrete, also giving it vertical and horizontal vibration. It is necessary to pierce the entire volume of concrete. The number of “punctures” with the rod is calculated so that 1 “puncture” falls on 10 sq.cm of concrete surface; bayoneting must be done evenly in a spiral from the edges of the formwork to its middle. In this case, the crushed stone is compacted, air leaves the mixture, and water rises to the surface of the concrete mixture.

After carefully compacting the concrete, the crushed stone “settled” tightly, excess water and air were removed. The result was a high-quality casting.

Continued success to you, dear readers of the blog “How to build a house” in building your home!

Vibrator tasks

Regardless of the design and scope of application, a vibrator for concrete compaction must solve a number of problems for the builder:

- Increasing the strength of a structure by removing excess moisture and air bubbles from the mixture.

- Extending the service life of the structure.

- Making concrete homogeneous.

- Uniform filling of the formwork with mortar.

- Increasing the service life of reinforced concrete structures.

Additionally, the vibrating tip eliminates the need for layer-by-layer pouring of mortar, which speeds up the process of constructing reinforced concrete and concrete structures.

Types and design of vibrators

According to the method of transmitting mechanical vibrations - vibrations - to the mixture, concrete vibrators are divided into:

- Deep - the working part of the vibrating tip for the hammer drill is lowered into liquid concrete.

- Submersible - used for pouring walls, pillars - mounted vertically on formwork when working outdoors.

- Surface – compact horizontally poured concrete.

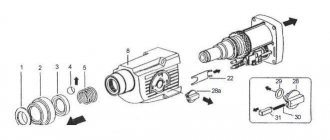

Assembled device

Structurally, a deep concrete vibrator is represented by an attachment or a vibrating tip connected to a hammer drill. Consists of four fundamental components:

- The drive that powers the vibration device is the power unit of the hammer drill.

- Flexible shaft.

- Protection made of durable rubber or other polymer material with similar properties.

- The tip, represented by a vibrating mace.

The last component has a mechanical effect on the cement mortar.

Also, according to their design, vibrating tips are divided into:

- Pendulum - the mechanism inside performs post-swimming and return movements with small amplitude.

- Eccentric - vibration is generated by a rotating shaft with an offset center.

Difference in design

Recommendations

Making a vibrator using the methods described are common options, although there are other methods. It is enough just to select the vibration source and then adapt the tip to it.

The main advantage of a homemade tool is that manufacturing is cheap, and after the work is completed, its main element can be used for its intended purpose. When assembling the equipment, it is necessary to make all joints reliable, since the concrete creates powerful pressure, actively counteracting vibrations.

Structure of a deep vibrator

A homemade deep concrete vibrator, made from a hammer drill, consists of the following components.

- Flexible transmission shaft up to several meters long, depending on the need and the power of the electric motor.

- Durable rubber seals installed between the hose with the cartridge and the mace - tip.

- The vibrating part can be cylindrical or conical - it tapers from the beginning, which is located at the hammer drill, to the end. The second form of vibrating attachment is used when working with a solution of increased density.

- The body is represented by a piece of stainless tube with bearings inside.

- A shaft with a displaced center of gravity is installed on the bearings, which generates the necessary mechanical vibrations. Their frequency depends on the design of the device and the rotation speed of the electric motor of the hammer drill.

A submersible vibrator from a rotary hammer operates at a frequency of 10,000 to 20,000 rpm; its shaft is reliably protected on top by a polymer material that does not allow water to pass through, for example, a rubber hose.

Miniature vibrating tips can be operated by one person; if the shaft is more than 1-2 meters long, an assistant is involved in the work.

What is a vibrating screed

The vibration lath is a rigid structure consisting of a steel lath with a handle, which contains a motor with a vibrator. Thanks to the vibration movements, the concrete solution is evenly compacted, and the lath itself creates a smooth surface.

Types of vibrating slats

A vibrating screed for concrete is a popular construction tool for screeding. Professional vibrating screeds are divided into several types.

floating

Using guides, the top layer of concrete is leveled.

The engine power compacts the concrete solution to a depth of 15 centimeters.

Telescopic

Such devices have sliding slats, which allows you to level a large area at the same time.

Before starting work, the slats are fixed to the required distance, which simplifies the work.

Sectional

They have a large grip, which is ideal for industrial construction. They have a collapsible design, which makes them convenient for transportation from site to site. Equipped with a powerful engine.

Aluminum

This type of vibrating screed is designed for processing freshly laid concrete. Designed for private construction. Thanks to its lightness, it is easy to manage.

Based on the type of engine, there are gasoline and electric vibrating screeds.

As noted above, a gasoline vibrating screed is more powerful and, accordingly, more expensive. Electric vibrating screeds have less power, but they are recommended for use in enclosed spaces.

Gasoline engines emit harmful substances during operation, which is noticeably noticeable in confined spaces.

Examples of good vibrating screeds

The Spanish vibrating screed ENAR is perfect for professional use.

The features of this tool are:

- ease of use;

- compacts concrete to a depth of 15 centimeters;

- does not sink into the concrete surface;

- profile length reaches 4 meters;

- Ideal for working on freshly laid concrete.

The price range for a vibration screed with a Honda gasoline engine with a power of 0.7 hp starts from 44,000 to 51,000 rubles. Weight depends on the chosen model and varies from 15 to 25 kg.

When buying a vibrating screed, remember that it must fully meet your requirements and be suitable for your construction site.

How to make a deep vibrator from a hammer drill

With a competent approach and the availability of primitive plumbing skills and tools, there will be no problem in creating an internal vibrator from a household hammer drill. The use of a construction power tool motor is determined by a couple of factors. Firstly, it is a powerful, reliable motor that can handle the load lightly. Secondly, the motor generates high-frequency shocks that cause vibrations with a frequency of up to 5000-10000 beats/min.

A flexible transmission shaft of a vibrator for compacting concrete can be purchased and made with your own hands from steel wire - knitting. It will be needed approximately 3.5 times longer than the length of the shaft itself.

To make a deep mechanism, you will need the following tools and materials:

- shaft 30-50 cm long;

- a pair of bearings with an internal diameter corresponding to the diameter of the shaft - it can be machined;

- the third bearing is smaller in diameter than on the shaft - the seat for it is machined;

- bench vise, hammer;

- welding inverter, grinder with a metal disc;

- a piece of durable hose;

- steel wire.

The simplest vibrator for concrete from a hammer drill can be made with your own hands from:

- SDS+ shank, cut from a worn or broken drill;

- a piece of metal plate ~3-5 mm thick.

The shaft is turned on a lathe or using a grinder. One end is machined to the thickness of the inner diameter of the bearing. The second one can be made even thinner or left untouched.

- A pair of bearings is pressed onto the shaft at a distance of at least 10 cm from its edges.

Shaft turning

- A smaller bearing is pressed onto the thicker machined end.

Pressing on the bearing

- A hole with a diameter corresponding to the thickness of the cable is drilled at the end of the opposite end of the shaft, and it is inserted into the hole. The cable can be carefully welded.

Cable insert

- The shaft of the vibrating tip for concrete is clamped with a vice, and part of the material is removed from it to shift the center of gravity - it will begin to vibrate when rotated.

Center of gravity shifts

- The end where the bearing is pressed is flared so that it does not fly off during operation of a self-made concrete vibrator.

On a note! Alternatively, a thick plate or rod is welded to the thin rod to shift the center of gravity instead of cutting out part of the shaft.

- The remaining bearings are held in place by punching the shaft around the inner ring.

- Steel wire is wound around a metal rod to give it the shape of a spring.

Creating a Flexible Shaft

- The rod is removed from the spring.

- The spring is inserted into a rubber hose or sleeve. It should fit effortlessly, with little play.

Dressing protection

- A rubber hose is put on the thin end of the metal shaft and tightened with a clamp or pair.

Fixing the connection

- The vibrating shaft is placed in a metal pipe casing. It is tightly welded on one side, and a cable wound like a spring is connected to the vibrator shaft on the other to compact the concrete.

Its end is clamped into the jaw chuck of a drill or the toothed chuck of a hammer drill. If necessary, an SDS+ shank is welded to the end of the cable to quickly connect the vibration mechanism to the hammer drill chuck without adapters.

Other vibration table options

In addition to the traditional stationary vibrating table proposed above, there are other devices.

For example, a combined mechanism for compacting paving slabs and sifting sand.

In this case, the frame with the mesh is installed on the tabletop, sand is poured on top and vibrations are turned on. Screening is carried out to the fraction specified by the mesh size. Be sure to have sides on the table top and have a solid surface! A box with an inclined outlet for pouring sifted sand is installed under the tabletop; the engine is protected by a casing.

If desired, the size of the table top can be increased, in this case the number of legs also increases - up to 6 or 8 pieces, and the frame itself is strengthened

Please note - the number of shock absorbers corresponds to the number of frame supports!

If for some reason you are not satisfied with fastening shock absorbers using pins and nuts, you can fix them using cups. In this case, the inner diameter of the cups and the outer diameter of the spring should approximately match, guaranteeing a gap of 1...2 mm.

Another drawing will help you make a vibrating table for paving slabs with four supports.

The dimensions 300 mm and 180 mm in this drawing refer to the dimensions of the box for installing the electric motor.

If it is necessary to increase the number of supports and, accordingly, add reinforcing beams to the frame, the engine can be offset from the center, as shown in the diagram below.

It is also acceptable to use transmission mechanisms, when the engine is installed on the frame of the vibrating table, and vibration is transmitted to the tabletop using a pulley.

Surface vibrator

You can make a surface vibrator for concrete in ten minutes with your own hands. For this, in addition to a hammer drill, you will need the shank of an old drill and a steel plate 3-5 mm thick with dimensions of approximately 40 × 60 mm - the dimensions depend on the power of the electric motor.

A shank about 60 mm long is cut from the drill or purchased separately. It is welded to the center of the plate perpendicularly with strict observance of the right angle.

The simplest model

The surface vibrator is suitable for compacting, improving the physical and performance properties of concrete poured into formwork. The nozzle is inserted into the chuck, applied to the wooden formwork structure, after which the electric motor of the hammer drill is started in impact mode.

Tips for using a homemade vibrator

Professionals recommend adhering to the following recommendations when using a homemade vibrator for pouring concrete from a hammer drill.

- The device is immersed vertically in the solution; horizontal movements should not be made.

- When pouring layer-by-layer, a vibrating tip for concrete from a hammer drill is immersed in each layer to ensure reliable adhesion to the previous one.

- When pouring layer-by-layer, it is not recommended to keep the device in the solution for a long time - it can delaminate the concrete.

- The tip should not come into contact with the walls of the formwork or reinforcement included in the structure.

You can make an internal vibrator for concrete with your own hands in a few hours from raw materials purchased for a hundred rubles at a metal collection point. It can work with both a drill and a hammer drill. A surface vibrator for concrete is made in five minutes from a piece of metal and a drill shank; it only works in impact mode on a hammer drill.

For what purposes is it used?

Deep devices are used for the construction, casting or assembly of monumental structures made of concrete (simple and reinforced). The vibrator is also designed to break up lumps of cement in poorly prepared mortar.

The electric apparatus is used for pouring floor slabs, columns and the following types of foundation:

pile; slab; tape; screw; shallow; columnar.

The effectiveness of working out the solution with a vibration device is clearly demonstrated when coarse crushed stone is used in the work. In such an environment, air is stably retained, and it is only possible to expel it using a hardware method.