Article reading time: 20 minutes

Author of the article:

Riveted connection of parts is widely used in construction, mechanical engineering, instrument making and many other industries. Rivets are a wide category of hardware that allows you to create strong and rigid permanent connections. The mounting units are designed for high durability under significant operating loads. Let's look at the main features, advantages and disadvantages of rivet joints.

Rivet connection - structural features

Riveted connections are permanent connections that are used to connect structural elements made of different materials. As a rule, they are used to fasten sheet metal parts. A rivet joint consists of two or more mating parts and a rivet, which creates the forces that hold the connecting members together. The rivet is inserted into coaxial mounting holes made in mating products by drilling or punching. The method of making holes is chosen depending on the material of the parts and their thickness.

The rivet consists of the following parts:

- round rod;

- embedded head, made during the manufacturing process of the fastener;

- closing head, which is formed during the riveting process.

This is a classic simple rivet design that has a wide range of applications. Also, a significant number of types of rivet fasteners have been developed for the installation of individual components. Today, special upsetting machines are used for the production of rivets. The rivet shank can be solid or have a through hole.

Riveting is done manually using a special tool, or using pneumatic riveting hammers and presses. Often, many rivets installed along a single axis are used to connect parts. This connection is called a rivet seam.

Hello student

General information

Riveted connections belong to the class of permanent connections.

They are one of the most common and reliable methods of connecting parts in general mechanical engineering, shipbuilding, and especially in the design of aircraft. For example, in a wide-body aircraft, up to 75% of all connections are made using rivets. On the IL-86 aircraft, the total number of rivets reaches almost 1.5 million pieces.

The advantages of riveted connections include the possibility of using:

□ for connecting non-weldable parts;

□ in critical structures that endure large vibration or repeated loads;

□ in structures that do not allow welding due to warping or the danger of tempering of heat-treated parts.

In addition, riveted joints are more stable and better controlled than welded ones.

The disadvantages of riveted joints are:

□ large mass of the connection;

□ higher manufacturing cost;

□ increased metal consumption;

□ noise and vibration during the manual riveting process.

The rivet is a rod of round cross-section with a rivet head at the end. The embedded head 1 is made simultaneously with the rod, and the closing head 2 is formed during riveting. The diameter of the hole for the rivet in the parts to be joined is made 0.2... 0.5 mm larger than the diameter of the rivet rod. As a result of riveting, the rivet shank settles and tightly fills the hole. The most widely used are solid bar rivets for general machine-building applications with a rivet head of various shapes, the closing head of which is formed by pressing or impact. In press riveting, the closing head of the rivet is formed by uniform compression of the rod on semi-automatic presses and riveting machines.

There is a distinction between single and group riveting, in which several rivets are riveted in one press stroke, which significantly increases productivity. Impact riveting is performed using pneumatic riveting hammers. The formation of the closing head occurs during the process of impact and upset of the rivet rod. The quality of press riveting is higher than impact riveting. Therefore, when designing riveted connections, the possibility of using both single and group press rivets for rivets with a flat or countersunk head is taken into account.

In connections streamlined by air flow, rivets with a countersunk head with a cone angle a = 90° at d = 10 mm and a = 120° at d = 2... 6 mm are used. The method of making sockets for the heads of countersunk rivets depends on the thickness of the parts being connected. When the thickness of the skin is greater than the height of the embedded head, the nest is formed by countersinking; for skins with b < 1.2 mm - by stamping or stamping of the skin and countersinking of the frame. When the thickness of the skin is less than the height of the head, rivets with a = 120° are used.

To connect parts made of composite materials (fiberglass laminates, carbon fiber reinforced plastics, etc.), semi-hollow and hollow metal rivets d = = 1... 10 mm are used. A blind hole in the shank of a semi-hollow rivet reduces the riveting force, reduces the increase in the diameter of the rivet shank and increases the durability of the connection. Hollow rivets are intended for connecting parts made of elastic materials and for non-force connections of metal parts.

Rivets are made from aluminum alloys (V65, D18P, D19P, AMg5P, etc.), steels (10, 15, 20G2, 12Kh18N9T, ZOKHMA), brass (L63) and copper (M2). When connecting parts made of light alloys, as well as light alloys and steel, it is recommended to use rivets made of aluminum alloys, since the large riveting forces required to rivet steel rivets cause significant deformation of parts made of light alloys. The most common rivets are made from alloy B65. In structures operating at 150...250 °C, rivets made of D19P alloy are used. To connect parts made of deformable alloys AMts, AMgZ and non-metallic materials, rivets made of ductile aluminum alloy AMg5P are used. Parts made of titanium alloys and steels are connected with steel rivets. Rivets made of corrosion-resistant steel 12Х18Н9Т are used to ensure corrosion resistance of the connection, also at temperatures above 250 °C.

Rice. 1

Rice. 2

Rivets made of light alloys and steel rivets d < 10 mm are cold riveted. Large-diameter steel rivets are riveted using the hot method—by heating the end of the rivet.

In aviation technology, along with solid rivets for general use, various types of special rivets are used (OST 1).

In power connections where significant shear forces are applied and the strength of light alloy rivets is insufficient, rivets with high shear resistance are used. Rod 1 of such a rivet (d = 5... 12 mm) is made of steel 25KhGSA or ZOKHGSA, and ring 2 is made of aluminum alloy D18. The formation of the closing head occurs by compressing ring 2 around the annular recess of rod 1. When forming a connection with these rivets, the rod does not settle - it must be placed in a hole machined with a reamer with an H8 tolerance.

It is recommended to use rivet bolts instead of a bolt with a nut if there are approaches to the connection for the use of a special tool. An aluminum alloy rod with a diameter d = 3, 5... 10 mm has a smooth cylindrical section, equal in length to the thickness of the package, and a section with knurled annular ribs and a tear-off neck. The crimp ring is made of aluminum alloy or mild steel. The installation of rivet bolts is not accompanied by noise and vibration, the mass of such a connection is 1.2... 1.5 times less, and the fatigue tensile strength is 2 times higher than that of a bolted connection made of the corresponding materials.

For one-way access to the riveting area, explosive rivets, core rivets and cap nuts are used. Explosive rivets have a chamber 3 at the end of the rod, which is filled with an explosive substance. The rivet is placed in place in a cold state and heated to 500 ° C, an explosion occurs in the chamber, unfolding the free end of the rod.

Rivets with a core consist of two parts - a piston with a countersunk or semicircular head 3 (from D18P or 1X18N9T) and a core 4 (from D16P or 3X13). The formation of the closing head occurs when the core is pulled through the piston hole. The protruding part of the core comes off.

Piston nuts consist of a thin-walled piston with an internal thread in its end part. When the screw is turned, the thin wall of the piston is deformed, forming the closing head of the rivet.

A connection made by a group of rivets is called a rivet seam. According to the design, rivet seams are made overlapped, end-to-end with one overlay and two overlays. The rivets in the connection are arranged in rows or in a checkerboard pattern.

Depending on the number of rivet sections working for shear, the connection can be single-cut or double-cut. In the design of aircraft, single-shear joints are mainly used. According to their purpose, rivet joints are divided into strong and durable. Strong connections serve to provide strength, absorb external load and transfer it from one element to another. Strong-tight connections, while withstanding significant forces, also ensure tightness (riveted tanks, sealed cabins, etc.).

The butt joint with one overlay is the most common joint in aircraft and helicopter structures. It is used to connect the external streamlined skin with stringers, spars, frames, etc. In combination with secret riveting, this connection meets the requirements of modern aerodynamics. Structural elements that transmit large forces, such as spars, frames, beams, landing gear components, etc., are butt-joined with two overlays. Overlap joints are used to fasten electrical equipment elements and other units inside the airframe.

Literature used: Machine parts and design fundamentals: textbook. for universities / G. I. Roshchin, E. A. Samoilov, N. A. Alekseeva and others; edited by G. I. Roshchin and E. A. Samoilova. - M.: Bustard, 2006. - 415, [1] p.: ill. - (Higher education).

Download abstract: You do not have access to download files from our server. HOW TO DOWNLOAD HERE

Archive password: privetstudent.com

Material of manufacture

The stability, reliability, and strength of a riveted joint are determined to a large extent by the material of the rivet. It also determines the convenience and efficiency of installation and the need to use additional tools or equipment. In most cases, low-carbon steel grades, copper, aluminum, and some other types of non-ferrous metals and alloys are used to make rivets.

Taking into account the characteristics of rivet joints, the rivet material must meet the following basic requirements:

- a sufficient level of ductility for riveting;

- comparable coefficient of thermal expansion from the materials of the elements being connected - eliminates the occurrence of additional stresses that lead to wear and destruction of the connecting unit;

- homogeneous chemical composition of the materials of the parts being connected (steel-steel, aluminum-aluminum, copper-copper, etc.) - prevents the formation of galvanic currents, which lead to intense corrosion of metals.

Correct selection of rivet material, along with compliance with installation technology and selection of dimensional characteristics of fasteners, is an important condition for the durability and reliability of the connection.

The material directly affects the installation technology of riveted joints. Riveting using steel rivets with a diameter of no more than 10 mm, as well as fasteners made of copper, aluminum, brass, and other light alloys, is done using a cold method. Installation of connections from steel rivets with a diameter of over 10 mm is carried out using a hot method in order to achieve the required ductility of the metal.

Types of rivet connections

In industry and construction, many types of rivets and connections made with their help are used. The classification of rivet joints is provided according to the following main criteria:

- Functional purpose.

- Seam design.

- Number of slices.

- Number of rows of rivets.

- Mortgage head shape.

- Shape of the rod.

According to their functional significance, strong, dense and combined types of rivet joints are distinguished. Durable connections are designed to withstand operating loads. Dense - maintain the tightness of the connecting unit. Combination rivets and riveted joints combine these functions. According to the design of the connecting seam, joints with an overlap and a butt seam are distinguished. The first type is the most common. When installing an overlapping seam, special overlays are used.

Based on the number of cut lines that pass through the rivet shaft under the influence of operational loads, single-cut and multi-cut types of rivet joints are distinguished. For multi-slice types, the number of cut lines is not limited.

Based on the number of rivet rows, there are single-row, double-row, three-row, etc. connecting units. The total number of rows is not limited by regulatory requirements. Depending on the shape of the embedded heads, there are the following types of rivets and riveted joints:

- semicircular;

- cylindrical;

- semi-secret;

- secret, etc.

Another important criterion is the shape and design of the rivet shank. The rods can be:

- solid - traditional type of rod without a hole;

- hollow - a through hole is made in the body of the rivet rod;

- semi-hollow - the rod is divided into two halves, one of which has a hole in it, and the second is solid.

The main regulatory document regulating the types of riveted joints, methods of their implementation, as well as their dimensional characteristics, is GOST 10303-68. In addition, there are several other GOSTs that regulate this area.

Types of rivet seams

Rivets Read more: Basic performance criteria when calculating machine parts

3. Types of rivet seams

The place where parts are connected with rivets is called a rivet seam, which are divided into three types [24].

A strong seam has several rows of rivets and is used for riveting beams, columns, bridges, etc.

A tight seam is used for hermetic structures (tanks not exposed to high pressures) under light loads. To seal the seam, use gaskets made of drying oil-impregnated paper or fabric. Riveting is done in a cold way.

A strong-tight seam is made by hot riveting using riveting machines, followed by embossing the rivet heads and the edges of the sheets. Riveted seams are divided into single-row, double-row and multi-row, and depending on the location of the rivets - into parallel and staggered [20].

In each riveted joint, the rivets are arranged in one, two or more rows.

In accordance with this, rivet seams are divided into single-row, double-row, multi-row, parallel and staggered (Fig. 4).

There are manual riveting, mechanized riveting, which uses pneumatic riveting hammers, and machine riveting, performed on single and group riveting presses.

For manual riveting, metalworker’s hammers with a square striker, supports, crimping, tensioning and chasing are used [19].

The weight of the hammer is selected depending on the diameter of the rivet.

The supports provide support when riveting the rivet rod. The shape and dimensions of the supports depend on the design of the parts being riveted and the diameter of the rivet rod, as well as on the selected riveting method (direct or reverse). The support should be 3-5 times more massive than the hammer.

The crimps are used to give the closing head of the rivet the required shape after upsetting. At one end of the crimp there is a recess in the shape of the head of the rivet.

Rice. 4. Rivet seams: a - single-row in an overlap connection; b - single-row in a butt joint; c - single-row in a butt joint with one overlay; g - double-row with a staggered arrangement of rivets in a butt joint with one plate

The tension is a barb with a hole at the end. Tension is used for upsetting sheets [7].

The embossing is a metalworking chisel with a flat working surface and is used to create a tightness of the rivet seam, achieved by crimping (countering) the closing head and the edge of the sheet.

There are two types of riveting: ordinary, when both rivet heads rise above the surfaces of the riveted parts, and hidden, when the rivet heads are hidden flush with the surfaces of the riveted parts. Parts made of high-quality steel are riveted with parts made of roofing steel using rivets with a diameter of 2...3 mm. In this case, the rivet heads should be located on a thinner part. The parts are connected with riveted seams in one or less often in two rows. The sheets to be joined are overlapped (Fig. 5).

Rice. 5. Riveted seams: a - lap joint with one row of rivets; b - lap joint with two rows of rivets; 1 - sheet; 2 - rivet; d - hole diameter

The pitch between the rivets of riveted sheets for single-row seams is made at least 3d. The distance from the center of the rivet to the edge of the parts to be joined should be 1.5d of the rivet shank. The diameter of the hole for the rivets is drilled 1/10 larger than the diameter of the rivet rod. When parts are blind riveted, the holes for the heads in the parts are countersunk at an angle of 60...90° to a depth equal to the height of the embedded head. The working operations of riveting (Fig. 6) are performed with the following tools: support 4, upsetting 1, crimping 6 and hammer 5 weighing no more than 0.3 kg.

Rice. 6. Working operations of riveting: a - upset of the joined sheets; b - riveting the rivet rod with a hammer; c - formation of the head; 1 - draft; 2 - rivet; 3 - riveted sheets; 4 - support; 5 - hammer; 6 - crimping

The support is intended for laying the embedded head of the rivet, therefore the surface of the support on which the embedded head rests must have a hole in the shape of the head. Upsetting serves to compact the riveted sheets 3, crimping serves to finalize the closing head of the left rivet. Riveting of parts begins with placing light rivets at the ends of the seam and several rivets symmetrically placed between the light rivets. The riveting process consists of the following operations: adjusting the riveted parts; marking parts for drilling holes in them for rivets; drilling holes (for blind riveting and countersinking); installation of rivets; settling of the riveted parts for a tight connection between them and one another and to the closing head of the rivet; final formation of the closing head by crimping [4].

Rivets Read more: Basic performance criteria when calculating machine parts

Information about the work “Calculation of rivet seams”

Section: Industry, production Number of characters with spaces: 47713 Number of tables: 0 Number of images: 16

Similar works

Connections of machine parts and assemblies

71478

1

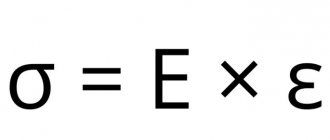

27

...bolt. Usually they assign σ0 = (0.4?0.7) σT. In order for connections to operate under design force conditions, it is necessary to control the tightening of connections. 14. Connections with interference The connection of machine parts with interference - the difference in landing dimensions - is carried out due to their preliminary deformation. With the help of tension, parts are usually connected to cylindrical and less often conical...

Rules for the design and safe operation of pressure vessels for nuclear energy facilities

136667

0

0

... vessels must include: an employee of the organization that owns the vessel, appointed by order of this organization to supervise the technical condition and operation of pressure vessels (hereinafter referred to as the supervisor); the person responsible for the good condition and safe operation of the vessels; other employees of the organization that owns the vessel and specialized organizations. ...

Horizontal oil settling tanks with partitions

50220

1

5

I settler OG-200S, which is most widely used in the fields both for preliminary dehydration of oil and at the stage of its dehydration and desalting. The horizontal settling tank OG-200S is a cylindrical tank mounted on a base frame (Figure 1). The settling tank is divided by a partition into two compartments: separation and settling, which are connected by two ...

Calculation of oil product losses

54378

3

13

... “small breaths” for 1 day: , where is the average mass content of gasoline vapors in the gas-air mixture; – volume of displaced steam-air mixture. Oil product losses from “small breaths” per month: . 3.2 Calculation of oil losses from “reverse exhalation” The volume of gas space after injection of an oil product is determined: where FH is the surface area of the oil product. 3.2.2 Determine the height...

Where are riveted joints used?

The use of rivets for a long time remained the most common method of installing permanent connections before the development of welding technologies reached a sufficiently high level. However, even now the use of rivet joints is widespread in many industries. As a rule, they are used to connect structural parts made of sheet materials - steel, non-ferrous metals, plastic, etc. Large diameter rivets are used to connect elements of profiled metal - channels, I-beams, angles and others.

Rivets create strong connecting units with increased resistance to vibration loads. Therefore, the main areas where rivet connections are mainly used are those areas in which critical structures are regularly exposed to vibration and repeated loads. They are also used in the automotive industry, aircraft manufacturing, shipbuilding, instrument making and other industries.

In addition, in mechanical engineering and construction, rivet joints are used in cases where welding cannot be used:

- the materials of the parts to be connected cannot be welded to each other;

- when welding there is a danger of surface warping;

- the use of welding can lead to the tempering of parts that have undergone heat treatment;

- the use of welding is difficult for structural reasons or due to special conditions for performing installation work.

There are a large number of varieties of riveted joints that have become widespread in certain industries when installing various structures.

Advantages and disadvantages of rivet fastening

Like any type of fastening elements, rivets have their advantages, thanks to which the scope of rivet joints remains quite wide, and disadvantages that limit their use. Let's look at their main advantages and disadvantages.

Advantages of rivet joints

Among the main advantages of riveted joints are the following:

- simplicity of technological execution of connecting units - no highly qualified personnel performing installation work are required;

- the ability to install complex assemblies - rivets allow you to connect two or more parts from different structural materials;

- the ability to connect non-weldable and dissimilar materials;

- no thermal effect on the materials of the parts being connected during installation - the technology allows you to connect elements for which the use of welding is unacceptable;

- high level of reliability, long service life of the assembly unit;

- increased resistance to vibration and repeated loads - the ability to install critical structures operated in difficult conditions.

Thanks to these advantages, rivet connections remain a relevant method of erecting structures, despite the available alternative technologies.

Disadvantages of riveted joints

At the same time, there are characteristic disadvantages of riveted joints, as a result of which their use is significantly reduced.

Main disadvantages:

- increased material consumption - rivets require increased metal consumption, which increases installation costs;

- increased labor intensity of installation work due to the need to complete the connection assembly;

- the need to use a special riveting tool;

- the need for a hot installation method for large diameter steel rivets;

- weakening of the structure and creation of additional stresses with a large number of holes for rivets;

- deformation of the rivet joint and rapid destruction if the hole diameter is incorrect.

Due to these disadvantages, rivet connections are rarely used if it is possible to install the structure using welding or threaded fasteners.

Rivet connections

Riveted joints consist of two or more sheets or parts connected (riveted) into a permanent structure using rivets

(Fig. 18).

Rivet

called a round rod that has a formed capping head

1

2

formed during the riveting process at its other end. In this case, the parts are strongly compressed, forming a strong, immovable, permanent connection. The shape and dimensions of the rivets are regulated by the standard (Fig. 19).

Rivet seam

called

a connection made by a group of rivets (

Fig. 20).

Rice. 18. Riveted connections

Rice. 19. Formation of a rivet seam

Rice. 20. Single row rivet connection

Holes for rivets in parts are pressed or drilled. When punching, small cracks form along the periphery of the holes. Cracks can cause the rivet seam to fail during operation. Punched holes are used in low-critical structures. Drilling is a low-productivity and expensive process. Drilled holes are used in structures where high reliability is required. For large hole diameters, punching followed by drilling is practiced.

Each rivet has its own zone of action D

, which is affected by compression deformation at the joint of parts. If the action zones of adjacent rivets intersect, the connection will be tight. Due to plastic deformations during the riveting process, the rivet shanks fill the holes and the rivets tighten the parts being connected. As a result, the relative shear of the riveted parts is resisted by both the rivet rods and the frictional forces arising at the joint surface.

To ensure the tightness of the seam, embossing (plastic deformation of sheets, for example, with pneumatic hammers) is sometimes performed around the rivets and along the edges of the sheets.

Rivets are supplied as finished products.

The rivet connection is obtained in the following way.

Rivets are inserted into the holes of the parts to be joined (see Fig. 19). Under the mortgage head 1

install support tool.

Using a special riveting machine or manually (with blows of a hammer, sledgehammer), the protruding end of the rivet ( ) is crimped into the closing head 2.

For steel rivets with mm, cold riveting is performed, the same applies to rivets made of non-ferrous metals and alloys; s mm with heating of the rivet to a light red heat (1000-1100 0C). This method ensures a higher quality of the rivet seam, since the rivets shorten as they cool and pull the parts together, creating large friction forces at the junction of their surfaces, which prevent the relative shift of the parts under load.

Diameters of holes for rivets dOTV

selected according to the standard depending on the diameter of the rivet. For cold riveting we can recommend

dOTB = d3 +

0,05

d3

,

for hot riveting

dOTB = d3 +

0,l

d3,

where d3 —

diameter of the rivet being installed.

Advantages and disadvantages of rivet joints compared to other types of permanent joints.

Advantages:

— high connection reliability;

— convenience of riveting quality control;

— increased resistance to shock and vibration loads;

— the ability to connect parts made of difficult-to-weld metals, such as aluminum;

— do not cause temperature deformations;

— parts are not destroyed during disassembly.

Flaws:

- high cost, since the process of obtaining a rivet seam consists of a large number of operations (marking, punching or drilling holes, heating the rivets, laying them, riveting) and requires the use of expensive equipment (machines, presses, riveting machines).

— increased material consumption for this connection (due to the weakening of the parts being connected by holes for rivets, an increase in their thickness, the use of overlays, etc.);

- parts are weakened by holes;

— high noise and shock loads during manufacturing;

— impossibility of connecting parts of complex configurations.

Application area.

Currently, due to the rapid development of welding, riveted joints have limited use (in structures for which welding and gluing methods are not yet sufficiently developed or ineffective, as well as in joints operating under high vibration or shock loads with high requirements for connection reliability) . Also in connections of final processed parts, in which the use of welding is unacceptable due to their warping when heated. A large volume of riveting and assembly work is carried out in the manufacture of aircraft. Some aircraft have more than a million rivets. Rivet joints are used in hoisting and transport machines, in the construction of railway bridges, boiler making, etc.

Classification.

Rivet seams are classified:

- according to their intended purpose - strong seams (bridge and crane trusses, aircraft, etc.), ensuring the strength of the connection, strong-tight (in boilers and tanks with high pressure), dense (in tanks with low internal pressure), ensuring strength and tightness;

- according to the relative position of the riveted parts - butt seams with one or two overlays (see Fig. 18) and overlapping seams (see Fig. 19);

- by the number of rows (for butt seams the number of rows is taken into account on one side of the joint) - single-row (see Fig. 20) and multi-row (Fig. 21);

- according to the location of the rivets in the rows - parallel (Fig. 22) and checkerboard (Fig. 23) seams;

- according to working conditions (according to the number of cut planes) - single-cut seams - with one cut plane in each rivet (see Fig. 20, 22) and multi-cut seams - with several cut planes in each rivet (double-cut - see Fig. 18; 23) .

Rice. 21. Multi-row rivet connection

Fig.22. Multi-row rivet connection