It is difficult to clean pipes from rust and walls from old putty using a metal brush and sandpaper. In this case, scratches from the tool remain on the surface.

There is a lot of dust and small particles flying in the air that are harmful to human health. The hydrosandblasting machine operates without dust and significantly speeds up the cleaning process without damaging the surface being treated.

Low compression in cylinders

On old, worn-out power units, the cause of highly jumping revolutions is low compression. It is not possible to solve this problem in any way. It is necessary to replace the cylinder block or the entire engine, which leads to significant costs.

Compression problems arise for the following reasons:

- unit wear;

- the appearance of scuffing;

- merciless operation of the engine.

https://youtube.com/watch?v=nfg_O5KOhsk

What can you use, besides sand, to make your own sandblasting chamber?

In addition to sand, other types of consumables are suitable for operating the device:

- Nickel and cooper slag. Some of the most popular options for sandblasting, which are obtained from copper and nickel production waste. The cost is the same as treated sand, but they are stronger and harder.

- Steel and cast iron shot. Not only the most expensive option, but also the most durable. Used for quick but rough surface treatment.

- Pomegranate sand. Harder than ordinary sand, but just as fragile. It is expensive and rarely used for work.

- Glass and stainless steel shot. Sandblasting glass is mainly used for cleaning stainless steel surfaces.

- Electrocorundum. Solid crystalline form of aluminum oxide. Virtually undamaged and suitable for even the most contaminated surfaces.

Steel and cast iron shot is the most durable abrasive.

If you look at photos of sandblasting, you will notice that the chamber is a rectangular structure. Most often this is a box welded from a metal corner, which is lined with thin steel sheets up to 1 mm thick

To make it easier to control the amount of abrasive during operation, it is best to place a glass or plastic viewing window along the long side.

On the front wall of the chamber there are 2 symmetrical holes with a diameter of 100-120 mm, into which special thick gloves are inserted. It should be borne in mind that they will be constantly exposed to abrasive forces, so replacing these elements should not cause difficulties.

The bottom of the chamber is made of reinforced mesh, under which there is a trench for used abrasive. Comfortable work is ensured by lighting. To do this, just take 2 lamps of the required size. The sandblasting gun is placed inside the chamber, and air is supplied using a hose connected to the outside. Thus, the material will not fly out, which will make it possible to reuse it. In fact, this design option allows you to create a sandblasting gun with an abrasive recycling system.

On a note! If you plan to clean non-standard products of large shape, it is recommended to cover the side edges with a durable tarpaulin. To make the camera as convenient as possible, you should not do the work by eye - it is better to prepare a drawing first. In addition to sand, nickel and cooper slag, garnet sand, glass and stainless steel shot, as well as electrocorundum are used.

Range

This section contains offers of equipment from domestic and foreign manufacturers, namely:

- Russian companies: Bezhetsky plant ASO, VPK PST, PK PST, Velikoluksky Mechanical Plant LLC, Zitrek;

- Chinese company AE&T;

- German company Contracor.

The maximum productivity of the devices presented in this section can reach 15, 20 or 37 sq. meters per hour. The loading tank capacity of the offered models varies from 19 to 250 liters. It must be remembered that the absence of an abrasive recovery function requires periodic collection of the used composition (if such a possibility exists), cleaning, sifting and reloading.

If there is no possibility of recovering the abrasive used, then you need to take care of the required amount of abrasive to complete the work within the agreed time frame. Among the pressure-type units presented, there are models whose design includes a filter-oil separator, there are configurations with remote control, and there is a model with a recuperator vacuum cleaner.

Each model has been tested and proven to meet the requirements of certification standards. The manufacturer's warranty once again confirms the reliability of the devices.

Main processing rules

You can get a truly high-quality processing result only by selecting good equipment, consumables and components. The abrasive material must be ideally suited for the specific type of work, otherwise the surface will not be cleaned sufficiently or will be scratched.

Sandblasting discs

The higher the performance of the sandblasting compressor, the faster the cleaning will occur, and the greater the efficiency. It is necessary to select installations with hoses of significant diameter to reduce pressure losses. Couplings and connectors must exactly match the diameters of the hoses

You should also pay attention to the quality of the nozzle - the most durable ones are made from boron carbide, however, they cost much higher than others

What is a sandblasting gun and its purpose?

A sandblasting gun is a nozzle for a compressor, which is designed to clean car body surfaces from stubborn dirt and paintwork. The sandblasting attachment is popular in auto repair shops for painting cars, but nothing prevents a home craftsman from buying a gun for a compressor and using it to clean any metal surface, which is often done before painting, patination and anodizing.

Externally, the nozzle almost completely resembles a gun for blowing or painting a compressor, but there is still a difference. The main structural elements of the device are:

- Metal body in the form of a pistol

- Channel - hose for supplying abrasive substance to the gun

- Nozzle - a hole through which sand flies out under pressure and hits the surface being treated.

- Handle with trigger - designed to hold the tool body, as well as to start the sandblast feed

- Adjustment screws for adjusting air pressure and abrasive feed rate

The most important element of the device is the nozzle, which must be made of high-strength materials such as tungsten or ceramics. If you choose sandblasting guns for a compressor with a nozzle made of plastic or thin metal, then such a tool will not last long. The nozzle will very quickly fail under the influence of abrasive substances.

The operating principle of a compressor sandblasting gun is that fine sand flies out of the nozzle under the pressure created by compressed air. This removes paintwork and other contaminants from metal surfaces.

This is interesting!

Sandblasting is intended not only for processing metal surfaces, but also for removing contaminants from plastic, wood and other materials.

How to make sandblasting with your own hands?

In order to assemble a sandblast, you will need quite accessible materials.

- The main element is the working chamber. It can be made from a metal cylinder, a gas cylinder, or from a fire extinguisher, as we have already said. Care must be taken with a gas cylinder: before use, blow the empty cylinder with air using a compressor to remove any remaining gas.

Sandblasting can - Tees, ball valves and fittings are sold at your local plumbing store. As well as water hoses of the appropriate diameter.

Shut-off valves, clamps, fittings - To secure the hoses, clamps, fittings and FUM tape are used.

- And you will need to figure out what to make the “legs” from for future installation.

Let's look at the assembly process step by step.

- Remove the contents from the cylinder and release the pressure. As already mentioned, blow out the gas cylinder with a compressor.

- Drill three holes in the cylinder. The top one is the widest - for loading sand. A neck with a sealed lid will then be installed into it. The second hole is also made at the top; a fitting will be installed in it for connecting to the compressor. And the third hole at the bottom for installing a sand supply tap.

Large filling hole at the topSide, top hole for supplying air to the cylinder

Bottom sand hole

- Weld a ball valve into the lower hole, which will regulate the intensity of the sand flow. Connect a plumbing tee to the tap outlet, in which sand and air will be mixed.

Screw in the tap at the bottom - A pipe of suitable diameter with a lid is welded into the upper wide hole.

- A fitting is welded into the second upper hole into which the hose from the compressor will be connected.

Screw in the air supply valves - The air from the compressor must be divided into two streams; a tee is used for this: a ball valve and a compressor are connected to one outlet, the other two to the upper and lower air supply hoses to the cylinder.

- One of the hoses from the compressor is connected to the upper fitting of the cylinder.

We connect the hoses to the top taps of the sandblaster - The second hose from the compressor is connected to the lower tee of the cylinder.

Connecting pipes at the bottom of the cylinder - A hose for the air-sand mixture is connected to the remaining outlet of the tee at the bottom of the cylinder.

- Fittings are used to connect tees to hoses. The hoses can be sealed at the fittings with plumbing FUM tape and secured with clamps.

- A ball valve is installed in the sandblasting gun to adjust the power of the output flow. A hose with an air-sand mixture is connected to one of the faucet outlets, and a homemade or purchased nozzle is installed in the second.

Homemade nozzle from a car candle and stopcock - Weld legs of sufficient height to the cylinder; if desired, you can paint the cylinder.

Ready-made sandblasting

If this description is not entirely clear to you, we recommend watching the video below with a detailed description of the work.

The main elements on which the effectiveness of a sandblasting installation depends are the compressor and the nozzle. The optimal compressor option is one with the ability to adjust power (the maximum is not always needed).

The diameter of the nozzle depends on the tasks to be performed. In household or home repairs, this is usually cleaning small parts, so you can make a nozzle from a ceramic part from a spark plug. The ceramic is strong enough, and the hole in it is just the right diameter.

Safety precautions when working with sandblasting

There are a large number of risk factors in sandblasting. The most dangerous are abrasive dust and suspended particles of dirt. The most vulnerable places in a person are the eyes and respiratory system. Therefore, it is necessary to prepare for work carefully.

The sandblaster must:

- Wear protective clothing made from abrasion-resistant material.

- Protect your hands with gauntlets.

- Protect your head with a special helmet into which purified air is supplied. There must be an air filter.

Basic safety rules:

- Minors should not be allowed to work in sandblasting.

- A person must undergo a training course and be a certified specialist.

- It is prohibited to consume or be under the influence of alcohol or drugs.

- All persons involved in servicing the sandblasting machine must familiarize themselves with the safety regulations each time before starting work.

- Cleaning in cells should only take place under the supervision of persons outside.

- When working at height, it is necessary to use safety belts.

- Persons not involved in the process are prohibited from entering the work area.

- When working near electrical installations or electrical wiring, the power must be turned off.

- The sandblasting machine must be sealed, have a safety valve and a passport indicating the operating pressure.

If safety precautions are followed and the sandblasting device is used correctly, the unit will last for many years. And if it was purchased for your workshop, then you can even develop a business that will generate considerable income.

3Hydrodynamic cleaning

Treatment of pipes and surfaces using the hydrodynamic method differs from the options described above solely in the aqueous composition of the processing jet.

| Advantages | Flaws |

| It is characterized by low cost of consumables and exceptional safety for the environment. | Unlike sandblasting, a hydrodynamic machine will not be able to remove deep layers of rust, bitumen or industrial tar. Such cleaning will require a huge water pressure and, accordingly, a large power of the hydrodynamic machine, which is not economically feasible. |

Scope of application of hydrodynamic cleaning machines

It is most effective to use this type of equipment for cleaning pipelines of any type, removing blockages and washing away contaminants. Hydrodynamic cleaning is also used to treat sewer systems, storm drains and drainage wells.

You can familiarize yourself with machines for hydrodynamic cleaning in the corresponding section of the site.

Thus, each of the available types of equipment: be it a sandblaster, a hydrosandblasting unit or a hydrodynamic apparatus has its own areas of application in which it exhibits the maximum level of efficiency.

We recommend that you read:

- Which sandblasting unit to choose: injection or pressure.

- We analyze the advantages and disadvantages of shot blasting machines

- What will happen with untreated compressed air during sandblasting?

Get more detailed advice on the use of a specific type of equipment at your facility. Just call us by phone 8-800-555-95-28

, write an email to [email protected] or fill out the online form on the website. Your request will be processed as quickly as possible, and you will receive the information you are interested in, as well as specialist assistance in selecting equipment.

How to choose the right sand for sandblasting?

How to choose the right sand for sandblasting?

First of all, it is necessary to take into account the nature of the planned work. What are you going to do: clean an old rusty tank or paint an elegant design on the glass?

Additionally, please note the following:

- What is the strength and thickness of the contamination? Perhaps the abrasive is too fine or not hard enough to cope with this.

- The stronger the surface being processed, the harder the consumable is needed. The softer the base itself, the higher the likelihood of damage from too hard sand. For example, to process steel parts of a car you need steel or cast iron shot. Garnet sand and electrocorundum are used when working with alloy steel, titanium, and so on, when the hardness of quartz and slag is already low. To apply beautiful designs on mirrors and glass, as well as to frost glass, you will need the purest, fine, uniform sand. For working with tempered glass – electrocorundum 0.1-0.8 mm.

- To what condition does the surface need to be brought? The larger the fraction, the rougher the work. For example, to polish a base made of copper or aluminum to a shine, use a small consumable - up to 0.3 mm. If you want to peel off a durable paint coating without damaging the surface, you need a fraction of 0.3-0.6 mm. To remove rust, you need sand or slag of medium size - 0.6-1.6 mm.

- Work completion time. Particles with sharp edges and high hardness (crushed sand, crushed shot, electrocorundum) will level or clean the surface much faster, but rougher than round sand of a similar fraction. Coarse sandblasting abrasives are used to remove welding scale or remove thick bitumen coatings.

- Possibility of collecting the remaining mining. In its absence, it is economically correct to load Cooper, Nickel slag and quartz sand into the gun.

Features and purpose

Sandblasting of metal is a process of cleaning the surfaces of metal structures and other metal products from traces of corrosion, soot, old coatings (for example, varnishes, paints), scale after welding or cutting, foreign deposits by exposing them to a mixture of air with particles of abrasive materials supplied through high pressure nozzle to the metalworking site. As a result of this, separation or complete erasing of all excess from the surface of the metal product being cleaned occurs.

However, it is worth noting that, unfortunately, sandblasting cannot remove fatty deposits, since they penetrate too deeply into the metal. After the surface cleaning process with a sandblaster, oil stains should be treated with appropriate solvents that will degrease such areas before subsequent coating.

The scope of application of sandblasting equipment is quite wide:

- factory processing of metal products and structures before applying paint and varnish coatings to finished products;

- during repair work on the main equipment of thermal power plants (for cleaning tubes of condenser and boiler units, the inner surface of all kinds of vessels and pipelines, turbine blades);

- in metallurgical production;

- at aircraft factories in the manufacture of aluminum parts;

- in shipbuilding;

- in the production of mirrors and glass with complex textures;

- in construction;

- at car service stations and in workshops where bodywork and straightening work is carried out;

- in engraving workshops;

- in the manufacture of metal-ceramic prostheses;

- at electroplating enterprises;

- After sandblasting, defect detection of metal structures is possible, the operation of which must be carried out in accordance with GOST standards.

At home, such equipment is still used infrequently - mainly by owners of private houses and large garden plots with outbuildings. It may be necessary when cleaning existing metal surfaces before painting or applying protective agents.

Manufacturing method from a spray gun

Sandblasting can also be done using a spray gun. For assembly you need to prepare:

- a gun that functions as a mixing valve;

- handle with air supply device;

- a plastic bottle that acts as a tank for abrasive;

- tee;

- ball valve for regulating sand supply.

Using an airbrush instead of a spray gun will allow you to apply abrasive at higher pressure due to the smaller thickness of the outlet channel.

Assembly is performed in the following sequence:

- The gun is bored to increase the diameter of the output nozzle.

- The mixing tee is attached to the gun.

- The supply and circulation hoses are installed and attached.

The abrasive is released after the trigger is pressed. The volume of a small plastic bottle is enough to clean surfaces for 30 minutes.

How does a sandblasting machine work?

Having taken up the manufacture of a sandblasting machine, you must carefully study the principle of its operation, prepare all the necessary tools and elements of its design. A homemade sandblaster, if assembled correctly, is practically in no way inferior to serial equipment in its capabilities. At the same time, it is possible to manufacture a device that allows you to effectively carry out work on cleaning surfaces made of various materials with minimal financial costs.

Sandblasting machine diagram

A homemade sandblasting machine, like a serial one, works on a principle somewhat reminiscent of the operating principle of a conventional device for spraying paints and varnishes - a spray gun. Meanwhile, there are still differences in the operation of such devices, which does not make it possible to replace them with each other.

The main element of any device for sandblasting is a compressor, which is necessary in order to create an air flow with the required pressure in the installation lines. Passing through the main hose past the hose for collecting abrasive material, the air flow creates a vacuum, which causes the abrasive to begin to be sucked into the main line and mixed with the air stream. The already formed flow of working material, consisting of air and abrasive, enters the nozzle, through the hole of which it is supplied under high pressure to the surface being treated.

The air inlet is made near the place where the condensate is drained, so that the flow loses most of the moisture, hitting the wall of the receiver

In addition to the compressor, the most important element of a sandblasting installation, which largely affects the efficiency of its operation, is the nozzle, which ensures the formation of an abrasive jet with the required characteristics. At home, you can only make a ceramic nozzle by using old spark plugs from which the metal electrode is removed. Serial nozzles, characterized by increased wear resistance, are made of steel coated with boron carbide or tungsten carbide, less often - of ordinary steel, cast iron and ceramics (such products quickly lose their characteristics under constant exposure to abrasive material).

Homemade metal nozzles turned on a lathe do not last long, but they cost practically nothing

Main components of sandblasting machine

Homemade sandblasting is assembled on the basis of standard schemes, differing in the method of supplying sand to the contaminated part. Despite the existing design differences, the components for both options are the same:

- compressor - a device for pumping air mass;

- a receiver necessary to create the necessary air supply;

- abrasive tank;

- gun - the main device designed to supply an abrasive mixture to the surface to be cleaned;

- hoses.

In order to increase the duration of continuous operation and maintain the supply pressure, it is recommended to equip the sandblaster with a moisture separator. When using a plunger compressor, an oil filter system should be installed on the air intake duct.

The device, regardless of the assembly scheme, forms a combined output flow of air and abrasive. When assembled according to a pressure circuit, sand under the influence of pressure enters the outlet pipe, in which it is mixed with the air supplied from the compressor. To form a vacuum in the abrasive supply channel in ejector devices, the Bernoulli effect is used. Sand is fed into the mixing zone under the influence of only atmospheric pressure.

The existence of many options for sandblasting manufacturing schemes is explained by the possibility of creating it from materials at hand, which often seem unnecessary. To understand the essence of the process, it is enough to consider the general principles of assembly.

Areas of application

Today, there are a large number of areas where sandblasting guns can be used. Thus, surface treatment with sand is relevant in the following cases:

- removing rust and paint residues before applying various protective coatings to the surface (for example, anti-corrosion compounds);

- grinding parts and products made of wood, stone, plastic, ceramics, metal and other materials (this is necessary in order to subsequently apply further coating to a particular surface);

- applying inscriptions and drawings on various types of surfaces;

- frosting of glass (for applying patterns to it, the procedure is also used for the production of tableware);

- restoration of various objects;

- degreasing products before covering them with varnish or paint;

- processing walls to give them a special roughness;

- creating the so-called “aging” effect (relevant in the process of processing furniture and decorative interior items: for example, boxes or frames);

- polishing of automobile parts.

Advantages and types of sandblasting

Sandblasting as equipment has many advantages, among which are the following:

- smoothing, leveling the surface;

- cleaning hard-to-reach places and elements;

- high performance;

- high-quality surface preparation before applying paint, varnish or protective coating.

There are several types of sandblasters, two of which are commonly used for surface cleaning. These include closed-type and open-type sandblasting. The closed one is essentially a sandblasting chamber. Open type - mobile, mainly used when working with outdoor objects.

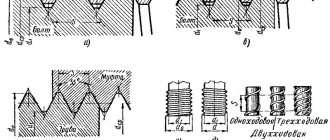

Sandblasting can also be of injection, pressure or vacuum type. They differ from each other in the way they supply abrasive particles to clean the surface.

Overview of species

In general, there are 3 types of abrasive cleaning of metal surfaces, which have certain rating boundaries between each other: light, medium and deep. Let's look at a brief description of each type.

Easy

An easy type of metal cleaning includes the removal of visible dirt, rust, as well as peeling old paint and scale. Upon inspection, the surface appears fairly clean. There should be no contamination. Traces of rust may be present. For this type of cleaning, sand or plastic shot is mainly used at a mixture pressure of no more than 4 kgf/cm2. Processing is carried out in one pass. This method is comparable to manual cleaning with a wire brush.

Average

With medium cleaning, a more thorough treatment of the metal surface is achieved by increasing the pressure of the air-abrasive mixture (up to 8 kgf/cm2). An average type of treatment can be considered such if only about 10% of the total area remains on the metal surface after passing through the sandblasting nozzle. There may be some minor scale present.

Deep

After deep cleaning, there should be no dirt, scale, or traces of rust left. In fact, the metal surface should become perfectly clean and smooth, almost white clean. Here the pressure of the mixture of air and abrasive material reaches 12 kgf/cm2. The consumption of quartz sand with this method increases significantly.

Based on the use of working material in the mixture, two main types of cleaning are distinguished:

- air-abrasive;

- hydrosandblasting.

The first uses compressed air mixed with various abrasive materials (not just sand). In the second, the working component is water under pressure, into which sand particles (most often), glass beads and finely chopped plastic are mixed.

Hydrosandblasting has a softer effect and more thorough surface cleaning. Often, even oil stains can be washed out using this method.

Advantages of hydrosandblasting

Sandblasting replaces the labor-intensive process of removing dirt and coating residues and removing scale. Hydrosandblasting has advantages over the traditional method of surface treatment using compressed air:

- absence of dust harmful to humans;

- the surface is obtained with a slight roughness, which increases adhesion;

- gentle processing;

- abrasive consumption is reduced;

- cleaning stone, masonry, soft metals;

- cleaning intensity is adjusted;

- the remains of caustic soda and other cleaning materials are washed away;

- work in hard-to-reach places.

With water, sand removes dirt, rust, and old decorative coatings from metal, ceramic and stone surfaces. Grains of sand dislodge dirt, creating a matte surface. Primer and paint adhere well to it. Polishing is done quickly, with minimal effort. The macrostructure of the alloys is examined on samples treated with hydrosandblasting, and etching begins without lengthy grinding.

Sand particles moistened with water are heavier than dry ones. They hit the surface with great force, performing active cleaning. As a result, the consumption of abrasive material is reduced by up to 4 times.

During processing, water dissolves and washes away the remaining detergents remaining in microcracks after the previous washing of parts. Acoustic soda has a particularly harmful effect on metals and stone. When dry sandblasting, it gets deeper into the cracks and gradually destroys the material.

Disadvantages include splashing water and puddles on the floor. Hygroscopic materials cannot be processed.

Important!

Water pressure is adjustable 2-7 kg/cm2. You must wear a special suit and follow safety precautions to avoid serious injury.

Overview of species

Sandblasting glass can be done in different ways:

- matte image on a transparent background (painting only the sketch);

- matte background with a transparent pattern (processing of most of the glass);

- bronze sandblasting (using dark tinted material of a brownish tint);

- matting of different densities (processing elements under different pressures);

- “floating” effect of the pattern on the mirror;

- sandblasting treatment on the inside of glass;

- volumetric artistic cutting (deep application of a 3D pattern using the technique of alternately spraying several layers of a pattern onto a matte surface).

Matting is the simplest technique that allows you to achieve flat designs with clearly defined boundaries. If the matting is multi-layered, it is called artistic. In this case, the transitions of textures, tones and colors are more pronounced. Such images are clearer and more naturalistic.

Artistic step-by-step matting takes more time; it is used when processing glass of different thicknesses (from 6 mm). During its implementation, not only film, but also metal templates are used. At the same time, metal templates are distinguished by the simplicity of their ornamentation. Film analogues are used to create complex patterns.

Color tinting allows you to obtain any shade of the glass surface. It is distinguished by the application of sandblasting to the inside of the glass. The facial remains smooth and even, which simplifies care. In order to increase service life, a protective film is applied to the inside. Amalgam involves applying a pattern to the inside of the glass.

Colored glass processing using sandblasting technology involves creating a colored pattern (for example, stained glass, diamonds) or a pattern that glows in the dark. The sandblasting technique is used in the production of compositions with a velvet texture. Cutting or engraving is used to create a detailed drawing.

Sandblasting technology allows you to apply a winter ornament pattern. In this case, the technology of creating an icy pattern (frost effect) is used. For this purpose, a homogeneous mixture is used in the work.

Purpose of the device

Sandblasting machine

The purpose of the sandblasting machine is abrasive processing of materials. Let's look at all the use cases in detail:

- Metal processing. In production, often during the delivery of metal, the latter becomes covered with rust. This is acceptable for raw materials, but not for the finished product. A sandblasting machine effectively removes any dirt and rust of any depth from the metal surface. After processing, the paint adheres well to the item.

- Glass processing. A matte layer of roughness is applied to the glass with sand, which makes it opaque. You can also use a sandblasting machine to apply various types of designs.

- Household use. Among other things, low-power sandblasters are often used to clean dishes.

- Stone processing. Before painting, the previous layer must be removed from the surface. Thanks to a sandblasting machine, this can be done quickly, immediately preparing the surface for future painting.

Suit for working with a sandblasting machine

It is necessary to pay special attention to the fact that during processing, sand removes the upper part of the material, and does so in fragments, leaving the surface rough. Paint adheres well to such micro-irregularities

Therefore, sandblasting combines removing the previous layer of paint and preparing the surface for a new treatment.

Option for a sandblaster made from a fire extinguisher

The circuit diagram of a fire extinguisher apparatus is similar to a device assembled with your own hands from a cylinder.

To seal the top of the fire extinguisher on turning equipment, a plug should be made in advance. A sealing rubber ring is put on it, and the part is screwed into the upper neck of the fire-fighting device. The existing hole is intended for filling sand.

At the next stage of manufacturing the sandblasting machine, holes are drilled with your own hands: on the body near the top and in the bottom. The places are pre-cleaned of factory paint, and welded into the holes according to the welding strip. Legs are welded to the bottom of the fire extinguisher, for the manufacture of which you can use a round rod or fittings.

To make tightening and unscrewing easier, a knob is welded to the plug. After assembling and installing the fitting system, the manufactured sandblaster is ready for use.

Sandblasting Equipment

Sandblasting of metal is carried out using special devices, which consist of several parts:

- A compressor is an element of a sandblasting machine that pumps up operating pressure. The stronger the material being processed, the more powerful the compressor is needed.

- Container for mixing abrasive with air. It has an inlet (for air) and an outlet (for discharging the finished mixture).

- Nozzle - through it the suspension is supplied to the working surface. It is better to perform metal processing using tungsten and ceramic elements.

There are several types of installations for cleaning materials from corrosion. These can be stationary and portable models. The first include sandblasting chambers. These are closed structures that allow you to clean parts of a certain size by reusing the abrasive. However, the main disadvantages of the cameras include the limitation on the size of the workpieces processed.

Sandblasting nozzle

How to choose a water machine?

When choosing a model of a hydrosandblasting machine, you should decide on the dimensions of the parts to be processed and the type of equipment:

- stationary camera;

- mobile installation.

To clean parts before coating them with paint and other materials, cleaning from scale and dirt is carried out in chambers. Their dimensions are determined by the dimensions of the workpieces.

Builders need mobile units with water tanks to clean facades and pipelines. Large metal structures are processed similarly. The power and size of the nozzle cone determines how much area can be processed per unit of time.

Kinds

Today there are several types of sandblasting guns. For example, you can find an electric air gun, a portable device and many other models in the market.

According to the method of releasing the mixture

According to the method of ejecting the abrasive mixture, guns can be point-based (that is, sand is directed from the nozzle in a straight line to a specific point), or they can have a wide range of action. Often the first versions of devices are considered more effective.

According to the abrasive supply option

Depending on the supply of abrasive material, devices can be:

with a tank (such a gun is similar in characteristics to a spray gun);

Recommendations for selection

The choice of material for a sandblasting machine will be influenced by the type of surface, its condition and other characteristics:

- Thickness of the coating layer that is planned to be removed, surface strength. Low-hardness abrasives are not suitable for durable elements, since their processing will not give the desired results;

- For harder objects, the hardest abrasive should be selected, and for soft elements, a less hard one;

- To get a minimum number of dents and chips, it is better to use fine abrasives;

- Hard machining raw materials with sharp edges will be able to complete the process at a higher speed than round-shaped abrasives;

- If you plan to treat the surface once, then you can choose an inexpensive option in the form of quartz sand or cooper slag.

Granulated plastic, glass beads, and glass beads are also used as abrasive materials. Any type of abrasive for a sandblasting machine has its own properties, so all that remains is to make the right choice, taking into account the work being carried out.

Abrasive test sandblasting electrocorundum VS sand

How does he work?

First, a little about how the device works. By design, sandblasting is made of the following components:

- storage receiver;

- air compressor;

- container with abrasive elements;

- spray gun;

- automation and control devices;

- connecting hoses.

Most often, the power and productivity of the device does not depend on the compressor, but on the size of the internal resistance, the maximum pressure and the length of the operating hoses. The principle of operation of the unit depends on the type of sandblasting and may differ slightly, but at the heart of their work is: a compressor that creates air pressure that is pumped into the receiver chamber.

After the appropriate pressure appears, the air flow is supplied to the gun, and soon a vacuum is created, which draws in the abrasive particles and delivers them at high speed to the workpiece.