Varieties

There are three large groups, we will tell you more about each of them below.

Radial

Between two cages with technological grooves there are rolling elements in one or two rows, fixed in the cage. All this must be lubricated or covered with a protective casing to prevent dirt from entering.

A similar model is where the outer hoop is processed from the inside into a hemisphere, but the axis of the housing hole and the rotation shaft are not fixed. This technical solution is used in agricultural machinery when it is impossible or impractical to combine the planes of rotation and fastening. They are called floating.

Radial ball single row bearing, table of sizes and series

| ISO | Analogue GOST | Inner diameter(mm) | External mm | Width(mm) | Weight(kg) |

| 691 | 1000091 | 1 | 4 | 1,6 | 0,0001 |

| 602 | 12 | 2 | 7 | 2,8 | 0,0006 |

The parameters range from three millimeters to several meters. Internal holes make it possible to achieve rotation of the axes from 1 ml, this is used in micromechanics (hand and wall clocks, printers, scanners, measuring instruments, computers, disk drives, coolers). One and a half meter turning points work on heavy mining equipment (excavators, loaders, tunneling machines), on screw drives in shipbuilding, anywhere where large masses are required to be moved.

Supporting

For high loads along the axis of rotation, parts are used that consist of two washers with a groove, between which a separator with spheres is placed. One of the rotation planes rests on the block, and the second surface is fixed on the shaft. They are used in the manufacturing industry, wind turbines and other structures where longitudinal loads exist.

Table of dimensions of thrust ball bearings in millimeters

| Named. ISO | Russia GOST | Parameters in mm dw dg Dg T | Tonnage (Kn)Dyn. Stat. | Weight |

| 54202 | 48202 | 10 17 32 24 | 16,6 24,6 | 0,088 |

| 54205 | 38405 | 5 27 60 45 | 55,6 89,4 | 0,63 |

| 52205 | 38205 | 20 27 47 28 | 27,6 50 | 0,22 |

| 54406 | 48406 | 20 30 70 52 | 72,8 125 | 1 |

Such devices work on the A-pillars of cars and allow the entire rotating unit to move smoothly, constantly supporting the entire weight of the car. Manipulation of the crane boom is ensured by support on a similar product. The junction of a semi-trailer and a heavy-duty tractor also operates on the same principle. In an industry where it is necessary to use strong impacts on materials, not a single machine can do without thrust units.

Support-radial

In cases where it is necessary to provide properties of two types in the model, this mechanism is used. The reaction of the rolling elements is directed both perpendicularly and along the axis. The design can be single or double row.

Due to the combination of multidirectional reactions to force, a product consisting of two such parts provides complete fixation in space. When designing, you can get by with one compact device. The structural features allow for long-term operation without maintenance. Accordingly, the final cost of the product is reduced.

All the types described above are in the trade and production catalogue.

Dimensions of balls in the bearing

1. By providing his personal data when registering on the site, the User gives the Operator his consent to the processing and use of his personal data in accordance with Federal Law No. 152-FZ “On Personal Data” dated July 27, 2006 in various ways for the purposes specified in these Rules.

2. Personal data means any information relating to a directly or indirectly identified or identifiable individual (subject of personal data) and which can be used to identify a specific person or communicate with him.

3. Personal data of Users is stored exclusively on electronic media and processed using automated systems

4. The Operator uses the User’s personal data for the purposes of: - registering the User on the Site; — receipt by the User of the requested information about the Operator’s services; — the User receives personalized advertising; — to fulfill its obligations to the User.

5. The Operator undertakes not to disclose information received from the User. At the same time, disclosure of information is not considered a violation of obligations in the case where the obligation for such disclosure is established by the requirements of the current legislation of the Russian Federation.

6. The processing of the User’s personal data is carried out without a time limit, in any legal way, including in personal data information systems using automation tools or without the use of such tools

7. The Operator blocks personal data relating to the relevant User from the moment of application or request from the User or his legal representative or the authorized body for the protection of the rights of personal data subjects for the period of verification, in the event of detection of unreliable personal data or unlawful actions.

8. The user’s personal data is destroyed when:

— the User’s own deletion of data from his personal page using the “delete account” functionality available to the User using profile settings; — removal by the Operator of information posted by the User, as well as the User’s personal page in cases established by the purchase and sale agreement (offer); — when the subject of personal data withdraws consent to the processing of personal data.

Preparation method

The main difficulty in production is the high requirements for precision processing of parts. Therefore, if assembly can be carried out by almost all organizations, the production of external races and rolling elements is always carried out at large specialized factories.

The process consists of:

- • Material preparation (quality check, rejection). Here parts that have flaws are removed: microcracks, cavities and foreign inclusions.

- • Formation of blanks. Washers are cut from round timber using a special automatic device, after which they are fed to a press, where a ring is obtained. Then they are sent for rolling and brought to sizes that roughly match the final sample. For each specific case, different molding mandrels are used. The result is a blank that roughly replicates the final product, only a little larger.

- • Machining by turning. The process involves specific machines with program numerical control. Human participation is reduced to a minimum, while the number of defects is reduced. Here the product is brought to the required parameters, achieving an accuracy of one hundred microns or higher.

- • Sanding. The operation allows you to achieve an accuracy of ten Mk or less. The surface acquires a characteristic glossy appearance, necessary for unhindered sliding.

- • Hardening. After this stage, the required performance qualities are achieved. The workpiece is subjected to heating and cooling according to the technological map. In other cases, cementation is used using high-frequency current, then the hardness will be non-uniform.

- • Labeling. Apply with a laser device or similar to welding.

- • Inspection by the Technical Control Department (QCD). In particularly critical batches, parts of the samples are subjected to random testing.

Materials for production

When equipment operates, all elements are subject to constant loads, such as mechanical deformation and friction. Therefore, there are a number of strict requirements for the raw materials used. The final product must meet a whole list of qualities:

- • abrasion resistance;

- • ability to maintain caliber;

- • hardness;

- • viscosity;

- • ability to resist repeated deformations.

High-carbon chromium steel is used as the starting material. It is equally good for both cages and the rolling element. But there are cases when the unit is operated under conditions of repeated shock loads. In this option, the parts are made from iron with a low carbon content. The creation of a hard surface is achieved by subsequent saturation. The result is a mechanism with a rigid outer layer and a viscous middle.

The main materials are steel:

- • chromium ShKh 15, 15 ST, 20 ST, ShKh 4;

- • cemented 18ХГТ, 20Х2Н4А, 15 Г 1, 15Х, 08, 10.

Bronze, aluminum, cast iron and plastic can be used to produce separators. This is due to the fact that the main problem is the friction of the rolling element against the race during operation. Deformation loads between these parts are insignificant. This device is designed to distribute evenly around the perimeter of the hoop.

Materials

GOST 3722-81 allows for the production of structural bearing elements from chromium-carbon steel of the ShKh15 variety. When the buyer requires a ball with other characteristics (in particular, hardness), from other materials, it is produced individually. They use ШХ4, 95Х18,12Х18, etc.

The process requires the use of high-quality steel wire. We are talking about chromium or molybdenum-silicon steel.

Low-carbon steel is needed to produce hunting shot or for special-purpose products; the use of refractory steel is encouraged: brass, aluminum, copper, and other polyamide and polymer materials.

The latest research is extremely interesting, which has made it possible to obtain an innovative synthetic base - silicon nitride. This synthetic ceramic is a separate type characterized by self-reinforcement.

Marking of spheres for ball bearings, their sizes and interpretation

The main value is the diameter, designated in the tables by the letter d. The industry produces models with dimensions from 0.25 to 150 mm.

To make it easier to work with friction-reducing units, the parameters of the links have been unified. The industry produces them in a strictly defined format. According to the accuracy class, the product is marked with numbers: 3; 5; 10; 16; 20; 28; 40; 60; 100; 200, which indicate the level of processing. The lower the value, the rougher the execution.

The standard weight is calculated from the steel density of 7.85 kilograms per decimeter. The letter H is placed in the marking before the linear gauge, in cases of use in standard rolling mechanisms. In other versions, the abbreviation B is used.

The size table for ball diameters of ball radial and roller bearings is given below

| Distance in mm | In inches | Weight 1000 pcs in kg |

| 0,300 | — | 0,00011 |

| 0,400 | — | 0,00026 |

| 0,600 | — | 0,00089 |

| 0,680 | — | 0,00129 |

Balls GOST 3722-81

STATE STANDARD OF THE USSR UNION Rolling bearings BALLS GOST 3722-81 ST SEV 1990-79)

This standard applies to balls used in rolling bearings and as separate parts.

The standard fully complies with ST SEV 1990-79.

1. MAIN DIMENSIONS 1.1. The dimensions and weight of the balls must correspond to the values indicated in the table. 1.

| Nominal ball diameter Dw | Weight 1000 pcs., kg ~ | Nominal ball diameter Dw | Weight 1000 pcs., kg ~ | Nominal ball diameter Dw | Weight 1000 pcs., kg ~ | Nominal ball diameter Dw | Weight 1000 pcs., kg ~ | ||||

| mm | Inch | mm | Inch | mm | Inch | mm | Inch | ||||

| 0,250 | — | 0,00008 | 6,000 | — | 0,887 | 19,000 | — | 28,2 | 45,000 | — | 374 |

| 0,300 | — | 0,00011 | 6,350 | 1/4 | 1,050 | 19,050 | 3/4 | 28,4 | 46,038 | 1 13/16 | 401 |

| 0,360 | — | 0,00016 | 6,500 | — | 1,130 | 19,844 | 25/32 | 32,1 | 47,625 | 1 7/8 | 444 |

| 0,397 | 1/64 | 0,00025 | 6,747 | 17/64 | 1,260 | 20,000 | — | 32,9 | 49,212 | 1 15/16 | 490 |

| 0,400 | — | 0,00026 | 7,000 | — | 1,410 | 20,638 | 13/16 | 36,1 | 50,000 | — | 514 |

| 0,500 | — | 0,00051 | 7,144 | 9/32 | 1,500 | 21,000 | — | 38,0 | 50,800 | 2 | 539 |

| 0,508 | — | 0,00054 | 7,500 | — | 1,730 | 21,431 | 27/32 | 40,4 | 52,388 | 2 1/16 | 591 |

| 0,600 | — | 0,00089 | 7,541 | 19/64 | 1,760 | 22,000 | — | 43,8 | 53,975 | 2 1/8 | 646 |

| 0,635 | — | 0,00105 | 7,938 | 5/16 | 2,060 | 22,225 | 7/8 | 45,1 | 55,000 | — | 684 |

| 0,680 | — | 0,00129 | 8,000 | — | 2,100 | 23,000 | — | 50,0 | 57,150 | 2 1/4 | 767 |

| 0,700 | — | 0,00141 | 8,334 | — | 2,380 | 23,019 | 29/32 | 50,1 | 60,000 | — | 887 |

| 0,794 | 1/32 | 0,00206 | 8,500 | — | 2,520 | 23,812 | 15/16 | 55,5 | 60,325 | 2 3/8 | 902 |

| 0,800 | — | 0,00210 | 8,731 | 11/32 | 2,730 | 24,000 | — | 56,8 | 61,912 | 2 7/16 | 975 |

| 0,840 | — | 0,00243 | 9,000 | — | 3,000 | 24,606 | 31/32 | 61,2 | 63,500 | 2 1/2 | 1052 |

| 0,850 | — | 0,00252 | 9,128 | 23/64 | 3,120 | 25,000 | — | 64,2 | 65,000 | — | 1128 |

| 1,000 | — | 0,00411 | 9,525 | 3/8 | 3,550 | 25,400 | 1 | 67,3 | 66,675 | 2 5/8 | 1218 |

| 1,191 | 3/64 | 0,00694 | 9,922 | 25/64 | 4,010 | 26,000 | — | 72,2 | 69,850 | 2 3/4 | 1400 |

| 1,200 | — | 0,00710 | 10,000 | — | 4,110 | 26,194 | 1 1/32 | 73,8 | 73,025 | 2 7/8 | 1600 |

| 1,300 | — | 0,00903 | 10,319 | 13/32 | 4,510 | 26,988 | 1 1/16 | 80,8 | 75,000 | — | 1733 |

| 1,500 | — | 0,0139 | 10,716 | 27/64 | 5,060 | 27,781 | 1 3/32 | 88,1 | 76,200 | 3 | 1818 |

| 1,588 | 1/16 | 0,0164 | 11,000 | — | 5,470 | 28,000 | — | 90,2 | 79,375 | 3 1/8 | 2054 |

| 1,984 | 5/64 | 0,0321 | 11,112 | 7/16 | 5,640 | 28,570 | 1 1/8 | 95,8 | 80,000 | — | 2103 |

| 2,000 | — | 0,0329 | 11,500 | — | 6,250 | 30,000 | — | 111 | 82,550 | 3 1/4 | 2311 |

| 2,381 | 3/32 | 0,0554 | 11,509 | 29/64 | 6,260 | 30,162 | 1 3/16 | 113 | 85,725 | 3 3/8 | 2588 |

| 2,500 | — | 0,0642 | 11,906 | 15/32 | 6,930 | 31,750 | 1 1/4 | 132 | 88,900 | 3 1/2 | 2886 |

| 2,778 | 7/64 | 0,0881 | 12,000 | — | 7,100 | 32,000 | — | 135 | 90,000 | — | 2995 |

| 3,000 | — | 0,111 | 12,303 | 31/64 | 7,650 | 32,544 | 1 9/32 | 142 | 92,075 | 3 5/8 | 3207 |

| 3,175 | 1/8 | 0,132 | 12,700 | 1/2 | 8,420 | 33,338 | 1 5/16 | 152 | 95,250 | 3 3/4 | 3550 |

| 3,500 | — | 0,176 | 13,000 | — | 9,030 | 34,000 | — | 162 | 98,425 | 3 7/8 | 3917 |

| 3,572 | 9/64 | 0,187 | 13,494 | 17/32 | 10,100 | 34,925 | 1 3/8 | 175 | 100,000 | — | 4108 |

| 3,969 | 5/32 | 0,257 | 14,000 | — | 11,300 | 35,000 | — | 176 | 101,600 | 4 | 4308 |

| 4,000 | — | 0,263 | 14,288 | 9/16 | 12,000 | 35,719 | 1 13/32 | 187 | 104,775 | 4 1/8 | 4725 |

| 4,366 | 11/64 | 0,342 | 15,000 | — | 13,900 | 36,000 | — | 192 | 107,950 | 4 1/4 | 5168 |

| 4,500 | — | 0,374 | 15,081 | 19/32 | 14,100 | 36,512 | 1 7/16 | 200 | 108,000 | — | 5175 |

| 4,763 | 3/16 | 0,444 | 15,875 | 5/8 | 16,400 | 38,000 | — | 225 | 110,000 | — | 5468 |

| 5,000 | — | 0,514 | 16,000 | — | 16,800 | 38,100 | 1 1/2 | 227 | 111,125 | 4 3/8 | 5637 |

| 5,159 | 13/16 | 0,564 | 16,669 | 21/32 | 19,000 | 39,688 | 1 9/16 | 257 | 114,300 | 4 1/2 | 6134 |

| 5,500 | — | 0,684 | 17,000 | — | 20,200 | 40,000 | — | 263 | 120,000 | — | 7100 |

| 5,556 | 7/32 | 0,705 | 17,462 | 11/16 | 21,900 | 41,275 | 1 5/8 | 289 | 127,000 | — | 8415 |

| 5,800 | — | 0,802 | 18,000 | — | 24,000 | 42,862 | 1 11/16 | 324 | 150,000 | — | 13865 |

| 5,953 | 15/64 | 0,867 | 18,256 | 23/32 | 25,000 | 44,450 | 1 3/4 | 361 | |||

1.2. The designation of balls used as individual parts must consist of the nominal diameter in millimeters, the degree of accuracy and the designation of this standard. The symbol for balls used in rolling bearings is supplemented by the letter H, placed before the designation of the nominal diameter. The symbol for balls that are not sorted by diameter is supplemented with the letter B before the designation of the nominal diameter. The deviation of the average diameter, the different sizes of balls in diameter in a batch, the variability of the unit diameter, the deviation from the spherical shape (without taking into account waviness) and the surface roughness should not exceed the values specified in the table.

| Degree of accuracy | Nominal ball diameter Dw, mm | Deviation of the average diameter of balls used as individual parts Dwm | Variation in the size of balls in diameter in the VDwL pariah | Variability of unit diameter VDws | Deviation from the spherical norm | Surface roughness | |

| Ra | Rz | ||||||

| µm, no more | |||||||

| 3 | From 0.25 to 12 | ± 5 | 0,13 | 0,08 | 0,08 | — | 0,100 |

| 5 | » 0,25 » 12 | ± 5 | 0,25 | 0,13 | 0,13 | 0,020 | 0,100 |

| 10 | » 0,25 » 25 | ± 9 | 0,50 | 0,25 | 0,25 | 0,020 | 0,100 |

| 16 | » 0,25 » 25 | ± 10 | 0,80 | 0,40 | 0,40 | 0,032 | 0,160 |

| 20 | » 0,25 » 38 | ± 10 | 1,00 | 0,50 | 0,50 | 0,040 | 0,200 |

| 28 | » 0,25 » 38 | ± 12 | 1,40 | 0,70 | 0,70 | 0,050 | 0,250 |

| 40 | » 0,25 » 50 | ± 16 | 2,00 | 1,00 | 1,00 | 0,080 | 0,400 |

| 60 | » 0,25 » 80 | ± 30 | 3,00 | 1,50 | 1,50 | 0,100 | 0,500 |

| 100 | » 0,25 » 120 | ± 40 | 5,00 | 2,50 | 2,50 | 0,125 | 0,600 |

| 200 | » 0,25 » 150 | ± 60 | 10,00 | 5,00 | 5,00 | 0,200 | 0,800 |

Notes:

1. Roughness values Rz are established for balls of the 3rd degree of accuracy of all diameters; for balls of other degrees of accuracy with Dw < 3 mm. 2. At the customer’s request, it is allowed to produce balls used in the form of separate parts with maximum deviations that differ from those indicated in the table.

Characteristic

They are divided into groups according to design features and areas of application. Each sample has its own parameters:

- • Dimensions include the size of the shaft and fit, the width of the holder.

- • Weight depends on the version.

- • Degree of protection (open, partially closed, completely sealed).

- • Permissible loads.

- • Possible revolutions.

Most of the information is encrypted in the markings. For example, a radial single row is signed like this:

- • the first field indicates the width;

- • variety in design;

- • configuration;

- • number 0;

- • data on diameters;

- • shaft fit standard.

Additional letters indicate technical features, such as row row and separator material.

Short cylindrical rollers GOST 22696

In the sorting attribute: letter D

rollers not sorted by length are designated by the letter

B

; rollers not sorted by diameter and length are designated.

For short cylindrical rollers, 6 degrees of accuracy are established: I, II, IIA, III, IIIA, IV.

The measure of accuracy of short cylindrical rollers is influenced by the following values: - maximum deviations of the average diameter of the roller - variation in the size of the rollers by diameter in a batch - variability of diameter - variation in length - maximum deviations of the length of the rollers - cutting - taper - end runout

Table of ball bearings by size, how to choose them

You can get detailed information on the trade and production website. They provide a wide range of similar products.

| ISO name | Russia analogue of GOST | Rolling distance | Number |

| 608 | 18 | 3,97 | 6 |

| 624 | 24 | 2,38 | 6 |

| 627 | 27 | 3,97 | 7 |

| 693 | 1000093 | 1,58 | 6 |

| 698 | 1000098 | 3 | 8 |

| 6001 | 101 | 4,76 | 8 |

Metal Ball Usage Chart

| Caliber in mm | Marking | Number of peas in pieces |

| 1,587 | 13; 60113; 80213; 1060393; 1080093 | 6 |

| 33; 60223; 80123; 160023; 180023 | 7 | |

| 2,381 | 24; 60424; 80024; 160024; 180324 | 6 |

| 1000096; 1060096; 1080096 | 8 | |

| 1000802; | 12 | |

| 3,500 | 1002099; 1063099; 1080499 | 7 |

| 1050903 | 11 | |

| 1, 300 | 2003083 | 7 |

| 1006084 | 9 | |

| 2,000 | 1007094; 1060394; 1980494 | 7 |

| 1007095; 1060695; 1080595 | 8 | |

| 1007088 | 10 |

Parameters, characteristics and dimensions of ball bearings in the table.

| Type name | Marking | d | D | b | r | Weight, kg) |

| 60000 | 80000 | 3 | 10 | 4 | 0,3 | 0,002 |

| 60025 | 80025 | 5 | 16 | 0,5 | 0.006/td> | |

| 600200 | 80200 | 10 | 30 | 9 | 1,0 | 0,032 |

| 60203 | 80203 | 17 | 40 | 12 | 1,0 | 0,065 |

| 60205 | 80205 | 25 | 52 | 15 | 1,5 | 0,125 |

| 6027 | 8027 | 35 | 72 | 17 | 2,0 | 0,290 |

Application of balls in rolling bearings

Ball size table - nominal diameter D. Weight per 1000 pcs. kg

| D, mm | weight 1000pcs, kg |

| 0,25 | 0.00006 kg. |

| 0,3 | 0.00011 kg. |

| 0,36 | 0.00016 kg. |

| 0,397 | 0.00025 kg. |

| 0,4 | 0.00026 kg. |

| 0,5 | 0.00051 kg. |

| 0,508 | 0.00054 kg. |

| 0,6 | 0.00089 kg. |

| 0,635 | 0.00105 kg. |

| 0,68 | 0.00129 kg. |

| 0,7 | 0.00141 kg. |

| 0,794 | 0.00206 kg. |

| 0,8 | 0.0021 kg. |

| 0,84 | 0.00243 kg. |

| 0,85 | 0.00252 kg. |

| 1 | 0.00411 kg. |

| 1,191 | 0.00694 kg. |

| 1,2 | 0.0071 kg. |

| 1,3 | 0.00903 kg. |

| 1,5 | 0.0139 kg. |

| 1,588 | 0.0164 kg. |

| 1,984 | 0.0321 kg. |

| 2 | 0.0329 kg. |

| 2,381 | 0.0554 kg. |

| 2,5 | 0.0642 kg. |

| 2,778 | 0.0881 kg. |

| 3 | 0.111 kg. |

| 3,175 | 0.132 kg. |

| 3,5 | 0.176 kg. |

| 3,572 | 0.187 kg. |

| 3,969 | 0.257 kg. |

| 4 | 0.263 kg. |

| 4,366 | 0.342 kg. |

| D, mm | weight 1000pcs, kg |

| 4,5 | 0.374 kg. |

| 4,763 | 0.444 kg. |

| 5 | 0.514 kg. |

| 5,159 | 0.564 kg. |

| 5,5 | 0.684 kg. |

| 5,556 | 0.705 kg. |

| 5,8 | 0.802 kg. |

| 5,953 | 0.867 kg. |

| 6 | 0.887 kg. |

| 6,35 | 1.05 kg. |

| 6,5 | 1.13 kg. |

| 6,747 | 1.26 kg. |

| 7 | 1.41 kg. |

| 7,144 | 1.5 kg. |

| 7,5 | 1.73 kg. |

| 7,541 | 1.76 kg. |

| 7,938 | 2.06 kg. |

| 8 | 2.1 kg. |

| 8,334 | 2.38 kg. |

| 8,5 | 2.52 kg. |

| 8,731 | 2.73 kg. |

| 9 | 3 kg. |

| 9,128 | 3.12 kg. |

| 9,525 | 3.55 kg. |

| 9,922 | 4.01 kg. |

| 10 | 4.11 kg. |

| 10,319 | 4.51 kg. |

| 10,716 | 5.06 kg. |

| 11 | 5.47 kg. |

| 11,112 | 5.64 kg. |

| 11,5 | 6.25 kg. |

| 11,509 | 6.26 kg. |

| 11,906 | 6.93 kg. |

Scope of application

This node is widespread. Wherever the shaft rotates, one type or another is used. It allows you to extend service life, reduce friction losses and prevent overheating. Depending on the application conditions, the grease for ball bearings also differs.

Open models are used inside mechanisms, usually in the presence of liquid oils, such as Nigrol, Litol, Avtol. Lubrication and cooling occurs due to circulation within the structure. Closed models are supplied from factories already processed and refractory. In special cases, graphite is used, which has the property of reducing friction.

How to disassemble a spherical ball bearing: video

At first glance, it is not clear how the rolling elements can get between the races. In fact, the process goes like this:

- The separator is removed. Usually the two halves are fastened with rivets, which are removed by drilling.

- After this, the remaining insides are rolled close to each other and the ring is freely removed.

The radial support device allows you to remove two halves of the hoop. The floating one is easily separated after removing a few metal peas. This is achieved by extending the antennae that hold them in place. In samples with a bronze divider, a special technological hole is made, from which dismantling begins.

How different types of ball bearings are assembled: photo

The inner ring is placed in place when the rolling elements are assembled flush together. After this, they are distributed evenly around the perimeter, and a structure is placed on them on both sides, fixing the position, and the halves are fastened together with rivets.

Technology does not allow adding more, because assembly will become impossible. If a lot of pressure is created on the assembly, then the developers place a larger number of balls, but for this they have to make a technological hole in one of the cages. With this assembly method, the area of support is doubled. Fixation is carried out using a bronze device. The disadvantage is the high cost.

Model with a spherical body. In this case, we can rotate the inner ring ninety degrees relative to the outer one. If four peas are missing from the set, then the entire assembly can be easily removed and inserted. This becomes clear from the photo. Installation on the inner surface is carried out by bending the holding antennae.

For centuries, humanity has been using products such as ball bearings. In ancient times they had a primitive appearance. Nowadays, these products have been improved. Most machines, equipment and components use ball bearings.

History of origin

The bearing is a part that was invented quite a long time ago. The first finds that can be considered as prototypes of modern ball bearings date back to the Stone Age. At that time, ancient man already had the skills to drill holes in stone. Thanks to them, the first sliding bearing was created. The predecessors of the modern roller bearing in ancient times were wooden logs that people used to move heavy loads. They were actively used in Ancient Egypt, where they were used to move heavy stones to the construction site of the pyramids.

In 330 BC, the first prototype of a rolling bearing was invented. It was invented by Diad, an engineer who lived during the times of ancient Greece. Leonardo da Vinci used rolling bearings in his inventions. Metal bearings close to modern designs appeared in 1785. England is considered to be the birthplace of their invention. It was only at the end of the 19th century that mass production of ball bearings began. This was largely due to the introduction of abrasive processing.

If we talk about a turning point in the history of these products, then 1853 is that year. It was at this time that the engineer Friedrich Fischer designed the first bearing bicycle . After some time, in the 20s of the 19th century, roller bearings became widely used. A few decades later, needle and tapered bearings appeared.

Bearing classification

Currently, bearings are generally understood as parts of different diameters and sizes, made of metal, which are components of a support that support various movable structures. If we talk about the main function of a ball bearing, it is to transfer loads from a moving unit to other structural elements with less resistance.

At the moment, there are several varieties of these products, differing in operating principles. Based on this criterion, they are usually divided into the following types:

- rolling;

- slip;

- gas-dynamic;

- dynamic;

- magnetic.

In the mechanical engineering industry, two types of these products are most widespread:

Next, we will take a closer look at what kind of device a ball bearing has.

Speaking about its design, it is necessary to note two rings that act as the main elements. In addition, a component of such products is a rolling body and a separator. Note that some bearings do not have a cage.

Rolling bearings of different diameters and sizes , which do not have a cage, have a high load capacity. However, they have low speed characteristics. The raceways in such products are located on the end surface of the ring, as well as inside it. When products operate, the rolling body moves along them.

Long cylindrical rollers GOST 25255

In the sorting attribute: letter D

rollers not sorted by length are designated by the letter

B

; rollers not sorted by diameter and length are designated.

Three degrees of roller accuracy are established, designated in order of decreasing accuracy by numbers: I; II; III.

The measure of accuracy of long cylindrical rollers is influenced by the following values: - variation in diameter of rollers in a batch - maximum deviations in roller length - variability of diameter - variation in length - cutting - end runout - roughness parameter

Classification of rolling bearings

Rolling bearings can be classified into several types. Based on such a parameter as the type of rolling, these products are divided into ball and roller.

Based on the criterion of perceived loads, these products are divided into the following types:

Based on such a parameter as the number of rolling rows , these products are divided into:

The state standard divides these products into 11 types. Important characteristics are the outer and inner diameters and thickness. The quality of workmanship is of great importance, since the machine’s efficiency, performance and service life depend on it. On modern machines, contact products are most often installed, and along with them, non-contact bearings of different diameters and sizes.

Symbol of balls according to GOST 3722

for example:

Ball H 25.4 G 20 ball with a diameter of 25.4 mm with 20 degrees of accuracy

In additional notation:

the letter “N”—balls used in rolling bearings. letter "B" - balls not sorted by diameter.

Ball diameter:

designation of nominal diameter in millimeters

Degree of accuracy:

The measure of precision of balls is influenced by the following quantities: - deviation of the average diameter of balls used in the form of individual parts - variation in the size of balls in diameter in a batch - variability of a single diameter - deviation from the spherical shape - surface roughness parameters.

There are 11 degrees of precision

balls according to

GOST

: G 200; G 100 ; G 60; G 40; G 28; G 24; G 20; G 16; G 10; G 5; G 3; (listed in order of increasing accuracy)

Accuracy classes

steel balls according to

DIN 5401

: G700, G600, G500, G300, G200, G100, G80, G40, G28, G20, G16, G10, G5, G3 (listed in order of increasing accuracy)

Main types of products

Radial ball bearings are a component with a wide range of applications. They can be used in conditions where it is not possible to apply persistent modifications. These products are designed for radial load . In addition, they are able to withstand small axial loads. One of their features is good speed performance. However, they cannot withstand shaft distortions. In addition, they have a low load capacity. If we talk about the leaders in the production of these products, then these are companies from Sweden and Japan.

Thrust ball bearings are products of a certain diameter, designed to operate under axial load. This type of ball bearings cannot withstand radial loads. They are characterized by high speed qualities, but their load capacity is quite low.

Single row thrust bearing

One of their features of such products is that they can be operated under light loads and low speeds . The state standard divides this type of product into single and double.

Radial thrust bearings are similar in design to radial thrust bearings. The main difference between these products is that they must work simultaneously with both axial and radial loads. If these conditions are not met, then such products will not be able to be used. When used, they provide good speed.

It must be said that these products can be combined into duplexes and triplexes. This provides them with the ability to withstand axial and radial loads simultaneously. This variety is widely used in the production of machine tools and in the automotive industry.

Double row radial bearings

This type of product was invented in 1907. The inventor of this type of product was Sven Vingquist. He later became the founder and head of the Swedish company SKF. Thanks to his invention, it became possible to transfer all the power from one steam engine to weaving machines located in the workshop. The invention created by the engineer was based on a ball bearing. However, the product had certain differences. The main thing was that it had a spherical surface located on the outer ring. This makes it possible for the tides to function. Due to this, he could work with bending and misalignment of the shafts.

Spherical ball bearing

Products of this type are characterized by a high degree of susceptibility to radial loads. In addition, such a product, which could be of a certain diameter, is only able to withstand minor axial loads. The name of these products is associated with the presence on their inner surface of an outer ring having a spherical surface. The spherically machined raceway allows the product to self-align. These products can be used in units equipped with non-rigid shafts.

Ball diameter in bearing

?The designation of all listed characteristics is made up of signs (numbers). The meanings of the numbers are determined by the places they occupy in the symbol (when reading from right to left): the main and second ones are the symbol for the diameter of the bearing hole (for bearings with a hole diameter of 10 mm or more); the third is a series of diameters; fourth - type of bearings; fifth and sixth – design; the seventh is a series of widths (elevations).

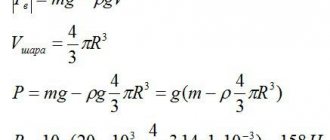

The diameter of the ball (for depiction in the drawings) is calculated by the formula: Dsh = 0.32 (D - d) where d is the diameter of the hole in the inner ring of the bearing, D is the diameter of the outer cylindrical surface of the outer ring of the bearing. The values of these two sizes can be found in GOST standards for the corresponding bearings or in encyclopedias on bearings . Key: Training manual “Design of units and parts of machines”, authors P.F. Dunaev, O.P. Lelikov. Page 161 (for the 2004 edition). The encyclopedic plates in the same book give the values of ball diameters for different bearings of the light and regular series for the diameter of the hole of the inner ring of the bearing in the range from 20 to 80 mm. for balls for various bearings (in technical circumstances the main values are contained).

The classification of rolling bearings is carried out on the basis of the following symptoms: According to the appearance of the rolling elements Ball, Roller (needle, if the rollers are thin and high); Based on the perceived load Radial (load along the shaft axis is not allowed). Radial - persistent, persistent - radial. They absorb loads both along and across the shaft axis. Often the load is along the axis of only one flow. Persistent (load across the shaft axis is not allowed). Linear. They provide mobility along the axis; rotation around the axis is not standardized or impossible. There are rail, telescopic or shaft linear bearings. Ball screw drives. The screw and nut are connected through the rolling elements. By the number of lines of rolling elements Single-row, Double-row, Multi-row; According to the ability to compensate for the misalignment of the shaft and bushing, self-aligning. Non-self-aligning.

Production of balls for bearings When you hold small metal balls made from ball bearings , you can’t help but see how smooth and perfectly round they are. To achieve such shapes and turn light metal wire into shiny metal balls, it is necessary to follow a rather complicated technological process that ensures the production of balls with an accuracy of hundredths of a micron. The ball is one of the most technologically complex parts. The main periods in the manufacture of balls for bearings 1. Cutting blanks for bearing balls From a coil of steel wire, blanks are cut with the approximate shape of the future ball. The workpieces, placed between two disk dies with grooves, are rolled until they are given a spherical shape (maximum pressure 20 tons). This type produces balls with a tolerance of 100 microns from the last size.

Stamped blanks of balls are early subjected to rough abrasive processing in special drums filled with abrasive chips, where the removal of ?‚?¤ Saturn ?? rings and center protrusions. Then the blanks shaped in this way go into ball-processing machines, which consist of a lower stationary and an upper rotating faceplate, equipped with cast iron disks of a special profile, between which the blanks are repeatedly rolled under pressure of up to 20 tons, acquiring a spherical shape with an allowance for subsequent grinding and finishing. Then the balls are subjected to heat treatment: heating, hardening and annealing in special muffle furnaces, giving the balls the required hardness (HRC 60 - 62).

The balls are made according to GOST 3722 from chromium-carbon steel, type ШХ15. At the customer's request, balls can be made from other grades of steel and fabrics. Balls are made heat-treated with a diameter of up to 45 mm of hardness 62... 66 HRC and with a diameter of over 45 mm of hardness 60... 66 HRC, but they can also be created with a different hardness. Balls of the same degree of accuracy are sorted into groups with very strict diameter tolerances. Any group is packaged in some kind of box. The size of the sorted group of balls is indicated in the markings on the box in direct terms of the usual deviation of the nominal diameter of the balls , for example: ball 5.953 - 20 GOST 3722 - 81 deltaDwm L = 1.0 microns.

Related posts:

- Bearing designation

- Wheel bearing size

- Symbol…

- GOST rolling bearings

- Bearing markings

Principles for developing a design project for outdoor advertising ra86.ru. https://pharmex-market.ru nebulizer prices.

Production and prices

The manufacture of products such as ball bearings is a rather complex technological process. It includes several stages. The most difficult part is making the balls themselves.

The first stage is stamping blanks . Steel wire is used to form them. After this, the workpieces are rolled in order to give them a spherical shape and a certain diameter.

The second stage is the processing of the balls before hardening. During this stage, abrasive processing of the balls occurs. After this, the tumbled balls are subjected to heat treatment.

Ball grinding is the final stage of production. This procedure is performed on a grinding machine. When the operation is completed, the finished products are sent for washing. After this, they are monitored. Next, sorting is carried out into selection groups depending on diameter, followed by packaging.

The demand for ball bearings of different diameters today is quite high. Consumers who are interested in purchasing them, of course, have questions regarding their cost. It must be said that the price of ball bearings can vary. It varies from 19 to 6.5 thousand rubles. The price of the product is influenced by the bearing brand, diameter and manufacturer.

Bearings by numbers and rolling elements by size

| Bearing GOST | Rolling element type | Diameter D, mm. | In bearing pcs. | Weight 1000pcs, kg. | steel grade |

| 118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 119 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 120 | Balloons | 14.288 mm. | 15 pcs. | 12 kg. | ШХ15 |

| 211 Yu | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | 95Х18Ш |

| 211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 211 R | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | EI-347 |

| 307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 824 | Balloons | 14.288 mm. | 23 pcs. | 12 kg. | ШХ15 |

| 1217 | Balloons | 14.288 mm. | 42 pcs. | 12 kg. | SHH-15 |

| 1310 | Balloons | 14.288 mm. | 26 pcs. | 12 kg. | SHH-15 |

| 1516 | Balloons | 14.288 mm. | 40 pcs. | 12 kg. | SHH-15 |

| 1608 | Balloons | 14.288 mm. | 24 pcs. | 12 kg. | SHH-15 |

| 8309 | Balloons | 14.288 mm. | 13 pcs. | 12 kg. | ШХ15 |

| 11215 | Balloons | 14.288 mm. | 42 pcs. | 12 kg. | SHH-15 |

| 11309 | Balloons | 14.288 mm. | 26 pcs. | 12 kg. | SHH-15 |

| 36118 | Balloons | 14.288 mm. | 20 pcs. | 12 kg. | ШХ15 |

| 36211 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 46118 E | Balloons | 14.288 mm. | 20 pcs. | 12 kg. | ШХ15 |

| 46118 | Balloons | 14.288 mm. | 21 pcs. | 12 kg. | ШХ15 |

| 46211 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 46307 B | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 46307 | Balloons | 14.288 mm. | 11 pcs. | 12 kg. | ШХ15 |

| 50118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 50211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 50307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 50706 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 60118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 60120 | Balloons | 14.288 mm. | 15 pcs. | 12 kg. | ШХ15 |

| 60211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 60307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 66211 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 80118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 80120 | Balloons | 14.288 mm. | 15 pcs. | 12 kg. | ШХ15 |

| 80211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 80307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 111217 | Balloons | 14.288 mm. | 42 pcs. | 12 kg. | ШХ15 |

| 111310 | Balloons | 14.288 mm. | 26 pcs. | 12 kg. | ШХ15 |

| 111608 | Balloons | 14.288 mm. | 24 pcs. | 12 kg. | ШХ15 |

| 116211 | Balloons | 14.288 mm. | 13 pcs. | 12 kg. | ШХ15 |

| 126211 R | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | EI-347 |

| 150211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 150307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 160118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 160211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 170307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 176211 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 176211 R | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | EI-347 |

| 176307 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 178826 | Balloons | 14.288 mm. | 58 pcs. | 12 kg. | ШХ15 |

| 178828 | Balloons | 14.288 mm. | 64 pcs. | 12 kg. | ШХ15 |

| 180118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 180211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 180307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 180607 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 180707 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 236211 | Balloons | 14.288 mm. | 28 pcs. | 12 kg. | ШХ15 |

| 276211 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 276211 R | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | EI-347 |

| 276307 | Balloons | 14.288 mm. | 22 pcs. | 12 kg. | ШХ15 |

| 436118 | Balloons | 14.288 mm. | 40 pcs. | 12 kg. | ШХ15 |

| 436211 | Balloons | 14.288 mm. | 28 pcs. | 12 kg. | ШХ15 |

| 446211 | Balloons | 14.288 mm. | 28 pcs. | 12 kg. | ШХ15 |

| 446307 B | Balloons | 14.288 mm. | 20 pcs. | 12 kg. | ШХ15 |

| 450211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 450307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 460807 | Balloons | 14.288 mm. | 13 pcs. | 12 kg. | ШХ15 |

| 460808 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 466307 | Balloons | 14.288 mm. | 22 pcs. | 12 kg. | ШХ15 |

| 530211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 750118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 750211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 750307 | Balloons | 14.288 mm. | 7 pcs. | 12 kg. | ШХ15 |

| 920923 | Balloons | 14.288 mm. | 23 pcs. | 12 kg. | ШХ15 |

| 950118 | Balloons | 14.288 mm. | 21 pcs. | 12 kg. | ШХ15 |

| 950119 | Balloons | 14.288 mm. | 23 pcs. | 12 kg. | ШХ15 |

| 998705 | Balloons | 14.288 mm. | 8 pcs. | 12 kg. | ШХ15 |

| 1000840 | Balloons | 14.288 mm. | 21 pcs. | 12 kg. | ШХ15 |

| 1160211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 1180211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 1580211 | Balloons | 14.288 mm. | 10 pieces. | 12 kg. | ШХ15 |

| 2180120 | Balloons | 14.288 mm. | 15 pcs. | 12 kg. | ШХ15 |

| 2310118 | Balloons | 14.288 mm. | 14 pcs. | 12 kg. | ШХ15 |

| 3166118 | Balloons | 14.288 mm. | 42 pcs. | 12 kg. | ШХ15 |

| 3286308 | Balloons | 14.288 mm. | 24 pcs. | 12 kg. | ШХ15 |

| 7568148 | Balloons | 14.288 mm. | 50 pcs. | 12 kg. | ШХ15 |

| 9218407 | Balloons | 14.288 mm. | 12 pcs. | 12 kg. | ШХ15 |

Bearing balls are an integral part of the part, without which its functioning is simply impossible.

The production of such balls is highly precise. During the manufacturing process, it is necessary to achieve specific ball sizes so that friction during bearing operation is minimal. As a rule, the manufacture of this part is carried out by separate qualified personnel using special equipment. At the same time, the production cycle for producing balls can be completely different, depending on the materials used. For example, ceramic balls should have less weight, and also not lose resistance to deformation and temperature during processing. Therefore, their production takes a little longer. Materials used to produce balls

For the manufacture of these small and technologically complex parts, only high-quality steel is used:

- Molybdenum steel is known to many hunters. Fractions are made from it, and of course balls for bearings. Most often, it is not used in its pure form, but a little copper, cermets, brass, aluminum, and polymers are added.

- Balls made of chromium-carbon steel have increased strength and hardness. This material is quite expensive, so it is often used for special-purpose bearings.

- The synthetic metal alloy is often used in ball bearings. A special property of silicon nitride is that products made from it are capable of self-reinforcement.

Balls made of steel are most often used in rolling units. Such ball bearings are indispensable in agricultural activities, where the strength of the part is important. They are suitable for the automotive industry. Often used in various devices for the production of confectionery products and paints and varnishes. In household use, you can find bearings with steel balls in a regular pen refill. Various warehouse equipment, for example, a lift, a hydraulic trolley, cannot do without such ball bearings. The mechanisms of door handles and other furniture fittings also use bearings with steel balls.

If the bearing is used in an aggressive environment, its balls are made of an alloy with a high nickel content. And in case of extreme conditions, rolling elements are made from ceramics.

How are ball bearings made?

As previously mentioned, balls are one of the most technologically complex parts in a bearing design. Their production occurs in several stages:

- First, the ball blanks are stamped. Piece blanks are formed on special machines, but not all of them immediately take the desired shape; some of them have deviations and various protrusions. After this, the resulting blanks are rolled until they take the desired spherical shape.

- The resulting workpieces are processed before hardening by subjecting them to abrasive processing. Under high pressure, the workpieces are repeatedly rolled, as a result of which the product acquires a spherical shape with an allowance. And after this comes heat treatment of the parts. At this stage, the balls are heated, hardened and annealed in special furnaces. The output is smooth and hard balls.

- After this, the resulting balls are ground to the desired size on a grinding machine. The products are driven through the grooves several times, as a result of which they are completely polished to the required accuracy. High-precision models are subject to additional fine-tuning. The finished balls are washed, sorted into groups and packaged.

Bearing ball manufacturers

Balls for bearings can be purchased from both Russian and foreign manufacturers. They are manufactured in Saratov, Samara, at Moscow Bearing OJSC, in Tomsk, Yekaterinburg and other cities of Russia. As for foreign manufacturers, bearing balls from Germany, China, Slovakia, India, Japan, etc. are on sale.

Russian and Chinese products are inexpensive, and the quality of many brands is not inferior to analogues from famous factories from other countries. Balloons from Slovakia will cost a little more. And the most expensive are the balls from Japan and Germany.