Technical data

- Ball screw drives, pdf, English, volume -4.41 MB:

- Instructions for the ball screw, pdf file, volume 209 kb:

SNR produces rolled and ground ball screws (Ball Screws). A wide range of nuts, processing options and extensive technical knowledge allow us to design ball screws according to the special requests of our customers.

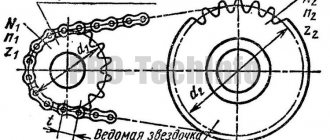

Ball-and-wound drives are used in a wide variety of industries, such as metalworking, woodworking, aircraft manufacturing, automatic assembly lines, and semiconductor manufacturing.

Stroke variation and tolerance

The accuracy classes of ball screws are determined in accordance with ISO 3408. The accuracy determines the maximum permissible deviation of the ball screw stroke per useful stroke lu. For accuracy classes t7-t10, the average deviation on a stroke is 300 mm in any part of the thread.

lu - useful stroke - this is the stroke plus the length of the ball nut le - run-out - this is the axial stroke beyond the useful stroke, which serves for safety. Limited stroke and rigidity tolerances for useful stroke are not used. lo - nominal stroke is the axial stroke of the nominal pitch multiplied by the number of rotations of the ball nut relative to the spindle C - user-defined useful stroke adjustment. The difference between the useful and actual stroke is determined by the user (standard c=0) ep - the upper and lower limits of the actual stroke form the accuracy ranges for the average stroke Vup - the permissible deviation of the useful stroke is higher than the useful stroke lu V300p - the permissible deviation for a stroke length of 300 mm V2πp - the permissible deflection per revolution

Permissible stroke deviations

| Screw length lu, mm | Accuracy class | ||||||||||

| T0 | T1 | T3 | T5 | T7 | T10 | ||||||

| from | before | ep | vu | ep | vu | ep | vu | ep | vu | ep | vu |

| 0 | 315 | 4 | 3.5 | 6 | 6 | 12 | 12 | 23 | 23 | 52 µm / 300 mm | 210 µm / 300 mm |

| 315 | 400 | 5 | 3.5 | 7 | 6 | 13 | 12 | 25 | 25 | ||

| 400 | 500 | 6 | 4 | 8 | 7 | 15 | 13 | 27 | 26 | ||

| 500 | 630 | 6 | 4 | 9 | 7 | 16 | 14 | 32 | 29 | ||

| 630 | 800 | 7 | 5 | 10 | 8 | 18 | 16 | 36 | 31 | ||

| 800 | 1000 | 8 | 6 | 11 | 9 | 21 | 17 | 40 | 34 | ||

| 1000 | 1250 | 9 | 6 | 13 | 10 | 24 | 19 | 47 | 39 | ||

| 1250 | 1600 | 11 | 7 | 15 | 11 | 29 | 22 | 55 | 44 | ||

| 1600 | 2000 | — | — | 18 | 13 | 35 | 25 | 65 | 51 | ||

| 2000 | 2500 | — | — | 22 | 15 | 41 | 29 | 78 | 59 | ||

| 2500 | 3150 | — | — | 26 | 17 | 50 | 34 | 96 | 69 | ||

| 3150 | 4000 | — | — | 32 | 21 | 62 | 41 | 115 | 82 | ||

| 4000 | 5000 | — | — | — | — | 76 | 49 | 140 | 99 | ||

| 5000 | 6300 | — | — | — | — | — | — | 170 | 119 | ||

Tolerance for stroke changes within an interval of 300 mm (international standards)

| Accuracy class | T0 | T1 | T3 | T5 | T7 | T10 |

| e300 DIN, ISO | 3.5 | 6 | 12 | 23 | 52 | 210 |

| e300 JIS B 1192 | 3.5 | 5 | 8 | 18 | 50 | 210 |

| e2π | 3 | 4 | 6 | 8 | — | — |

Operating test and bearing strength test according to ISO 3408-3

Measuring the radial runout t5 of the outer diameter of the shaft on the segment l5 to determine straightness with respect to AA'

| Nominal diameter d0v mm | I5 | t5p in µm/interval I5 | ||||||

| accuracy class | ||||||||

| from | before | 0 | 1 | 3 | 5 | 7 | 10 | |

| 6 | 12 | 80 | 16 | 20 | 25 | 32 | 40 | 80 |

| 12 | 25 | 160 | ||||||

| 25 | 50 | 315 | ||||||

| 50 | 100 | 630 | ||||||

| 100 | 200 | 1250 | ||||||

| Nominal diameter I1/d0 | t5max in µm/I1>4*15 | ||||||

| From | before | 0 | 1 | 3 | 5 | 7 | 10 |

| — | 40 | 32 | 40 | 50 | 64 | 80 | 160 |

| 40 | 60 | 48 | 60 | 75 | 96 | 120 | 240 |

| 60 | 80 | 80 | 100 | 125 | 160 | 200 | 400 |

| 80 | 100 | 128 | 160 | 200 | 256 | 320 | 640 |

Measurement of radial runout t6.1 of the support journals in relation to AA' at l6≤l. For length l6>l the condition must be satisfied

| Nominal diameter d0v mm | l in mm | t6.1p in µm/interval l | ||||||

| accuracy class | ||||||||

| from | before | 1 | 3 | 5 | 7 | 10 | ||

| 6 | 20 | 80 | 10 | 12 | 20 | 40 | 63 | |

| 20 | 50 | 125 | 12 | 16 | 25 | 50 | 80 | |

| 50 | 125 | 200 | 16 | 20 | 32 | 63 | 100 | |

| 125 | 200 | 315 | — | 25 | 40 | 80 | 125 | |

Measurement of radial runout t7.1 of the screw end journals in relation to the support journals for l7≤l. Suitable for length l7>l

| Nominal diameter d0v mm | l in mm | t7.1p in µm/interval l | ||||||

| accuracy class | ||||||||

| from | before | 1 | 3 | 5 | 7 | 10 | ||

| 6 | 20 | 80 | 5 | 6 | 8 | 12 | 16 | |

| 20 | 50 | 125 | 6 | 8 | 10 | 16 | 20 | |

| 50 | 125 | 200 | 8 | 10 | 12 | 20 | 25 | |

| 125 | 200 | 315 | — | 12 | 16 | 25 | 32 | |

End run-out t8.1 of the shoulder of the propeller support pin relative to the support pin.

| Nominal diameter d0v mm | t8.1p in µm | |||||

| accuracy class | ||||||

| from | before | 1 | 3 | 5 | 7 | 10 |

| 6 | 63 | 3 | 4 | 5 | 6 | 10 |

| 63 | 125 | 4 | 5 | 6 | 8 | 12 |

| 125 | 200 | — | 6 | 8 | 10 | 16 |

Axial runout t9 of the nut bearing surface in relation to AA' (only for preloaded ball nuts)

| Flange diameter D2v mm | t9p in µm | ||||||

| accuracy class | |||||||

| from | before | 0 | 1 | 3 | 5 | 7 | 10 |

| 16 | 32 | 8 | 10 | 12 | 16 | 20 | — |

| 32 | 63 | 10 | 12 | 16 | 20 | 25 | — |

| 63 | 125 | 12 | 16 | 20 | 25 | 32 | — |

| 125 | 250 | 16 | 20 | 25 | 32 | 40 | — |

| 250 | 500 | — | — | 32 | 40 | 50 | — |

Radial runout t10p of the outer diameter of the nut in relation to AA' (only for ball nuts with preload)

| Flange diameter D2v mm | t10p in µm | ||||||

| accuracy class | |||||||

| from | before | 0 | 1 | 3 | 5 | 7 | 10 |

| 16 | 32 | 8 | 10 | 12 | 16 | 20 | — |

| 32 | 63 | 10 | 12 | 16 | 20 | 25 | — |

| 63 | 125 | 12 | 16 | 20 | 25 | 32 | — |

| 125 | 250 | 16 | 20 | 25 | 32 | 40 | — |

| 250 | 500 | — | — | 32 | 40 | 50 | — |

Changing the parallelism t11 of the cylindrical nut relative to AA' (only for preloaded ball nuts)

| t11p in µm per 100 mm (cumulative) accuracy class | |||||

| 0 | 1 | 3 | 5 | 7 | 10 |

| 14 | 16 | 20 | 25 | 32 | — |

Tests for compliance with specifications 3408-3

Measuring the braking torque at the load Δ Tp

Braking torque via load Tpr

The ball screw torque required to turn the ball nut against the screw (or vice versa) without external load. Possible frictional moments due to the sealing element are not taken into account.

Total braking torque Tt

The torque required to turn a ball nut against a ball screw (or vice versa) without external load, including the frictional moment of the sealing elements

Torque Variation

Fluctuation value of a predetermined braking torque under preload. Positive or negative value relative to the average torque

Measurement method

Preload generates a dynamic friction torque between the nut and the threads in the ball screw. This is measured by moving the threaded spindle at a constant speed while the nut is held in place by a special locking device. The measured force F is used to calculate the braking torque of the threaded spindle.

| Average torque Tp0 [Nm] | Overall length [mm] | |||||||||||||

| Up to 4000 | From 4000 to 10000 | |||||||||||||

| 40 | (Thread length/screw diameter)≤40 | — | ||||||||||||

| ΔTpp (in % up to Tp0) accuracy class | ΔTpp (in % up to Tp0) accuracy class | ΔTpp (in % up to Tp0) accuracy class | ||||||||||||

| from | before | 0 | 1 | 3 | 5 | 7 | 0 | 1 | 3 | 5 | 7 | 3 | 5 | 7 |

| 0.2 | 0.4 | ± 30 % | ± 35 % | ± 40 % | ± 50 % | — | ± 40 % | ± 40 % | ± 50 % | ± 60 % | — | — | — | — |

| 0.4 | 0.6 | ± 25 % | ± 30 % | ± 35 % | ± 40 % | — | ± 35 % | ± 35 % | ± 40 % | ± 45 % | — | — | — | — |

| 0.6 | 1.0 | ± 20 % | ± 25 % | ± 30 % | ± 35 % | ± 40 % | ± 30 % | ± 30 % | ± 35 % | ± 40 % | ± 45 % | ± 40 % | ± 45 % | ± 50 % |

| 1.0 | 2.5 | ± 15 % | ± 20 % | ± 25 % | ± 30 % | ± 35 % | ± 25 % | ± 25 % | ± 30 % | ± 35 % | ± 40 % | ± 35 % | ± 40 % | ± 45 % |

| 2.5 | 6.3 | ± 10 % | ± 15 % | ± 20 % | ± 25 % | ± 30 % | ± 20 % | ± 20 % | ± 25 % | ± 30 % | ± 35 % | ± 30 % | ± 35 % | ± 40 % |

| 6.3 | 10 | — | — | ± 15 % | ± 20 % | ± 30 % | — | — | ± 20 % | ± 25 % | ± 35 % | ± 25 % | ± 30 % | ± 35 % |

Principle of operation

The screw is driven into rotation by a drive electric motor, the nut is fixedly fixed on the working part of the machine (support, carriage, spindle head, steady rest, and so on). In this case, an axial force arises acting on the balls located inside the nut, under the influence of which they begin to roll in closed helical grooves. The reaction force acts on the nut, and since it is rigidly connected to the part being moved, it forces the latter to move along the guides of the machine. What is the difference between the operation of a ball screw and a conventional screw drive with trapezoidal threads, which was previously used on machine tools?

- 1. When the lead screw of the previous design rotated, sliding friction arose in the contact zone of the two parts, characterized by a friction coefficient (bronze on steel, lubricated) f = 0.07–0.1. In a mechanism with ball elements, rolling friction operates with a coefficient f = 0.0015–0.006. As can be seen from the given values, helical ball gears require significantly less drive motor power.

- 2. To accurately position the carriage or support of the machine, before stopping the working element, it is necessary to slow down the speed of its movement. Upon reaching a certain minimum speed threshold, micro-stops—sticking—of the moving unit are possible. At the moment of resumption of movement, its character is determined by static friction, which during sliding significantly exceeds the friction of movement. This causes jerks that impair positioning accuracy. With rolling friction, this disadvantage is practically reduced to zero.

Axial clearance and interference

Through interference, the ball screw gap is eliminated and rigidity increases. Moreover, the positioning accuracy of the ball screw is also improved. The tension of a single nut is achieved by installing balls of selected sizes. Double nut tension is created by pulling two nuts against each other.

Table 1 Combination of axial clearance and interference

| Symbol | 0 | 1 | 2 | 3 | 4 |

| Axial clearance | Yes | No | No | No | No |

| Preload | No | No | easy | average | high |

| % of dynamic maximum permissible load | — | — | ~3 | ~5 | ~7 |

table 2

| C.I. | S.K. | S.C. | DC | S.U. | D.U. | S.E. | |

| 0 | * | * | * | * | * | * | * |

| 1 | * | * | * | * | * | * | * |

| 2 | * | * | * | * | * | ||

| 3 | * | * | |||||

| 4 | * | * |

Combination of axial clearance 0

Table 3

| Spindle diameter | Axial clearance of screwed ball screw |

| 04-14 | 0.05 |

| 15-40 | 0.08 |

| 50-100 | 0.12 |

High-speed or high-speed ball screws

High-speed ball screw

An increase in the speed of movement of the nut relative to the screw is achieved by increasing the pitch between the grooves, compared to a standard screw, by 3-5 times; for a conventional transmission ball screw with a diameter of 16-32mm, the pitch is 5-10mm, for a high-speed gear of the same diameters - 16-32mm and a multiple screw diameter.

Due to an increase in movement speed, there is a loss in rigidity and maximum load on the transmission (to a greater extent) and accuracy (to a lesser extent).

Critical ball screw rotation speed

Like any torsion shaft, the ball screw has a critical speed, which is harmonic oscillation. Constantly rotating the ball screw within the critical speed range will shorten the operating period and may affect the performance of the machine. The critical speed is a function of the ball screw diameter, length, and mounting configuration. The axial clearance of the nut does not affect the critical speed nk.

The operating speed should not exceed 80% of the critical speed. The formula below for calculating the permissible nkzyl speed takes into account this safety factor of 0.8.

,where Nk – critical speed (rpm) Nkzyl – operating rotation speed (rpm) α – safety factor (=0.8) E – elastic modulus (E=2.06*105 N/mm2) l – geometric moment of inertia (mm2) d2 – diameter of the ball screw rod (mm) γ – specific density of the material (7.6*10 -5 N/mm3) g – constant value of earth’s gravity (9.8*10 3 mm/s2) A – cross-section of the ball screw (mm2) lk – unsupported length between two bodies f – installation correction factor

| Floating – floating | λ=3.14 | f=9.7 |

| Hard - floating | λ=3.927 | f=15.1 |

| Hard - hard | λ=4.730 | f=21.9 |

| Hard - loose | λ=1.875 | f=3.4 |

The maximum permissible speed of the ball screw is limited.

For SC/DC nuts d0*nkzyl≤120 000

For CI, SK, SU/DU, SE nuts d0*nkzyl≤90 000, where d0 is the central diameter of the spindle, mm

Please contact our engineers if the required speed exceeds DN, or if the ball screw is used at higher speeds.

Permissible axial load for the propeller (longitudinal stability)

Like other screws, ball screws can withstand a limited axial load. If the load exceeds the maximum permissible values, this leads to damage to the screw. The permissible axial compression is a functional dependence of the length, diameter and type of mounting of the screw. The maximum compressive load should be 50% or less of the theoretically permissible load. The calculation using the formula below takes this safety factor into account.

, where Fk – theoretical maximum permissible axial load Fkzyl – maximum permissible working axial load α – Safety factor (=0.5) E – elasticity modulus ( E = 2.06*10 5 N/mm2) l – geometric moment of inertia l= d2 – diameter of the ball screw rod (mm) lk – length without support m,N factor associated with

| Floating - floating | m=5.1 | N=1 |

| Hard - floating | m=10.2 | N=2 |

| Hard - hard | m=20.3 | N=4 |

| Hard - loose | m=1.3 | N=0.25 |

Application area

Ball screws are widely used in many industries: machine tool building, robotics, assembly lines and transport devices, complex automated systems, woodworking, automotive industry, medical equipment, nuclear energy, space and aviation industries, military equipment, precision measuring instruments and much more. Some examples of using these nodes:

- Feed drives for CNC machines. The first mass-produced machining center IR-500 in the USSR had 3 processing coordinates. Modern systems contain a significantly larger number of linear actuators. For example, Tornos multi-spindle longitudinal turning machines of the MULTI SWISS series have 14 controlled axes.

- Movement of the piston-rack of the steering mechanism of cars (MAZ, KAMAZ, Gazelle).

- Vertical movement of the carriage of the VECTORUS iPro and sPro series production 3D printer.

Basics of calculation

Average rotation speed and average load

If speed and load vary, life calculations should be made using average values of Fm and nm

For the average rotation speed nm, in case of speed changes, the following formulas apply:

where nm is the average speed, q is the fraction of time

For the average load Fm, in case of load changes, the following formula is used:

, where Fm – average load q – fraction of stroke or time at constant speed

For average load Fm, if rotation speed and load change, the formula applies:

where Fm is the average load q is the fraction of time nm is the average speed.

Nominal life

Resource L, expressed in number of revolutions:

L – resource, Fm average load, Сa – dynamic load

Resource expressed in hours Lh

Lh – life in hours L – life in revolutions nm – average rotation speed (rpm) ED – operating time (%)

Motor driving torque and external force

Drive torque Mta To convert rotary motion into reciprocating motion:

Drive torque Mte for converting reciprocating motion into rotary motion

where Mta – drive torque (Nm) Mte – resistance moment (Nm) F – working load (kN) P – pitch (mm) η – efficiency (about 0.9) η' – efficiency (about 0.8)

When using double preload nuts, the idle torque must be taken into account:

Drive power Pa

Pa – drive power Mta – drive torque n – rotation speed

Ball screw drives (ballscrews). Basic theoretical information.

Material provided by the site "Designer's Handbook"

Ball screws (ball screws)

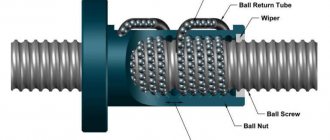

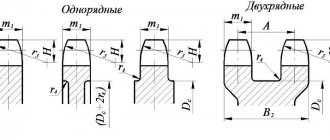

A ball screw (ball screw) consists of a screw and a nut and is used to convert rotational motion into linear motion. In the ball screw, screw 7 and nut 2 have helical grooves (threads) of a curved profile, which serve as raceways for balls placed between the turns of the screw and nut (Fig. 1). The most widely used threads are those with a semicircular profile. In this case, rotation of the nut secured against axial movements causes translational movement of the screw, or rotation of the screw secured against axial movements leads to translational movement of the nut. Basic geometric parameters of the transmission: nominal diameter d

0

,

i.e.

the diameter of the location of the centers of the rolling elements, the pitch P

of the thread and the diameter

D

ω of the rolling elements (usually

Dω = 0.6P).

The main advantages of a ball screw:

- the ability to create large axial forces;

- low friction losses (transmission efficiency 0.9 and above);

- the ability to obtain translational movement with high accuracy;

- small dimensions with high load-bearing capacity;

- significant resource.

The disadvantages include the complexity of the nut design, the need for high manufacturing precision and good protection of the transmission from contamination. Ball screws are used

in precision movement mechanisms, in tracking systems and in critical power transmissions (machine tools, robotics, aviation and space technology, nuclear energy, press-forging equipment, etc.).

Device and principle of operation.

When the screw rotates, the balls are drawn into motion along the screw grooves, progressively move the nut and, rolling out of the thread, return to their original position through the bypass channel (return channel).

Thus, the movement of the balls occurs along a closed circuit inside the nut. The most common ball screw design is one in which the return channel connects two adjacent turns.

Ball screw with preload.

In order to eliminate the axial gap in the screw-nut interface and thereby increase the axial rigidity and accuracy of movement of the driven element, the ball screw is assembled with

preload.

For a transmission with a semicircular thread profile, the interference is created by installing two nuts followed by their relative axial displacement. The relative displacement of the nuts is carried out by installing spacers between them or by their relative angular rotation. The thread profile and nut design (ball return channel, tension adjustment, etc.) are determined by the manufacturer.

ACCURACY STANDARDS

According to their accuracy parameters, ball screws are divided into positional and transport

(OST 2 R31-7-88). Positional ball screws allow indirect measurement of axial displacement depending on the angle of rotation and thread stroke of the screw. In transport ball screws, displacements are measured directly using a separate measuring system that does not depend on the angle of rotation of the screw. The kinematic and geometric accuracy classes of ball screws must comply with OST 2 RZ 1-4-88. According to this standard, accuracy classes are established for positional (P) and transport (T) ball screws, respectively: P1, PZ, P5, P7 and T1, TZ, T5, T7, T9. T10.

Kinematic accuracy

Ball screws are characterized by the kinematic error of the screw pair - the difference between the actual and nominal axial displacements of one of the mating parts of the screw pair in their relative motion.

The largest kinematic error is understood as the largest algebraic difference in the values of the kinematic error of the screw pair within a given length of axial movement. The dependence of the kinematic error of the screw pair on the nominal axial displacement is shown in Fig. 2. The deviation of the kinematic error over the entire measured length l

and thread should not exceed the permissible value

e

p

.

V

300r - width of the oscillation band of the kinematic error within 300 mm of the measured thread length;

V

2πр is the width of the deviation band of kinematic error pulsations within one revolution, i.e.

within the thread stroke P

h.

The permissible values of standardized indicators (Tables 5 and 6) are regulated by OST 2 RZ1-4-88, which takes into account ISO requirements.

5. Acceptable values of indicators V

300r and

V

2πr, mm

| Index | Accuracy class | |||||

| P1,T1 | PZ, TZ | P5.T5 | P7,T7 | T9 | T10 | |

| V 300rub | 0,006 | 0,012 | 0,023 | 0,052 | 0,100 | 0,210 |

| V 2πр | 0,004 | 0,006 | 0,008 | 0,012 | — | — |

MAIN CHARACTERISTICS OF BALL SCREWS

According to OST 2 R31-5-89, the quality of materials, processing and assembly of ball screws must comply with GOST 7599-82, and for export deliveries - OST2 N06-1-86. Radial clearance

between the screw and the nut before creating preload for a ball screw with a semicircular profile must correspond to the values given in the table. 8. Radial clearance is measured when the assembled nut is displaced in the radial direction under the influence of a force exceeding the gravity of the nut by 1.5-2 times. The measuring tip of the indicator should touch the outer surface of the nut.

8. Ball screw radial clearance before preload is created

| Nominal diameter d 0 | Thread pitch R , mm | Radial clearance, mm | |

| maximum | minimum | ||

| 16 | 2,5 | 0,020/- | 0,056/- |

| 25 | 5,0 | 0,093/0,107 | 0,067/0,073 |

| 25 | 10,0 | 0,170/0,170 | 0,110/0,113 |

| 32 | 5,0 | 0,096/0,110 | 0,064/0,075 |

| 32 | 10,0 | 0,170/0,171 | 0,110/0,112 |

| 40 | 5,0 | 0,096/0,110 | 0,064/0,072 |

| 40 | 6,0 | 0,101/0,113 | 0,059/0,065 |

| 40 | 10,0 | 0,161/0,173 | 0,119/0,126 |

| 50 | 5,0 | 0,101/0,110 | 0,059/0,061 |

| 50 | 10,0 | 0,163/0,175 | 0,117/0,125 |

| 50 | 12,0 | 0,183/0,197 | 0,137/0,146 |

| 63 | 10,0 | 0,165/0,177 | 0,115/0,123 |

| 80 | 10,0 | 0,167/0,179 | 0,113/0,121 |

| 80 | 20,0 | 0,247/0,273 | 0,193/0,211 |

| 100 | 10,0 | 0,170/0,192 | 0,110/0,118 |

| 100 | 20,0 | 0,250/0,276 | 0,180/0,198 |

| 125 | 20,0 | 0,422/0,430 | 0,338/0,350 |

Note. The denominator shows the radial clearance values for screws with relief grooves (Fig. 1.6). Axial rigidity.

Axial stiffness is understood as the ratio of the axial force applied to the nut group acting on the transmission to its axial movement relative to the screw, provided that the screw does not rotate.

The axial stiffness values must be no less than the values given in table. 9 and 10. When measuring stiffness, the body of the nut group and the screw are kept from turning. A measuring device is attached to the screw, allowing simultaneous measurements of the displacement of the housing (nut) relative to the screw at three points evenly spaced around the circumference using linear displacement sensors. An axial force F is applied to the screw.

The values of the force

F

applied to the screw when determining the axial stiffness are given in table.

11. Load capacity.

The values of dynamic

C

a and static

C

0a load capacities, as well as the minimum and maximum values of the ball screw idling moment

T

xx are given in table.

12. Ball screws are characterized by a basic static axial load capacity C

0a and a basic dynamic axial

C

a.

Basic static axial load capacity C

0a

is

the static axial force (N) that causes a total permanent plastic deformation of the ball, screw grooves and nut equal to 0.0001 times the ball diameter.

9. Axial rigidity of housing ball screws

| Nominal diameter d0 , mm | Thread pitch R, mm | Stiffness for accuracy classes, N/µm | |||||

| P1 T1 | PZ TZ | P5 T5 | P7 T7 | — T9 | — T10 | ||

| 25 32 | 5 5 | 500 700 | 460 650 | 420 590 | 400 560 | — | — |

| 40 | 5 6 10 | 950 830 740 | 880 770 680 | 800 705 620 | 760 660 590 | — — — | — — — |

| 50 | 5 10 12 | 1250 1000 900 | 1150 920 825 | 1050 840 750 | 990 800 705 | — — — | — — — |

| 63 | 10 | 1350 | 1260 | 1150 | 1100 | — | — |

| 80 | 10 20 | 1700 1450 | 1570 1360 | 1430 1240 | 1350 1180 | — — | — — |

| 100 | 10 20 | 2200 2100 | 2040 1950 | 1860 1780 | 1770 1700 | — — | — — |

Notes: 1. Stiffness for accuracy classes T9 and T10 is not regulated. 2. For versions with one nut, the rigidity is not regulated, for versions with two - according to the values given in the table (in this case, the nuts are enclosed in a technological housing).

10. Axial rigidity of frameless ball screws

| Nominal diameter d0 , mm | Thread pitch R, mm | Stiffness for accuracy classes, N/µm | |||||

| P1 T1 | PZ TZ | P5 T5 | P7 T7 | — T9 | — T10 | ||

| 16 | 2,5 | 230 | 215 | 200 | 190 | — | — |

| 25 | 5 10 | 560 460 | 540 440 | 490 400 | 460 380 | — — | — — |

| 32 | 5 10 | 760 610 | 730 590 | 665 535 | 630 500 | — — | — — |

| 40 | 5 10 | 1050 820 | 1000 780 | 950 715 | 900 680 | — — | — — |

| 50 | 5 10 | 1250 1100 | 1200 1050 | 1100 980 | 1050 930 | — — | — — |

| 63 | 10 | 1550 | 1500 | 1370 | 1300 | — | — |

| 80 | 10 20 | 1900 1650 | 1800 1580 | 1650 1440 | 1570 1370 | — — | — — |

| 100 | 10 20 | 2450 2350 | 2350 2250 | 2150 2075 | 2050 1970 | — — | — — |

| 125 | 20 | 2850 | 2750 | 2525 | 2400 | — | — |

Note. The rigidity for accuracy classes T9 and T10 is not regulated.

11. Values of axial force F

when determining the rigidity of a ball screw

| Size d 0 x P, mm | F , kN | Standard size d 0 x | F , kH |

| 16x2.5 | 0,5 | 50x10 | 3,75 |

| 25x5 | 1,6 | 50x12 | 6,9 |

| 25x10 | 3,0 | 63x10 | 7,5 |

| 32x5 | 2,3 | 80x10 | 9,15 |

| 32x10 | 2,5 | 80x20 | 12,0 |

| 40x5 | 4,6 | 100x10 | 15,0 |

| 40x6 | 3,0 | 100x20 | 25,95 |

| 40x10 | 3,25 | 125x20 | 40,0 |

| 50x5 | 4,85 |

12. Main characteristics of ball screws

| Size d 0 x P, mm | Load capacity, N | Тхх, N m | ||

| static C0a | dynamic Ca | min | max | |

| 16x2.5 | 9600 | 5000 | 0,05 | 0,20 |

| 25x5 | 28100 | 16580 | 0,08 | 0,32 |

| 25x10 | 48800 | 46400 | 0,11 | 0,35 |

| 32x5 | 37500 | 17710 | 0,18 | 0,56 |

| 32x10 | 65000 | 49800 | 0,22 | 0,60 |

| 40x5 | 49400 | 19170 | 0,30 | 0,84 |

| 40x6 | 56400 | 23700 | 0,32 | 0,83 |

| 40x10 | 85900 | 54700 | 0,45 | 0,95 |

| 50x5 | 62800 | 20640 | 0,50 | 1,35 |

| 50x10 | 112500 | 57750 | 0,48 | 1,23 |

| 50x12 | 119900 | 65400 | 0,49 | 1,09 |

| 63x10 | 149700 | 62030 | 0,75 | 2,03 |

| 80x10 | 197700 | 66880 | 1,23 | 3,25 |

| 80x20 | 297600 | 143400 | 2,30 | 3,88 |

| 100x10 | 251100 | 71840 | 2,04 | 5,20 |

| 100x20 | 386400 | 151800 | 2,75 | 5,23 |

| 125x20 | 729000 | 278000 | 2,80 | 5,50 |

Note. The given values for case ball screws correspond to versions II, III and IV. Basic dynamic axial load capacity Ca is the axial force (N) that the ball screw can support with a basic life of 1 million screw revolutions. Basic load capacities correspond to gears made of commonly used steels [1, 3]. If the properties of the material differ from the usual ones, and also depending on the accuracy class, hardness of the working surfaces, etc., the value of the corrected static C

0

ar

and adjusted dynamic

Car

load capacity:

С

0

ar =

K0

С

0

а

and

С ar = KСa,

where

Ko

and

K are

correction factors (see p. 798).

The idle torque is measured in a controlled gear installed in the centers of the stand, with the screw rotating at a frequency of 100 min-1. All parameters in table. 9-12 are indicated for ball screws with three-circuit nuts. For ball screws with nuts with the number of circuits 1, 2, 4, 5 or 6, the values of axial stiffness and static load capacity should be reduced by 3; 1.5; 0.75; 0.6 or 0.5 times respectively. The dynamic load ratings must be reduced by 2.57; 1.42; 0.78; 0.64 or 0.55 times respectively. In ball screws with liners installed in the nut windows using orientation elements that combine the return channel with the nut thread in the contact area of the balls with the nut, the dynamic load capacity is 1.02 times higher, and the durability is 1.06 times higher. The values of the critical axial force must comply with OST 2 N62-6-85. Ball screw with preload.

In order to eliminate the axial gap in the screw-nut interface and thereby increase the axial rigidity and accuracy of movement of the driven element, the ball screw is assembled with

preload.

Gears used in machine tool construction are carried out with interference;

they consist of two nuts, each of which has three working turns. Bypass channels in special liners connect two adjacent turns. The balls in this case are divided into three circulating groups. The thread profile is semicircular.

The tension is created by the relative axial displacement of the nuts, which is carried out

by installing spacers

between them or by their relative

angular rotation.

In the latter case, the connection of the nuts to the body is made using gear couplings, in which the outer teeth are cut on the flanges of the nuts, and the inner teeth are cut on the body.

The numbers of coupling teeth differ by one, which allows the nut to be rotated relative to one another by a small angle, causing an axial displacement of a very small amount. If the number of teeth on the flange of one of the nuts is z

, and on the flange of the other (

z

+1), then turning both nuts in one direction by

k

teeth leads at a step

P

to their axial displacement by Δ = Pk / [

z

(

z

+ 1) ] For example, with

z

=92,

P

=10 mm and

k

=1 we have Δ =1.2 µm. The nuts are turned outside the screw on a special mandrel - a pipe with an outer diameter equal to the inner diameter of the screw thread along the recesses, after which the nuts together with the body are screwed onto the screw.

TECHNICAL REQUIREMENTS

Technical requirements for the main parts of ball screws used in machine tool construction are established by OST 2 R31-5-89 (Table 13). Screw accuracy standards are according to OST2 R31-4-88.

13. Technical requirements for the main parts of the ball screw

| the name of detail | Material | Hardness of working surfaces HRCе, | Parameter Ra, µm, working surface roughness, no more |

| Screw | Steel 8ХФ GOST 5950-73 Steel 8ХФВД TU 3-213-84 | 59-63 | 0,63 |

| screw | Steel 9ХС GOST 5950-73 Steel ШХ15 GOST 801-78 | 59-63 | 0,63 |

| Earbuds | Steel 9ХС GOST 5950-73 Steel 40Х GOST 4543-71 Iron powder PZhV 3.160.24 GOST 9849-86 | 40-50 | 2,5 |

| Balloons | Steel ШХ 15 GOST 801-78 | 63-67 | 0,040 |

Notes: 1. Heat treatment according to RTM2 MT11-1-81. 2. For balls, accuracy level 20 according to GOST 3722-81. 3. The difference in size of the balls in one gear is no more than 0.001 mm 4. The deviation of the average diameter of the balls at D

ω < 5 mm – ±0.0025 mm;

2) D

ω ≥ 5 mm ±0.0050 mm Screws are also made from steel grades KhVG and 7G2VM with volumetric hardening, steel grade 8KhV with hardening by induction heating, steel grade 20KhZMVF with nitriding. For nuts, steel grade KhVG with volumetric hardening and case-hardened steel grades 18KhGT, 12KhNZA, 12Kh2N4A are used. The balls are made of chromium steel grade ШХ20СГ. The materials of the screw, nut and rolling elements must ensure the hardness of the working surfaces is not lower than 61 NKSe. During assembly, the nut cavity is filled with plastic lubricant brand CIATIM-201 or CIATIM-203. Transmissions require good protection against contamination. The most commonly used are harmonica-shaped bellows, telescopic casings and dirt removers - plastic sealing nuts with two or three convex turns along the profile of the grooves. Contaminant removers are attached to each end of the main nut.

NOMENCLATURE OF QUALITY INDICATORS

The range of quality indicators used in assessing the quality level of ball screws used in metal and woodworking machines, sections, lines, complexes, industrial robots and press-forging equipment is established by OST 2 RZ1-6-87. Classification groups.

The following groups of ball screws are distinguished: with preload;

without preload (gears with clearance). The nomenclature of product quality indicators, designations and characterized properties must correspond to those given in table. 14. The same table provides data on the applicability of ball screw quality indicators in scientific and technical documentation. The corresponding signs mean: “+” - applicability; “±”—limited applicability; “-”—inapplicability of the quality indicator. For gears with interference, indicators 1.4, 1.5, 1.7 and 1.11 are basic, indicator 1.10 is not used, indicators 1.3, 1.8, 1.9 and 1.12 have limited applicability. For gears with a gap, the main indicators are 1.4, 1.10, indicators 1.5-1.9, 1.11 are not used, indicator 1.3 has limited applicability. The range of quality indicators can be supplemented or modified by introducing other quality indicators that reflect design features or clarify the indicators given in Table. 14. Thus, the indicators of technical efficiency can be the indicators e

p,

V

ir,

V

zоor,

V

2πр of kinematic accuracy, characterizing the accuracy (instability) of positioning, and the indicator of economical use of energy is the efficiency

r\,

characterizing the efficiency of energy use.

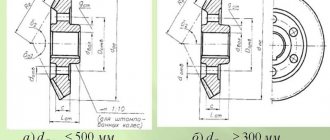

Mounting a nut on a screw

If ball screws and ball nuts are shipped separately, the screws must be installed by qualified personnel. Ball nuts must be mounted using a mandrel only. You can use the mandrel included with the ball screw. It is necessary to align the beginning of the screw thread to avoid damaging the seal and internal parts of the nut.

As standard, SNR ball screws are delivered with a nut installed. Dismantling the nut and spindle is not allowed (especially for preloaded nuts).

Note:

Ground ball screws with single or double nut are always shipped with the nut mounted, as are rolled screws with double nut.

Installation is carried out as follows:

Screw the nut onto the thread with light axial pressure. Then screw the nut down the entire length of the screw. Remove the mandrel only when the nut is completely screwed on. Secure the nut to prevent loosening. (use a rubber gasket or fix the support in the direction of the axis)

Important:

Use only original balls!

What to do, if…

Did the balls fly off while screwing the ball screw nut?

- Assemble the balls (the nut is only compatible with original balls) Loading power is ensured even when two or three balls are missing

- Carefully clean all components

- Use the mandrel as a mounting aid

- Put the balls back

- Start with the bottom stroke. Insert the balls into the circumference of the nut, the mandrel protects the balls from falling inside

Important:

Do not place idling balls between two baffles.