Bolt thread pitch definitions:

Place a straight edge on the threaded part of the bolt. If its millimeter divisions coincide with the tops of the threads, then you undoubtedly have a pitch of 1 mm. If not, then count the number of turns n on a certain segment of length L. Do not take the first thread into account, since the counting comes from it, and it is zero.

| Number of turns per 2 cm | Thread pitch, mm |

| 9 | 2,5 |

| 11 | 2,0 |

| 12 | 1,75 |

| 14 | 1,5 |

| 17 | 1,25 |

| 21 | 1,0 |

| 26 | 0,8 |

| 29 | 0,7 |

Divide the length of the taken segment in millimeters by the number of turns and get the pitch P.

P= L/(n-1) = 20 mm / (17-1) turns = 1.25 mm

It is important to take into account that the larger the threaded section you take for measurements, the smaller the error will be. A more accurate result can be obtained using a caliper by aligning the extreme tips of the threads with the tip of the tool jaws.

The thread pitch is closely related to the diameter of the bolted connection. Data on the correspondence of these two parameters are summarized in the table. We measure the outer diameter of the bolt, in our example we get 10 mm. From the table we see that the M10 bolt can have a thread pitch: 1.5 (main)

,

1.25 (fine)

,

1.0 (fine)

or

0.75 (superfine)

. The number obtained by calculation must exactly (or almost exactly) match the reference value. In our case, a metric thread of the second row with a fine pitch of 1.25 mm. Bolt designation: M10x1.25.

Accuracy classes and marking rules

A thread belonging to the inch type, as indicated by GOST, can correspond to one of three accuracy classes - 1, 2 and 3. Next to the number indicating the accuracy class, put the letters “A” (external) or “B” (internal). The full designations of thread accuracy classes, depending on its type, look like 1A, 2A and 3A (for external) and 1B, 2B and 3B (for internal). It should be borne in mind that class 1 corresponds to the coarsest threads, and class 3 corresponds to the most precise threads, the dimensions of which are subject to very stringent requirements.

Maximum size deviations according to GOST

To understand what parameters a specific threaded element corresponds to, it is enough to understand the designation of the thread that is applied to it. The designation in question is used by many foreign manufacturers who work according to American standards relating to elements of threaded connections.

An example of a symbol for an inch thread

This marking contains the following information about the thread:

- nominal size (outer diameter) – first digits;

- number of turns per inch of length;

- group;

- accuracy class.

If you have a question, how to determine the type and size of thread Connecting fittings for pipes and hoses

connections use the table below.

Please note the following:

- connections with inch threads are highlighted in color

- next to the inch step size in tpi the step size in mm is indicated

- connections with external tapered threads usually do not have a threaded groove

- BSPT and NPT conical fittings are very similar, but BSPT has a mark on the hexagon

An important note - situations are quite possible when the inch and metric pitches are very close in size (this is possible on JIC connections).

Read also: Scraper conveyor operating principle

In this case, it is possible to confuse the inch thread. American cylindrical inch thread UNF (Unified Thread Standard)

UNC UNF and metric threads.

Threaded fasteners are one of the most popular for attaching parts, assembling products, equipment, and structures. There is no industry where it is not used. There are many thread characteristics: pitch, tolerance range, number of starts, nominal diameter, profile type and others. One of these is units of measurement, inches or millimeters.

There is often a situation when it is necessary to replace a bolt, pin or screw, but the fastener purchased for maximum similarity “by eye” is not screwed into the mounting hole. One of the reasons is an attempt to screw a fastener with an external inch thread into a hole with a metric thread. Or vice versa. This situation often arises when replacing fasteners on products or equipment manufactured in the UK, USA, Japan, or Australia. There, inch threads have priority.

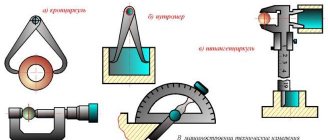

How to distinguish an inch thread from a metric thread? There are two main ways - by measuring the pitch and diameter or using a special tool.

Measurement

Fastener thread markings are done differently in metric and inch systems. In metric, this is an indication of the thread pitch (the distance between adjacent threads) in millimeters, while in inch it is the number of threads per inch.

Determining the type and size of fastener thread comes down to the following operations. Use a caliper to measure the diameter. Then, using an inch ruler or caliper, measure the number of threads in one inch and the thread pitch. You can also use a regular ruler with measured 2.54 mm (1 inch = 2.54 mm). The metric thread pitch on small fasteners can be found by measuring the distance between 10 turns and dividing the resulting value by 10. The resulting values should be compared with the table below. The maximum match in diameter, number of turns, pitch indicates the size and type of thread. It should be noted that there are many different types of inch threads. The table shows the most common ones in the diameter range from 8 mm to 64 mm.

You can also use a thread gauge to measure threads. This is its direct purpose. A thread gauge is a set of plates with protruding teeth for a specific thread, united on a single axis. The thread size is engraved or permanently inked on the plate itself. Checking the thread is done by applying plates that are closest in size to the thread. If there is a complete match, without gaps, the thread can be considered defined, and its size can be viewed on the thread gauge plate. Thread gauges are produced separately for metric, inch threads or both types.

Determination of nut thread pitch:

To measure the pitch of an internal thread, the best way is to select a counter bolt that would screw freely into the threaded hole, and then calculate it. If there are no suitable screws, then you can use the old, proven old-fashioned method. To do this you will need a piece of paper and a ruler.

Tear off a small strip of paper and place it in the nut. Press the paper against the thread with your finger until an imprint of the threaded surface remains on it. For better visibility, you can draw fuel oil or a marker along the edges of the coils. Applying a ruler to the print, measure the distance L between the extreme marks and count the number of marks n in this area minus the first (zero). Perform calculations using the formula P = L/(n-1).

For example, the print produced 6 clear marks on a segment of 10 mm.

P = L/(n-1) = 10 mm / (6-1) turns = 2 mm

Instead of paper, you can get an impression on the edge of a match or pencil. Knowing the internal diameter of the nut (in our case 14 mm) and the calculated pitch, we compare the obtained data with the table. We find in the thread row the value M14 and the desired pitch of 2.0 mm (main). Nut designation: M14x2.0.

In addition to metric bolted connections, inch fasteners are widely used in the modern technical world. Read the following article to learn how to determine the pitch of an inch bolt.

Main types of thread

Standard threads

There are several classifications of thread types.

Based on the unit of measurement of diameter and pitch, the following are distinguished:

- Metric.

- Inch.

- Modular (step is a multiple of Pi).

- Pitch (step is expressed in fractions of Pi).

By location:

- internal;

- external.

In direction of rotation:

- left;

- rights.

By number of visits:

- one-;

- two-;

- three-;

- and other multi-pass ones.

For a single-thread, the main pitch, or the distance between adjacent turns, is equal to the stroke, or the distance that the nut will advance in one turn. For a multi-start thread, the thread lead will be equal to the thread pitch multiplied by the number of starts.

According to the tooth profile:

- Triangular.

- Trapezoidal.

- Rectangular.

- Round.

According to the type of surface of the body of rotation on which the thread is applied

- conical;

- cylindrical.

And finally, by purpose:

- fastening - for fastening two or more parts to each other;

- for transmitting motion in various mechanisms (chassis);

- for compaction.

Classification of threads

The most common thread is metric, its designation begins with the letter M; if the thread has a reduced pitch, the number 1, 2 or 3 is placed in front of the M. Diameters are standardized from 1 millimeter to 60 cm in increments of 0.25 to 6 millimeters, respectively. M5 thread and M6 thread are most common as fasteners for radio equipment and household appliances.

Screen thread gauge for Android

Even an ordinary smartphone can replace a thread gauge in everyday life. To do this, you need to download the Android application “Thread pitch meter. Thread gauge" from the developers of the Smart Tools toolkit. Simply apply a screw to the screen, look for the exact match of the turns and find out the pitch. Various types of threads are available in the mobile application: metric, inch and pipe standards.

Screen thread gauge for Android

As for inch and metric threads, there are approximate matches. But it’s hard to imagine how you would try to screw a 1/2″-20 UNF bolt into an M12x1.25 hole. As for the M14x1.25 thread, yes, everything is correct.

Evgeniy Guryevich, 1) On threading tools, as well as in reference tables, it is indeed customary not to use the “X” sign. But not in the designation of LARGE, but MAIN THREADS. In practice, many foreign manufacturers still provide full markings of the thread size, for example 12x1.75, both on the tool and on the packaging with fasteners. Soviet and Russian companies producing cutting tools also often “sin” with this. You don’t have to look far for examples - this is the former Sestroretsk tool plant, the German company Reyher. This is done mainly so that the user does not have doubts about the correct choice of the product. It's no secret that most salespeople in stores, mechanics in factories, and sometimes even designers don't know (don't remember) the pitch table for not only small threads, but also major threads. In these cases, detailed size markings help.

What are metric and inch threads

Before you figure out how to determine the thread pitch using a thread gauge, you need to find out how a metric thread differs from an inch thread and vice versa? Threads according to the system of measures are divided into two main types:

- Metric - used on the following types of fasteners: bolts, screws, nuts, studs and others. The metric type of cutting originated in the Soviet Union and is actively used today

- Inch is the American cutting standard that home craftsmen encounter when working with plumbing products. However, inch cutting is found not only on plumbing fixtures, but also on fasteners

Let's look in more detail at the question of how metric threads differ from inch threads, and where they are used most often.

A distinctive feature of metric threads (GOST 24705-91) in the corresponding profile shape, which looks like an equilateral triangle.

The angle between the vertices of this triangle is 60 degrees, as mentioned above. The vertices or peaks are blunt in shape, that is, the projections for mating with the screw or nut are cut off. The unit of measurement used to indicate the screw diameter and thread pitch is millimeters. Threads of this type can have coarse and fine pitch, which depends on the scope of application of the relevant parts. Parts with small pitches are used primarily for adjustment, as well as in devices subject to dynamic loads. To designate large threads, markings in the form of the letter M and the corresponding number are used, for example, 20. This means that a metric thread with a diameter of 20 mm is cut on the workpiece. Small threads on the workpiece have a similar designation, only a digital value is added. This value indicates the thread pitch, for example 1.5 mm. The photo below shows a diagram of a metric thread device.

In addition to metric, inch threads are often used (GOST 6111-52).

Beginners who do not know about the existence of these two types of cutting face some difficulties. To understand what these difficulties are, consider the design features of inch threads. In profile it has a similar shape as the metric one, but its main difference is the modified angle between the vertices. This angle is 55 degrees, which distinguishes it in design from metric cutting. The unit of measurement used to indicate the dimensions of inch threads is inches. There are 25.4 mm in 1 inch, and two strokes are used to indicate inches. Inch thread can also be large or small, and is characterized by the number of threads per inch. It will not work to screw a nut with a metric thread onto a part with an inch thread, and vice versa.

Inch and metric threads are external and internal, and their main technical parameters are:

- Pitch is the distance between the two tops of the turns

- Depth - distance from top to bottom

- Profile angle is the distance in degrees between the side parts of the profile in the plane of the axis

- Outer diameter - the size of the workpiece in the area where the thread is present, measured at the tops of the turns

- The inner diameter is the distance that corresponds to the size of the cylinder with the coils present

Thread parameters Once you know the difference between a metric thread and an inch thread, you can begin to consider how to learn how to use a thread gauge. Although this device has a simple design, not everyone is able to correctly make the appropriate measurements (in addition, many do not know that there is a special tool). The effectiveness of the connection depends on the correctness of the actions performed.

How to measure a thread

Article reading time: 10 minutes

Any threaded connection is formed by two elements, one of which has an internal thread and the second an external thread, for example, a bolt and nut, a screw and a mounting hole in the parts being connected, etc. To obtain a tight and high-quality connection, the geometric parameters of internal and external threads must match exactly.

These main parameters include:

- internal and external diameter;

- depth;

- thread pitch.

Therefore, when selecting fasteners for installation work, the question often arises of how to measure the thread. Measuring the diameter and depth of a cut is usually not difficult. A more difficult task will be to measure the thread pitch, and incorrect selection of parts according to this parameter will either not allow them to be tightened at all, or will significantly deteriorate the quality of the connection, making it virtually unusable.

Slicing technologies

Cylindrical pipe threads, which are of the inch type (both internal and external), can be cut manually or mechanically.

Manual thread cutting

Cutting a thread using a hand tool, which uses a tap (for internal) or a die (for external), is performed in several steps.

- The pipe being processed is clamped in a vice, and the tool used is fixed in a driver (tap) or in a die holder (die).

- The die is put on the end of the pipe, and the tap is inserted into the inside of the latter.

- The tool used is screwed into the pipe or screwed onto its end by rotating a driver or die holder.

- To make the result cleaner and more precise, you can repeat the cutting procedure several times.

Cutting threads on a lathe Mechanically, pipe threads are cut according to the following algorithm:

- The pipe being processed is clamped in the machine chuck, on the support of which a thread-cutting tool is fixed.

- At the end of the pipe, using a cutter, a chamfer is removed, after which the speed of movement of the caliper is adjusted.

- After bringing the cutter to the surface of the pipe, the machine turns on the threaded feed.

It should be borne in mind that inch threads are cut mechanically using a lathe only on tubular products whose thickness and rigidity allow this to be done. Making pipe inch threads mechanically allows you to obtain a high-quality result, but the use of such technology requires the turner to have the appropriate qualifications and certain skills.

Measuring with a thread gauge

The best option for correctly measuring threads is to use a thread gauge. This is a special tool for measuring cutting pitch. The thread gauge is a body to which probes are attached in the form of thin plates with a comb. The shape of the comb exactly matches the standard thread with a certain pitch.

The following types of thread gauges are distinguished:

- Metric. Allows you to measure the thread pitch of a bolt, nut or other part with a metric thread with a diameter from 1 to 600 mm. The tool has up to 20 measuring plates and allows you to determine thread pitch from 0.4 mm to 7 mm. Indicated by the marking “M60” on the body.

- Inch. Used to measure inch threads, which are usually cut on pipes and pipeline parts, and are also sometimes used on fasteners. The pitch of an inch thread is determined by the number of threads per inch of length of the threaded part of the part. The thread gauge is equipped with 17 measuring plates with a number of turns from 4 to 28. The “D55” marking is used to mark the tool.

- Universal. Equipped with measuring plates for metric and inch cutting. Such thread gauges are widely used in workshops where it is necessary to simultaneously work with parts with both metric and inch threads.

Before determining the pitch, you need to measure the diameter of the thread with a caliper. This is necessary because the pitch range may depend on the diameter.

Accuracy classes and marking rules

A thread belonging to the inch type, as indicated by GOST, can correspond to one of three accuracy classes - 1, 2 and 3. Next to the number indicating the accuracy class, put the letters “A” (external) or “B” (internal). The full designations of thread accuracy classes, depending on its type, look like 1A, 2A and 3A (for external) and 1B, 2B and 3B (for internal). It should be borne in mind that class 1 corresponds to the coarsest threads, and class 3 corresponds to the most precise threads, the dimensions of which are subject to very stringent requirements.

Maximum size deviations according to GOST

To understand what parameters a specific threaded element corresponds to, it is enough to understand the designation of the thread that is applied to it. The designation in question is used by many foreign manufacturers who work according to American standards relating to elements of threaded connections.

An example of a symbol for an inch thread

This marking contains the following information about the thread:

- nominal size (outer diameter) – first digits;

- number of turns per inch of length;

- group;

- accuracy class.

Measuring thread pitch without a thread gauge

Parts with external thread

Often the need to determine the thread pitch arises sporadically, at one time. And, of course, in such a situation there is no thread gauge at hand, and it makes no sense to buy one for one-time measurements. It will be useful to learn how to measure the thread pitch with a ruler or caliper. These measuring tools make it quite easy to determine the desired parameter.

The easiest way is to measure the threads of a bolt or other externally threaded part. When measuring a metric thread, it is recommended that you first attach the ruler to the threaded part and try to align the millimeter divisions of its scale with the tops of the ridges of the threaded profile. If they coincide, then the step is 1 mm. Otherwise, you will have to carry out slightly more complex measurements.

To determine the thread pitch, you need to count the number of turns on a section of a rod of a certain length, for example, 10 mm or 20 mm. To obtain a more accurate result, it is recommended to take measurements on a 20 mm area. The required length is measured by applying a ruler to the bolt shaft, or using a caliper. It would be more accurate to measure the bolt thread pitch with a caliper. In the measured area, count the number of turns. After this, the length of the section must be divided by the resulting number of turns minus one turn. As a result, we obtain the value of the thread pitch.

When determining the pitch of an inch cutting, it is necessary to measure the length of the rod equal to one inch (25.4 mm). For accurate measurements, it is better to use a ruler or caliper with an inch scale. The number of turns in this area will be the thread pitch. If the length of the threaded section is less than one inch, then you need to determine the number of turns in a section of half an inch (12.7 mm), and then multiply the result by 2.

Internally threaded parts

There are two ways to measure the thread of a nut or other internally threaded part without a thread gauge. The first method involves selecting an exactly suitable counter bolt and then measuring its thread pitch. If you can’t find the counter bolt, then you need to use a strip of paper (this is method No. 2).

It should be pressed against the thread so that an imprint of the profile remains on the paper. You can improve the visibility of marks by tracing the edges with a marker. After this, on paper you need to mark the distance between the extreme marks with a ruler and count the number of turns. Then the resulting distance is divided by the number of turns minus one turn. Instead of measuring paper using this method, you can use a pencil, match or other soft wood product of a suitable size, which is pressed against the thread.

How to measure a nut

Most nuts have metric threads. Measuring the thread diameter will require a little more steps than in other cases. If possible, it is recommended to check the size of the bolt or screw used for it rather than the nut itself. This way you can achieve a more accurate result.

The value obtained after measuring the internal thread is an indicator of the internal diameter din.

In order to accurately determine the diameter of the metric thread of the hardware, you will need to find out the correspondence between din and the outer diameter of the bolt used. This is done using a special table.

Accuracy is controlled through the use of certain pass-fail gauges. One part should connect well with the nut, the second part, on the contrary, should not.

The nuts differ in appearance, and it is easy to determine upon detailed inspection. To find out the standard of the fastener, you may need to measure the height of the hardware, since there are high, low, extra high and other options.

Turnkey dimensions are also used to classify hex nuts. This is explained by the fact that hardware also differs in its types.

To accurately measure the thread pitch, it is possible to use the method considered in the case of a bolt. You will need a thread gauge or you will have to count the number of turns at the required interval.

Determining the dimensions of inch nuts

To check the thread dimensions of an inch nut, you need to examine the threads of the bolt or other hardware used with it. If you don’t have a suitable one at hand, but have information about the presence of an inch thread, then use the appropriate thread gauge. Do not forget to divide the resulting value by 25.4 mm.

Determining washer dimensions

For washers, a short designation in the form D is used, which stands for the diameter of the metric thread of the hardware used for the fastener.

To accurately measure indicators, a ruler or caliper is suitable. The result is a value that is slightly higher than the figure in the notation. This is explained by the fact that free movement is required during installation, which requires a small gap.

So, you have a bolt or nut with unknown thread parameters, and there is no measuring tool at hand other than a ruler. Let us immediately warn you that using a ruler can only get a rough result, so if you are going to regularly take such measurements, it is better to purchase a thread gauge or caliper.

Concept of thread pitch

Threads are used to connect a wide variety of products. To determine the bolt thread, you need to consider the distance between the same sides of the profile. The features of this concept include the following points:

- To determine the main parameters, a measurement is required.

- An inaccurate result can be determined by using a ruler.

- To increase the accuracy of measurements, you need to analyze several threads. That is why, depending on the length of the threaded surface, an analysis of 10 to 20 turns is carried out.

- It is recommended to take measurements in millimeters. In some cases the number is converted to inches.

The distance between the depressions can be measured using a special tool. The thread gauge is represented by a combination of special steel plates that have special cutouts. Various values are applied to the surface.

Measurements of the dimensions of the pattern on the protectors

How to measure tire tread if you need to assess the degree of wear? A depth gauge will help, which takes measurements along the entire tire tread. It should be taken into account that wear is almost always uneven, and the number of measurements should be at least 3...5, and on evenly distributed areas of the tire tread for assessment. Before measurements, the tire should be thoroughly cleaned of dirt, dust and fragments of small stones stuck inside.

Measuring tire tread with a digital depth gauge

Sometimes you need to solve the problem of how to measure the tire tread with a caliper to determine the degree of uniformity of wear. This establishes the wear of the tread tires not only in depth, but also along the radius of transition from the circle of protrusions to the circle of depressions. They do this. The depth of the pattern on the new tire tread is measured, and then the linear size of the visually changed zone on the used part. The difference will determine the degree of wear and help you make the right decision about replacing the wheel.

All measurements are made with a depth gauge, which must be installed strictly perpendicular to the tire tread.

Measuring tread wear with a Columbian

Measurement methods

There are quite a large number of different ways to determine the thread pitch. All of them are characterized by their own specific features that need to be taken into account. Common methods include:

- Using a regular ruler.

- The use of a special tool that can be used to determine the value in question. A thread pitch meter can be purchased at a specialty store.

- A caliper is a precision instrument. It is used quite often due to its high accuracy and versatility in use.

All of the above methods allow you to obtain fairly accurate data. The easiest way to take measurements is to use a thread-finding tool, but you can get by with a regular caliper.

The process of measuring turns

When considering how to determine the thread pitch, the features of the chosen method should be taken into account. When using a ruler it is enough:

- Measure the length of the rod on which the profile was applied. It is worth considering that by measuring the entire length of the rod, and not just part, you can determine a more accurate result.

- Count the number of turns.

- Take depth measurements to determine the main parameters of the threaded connection.

In this way, only the average can be determined. If errors were made during the cutting process, the distance between them may differ slightly.

An example of measurements looks like this:

- 20 turns are counted.

- We measure the length of the rod, for example, the indicator was 127 mm.

- We divide 20 turns by the length of the rod, the result is 6.35 mm. It corresponds to the pitch of the threads in millimeters.

To convert to inches, simply divide the calculated value in millimeters by 25.4. The result will be 0.25 or ¼ inch. If you measure yourself, there may be an error, so the result is rounded to an approximate standard value.

You can also find special templates on sale that can be used to check the features of the thread. This procedure is quite simple to perform:

- The most suitable template is selected. On sale you can find simply a huge number of special templates, which are represented by a plate with a certain profile. Such an element is not expensive; you can purchase it in various specialized stores.

- It is applied to the surface to monitor basic indicators. The template must fit without obstacles, and there should be no free space between the plate and the working surface.

If the template easily fits into the grooves, then the basic parameters of the surface can be determined.

Measuring thread pitch with a ruler and thread gauge

In addition, you can take measurements using a caliper. This tool has become widespread. The step-by-step actions are as follows:

- The depth gauge determines the height of the rod.

- The next step is to count the number of turns. This is quite difficult to do; you can use a marker to indicate the profile threads that have already been counted.

- The information obtained allows you to calculate the tangent of the angle of inclination.

Rating of high-quality and inexpensive thread gauges

CALIBRON 201960

This practical and relatively inexpensive set of custom templates is a favorite among experienced professionals. With its help, a person can easily determine whether the thread matches the diameter. The range is calculated using millimeter measurements. Useful both at home and in professional workshops. Product weight 0.025 kg. Dimensions declared by the manufacturer are 75x15x15 mm. The error factor is 15 microns. The set consists of 17 different templates.

Average price – 595 rub.

CALIBRON 201960

Advantages:

- high quality of assembly and consumables;

- excellent equipment;

- time-tested brand;

- packaging that can be used for further storage;

- service life.

Flaws:

NORGAU 045142002

This high-quality and practical device can be used both at home and in workshops. The kit contains 24 templates of standard diameter. The upper measurement limit is 6 mm. The lower measurement limit is 0.25 mm. It is based on the use of high-strength hardened spring-type steel. Plastic screws and nickel plating are used to make the case. The product comes in a branded shockproof case. It is used for measuring both external and internal markings.

NORGAU 045142002

Advantages:

- excellent equipment;

- shockproof case included;

- ergonomics;

- Taiwanese assembly;

- positive reviews.

Flaws:

STAYER PROFI 28041

A high-strength metal alloy is used to make this structure. The compact and easy-to-use device is equipped with two templates that are used to carry out standard measurements. It is based on the use of the metric system in increments of 0.5-1.75 mm. The set consists of 12 templates. Total weight – 30 g. Produced in Germany.

How much does the kit cost? The purchase will cost 305 rubles.

STAYER PROFI 28041

Advantages:

- copes well with the designated functionality;

- Excellent value for money and quality;

- strength;

- ergonomics;

- practicality;

- Two plates for pipe measurements are included in the kit.

Flaws:

GRIFF D55 D155005

This popular design is in high demand among domestic consumers, largely due to its affordable price. It is based on the use of the inch measuring system. Among other functions, it allows for measurements and auxiliary calculations regarding various elements and working parts. The design can also be used for standard measurements, but it will take some time to get used to. The device can be used not only by ordinary craftsmen, but also in production. The model is characterized by increased accuracy of measurements. The error rate is minimal, based on numerous reviews on the Internet. Due to its compact dimensions, the device is convenient to carry with you. The set contains 17 standard templates, the total weight of which is 30 g. Produced in the Middle Kingdom.

Average price – 180 rubles.

GRIFF D55 D155005

Advantages:

- 17 universal elements in the set;

- high build quality;

- affordable price;

- low error rate;

- compact dimensions;

- ergonomic shape.

Flaws:

Avtodelo M60 40384 11083

This practical and inexpensive device will allow you to take the necessary measurements both at home and at work. In addition, you don’t need any professional skills to work with the tool. Used to carry out the necessary metric measurements. Characterized by increased cutting accuracy. The manufacturing process uses the stamping method, due to which the manufacturer managed to achieve high quality assembly. Cracks, chips and gaps were not identified, as well as other factors that contribute to a decrease in the accuracy rate. Calibrated steel is used to make the structure. The material is characterized by resistance to mechanical damage and premature wear. The set consists of 20 elements, the total weight of which is 15 g. Produced in Russia. The body is made of flimsy plastic.

Avtodelo M60 40384 11083

Advantages:

- excellent build quality and auxiliary components;

- excellent equipment;

- compact dimensions;

- affordable price;

- The model is in demand among novice users.

Flaws:

Nuances of measurement

There are a few guidelines to keep in mind when using a caliper. An example is the information below:

- If there is a plate between the head and the end part of the product, then in this case it is recommended to use the main measuring scale and depth gauge. With such a process, it is possible to obtain indicators of the thickness of the washer, the height of the head, and the thickness of the intermediate element. Such data allows you to calculate the main parameters of a threaded connection.

- The accuracy of the results obtained can be significantly increased by cleaning the surface from various contaminants. To do this, you can use an abrasive material or special liquids to remove corrosion.

You can carry out the procedure in question yourself. As a rule, there are no problems with this.

In conclusion, we note that manufacturers indicate the pitch and many other important indicators. As a rule, they are applied to the head or other element.

Determining diameter at home

The need to find out the exact diameter arises only in two cases - there is no marking on the outside or the absence of conditionally control items with a known cross-section (fittings, adapters). By marking you can determine all the parameters - purpose, material of manufacture, wall thickness. With the help of fittings and adapters, they find out whether a particular pipe is suitable for water supply and heating.

You can take measurements at home using a ruler (tape measure), caliper, or micrometer. The accuracy of the results obtained depends on this. You can use other means - thread, a box of matches or any object whose dimensions are known and do not exceed the cross-section of the pipeline.

How to measure using a caliper?

This is a universal measuring device with which you can find out all the dimensions of the pipeline.

In addition to the maximum and minimum values, they differ in how the results are taken:

- In vernier scales (SC), millimeters are marked on the main scale, and fractions of mm on the auxiliary scale. When the rod moves, the pointer stops at a certain value.

- Dial (ShTsK) are needed for more accurate measurements. Fractions of mm are shown by a circular scale connected to the rod by a gear transmission. In digital (DCC) the value is displayed on the LCD screen.

How to measure the internal diameter of pipes using a caliper:

- Clean the inner surface from dirt and dust.

- Move the rod jaws to the zero position.

- Install them into the hole.

- Spread the sponges all the way, trying to get the maximum value.

To measure the outer section, you need to spread the jaws of the caliper and place them between the pipeline. To get an accurate result, you need to apply a little pressure. Repeat the procedure 2-3 times.

Before starting work, it is recommended to check the accuracy of the caliper readings by taking the dimensions of a standard object with known dimensions or cross-section.

We measure with a micrometer

A pipe micrometer is convenient for quickly taking readings of external dimensions. If you need to know the internal diameter, you should measure the wall thickness. Unlike calipers, most micrometer models give more accurate results, the average error is 3-5 microns.

Micrometer Applications

The procedure for carrying out internal measurements:

- Place the pipe between the heel and the spindle and take readings.

- Also find out the wall thickness.

- Subtract 2 thickness readings from the external dimensions.

The disadvantage of the device is the maximum size limitation. To increase accuracy, special attachments are used. When performing calculations, it is necessary to add the dimensions of the nozzles to the obtained indicators.

Laser sensors

The operating principle of laser sensors is based on scanning a surface with a laser beam. The rate at which radiation returns to the photodetector determines the distance traveled. To increase accuracy, the working head rotates, which makes it possible to take a large number of measurements per second. Such devices are used only in mass production, where control of the uniformity of wall thickness at a certain length is important.

Operating principle of pipe laser sensors:

- The measuring part of the device is placed inside the cavity.

- Fixation using roller clamps.

- Several series of measurements on different sections of the highway.

- Data reconciliation.

The advantage of the method is maximum accuracy and the ability to take measurements at various depths remotely. The disadvantage is expensive equipment. It is used only during the manufacturing process or when large quantities of pipes are used, where accuracy is important.

Measuring pipe diameter with a laser sensorHow to determine threads with a caliper or ruler

To determine the type of thread on the fitting, a caliper is needed.

How to correctly take measurements using a caliper is shown in the figure below.

Measurements must be made accurate to tenths of a millimeter.

| Outer diameter, mm | Inner diameter, mm | Thread pitch, threads per inch | Thread pitch | BSP | Metrics | Inch UNF | Inch NPT |

| 9,3-9,7 | 8,5-8,9 | 28 | 1/8″ | ||||

| 9,3-9,7 | 8,5-8,9 | 27 | 1/8″ | ||||

| 9,7-9,9 | 8,2-8,6 | 1,5 | M10x1.5 | ||||

| 10,9-11,1 | 9,7-10,0 | 20 | 7/16″-20 | ||||

| 11,6-11,9 | 10,2-10,6 | 1,5 | M12x1.5 | ||||

| 12,4-12,7 | 11,3-11,6 | 1/2″-20 | |||||

| 12,9-13,1 | 11,4-11,9 | 19 | 1/4″ | ||||

| 12,9-13,1 | 11,4-11,9 | 18 | 1/4″ | ||||

| 13,6-13,9 | 12,2-12,6 | 1,5 | M14x1.5 | ||||

| 14,0-14,3 | 12,7-13,0 | 18 | 9/16″-18 | ||||

| 15,6-15,9 | 14,2-14,6 | 1,5 | M16x1.5 | ||||

| 16,3-16,6 | 14,9-15,4 | 19 | 3/8″ | ||||

| 16,3-16,6 | 14,9-15,4 | 18 | 3/8″ | ||||

| 17,6-17,9 | 16,2-16,6 | 1,5 | M18x1.5 | ||||

| 18,7-19,0 | 17,3-17,6 | 16 | 3/4″-16 | ||||

| 19,6-19,9 | 18,2-18,6 | 1,5 | M20x1.5 | ||||

| 20,5-20,9 | 18,6-19,0 | 14 | 1/2″ | ||||

| 20,7-21,1 | 18,3-18,7 | 14 | 1/2″ | ||||

| 21,6-21,9 | 20,2-20,6 | 1,5 | M22x1.5 | ||||

| 22,0-22,2 | 20,2-20,5 | 14 | 7/8″-14 | ||||

| 22,6-22,9 | 20,6-21,0 | 14 | 5/8″ | ||||

| 23,6-23,9 | 22,2-22,6 | 1,5 | M24x1.5 | ||||

| 25,6-25,9 | 24,2-24,6 | 1,5 | M26x1.5 | ||||

| 26,1-26,4 | 24,1-24,5 | 14 | 3/4″ | ||||

| 26,3-26,7 | 23,7-24,1 | 14 | 3/4″ | ||||

| 26;6-26,9 | 24,3-24,7 | 12 | 1,1/16″-12 | ||||

| 29,6-29,9 | 27,4-27,8 | 2 | M30x2 | ||||

| 29,8-30,1 | 27,6-27,9 | 12 | 1,3/16″-12 | ||||

| 29,6-29,9 | 28,2-28,6 | 1,5 | M30x1.5 | ||||

| 32,6-32,9 | 30,5-30,9 | 2 | M33x2 | ||||

| 33,0-33,2 | 30,3-30,8 | 11 | 1″ | ||||

| 33,0-33,3 | 30,8-31,2 | 12 | 1,5/16″-12 | ||||

| 32,9-33,4 | 30,3-30,8 | 11,5 | 1″ | ||||

| 35,6-35,9 | 33,4-33,8 | 2 | M36x2 | ||||

| 37,6-37,9 | 36,2-36,6 | 1,5 | M38x1.5 | ||||

| 40,9-41,2 | 38,7-39,1 | 12 | 1,5/8″-12 | ||||

| 41,6-41,9 | 39,4-39,8 | 2 | M42x2 | ||||

| 41,5-41,9 | 39,0-39,5 | 11 | 1,1/4″ | ||||

| 41,4-42,0 | 39,2-39,6 | 11,5 | 1,1/4″ | ||||

| 44,6-44,9 | 42,4-42,8 | 2 | M45x2 | ||||

| 44,6-44,9 | 43,2-43,6 | 1,5 | M45x1.5 | ||||

| 47,3-47,6 | 45,1-45,5 | 12 | 1,7/8″-12 | ||||

| 47,4-47,8 | 44,8-45,3 | 11 | 1,1/2″ | ||||

| 47,3-47,9 | 45,1-45,5 | 11,5 | 1,1/2″ | ||||

| 51,6-51,9 | 49,4-49,6 | 2 | M52x2 | ||||

| 51,6-51,9 | 50,2-50,6 | 1,5 | M52x1.5 | ||||

| 59,4-59,8 | 56,5-56,8 | 11 | 2″ | ||||

| 59,9-60,2 | 56,4-56,7 | 11,5 | 2″ | ||||

| 63,3-63,6 | 61,3-61,8 | 12 | 2,1/2″-12 |

CONTACTS

st. B. Okruzhnaya 4-b, s. Petropavlovskaya Borshchagovka, Kiev-Svyatoshinsky district, Kiev region, 08130, Ukraine

Postal address: PO Box 70, Kyiv-162, 03162

information:

+38

branches

- Kyiv

- Sumy

- Krivoy Rog

- Kyiv

- Gorishni Plavni

- Vinnitsa

- Berdichev

- Kherson

- Khmelnitsky

- Pervomaisk

- Kyiv

- Lviv

SUPPLIERS

Manufacturers of components, materials and units

- ORLEN OIL

- Vitillo

- DLM

- Hydronit

- Fox-VPS

see everyone

What are the thread diameters?

Metric thread sizes - online reference according to GOST 24705-2004

| Nominal thread diameter D, external thread diameter d, mm | Pitch P, mm | Inner diameter along the bottom of the cavity d3, mm |

| 0,55 | 0,125 | 0,397 |

| 0,6 | 0,15 | 0,416 |

| 0,7 | 0,175 | 0,485 |

| 0,8 | 0,2 | 0,555 |

The concept of thread pitch (with photo)

Essentially, this is the distance between adjacent threads (sides of the same name) of the fastener. It is very clearly shown in the figure below:

As we have already found out, this parameter significantly affects the quality of the connection (which is one of the most popular and used for all kinds of parts). Therefore, it is simply necessary to find it with sufficient accuracy for each specific case. The approximate result can be determined using a meter or ruler. To get results as close as possible to the actual ones, you should judge not by one turn, but look at 10-20, over the entire surface of the rod. It is better to write down values in millimeters - when converting to inches, it is easier to lose a few decimal places.

Rules for using vernier calipers

In order for a measuring instrument to serve faithfully for many years, it is necessary to follow simple rules for its operation and storage. First of all, mechanical damage that may occur as a result of a fall or force should be avoided. In addition, during the process of measuring parts, the jaws of the caliper must not be allowed to skew. To prevent this from happening, they must be fixed in a certain position on the part being measured using a locking screw.

The device should only be stored in a soft case or hard case. The second option is preferable, as it can provide protection from accidental deformations. The place for storing the caliper must be chosen in such a way that sawdust from various materials, dust, water, chemical mixtures, etc. do not get there. Plus, the threat of heavy objects falling onto the tool must be eliminated.

After each use of the caliper, it must be thoroughly wiped with a clean, soft cloth.

Naturally, we should not forget about observing safety rules when operating this device. At first glance, it does not pose any threat to health, but this is not entirely true. The fact is that the ends of the jaws for measuring internal dimensions are quite sharp, so you can easily get hurt if handled carelessly. Otherwise, the tool is completely safe.

When performing any carpentry or plumbing work, you need to know how to measure with a caliper, as well as be able to use it. This common universal metric tool is used to take internal and external linear dimensions from a part. The caliper allows you to measure diameters (internal and external) and the depth of the hole.

GOST and the need for unification

For a long time, manufacturers performed theoretical calculations of thread pitch using their own methods and manufactured fasteners using their own technologies. With this approach, connectors from different brands often turned out to be incompatible or did not provide suitable joint quality, which often caused problems for users.

Particular difficulties arose during the assembly of machines, apparatus and other component equipment. Literally each element had to be marked separately so that later it could be placed correctly. Banal preventive cleaning of tools or machines, parts of which were supplied by two or more factories, turned into real torture.

Therefore, from the beginning of the 20th century, the issue of standardization became seriously concerned. The matter was approached with the utmost seriousness, taking into account even the experience of the 12th century, or rather the practice-tested formula stating that the distance between adjacent turns should be equal to 20% of the diameter of the rod. Naturally, they took into account that in those distant times the fasteners were made of wood, and only 20 years later they began to tighten the most loaded points with studs and protect them with nuts machined from a single piece of especially strong rock. Today, completely different materials are relevant, which have completely different requirements.

Food for thought

The first path to standardization began to be paved precisely in Russia: at the Tula plant they began to work according to Nikita Demidov’s drawings, and check the results using the calibers he proposed. This made it possible to control the accuracy of casting and execution of individual parts.

Yes, the famous industrialist did not think specifically about the thread pitch (how to measure it or find the optimal one), but sought to unify production as a whole. And he achieved his goal: in 1787, a commission under the tsarist army purchased 500 domestic guns and the same number of English ones. The inspectors disassembled each of them, arranged the elements according to their functional purpose and thoroughly mixed each group, after which they tried to assemble it. In the case of the Russian models, this was possible - even though they required grinding in, they eventually passed the zeroing - but the pride of the British craftsmen remained a pile of useless iron.

This was the impetus for the following events:

Each regiment created a platoon responsible for servicing weapons, and it regularly received consumables marked with notches to replace small items that had failed.

In France, in 1790, they approved the first pan-European basic system of measures, adopting m and its “derivatives” – cm and mm – as a unit of length, which is still used today; England, by the way, remained with its inches and feet.

What nut for the M16 bolt?

Hex nut M16

used with matching bolts, screws and studs.

It is important to take into account the strength class of the fastener;

it is not recommended to use bolts

and

nuts

Interesting materials:

How to find deleted correspondence in a telegram? How to find a deleted number on WhatsApp? How to find deleted Viber? How to set up a remote desktop connection? How to set up remote access to TeamViewer? How to set up remote desktop on your phone? What is the name of the key for deleting characters? What is the name of the operation to remove veins in the legs? What is the name of the operation to remove a double chin? What is the permanent hair removal procedure called?