A classic gasoline chainsaw requires periodic maintenance with replacement or cleaning of the air and fuel filters.

In the article we will talk about how to properly carry out the procedures for washing or replacing filter elements, as well as how often to do this.

All replacements and flushing are carried out exclusively with the engine stopped and cooled. Also, before carrying out work, it is necessary to disconnect the spark plug to prevent unexpected starting.

Washing the chainsaw air filter

In the instructions for any saw, cleaning the air filter element refers to procedures carried out after each use.

Filter option

Cleaning and replacing the filter

How to wash a chainsaw filter:

- Unscrew the top cover. The necessary compartment is located in the upper part of the body near the handle, regardless of the brand - be it Husqvarna, Sturm or Partner.

- Remove the filter - it can be inserted or screwed on.

- Wash the foam filter with warm water and soap and air dry. When cleaning with gasoline, the service life of the filter is reduced.

- Paper, mesh, felt - you can shake it out by lightly tapping the edge on a dense surface. They can also be cleaned/blown well with a compressor or vacuum cleaner.

- All dirt in the area around the engine must be wiped off.

- Reinstall the chainsaw air filter, making sure that all grooves and parts fit tightly into place. Close the cover and tighten the screws.

If the filter begins to deform, becomes denser and thinner, or holes and cuts appear, it must be replaced.

Replacing a chainsaw fuel filter

Like all fuel-powered equipment, chainsaws have a fuel filter, it is located in the fuel compartment.

The main symptom of a faulty chainsaw fuel filter is that it stalls when you press the gas.

How to change the filter on a chainsaw:

- When replacing the filter element, there is no need to drain the gasoline mixture.

- Take a thick wire and bend the end to the shape of a hook.

- Unscrew the fuel tank cap.

- Lower the hook into the tank and hook the tube with the filter at the end. The tube is short enough, so when removing the filter, do not pull too hard; it is only long enough to replace it.

- Hold the tube with one hand, pull the filter with the other and remove it from the port - insert a new one.

- Make sure the filter fits tightly into the port. Place the filter tube into the tank. When starting the engine, the filter will lower itself to the desired position at the bottom.

VIDEO INSTRUCTIONS » alt=»»>

How to clean a chainsaw fuel filter

If the filter looks fresh enough, you can skip replacing it and wash it with gasoline. The element is removed and installed back according to the described scheme.

How often do you change a chainsaw fuel filter:

- The average replacement frequency is once every two years; washing helps to slightly extend the service life.

- With heavy use, a new filter element will be required sooner. A sure sign of the need for replacement is that after washing, not much time has passed and the saw stalls again.

When operating a tool such as a chainsaw, its owner often faces a number of problems, one of which is a clogged carburetor. This can happen if the chainsaw is filled with low-quality gasoline or foreign debris gets into the fuel tank. In order to clean the carburetor of a chainsaw, you must first disassemble it.

An indispensable assistant for each of us

This model has a significant advantage, in particular, low weight, which contributes to more comfortable work, and is also quite economical, since the manufacturer equipped it with a two-stroke engine with a small volume. But, despite this functionality, the chainsaw is quite powerful. One of the most successful models is the Husqvarna 137.

As for the characteristics of the chainsaw, its weight is about 4.6 kg, despite the fact that this is the “clean” weight of the tool, without oil, fuel and chain tires. Of course, the fully equipped chainsaw will weigh much more, but the undeniable advantage is that thanks to the 38 cm long bar, the work becomes easier. This feature allows you to create deeper cuts.

The chainsaw from this manufacturer has very good power, which is about 1.6 kW, which contributes to a significant increase in the level of oscillating waves, and this is a significant drawback when working with this equipment. Naturally, when developing its own products, the manufacturer thought about how to reduce this type of vibration and supplemented the equipment with a so-called anti-vibration mechanism.

If we talk about shifts, then in order their number is 13 thousand and in order. 3000.

Inventory control is handled by a double wishbone design with an integrated throttle, which is actually quite inconvenient as some parts are difficult to get on site during servicing. Choose an inexpensive chainsaw for your home. This is not an easy task. If you decide to stop choosing this model, you will have to pay a considerable amount for such a chainsaw, since it is one of the most expensive in the product range of this manufacturer; its owner often has to deal with a number of problems, one of which is a clogged carburetor. This can happen if the saw is filled with low quality gasoline or if foreign fuel has entered the fuel tank. To clean the carburetor of a chainsaw, you must first disassemble it.

Cleaning correctly

To properly clean your chainsaw, you will need the following tools:

- Phillips and flat screwdriver,

- wrenches with heads of different sizes,

- special cleaning composition, cleaning cloth,

- ultrasonic cleaner.

Read also How to prune a Flamentan rose in autumn

The set of tools can be seen in the photo.

Cleaning the carburetor of a chainsaw should be done according to the following algorithm:

- First you need to drain the remaining fuel from the fuel tank. Remove the cover of the chainsaw by unscrewing the fasteners. We take out the filter and disassemble the housing, removing nuts and clamps if necessary.

- Remove the fuel mixture supply hose from its clamp, unscrew the fasteners of the carburetor top cover. Then remove the top cover and the blue gasket - this is the fuel pump membrane. To the left of the body there are spring clips, remove them, and then the screws. It is advisable to label the parts and schematically record the places from which they were removed, so as not to confuse anything during assembly.

- Remove the bottom carburetor cover, unscrew the screw and remove the needle valve and the spring under it. Then, using longitudinal force, remove the air damper and its axis.

- Remove the throttle valve, drive lever and throttle shaft.

- We lay out all the removed carburetor parts on a flat surface and inspect them to ensure integrity is maintained. Parts with a high degree of wear must be replaced with new ones.

- Using a specialized cleaning agent, wash the parts and dry with a lint-free cloth. The tubes must be blown under pressure using a pump.

- To achieve maximum effect, you can clean the carburetor on a Shtil chainsaw using a special cleaning bath, the basis of which is the cavitation effect. The bath is filled with diesel fuel, and the carburetor parts are immersed in it for several minutes. Finally, we dry the parts using a pump.

A detailed video with the cleaning process will help you do the job correctly.

After all the products have been dried, it is necessary to assemble the carburetor. Usually the detergent evaporates completely within a day. It is better to wait a day after cleaning, since residual detergents on the parts can get into the fuel compartment and release toxic gases during combustion.

Another important nuance associated with disassembling a chainsaw is that it is necessary to extremely accurately install and adjust the needle valve blade, otherwise the chainsaw may not start. You can use a blade to check that the petal is installed correctly. Having installed it on top, we see how freely the petal rotates. If no problems arise, then everything is in order and you can continue assembly. If movement problems still arise, then the petal must either be pressed down or the edge on it must be bent.

DIY chainsaw repair. Analysis of breakdowns and ways to eliminate them

It would seem, why would a summer resident who grows vegetables and fruits, or the owner of a suburban house with a small garden and several flower beds, need a chainsaw? The question disappears when there is a desire to build a bathhouse, update a greenhouse, knock down an old business, or simply make a bench for relaxation. Unfortunately, any mechanism from time to time needs maintenance and replacement of spare parts, and for this you need to have a good understanding of the structure of the product, and besides, repairing a chainsaw with your own hands will save time and money.

How to clean a chainsaw filter

It may be necessary to clean the Husqvarna chainsaw filter after each use. The cleaning process itself, depending on how dirty the filter is, can be done in two ways:

- A mechanical cleaning method, which involves blowing the filter.

- For higher degrees of contamination, the filter is washed in soapy water.

Important! It is forbidden to wash the filter in aggressive solutions: gasoline, diesel fuel, acetone.

How to clean a muffler on a chainsaw

Timely measures to clean the chainsaw muffler can significantly extend the life of the tool. There are several reasons for muffler contamination:

- long service life,

- low quality of the oil being poured,

- Incorrect carburetor settings.

To check the condition of the muffler, you need to dismantle it and look inside. If you need to remove the muffler on a Stihl chainsaw, you need to remove the muffler fasteners, the muffler itself, the plate and the reflector.

If you find carbon deposits inside the muffler, then this problem can be solved in two ways:

- Mechanical method (cleaning is carried out using brushes, sandpaper and special products). This path is possible if the muffler is disassembled.

- In the case of a non-removable muffler, special cleaning compounds are used in which the muffler is soaked for several hours.

By performing all the steps correctly, you can easily clean your chainsaw, extend the life of the tool and protect yourself while working.

A chainsaw is a simple device that, with proper care, can last a long time. At the same time, the saw is a tool subject to various loads and, therefore, breakdowns still occur. You will learn about what caused a certain malfunction and how to fix it from this article.

Operating a chainsaw. Some tips.

4.9 / 5 ( 14 votes)

After purchasing a chainsaw, if you have no operating experience, it is important to read the instructions in more detail. Branded saws - Stihl and Husqvarna - come with a full book on the operation and maintenance of the unit, but few users pay attention to this...

And it’s completely in vain, because the durability and reliability of the chainsaw directly depends on proper use and timely maintenance.

Let's talk about the most important points, perhaps you will be interested!

Proper starting of a chainsaw.

In fact, this issue is quite serious, since if you try to start it incorrectly, parts of the saw body may break (for example, a Stihl MS-180 chainsaw).

Therefore, it is important to familiarize yourself with the algorithm for starting the saw both on a cold and on a warm engine.

Gasoline mixture.

A very important point after purchasing a unit is to purchase high-quality oil for the gasoline mixture. Based on the results of numerous studies, the best oils are recognized as:

Stihl HP Ultra, Stihl HP and Husqvarna . Each of these oils will cope with its tasks perfectly.

Purchasing cheap and unknown brands of oils can significantly reduce the life of the chainsaw or damage the piston group parts. Since in domestic conditions with insignificant amounts of work, oil consumption will be symbolic, the savings will be very doubtful.

By the way, the above brands have different packaging forms (5l/1l/100ml/20ml), so it is not necessary to immediately purchase a “liter” bottle, it is very convenient.

Basic rules for preparing and storing gasoline mixtures:

Prepare the gasoline mixture in the proportion according to the instructions for your tool (usually 1:50, 1:40).

For convenience and accuracy of oil dosage, use a medical syringe.

Use high-quality and “fresh” AI-92 gasoline.

Do not store the finished mixture for more than 14-20 days after its preparation, due to the low quality of gasoline - the additives lose their properties.

Do not store the prepared gasoline mixture in plastic containers intended for food products.

Store the prepared fuel mixture in a cool, dark place, away from direct sunlight.

Preservation for the winter (or long inactivity) - drain the fuel mixture from the tank, start the saw and use up the remaining gasoline in the fuel system until it stops completely.

Saw set.

The saw set deserves very close attention. Unfortunately, few owners always use a sharpened chain when sawing and specialized oil for lubricating tires and chains.

It is the use of “dumb” chains that causes a very large list of breakdowns ( including failure of the piston group )

A simple and easy indicator of good chain sharpening is large chips when sawing.

If fine dust appears, then the chain needs to be sharpened.

You can “correct” the chain yourself using a file (high-quality files are made by Stihl) or with a set. But the best option would be to send the chain for sharpening to a trusted service center, where sharpening is carried out on a specialized machine, observing the factory sharpening angle. A very important point is the correct tension of the chain.

A too-tightened chain will place a heavy load on the engine, and sawing performance will suffer. Correct chain tension is considered when one link should be above the edge, and the two adjacent ones should barely touch.

The ideal operation option is to have several circuits and alternate their use. When constantly working with one chain, the drive sprocket wears out according to the wear pattern of the drive link, and after the change, the new chain will slip and experience dynamic shocks. If you rotate the tire frequently, it will also wear out more evenly. Use the headset size recommended by the manufacturer; increasing the size of the bar and chain will place additional stress on the engine.

Use special adhesive oil to lubricate chains, but it is more expensive than regular or used oil, but it will extend the life of your saw set and drive sprocket.

Check the wear condition of the drive sprocket. Operation is not allowed if the wear of the teeth is more than 0.5 mm.

Otherwise, premature failure of the chain and bar is possible.

Maintenance:

As the practice of repairs in service centers has shown, only about 3% of users follow the rules for using their tools: regularly clean them, blow out (change) filters, and take care of the condition of the saw set. For some reason, everyone else neglects these procedures, which later leads to serious repairs.

We agree that everyone should mind their own business, but these simple and simple steps will help you operate smoothly and extend the life of your units.

Air filter

Regularly check the condition of the air filter; it is the only protector of the carburetor and cylinder-piston group from external contaminants: sawdust, abrasives and other contaminants.

Frankly speaking, the filtration system on household models of chainsaws and brush cutters is not particularly reliable and well-thought-out in design; if we add to this a dirty air filter, then there can be no question of any proper operation of the unit.

A dirty filter can be washed in soapy warm water, dried and blown out. If this does not help, the filter must be replaced.

Fuel filter.

Regularly check the condition of the fuel filter; it is responsible for the quality and quantity of the gasoline mixture supplied from the tank to the carburetor.

Do not use fuel filters that have damage to their housing.

A dirty fuel filter, along with the low quality of gasoline in our country, will not allow your saw to operate at full capacity.

We recommend blowing out the filter once every six months, changing it once a year (minimum). Use high-quality original filters. The savings from using cheap filters are very doubtful.

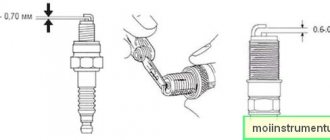

Spark plug

It plays an important role in starting up the unit and its stable operation. It is important to use good quality spark plugs (Bosch, NGK) and the markings specified in the instructions for the chainsaw.

Necessary skills and tools for repair

Most of the malfunctions of gasoline chain saws can be fixed with your own hands. True, this requires an understanding of the structure of the chainsaw and how the components function among themselves. As for the tools, the most often needed are:

- screwdrivers (slotted and power);

- combination wrench included in the kit or regular wrenches with heads of various sizes.

Read also How to make a cleaver from an ax with your own hands

Structural components of a chainsaw

All chainsaws are similar in design, regardless of whether they are European (ECHO, Stihl, Husqvarna) or domestic (Kedr, Ural). Inside the body there are the main elements: a fuel tank and an engine, and outside there is a starter, a handle, a part of a saw (pneumatic) with a chain. A sudden pull on the cable starts the motor, which starts the saw blade.

To begin with, we suggest that you familiarize yourself with the videos that show how the chainsaw works and how it works:

Sometimes the saw breaks down and requires disassembly. What can happen to such a simple mechanism as a chainsaw? At least the following:

- Stop starting;

- It starts but soon stops;

- Stops functioning in the section;

- He loses his power;

Most malfunctions are associated with interruptions in engine operation (fuel supply system, exhaust system, ignition, cylinder-piston part) or with malfunctions of other systems and components (clutch, chain brake, pneumatics, lubrication system). Let's look at the most common breakdowns and how to fix them.

A working chainsaw starts with a click and does not skip

Engine

In most cases, the following problems occur in engine operation:

- the engine stopped starting;

- the engine starts, but after a while it stalls;

- the engine is not able to develop the required power;

- The engine is extremely unstable.

How to check crankshaft seals

The presence of oil seal leaks can only be checked by getting to the crankshaft itself and carefully examining it for leaks. You can see how to do this correctly in the video:

How to check compression on a chainsaw

At a compression level below 8 atmospheres, the engine will not have enough power, which means the chainsaw will not be able to fully function.

To measure compression you need:

- Remove the protective cover and unscrew the spark plug.

- Insert the tip of the compression gauge into the hole where the spark plug should be located.

- Using the starting cord, rotate the piston and remember the maximum readings of the measuring device.

How to properly install a piston on a chainsaw

The work of replacing the piston for most models of modern chainsaws is carried out according to the following algorithm:

- The top and side covers are removed.

- The candle is unscrewed.

- The stoppers are removed from the shock absorbers and the handle is disconnected from the body.

- The drive sprocket and starter are removed.

- A piston stopper is installed in the spark plug hole and the nut securing the flywheel and clutch is unscrewed.

- The flywheel, clutch, and worm drive of the oil pump, located immediately behind the clutch mechanism, are removed.

- The screws securing the carburetor and air filter are unscrewed, after which these components are removed along with the engine control lever.

- The ignition coil is removed, as well as the muffler.

- The saw is turned upside down and, by unscrewing the screws securing it to the body, the engine is disconnected.

- The pan is unscrewed and the piston is removed.

- Since the piston is removed only together with the crankshaft, to disconnect it it is necessary to remove the retaining rings.

- The old piston is replaced with a new one, but as carefully as possible. This is caused by the high fragility of compression rings.

- The crankcase is put in place, and sealant is used instead of a gasket.

All subsequent actions are carried out according to the reverse algorithm of disassembly.

Assessment of the condition of the cylinder-piston group

Often the engine will not start or run at full power due to low cylinder pressure. This may be caused by piston or cylinder wear, sagging piston rings, or bearing wear. The condition of the piston cylinder assembly (CPG) can be partially checked by removing the muffler and looking into the open hole.

A compressor placed in the spark plug hole will help measure compression in the engine - the measurement results can also tell you about the condition of the CPG. Accurate data is obtained only after complete disassembly of the mechanism. If the piston is chipped or scratched, it must be replaced. The piston ring must be clean, free of carbon deposits and exactly in place.

Wear of the piston and crank mechanism is considered a serious problem

Based on the compression measurement results, one can judge the condition of the CPG parts

Fuel system

Malfunctions of the fuel system are also quite often the main reason that prevents a chainsaw from working as efficiently as possible. First of all, you need to check the quality of the fuel mixture.

Some owners prefer to use alcohol-containing solutions rather than the recommended brand of gasoline, or add more oil than required.

Gasoline leaks from a chainsaw

If gasoline drops periodically appear on the body of the chainsaw, then it is necessary to check the tightness of the fuel tank. Over time, it may dry out. Or the gasket has become “stiff” and it can no longer perform its direct function.

If full-fledged gasoline streams appear, then there is a high probability that you will have to change the burst hose connecting the carburetor and the fuel tank.

Gasoline does not enter the chainsaw cylinder

There are several reasons why the fuel mixture stopped flowing into the cylinder:

- The air filter is clogged.

- The carburetor settings have been lost.

- The carburetor membrane is no longer intact.

- The channels through which gasoline is transported are clogged.

Chainsaw won't idle

In this case, you should start looking for a problem with the filter elements. For the most part, it is precisely because of the reduced capacity of the air and gasoline filters that the idle speed begins to “float”.

If everything is in order with the filters, then you need to check the components of the gas supply system, and also make sure that there are no spontaneous changes in the carburetor settings.

Fuel supply system repair

Fuel cannot enter the cylinder for the following reasons:

- The fuel filter is dirty. Remove the fuel line and check the fuel flow. If the stream is weak, the filter may need to be cleaned. Pulls out through the filler hole of the fuel tank and cleans it; in case of severe contamination, it is replaced with a new one. As a preventative measure, it is recommended to replace the fuel filter every three months.

- The breather (hole in the fuel tank cap) is clogged. It can also be checked by disconnecting the tube; if clogged, clean it with a needle.

- Lack or insufficient fuel. There may be several reasons for the malfunction. The first reason is a clogged air filter. Air stops flowing into the carburetor in the required quantity, and therefore, due to the fuel mixture being too rich, the engine stops working. The dirty filter is carefully removed, cleaned and washed with water, then dried and installed again.

Another reason is improper carburetor adjustment. Adjustment is made with three screws.

Timely replacement of the fuel filter ensures full fuel supply

The fuel line and pneumatic actuator must fit tightly into the fittings

The throttle cable must be in place

During the work you need to follow the instructions, otherwise you can only make the situation worse.

And the last reason is a violation of the integrity of the membrane or clogging of the carburetor channels.

All parts must be clean, dry and in good condition.

Filter

A “rich” or “lean” fuel mixture will sooner or later cause a breakdown. Perhaps even expensive. To prevent this from happening, it would be a good idea to regularly check the filter for abrasions, as well as for breaks in the filter fabric itself.

Read also Marinade for saffron milk caps per 1 liter of water

How to check the fuel filter and replace it

To check the current condition of the fuel filter, you must perform the following steps:

- Remove the fuel hose from the carburetor fitting and direct it into a working container.

- Press the so-called “paging” button several times.

If gasoline flows unevenly and jerkily, then it’s time to install a new filter element. This is done quite simply:

- The fuel tank cap is unscrewed.

- Using tweezers or any other device, the filter itself is removed.

- After disconnecting the old filter, you need to install a new one and lower it into the fuel tank.

How to clean the air filter

If a sufficient amount of air is not supplied, the fuel mixture becomes too rich, which leads to disruption of normal engine operation. Regular purging of the air filter, and in particularly advanced cases, washing in a soapy solution will help avoid such problems.

Please note that washing in acetone, gasoline or other aggressive solutions is not allowed. This may lead to damage to the integrity of the filter element.

Where is the breather on a chainsaw?

This is a useful device for every owner. It doesn’t matter what model of chainsaw you have, sooner or later you will have to study it thoroughly in order to diagnose problems and repair the device yourself. Why is this necessary? Of course, such a working tool is not insured against breakdowns, but some are not serious enough to contact a service center (where you will have to leave a net amount). Sometimes a chainsaw can fail due to a simple clogging of the chainsaw. Don't know where the chainsaw's breathing apparatus is located? You will learn about this and much more from this article.

Malfunction of unspecified category

In some cases, owners of chainsaws have to solve more complex problems to fully restore the functionality of their cutting tool.

The chainsaw does not develop full power

In addition to the problem discussed above with a lack of gasoline or air entering the cylinder, the cause of low power may be a clogged muffler.

If you do not periodically clean the muffler clogged with combustion products, then the problem of poor engine power may not be the only one.

Carburetor depressurization and nozzle blockage

Over time, the screws holding the carburetor cover in place can become loose or the gaskets can become unusable. A clogged filter or improper replacement can lead to clogged injectors. All this also negatively affects the operation of the chainsaw and shortens its service life.

To prevent this, it is enough to periodically inspect the saw and, if necessary, evenly tighten the screws.

Chainsaw won't idle

It often happens that after long-term transportation and constant use, a chainsaw refuses to idle smoothly. As a rule, this problem is eliminated by adjusting the carburetor.

You can learn how to properly debug the carburetor from this video:

If the carburetor is tuned like a clock, then you need to check:

- Fuel system. It makes more sense to start with the fuel pump.

- Muffler. There is a high probability that due to the abundance of accumulated soot, the engine cannot function normally.

Chainsaw loses power under load

If during operation the power of the saw disappears somewhere, then the problem should be looked for in the following places:

- In the muffler. It, as you already understood, tends to get clogged.

- In a clogged fuel filter.

- A poorly functioning fuel pump.

Disassembling and cleaning the muffler

If the engine runs well at low speeds and starts to stall at high speeds, the cause may be the muffler spark arrester, which is clogged with combustion products.

- remove the muffler;

- disassemble (there are also non-dismountable models);

- remove carbon deposits using detergents;

- dry with a hairdryer;

- install in place.

Dry cleaning is unacceptable, as soot contains carcinogenic substances, the inhalation of which is hazardous to health. After removing the muffler, cover the exhaust port with a clean cloth.

Interruptions in the operation of the chainsaw indicate a possible clogging of the muffler

To avoid muffler clogging, it is necessary to monitor the composition of the fuel mixture. The amount of oil should not exceed the standards recommended by the manufacturer. Poor oil quality also negatively affects engine performance.

Malfunction of other systems

In some cases, chainsaw users report other problems that do not significantly affect the operation of the tool.

Why does a chainsaw smoke?

Most often, excessive smoke appears when oil is added excessively to the fuel mixture, which does not have time to burn completely. You should also check to see if the carburetor settings have gone wrong.

Recoil when starting a chainsaw

In most cases, recoil at the moment of startup signals the decompressor clamping. If the tool is not equipped with a decompressor, then most likely the ignition system is faulty.

Checking and adjusting the chainsaw carburetor

A correctly adjusted chainsaw carburetor ensures its efficient operation at full power with more economical fuel consumption.

The need to adjust the carburetor of a chainsaw appears infrequently, because the adjustment is first carried out by the manufacturer to achieve a rational operating mode. The adjusting screws are designed for more precise adjustment of the chainsaw carburetor if necessary.

When and why does this need arise?

Among the circumstances of violation of the fixation of the adjusting screws, the following are more common:

- Strong vibration or damage to the protective cap. This happens occasionally, but it still happens.

- Severe wear of the motor (piston). Of course, in this case it is worth taking more care of repairing the chainsaw motor, but still, adjusting the carburetor can improve its functionality for some time.

- Blockage in the carburetor due to damage to the air filter, the disgusting quality of gasoline, or due to the formation of scale. In this case, in addition to adjusting the carburetor, washing it cannot be avoided.

What signs indicate the need to adjust a chainsaw carburetor?

- Firstly, the engine does not start, or it starts, but then stalls. This in most cases occurs due to depletion of the fuel consistency.

- Secondly, a significant increase in fuel consumption and emissions. An increase in emissions indicates that the fuel does NOT burn one hundred percent, which means that the prerequisite may be an oversaturation of the fuel consistency.

The scheme for adjusting the carburetor of a chainsaw may differ slightly depending on the manufacturer (the process of adjusting the carburetor of a chainsaw of a certain brand and model is carefully described in the instruction manual), but the general principles remain similar for all brands. Purpose of saw adjustment. change the quantity and quality (richness) of the fuel mixture supplied to the engine cylinder.

To figure out how to adjust the carburetor on a chainsaw, you should learn to distinguish between three screws (some models have only one).

Screws L and H are similar only in appearance, in fact they are different

Each screw has its own letter designation:

- "L" is for the low speed option;

- “H” is needed to adjust the upper speed;

- “T” is needed to adjust the idle speed (for models with one screw, only this is located).

There are mandatory safety requirements that must be observed when adjusting the carburetor of any chainsaw:

- Make sure the chain is facing away from you.

- The saw must be placed stably on a level surface, and its cutting part must not touch any objects.

Please note: you will find clear values for the angle of rotation of the adjusting screws in the operating instructions for your chainsaw model. Strict adherence to the manufacturer's instructions will help you avoid damage to the motor.

The chainsaw carburetor option process consists of two steps: basic (the engine is turned off) and final (the engine is running and warm).

Sources:

https://zahidknyha.com.ua/ochistka/kuhnya/kak-pochistit-vozdushnyj-filtr-benzopily/

Malfunctions of Chinese chainsaws: review of popular ones and ways to solve them

Buying a cheap chainsaw made in China is not particularly difficult: a huge number of gas-powered tools from the Middle Kingdom are available in markets, construction hypermarkets and online stores. However, a low price almost always hides poor quality.

The most popular malfunctions of Chinese chainsaws include:

- Poor performance of the lubrication system. Clogged oil channels are cleaned, and if the oil pump fails, replacement is necessary.

- The starter cable breaks.

- Breakage of the plastic starter axis. To replace it, a regular metal bolt will do.

If there is the slightest suspicion that the chainsaw is not working properly, you should immediately carry out a full diagnostic of the tool. Only with proper operation and timely maintenance can you count on a long service life of the chainsaw.

Adjusting the chain brake

The chain brake often fails due to clogging of the brake band with grease or sawdust and the space under the cover. All parts must be cleared of blocks. The tape may simply be worn out and needs to be replaced.

Chain brake is reset by mechanical cleaning

Some parts of a chainsaw wear out faster than others. These include a sprocket, tire, chain, and anti-vibration elements. For quick replacement, it is better to always have spare parts on hand. Sharpening the chain should not be neglected.