Lanyard characteristics

Among the main technical and operational parameters, one can highlight the thread diameter, which determines the dimensions of all structural elements. The thicker the rod, the higher the loads the lanyard can handle. The characteristics of the device in terms of diameter are usually expressed in the metric system of measures - in the range from M8 to M20. Average values in specific quantities can be represented by a spectrum from 1/2 to 1 inch. In particular, a product with a 1/2-inch diameter can handle a load of about 680 kg.

The length of the device should also be taken into account. It most often depends proportionally on thickness, but there are exceptions. The average length is 20-50 cm. Again, this value will determine how wide the tension force adjustment range that the lanyard will allow. What is this from an operational point of view? The slinger will be able to control the rigidity of the cable tension through the lanyard mechanism. If, for example, he is handling a 15 cm device, then the range of adjustment will be minimal, while a length of 50 cm will give more options for adjusting the rigidity of the cargo fastener.

Operating parameters of lanyards

For the considered devices with couplings, the main operational characteristics are:

Permissible load. The length of the coupling (less commonly, its transverse dimensions). The length of the lanyard itself with the claws unscrewed (the threaded part does not come out of the coupling body, but completely fills it).

The standard defines an unambiguous relationship between the diameter of the threaded hole in the turnbuckle coupling and its load-bearing capacity. In particular, for stamped couplings the following relationships exist:

- with a load of up to 200 kg - M8;

- with a load of up to 300 kg - M10;

- with a load of up to 500 kg - M12;

- with a load of up to 1200 kg - M16;

- with a load of up to 2000 kg - M20;

- with a load of up to 3150 kg - M24, etc.

The maximum load-bearing capacity of a standard cargo lanyard with an open coupling is 6300 kg; if higher operational loads are required, the rigging is designed and manufactured according to individual orders. Closed turnbuckles are designed for a load capacity of up to 20,000 kg (with the exception of welded coupling structures, the load on which should not exceed 1,500 kg).

The load-carrying capacity of the lanyard is also determined by the type of cargo grip. The lowest permissible values are for hook-to-hook type grips, and the highest are for fork-fork type grips. The design of all components of the lanyard should not have stress concentrators, therefore, when transitioning from one part of the coupling, fork, hook, etc., the maximum possible radius transitions are provided.

The following mandatory requirements apply to standard lanyard designs:

- Strength category after stamping is not lower than KP25 according to GOST 8479;

- Lock nuts must be manufactured in accordance with GOST 5919 using cold heading methods. Thread grooves are not allowed;

- Metric threads on all parts must comply with the requirements of GOST 24705;

- Cast parts must be free of internal and external macrostructure defects (selective quality control must comply with the requirements of RD 34.17.402);

- Welded versions of couplings are performed using E42A electrodes with mandatory cleaning of finished seams.

- Steel lanyards have a surface anti-corrosion coating.

Requirements for lanyard parts

GOST 9690-71 provides the following options for the design of turnbuckle couplings:

Stamped closed couplings. Stamped open couplings. Cast couplings. Welded closed couplings. Welded open couplings.

In closed-type turnbuckles, the threaded part of the load element is completely located in the coupling body. This is considered safer, because if the gripping device suddenly breaks (which most often happens along the thread), its remains do not fly apart. Therefore, the maximum permissible tension force for closed lanyards is always greater than for open ones.

The manufacturing technology of the couplings also largely determines the capabilities of the lanyard. Thus, stamped couplings (the blanks for which are high-quality structural steel according to GOST 1050, steel grade 20 and higher) are strong and reliable. This is explained by the fact that the macrostructure of stamped products does not have cut fibers, and, therefore, there are no stress concentrators. The same is typical for cast couplings, however, the structure of the cast metal is coarser-grained, therefore, other things being equal, the body of a cast coupling will break faster than a stamped one.

Welded couplings have the worst load-bearing capacity: in the weld zone, the strength of the metal is reduced by 20...25% (for the same reason, it is strictly forbidden to restore damaged lanyards by welding).

The standard allows two designs of round turnbuckles: with a through hole in the middle of the body, and without it. In the first case, the conditions for rotation of the housing when tightening are improved, but the cross-section of the coupling is weakened. The starting material for such couplings is seamless steel pipes in accordance with GOST 8734 made of steel 25 (in low-critical turnbuckles, duralumin and ordinary quality steel St. 3 in accordance with GOST 380 can also be used).

For the compactness of coupling lanyards, the diameter of the cargo grips is important. In closed couplings it does not exceed M42, otherwise the coupling becomes heavy and difficult to adjust. Open type couplings do not have such restrictions.

Turnbuckle couplings are manufactured for the following types of grips:

BB (fork-fork). VU (fork-ring). UU (ring-ring). GG (hook-hook). VG (fork-hook). GU (hook-ring).

How to choose a lanyard?

When choosing a product, special attention should be paid to such a parameter as the maximum permissible load. If a lanyard is used to secure a load in a vertical position, then a large margin is required, approximately 600-900%.

Safety is also an important point. It is necessary to understand how securely the rope or cable grips the clamp.

IMPORTANT!

Design types with two hooks have the least safety.

When choosing, you should carefully study the product markings, which are indicated on the case or technical documentation; any certified product must have it.

In addition to the load, the size of the element must be taken into account. For example, if the installation will be carried out in cramped conditions. You also need to pay attention to the presence of anti-corrosion protection.

Before use, you need to check the lanyard as follows:

- Check if the threads match;

- Inspect for mechanical damage and deformation;

- Check for the absence of cracks and grooves.

IMPORTANT!

The kit must include lock nuts. Without them, the work of the lanyard may be meaningless, since under the influence of the load it will unwind.

GOSTs and other normative standardization documents

Requirements for lanyards are reflected in the standards:

- GOST 9690-71 - domestic standard;

- DIN 1748, DIN 1480 - European standards.

Operating principle and tension adjustment

Correct operation of the tensioners should ensure the simultaneous rotation of two screws in opposite directions. As soon as the tension reaches the permissible force, the process stops. The tension is easy to adjust. It can be loosened at any time without much physical effort.

Requirements for lanyard parts

In closed designs, the threads must be located in the coupling body. This option is safe, since if the gripping device is destroyed, it will not fly apart in all directions. That is why the permissible tension value for closed lanyards is greater.

The manufacturing technology of couplings is of great importance. Stamped couplings are more durable. And welded ones have the lowest load-bearing capacity.

Rules for using lanyards

The amount of force that acts on the mechanism during operation should not lead to deformation. If this happens, then you need to reduce the force and replace the damaged element. Before work, you need to know exactly the expected weight and select the part based on this. The load should only be along the axis line. Overload is not conducive to normal operation.

The product is not designed for lateral loads. Before use and immediately after, you need to check the fastening for compliance with safety standards, in order to avoid deformation. Before use, it is recommended to thoroughly rinse with gasoline, polish with a felt wheel and apply a protective lubricant containing molybdenum bisulfate and graphite additives. When used in difficult climatic conditions, periodically water with fresh water to wash off the salt. These simple recommendations will help you avoid getting stuck.

If the dimensions, loads are properly observed and maintenance is carried out in a timely manner, the lanyard will last a long time and cause a minimum of problems.

Lanyard device

Lanyard selection

Selecting a tool based on the expected load is a guarantee that it will not deform during operation. The tables that the seller has will help you do this, where the manufacturer indicates which model is designed for what. But the choice depends not only on the weight of the load, but also on the function.

The first parameter you need to pay attention to is the thread diameter. Screw fastening for M10, M8, M12, M20, M16, have different threads

The number following the letter “M” indicates the thread diameter in millimeters, M12 is a 12 mm thread. Marking T 10-01, T 30-01 indicates the load at which the part begins to collapse.

Lanyards are most often used when working outdoors, where they are exposed to moisture and temperature changes. Modern parts are not supplied without protection from such exposure; most often this is galvanizing.

GOST 9690-71

According to GOST 9690-71, there are the following types of lanyards:

- OS - with open coupling;

- OZ - with a closed coupling;

- ОШ - with a stamped coupling.

Types of lanyards:

- VU - fork-eye;

- BB - fork-fork;

- UU - ear-ear.

Lanyards manufactured in accordance with GOST 9690-71 are used on ships and other floating craft. OSH parts are made of carbon steel, in the following versions:

- VU - fork-eye;

- BB - fork-fork;

- УУ - ear-ear;

- VG - hook fork;

- GG - gak-kak;

- GU - gak-ear.

Lanyard OS are made of magnetic and carbon steels and come in the following versions:

- BB - fork-fork;

- УУ - ear-ear;

- VU - fork-eye.

ZS lanyard is made of steel with a high carbon content and in two types:

- BB - fork-fork;

- VG - fork-hook.

To protect against friction, graphite lubricant is applied to the surface of the rubbing elements. According to GOST, nuts are used to fix the position of the ears (forks). The main purpose of the part is to enhance linear tension. Do not use for lifting loads. When engaging the turnbuckle, there should be no loose turns on the coupling.

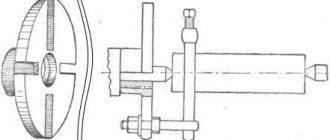

Ship lanyards OST 5.2314-79 (analogous to GOST 9690-71)

manufactures ship lanyards in accordance with OST5.2314-79 (analogous to GOST 9690-71) . GOST 9690-71 was canceled on January 1, 1981 and replaced by OST5R.2314-79. Ship lanyards are special technical devices made of carbon and low-magnetic steels, designed to adjust the degree of tension of chains, cables, and spacers. Turnbuckles allow you to increase or decrease this tension. A lanyard typically consists of a pair of screws that are counter-threaded, with hooks, forks, or rings on the outer ends. Screws are screwed into the housing with metal bushings at the ends. When the housing rotates, the screws move apart or move.

There are two ways to adjust the tension of the lanyards:

- by unscrewing from the coupling;

- by screwing.

The lanyard consists of:

- couplings with 2 threaded holes;

- two screws that are screwed into the coupling holes. Screw threads are multi-directional;

- There is also a fork, hook or ring at the ends of the screws. A cable is attached to this ring.

Features of ship lanyards

For lanyards made from carbon steels, semi-quiet and calm melt steel should be used; the materials of welded parts made of carbon steels should contain no more than 22% carbon. Forgings for lanyard parts must be normalized. The thread must be free of dents, marks and broken threads. Turnbuckle parts must have protective coatings, the type and thickness of the coating is in accordance with OST5.9048-71 (or according to the customer’s documentation). All rubbing surfaces of parts must be coated with graphite lubricant in accordance with GOST 3333-55. The presence of free turns of thread at the couplings of a loaded lanyard is not allowed. Average service life is 15 years. According to OST5.2314-79 (analogous to GOST 9690-71), turnbuckles must have forks (ears, hooks) to fix the position. To check the compliance of turnbuckles with the requirements of the standard, the manufacturer carries out acceptance and periodic tests. For acceptance tests, lanyards are presented in batches or individually. The batch must consist of lanyards of the same standard size, the same parts of which are made of material according to the same certificate. For acceptance tests, lanyards must be provided, the parts and assembly units of which have passed operational control for compliance with the requirements.

The coupling of each lanyard must be marked with:

- manufacturer's trademark

- permissible load, kN

- letters - “M” for lanyards made of low-magnetic steels

- month and year of testing

- lanyard serial number

- designation

- Register mark or company mark

Types of lanyards

Depending on the design or modification, these modern fasteners can be divided into the following types of lanyards:

fork-fork

(open stamped coupling, open welded coupling, closed welded coupling)

fork-ear

(open stamped coupling, open welded coupling)

ear-ear

(open stamped coupling, open welded coupling)

hook-hook

(open stamped coupling)

fork-hook

(open stamped coupling, closed welded coupling)

ear-hook

(open stamped coupling)

The lanyard is designed exclusively for axial or linear adjustment.

Standard sizes of lanyards

1. OS type

– lanyard with an open stamped coupling, made of carbon and low-magnetic steels in six versions:

| BB – with two forks (permissible load from 1 to 25 kN) | VU - with a fork and an eye (permissible load from 1 to 25 kN) | УУ - with two ears (permissible load from 1 to 25 kN) |

| GG – with two hooks (permissible load from 1 to 12 kN) | VG – with fork and hook (permissible load up to 1 to 12 kN) | GU – with hook and eye (permissible load from 1 to 12 kN) |

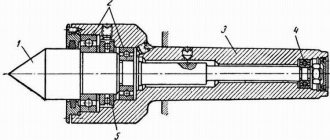

where: 1. open stamped coupling, 2. fork, 3. eye, 4. hook, 5. axle, 6. nut.

2. OS type

– lanyard with an open welded coupling, made of carbon and low-magnetic steels in three versions:

| BB – with two forks (permissible load from 20 to 200 kN) | VU - with a fork and an eye (permissible load from 20 to 200 kN) | УУ - with two ears (permissible load up to 20 to 200 kN) |

where: 1. open welded coupling, 2. fork, 3. eye, 4. axle, 6. nut.

3. Type ZS

– lanyard with a closed welded coupling, made of carbon and low-magnetic steels in two versions:

| VG – with fork and hook (permissible load from 1 to 16 kN) | BB – with two forks (permissible load from 1 to 16 kN) |

where: 1. open welded coupling, 2. fork, 3. hook, 4. axle, 6. nut.

Application of lanyards

Initially, a ship's lanyard was used on ships of the sailing fleet to remove slack in the rigging. Now it is widely used for tightening fastening cables during loading and securing cargo. This device is also indispensable when installing match fastenings, guy wires, and cable tension. In addition, the lanyard is used in construction and installation work. Tie lanyards are used as a fastening device when transporting cargo. If the load has a large mass, a lanyard with a chain is used for anchoring. When pulled, it gives a slight elongation. Its design is more reliable. Often such a device is used to install antennas, match, and secure them. In this case, the lanyard allows you to take up the slack that is inherent in steel cables and strings. All products have been tested for strength, fully comply with the standards established in the Russian Federation and have the required certificates.

Lanyard design

The standard design has three main components. This is a coupling and two threaded rods. The coupling can be closed or open - the choice on this basis depends on the conditions of use of the lanyard. A closed form is required in cases where there is a risk of mechanical damage or coarse sand getting into the mechanism.

The rods at both ends have devices for securing the load - this can be a ring or a hook. Both elements are screwed in from opposite sides along multidirectional threads, which increases the reliability of the mechanism. Usually, the lanyard is attached when it is disassembled. After hooking and fixing the load, the rods are brought together into a coupling with the necessary force. The material for all elements of the device is almost always high-strength stainless steel. Galvanized metal resists moisture, does not corrode and lasts longer under high loads. Another thing is that the formats and standard sizes of the structure can be different.

Manufacturers and prices

Models from domestic manufacturers are predominantly sold in this segment on the Russian market

In particular, the products of Sorokin, Zubr, Crepe-Comp, etc. receive attention from specialists

In terms of cost, the most affordable products are at the level of 300-400 rubles. These are products of small formats, often without special surface treatment at the production cycle stage. In the middle price segment, a lanyard for a cable costs 800-1000 rubles. Such devices are characterized by a high degree of reliability and a variety of configurations. The highest segment represents mechanisms with price tags of about 2 thousand. For this amount you can purchase a large-format lanyard for massive equipment that can withstand tens of tons of cargo.

Get the lanyard at the best price!

The Abtron company offers you to buy lanyards in St. Petersburg at very attractive prices for you! We work without any intermediaries and have a well-established structure of direct connections with our partners - world leaders in production in the segment of lifting and load-handling equipment. Plus, strict control at all stages of production and working with exclusively highly qualified specialists are some of the main factors that gave us a strong impetus in development.

From us you can purchase any model of GOST or DIN lanyard at quite reasonable prices, not exceeding the average market value. The entire wide range of this indispensable technical device for professional activities is presented in a convenient catalog for you. By purchasing a lanyard from us, you buy real European quality and the help of our specialists in choosing a device based on the characteristics you specify!

ATTENTION!

To clarify the price and delivery conditions, contact our online consultant or write to us. You can also immediately contact our office in the most accessible way for you. Dear customers, we remind you that delivery to the regions of Russia of the goods you have chosen is carried out by transport companies in St. Petersburg. delivers to the door of your chosen company for FREE.

Production technology

Ring-to-ring lanyard, hook-to-ring lanyard, fork-to-fork lanyard, and hook-to-hook lanyard devices operate under difficult operating conditions. This is due to the fact that when a load occurs, all elements work in tension, sometimes accompanied by bending.

It is also important that the force changes periodically over time, so the reliability and durability of the device also depends on the fatigue limit of the material

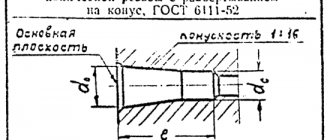

Standard sizes of ring-to-ring lanyard according to DIN 1480

The critical element of the drawing is the coupling. As a tensioner, it works under alternating loads. In addition, the frame structure of most standard couplings already contains stress concentrators at the transition points from the side posts to the threaded base. Therefore, these transitions in the drawings are designed in the form of radius curves, the diameter of which is determined by the overall dimensions of the assembled lanyard.

Ring-to-ring lanyard, hook-to-ring lanyard, fork-to-fork lanyard are never produced in welded versions. In addition, it is extremely undesirable to manufacture couplings by casting, even from high-quality structural steels (for example, from casting grade 45L according to GOST 977). The possibility of the presence of internal voids and cavities in the casting remains with any technological production option, which dangerously weakens the cross-section, especially at fastening points. The performance indicators of the milled versions should also be considered not very successful. During the machining process of the parts included in this assembly, the fibers of the metal macrostructure are cut, which reduces durability.

Hot stamping is considered the optimal method for producing parts included in the structure: during its course, plastic redistribution of the volumes of deformed metal occurs, while the fibers bend along the contour, maintaining the strength of the forging. During cold die forging, even hardening of the metal occurs, which makes it possible to produce devices from cheaper grades with a reduced carbon content (for example, from steel 20).

After stamping, the parts are subjected to heat treatment - normalization at 820...860 °C, followed by cooling in air. Quenching is carried out at the same temperatures of heating into oil. The final hardness should be in the range of 190…220 HB. For anti-corrosion protection, a galvanized lanyard is used.

International standardization of lanyards

The use of lanyards, especially large ones, implies extremely strong traction forces of tens of tons, therefore strict control is carried out over the quality of each part of the lanyard. Otherwise, at the slightest deformation of any element of the lanyard, an emergency situation may occur. All manufactured products are necessarily tested for quality standards: GOST 9690 71 (Russia, CIS), DIN 1480 and DIN 1478 (Germany).

Lanyard GOST

GOST lanyard designs are divided into the following types:

- ОШ - with an open stamped coupling.

- OS - with an open welded coupling.

- ZS - with a closed welded coupling.

In turn, all types of GOST lanyards differ in the types of their final fasteners:

- fork-fork lanyard;

- ring-ring lanyard;

- hook-hook lanyard;

- fork-ring lanyard;

- fork-hook lanyard;

- lanyard hook-ring.

These types of lanyards are made from high quality carbon steel and are then treated with a protective metal layer on top to prevent exposure to moisture and aggressive weather conditions. The shapes of the structures differ in volume (length of the coupling, screws and their working stroke), and in the size of the internal diameter of the thread of the holes in the coupling M6-M56.

The lanyard grade “M5-M36” indicates the thread diameter of the coupling holes.

In most cases, GOST lanyards are used in the shipbuilding industry, in the construction of bridges and high-rise buildings, as well as in such working industries that require tensioning of cables and wires, regulation of all kinds of guy wires.

Lanyard DIN 1480

DIN 1480 lanyards are made of high-quality steel S235JR or stainless steel A2 and A4, and comply with the established standards of the German DIN Institute, which is one of the world leaders in standardization. DIN lanyard can be with open or closed coupling. The steel structure of the device is additionally protected from external weather factors in the form of hot-dip galvanizing or galvanic coating. This type of lanyard is available with the following types of fasteners:

- ring-ring lanyard;

- hook-hook lanyard;

- lanyard ring-hook.

Just like the GOST lanyard, this technical device can have many modifications, differing in the length and width of the structure, weight, diameter of threaded screws, and permissible load (0.1-20 tf). There is a special type of DIN mini lanyard for home use, where it does not require much tensioning effort. Acid-resistant turnbuckles made of AISI 316 stainless steel with a closed body are used in environments where there is interaction with various acids and caustic substances.

Lanyard DIN 1480 is widely used for installation/dismantling work, for securing cargo during transportation, in construction work and in the operation of surface ships.

Lanyard with rod inside DIN 1478

This type of lanyard has a closed coupling and its main purpose is lifting work, which is why the DIN 1478 lanyard is also called a cargo lanyard. Lanyard fasteners basically look like this:

- fork-fork lanyard.

The lanyard is made of stainless steel with further surface galvanization to protect it from corrosion and aggression of weather conditions. Most often, this type of lanyard is used for lifting operations (lifting loads up to 20 tons), as well as for tensioning cables, chains and rigging devices.

Lanyard selection. Dimensions and specifications

The determining parameter for selection is the operating load, and for lanyards intended for fixing objects in a vertical position, as well as units such as elevators and lifts, such loads are determined with a margin of 600...900%.

For the safety of securing an object or load, the degree of coverage of the lanyard grip by the lanyard is also important. This is especially true for lanyards of the GG type, where the open part of the hook head does not prevent the load from slipping

The safest in this regard are fork-fork lanyards, in which the fastening pin is made of hardened steel and completely covers the hook of the sling.

The approximate maximum loads, depending on the standard size of the thread and the type of cargo grip - fork, eyelet and hook - are respectively, kg:

- for M6 – 100 and 40;

- for M8 – 200 and 80;

- for M10 – 500 and 150;

- for M12 – 2000 and 350;

- for M16 – 3000 and 700;

- for M20 – 4000 and 1000;

- for M24 – 6000 and 2000;

- for M30 – 10000 and 3000.

The choice of ratchet is made according to the chain caliber and its length:

- for 6 mm caliber the maximum load is 4000 kg;

- for caliber 8 mm - 6300 kg;

- for caliber 10 mm - 10,000 kg;

- for caliber 12 mm - 15000 kg;

- for caliber 16 mm - 20,000 kg.

The size and weight of the lanyards are also important. The manufacturer is obliged to certify the lanyards it produces, providing each product with relevant information about the limits of its safe use.

During constant and long-term operation, lanyards are subject to mandatory verification, which is carried out using the technology given in GOST 9690-71.

The price of lanyards depends on their design and load capacity. The price of coupling lanyards is in the range of 400...1500 rubles, ratchet - from 9000 to 16000 rubles.

Design

The insides of the part are not hidden, so it is more convenient to adjust the tension. The body is made by casting, forging or welding. And the holes for the screws are milled, they regulate the force. For difficult weather conditions, a closed type lanyard is used, which consists of three parts:

- Frame.

- Two screws (left and right thread).

- Screw heads (hook, fork and ring).

Each part of the device is precisely calibrated and will perform a specific function that meets the standards. International documents regulating the technical characteristics and production of lanyards - DIN 1480, DIN 1478. In the territory of the former USSR - GOST 9690-71.

PTR 7-1 lanyards (as these devices were previously called) helped keep steel ropes and cables under constant tension. But they did not have such a large number of heads, unlike modern models. There were oblong loops at the ends. The load for which the lanyard is designed was indicated in the name, based on the ton-force indicator. New models are designated by the parameter in kN. T 30-01, withstands 3 tf or 30 kN.

Types of screw lanyards

A screw lanyard consists of couplings with two screw holes and different thread directions. When the coupling is turned in one direction, the screws are screwed into the body, and in the other direction they are unscrewed. Thanks to this operating principle, you can easily change the length of the screed device.

The coupling body can be of open or closed type. Closed is used mainly in difficult operating conditions, for example, when icing or clogging with sand is possible.

Screw heads can be in the form:

- hook;

- forks;

- hairpins;

- rings.

There are also combinations of these types - fork-ring, hook-fork, etc. The tensioner with the fork-fork combination has the highest reliability indicator.

Stainless or galvanized?

Before choosing a lanyard, you need to take into account the external factors in which it will be used, as well as the degree of aggressive environmental influences.

If the work will take place in a dry room or for a short period of time outdoors, then a galvanized product will be suitable. But if the lanyard will be used most of the time outdoors or in places with high humidity, then closed-type stainless steel lanyards made of A2 steel are needed. In chemical plants, hot shops, swimming pools, etc., turnbuckles made of acid-resistant A4 steel are used.

What are cable-stayed fastenings (chain tensioners)

Chain tensioners or ratchets are cable-stayed fastenings with a hook-shaped grip. They are used to secure large and heavy loads with chains. Thanks to the presence of a lever or ratchet mechanism, a large tension can be created.

The chain tie is quite popular in the world, as it can be used to secure large loads. This manual mechanism is reliable and perfectly secures the load, which will not fall during transportation or move spontaneously.

Ratchet mechanism

A chain lanyard with this mechanism has rotation switches and two rotary hooks located at different ends of the structure. The principle of operation is that when the handle is turned, the hooks converge, thereby ensuring tension on the fastening chains.

Advantages of a ratchet type device:

- Easy to install into the fastening system;

- Does not require great physical effort during operation;

- There is no need to additionally fix the lever.

Lever tightening mechanism

Consists of 2 rotating gripping hooks, with the help of which the fastening chain is hooked and an eccentric lever. The tension of the chains is achieved by acting on the lever, which itself is clamped at the moment when it reaches maximum tension. The chain securely fixes the lever mechanism and prevents it from opening.

Advantages of this type of ratchet:

- Speed of installation;

- Simplicity;

- Small dimensions;

Types of rope clamps

Depending on the installation method and design, clamps are classified as:

- bolted;

- screw;

- wedge;

- pressed;

- canine;

- jammed.

All rope clamps are manufactured in compliance with GOST and DIN

U-clamp

This is a threaded u-bolt. The threaded elements are inserted into the compression structure and when the nuts are tightened, the cable is pressed against the bolt.

Tubular clamp

It consists of bushing clamps made of aluminum (for regular cables) or copper (for acid-resistant ones). For work in aggressive environments, stainless steel clamping products are used.

Basically, such clamps are used to connect cables to each other or to make loops at the ends of the cable. The tubular clamp is a one-time, non-removable element.

Flat cable clamp

Made from carbon steel. Comprises:

- pressure plate;

- screws;

- nuts with metric threads.

Based on the number of screws, there are single, double and triple clamps. The principle of operation is that as the nuts are tightened, the cable is clamped between the clamping elements.

Design and principle of operation of the lanyard

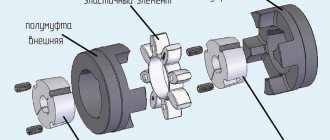

The device in question consists of four parts:

A cast or stamped coupling equipped with two threaded holes. The coupling can be in the form of a rectangular frame or an ellipse. Pairs of hooks or other load-handling elements (slings) with threads on the opposite part. Washers that distribute the load more evenly. Locking nuts that prevent spontaneous rotation of the grips.

A separate group consists of chain lanyards (ratchets), in which the tension occurs not due to the gradual screwing of the grips into the coupling, but due to the twisting of the tension chain located between the load grips. Chain lanyards are used when securing long loads on platforms. It consists of:

Chains (cable tensioner). Two slings. The tension mechanism, which, in turn, includes a ratchet and a shaft on which the ratchet wheel is mounted.

In simple designs of chain lanyards, instead of a ratchet, a lever is provided, the rocking movement of which removes slack in the chain tension.

The necessary fixing force is created due to the rotation of the slings. At the same time, the distance between them is reduced, the gaps are selected, and the tension of the held object between the lanyards is ensured.

Coupling turnbuckles are mainly used in pairs, which allows the tension force to be evenly distributed in the branches of the slings. The chain lanyard can be one-sided. The opposite end of such a lanyard is rigidly fixed to the supporting part of the platform. However, in this case, only the axial component of the tension force is perceived, which is why the ratchet cannot be used for lifting loads or holding objects in a vertical position.

Device and characteristics

The product consists of 4 elements, namely:

- Cast coupling having two threaded holes. It can be in the shape of an ellipse or a rectangular frame.

- Several elements for gripping loads (slings). Each of the elements is a rod with a thread on the opposite part. On these sides there is a head in the form of a fork, loop or hook.

- Washers, which are necessary to ensure that the current load is distributed evenly.

- Locking nuts that can prevent the tensioner from loosening on its own.

Classification and labeling

Since the lanyard is used in conditions of adverse atmospheric influences, the fasteners chosen are:

- Stainless steel;

- Made of galvanized metal.

Also, products are classified depending on the type of fastening at the ends of the screws:

- C+O (hook/ring);

- O+O (ring/ring);

- C+C (hook/hook).

FOR REFERENCE!

The ring hook type can be closed or open. Closed is used in most modern models; it is mainly used for securing fiber optic cables.

The lanyard marking contains information about the length and type of coupling, type of head, thread size, indicating the location of the left thread. The permissible load value is also indicated. The coating and type of construction is reflected in the technical documentation.

Material

To produce this fastener, only high quality steel is used. The product itself is produced by forging, then a protective layer is applied. This procedure is called “passivation” and is carried out by hot-dip galvanizing. Thanks to passivation, the fasteners are protected from corrosion and can be used for a long time in conditions of high humidity without loss of quality.

Couplings

Couplings are manufactured in three ways (GOST 9690-71):

- Welding;

- Casting;

- Stamping.

They also produce couplings of both open and closed types. Open type products can withstand up to 6.3t, and closed type - up to 20t.

Size and weight

Lanyard characteristics:

IMPORTANT!

The weight of a typical product depends on the material of construction and manufacturing methods.

Load capacity

The technical documentation for the product indicates its load capacity. It may depend on the type of gripping device.