Inverter-type welding equipment today is widely used in various industries, in public utilities, and in everyday life. The range of units is quite large and includes devices with different technical characteristics and functionality. To select the most optimal solution, it is necessary to analyze various parameters. In particular, you need to calculate how much power the welding machine consumes. This data can be easily calculated using a special formula.

Experienced welders are thoroughly familiar with the features of welding machines and understand the mechanism of operation of the equipment. If you are just starting to work with the inverter, be sure to read the instruction manual in detail. When calculating power consumption, the operating conditions of the equipment and the purpose of use should be taken into account.

Types of inverter devices

First of all, we recommend that you familiarize yourself with the types of inverter units. All models of this type are divided into three large groups. Each has its own characteristics. Let's take a closer look.

- Household or amateur. This includes models that are powered by a conventional single-phase 220V network. At maximum power, welding with such a unit can only take 20-30 minutes. Afterwards you need to give the device a chance to rest. This time is quite enough to perform one-time operations at home or in the garage. In addition, household inverters are inexpensive, compact in size and light in weight.

- Semi-professional. More powerful devices compared to units from the first category. They are capable of working for up to 8 hours without a break; they are purchased for use in auto repair shops and small enterprises.

- Professional. Welding equipment is designed for frequent use in difficult conditions. They are purchased for large enterprises and factories for the production of metal structures. They effectively weld parts from different metals, work for a long time without interruption, do not overheat, and are powered by a three-phase 380V network. But the models are also expensive.

If you buy equipment for use in the household, take into account one important nuance: the maximum load current should not be higher than 160A. Power circuit breakers and electrical fittings, which are installed in private houses and apartments, are not designed for a current higher than this value.

You cannot connect equipment with a current strength exceeding 160A to the household network. This can lead not only to the operation of the machines, but also to burnout of contacts or fire of electrical wiring. It's better not to let this happen. There are enough amateur-class models in the manufacturers' lines; choose a device from this category for home use, and buy professional ones only if you can connect the equipment to a 3-phase 380V network.

What else to look for when choosing

In conclusion, I will share my opinion on what additional functions would be useful for the device. After all, even minor parameters largely determine the quality and ease of use. For example, the protection class plays an important role for safety. This information must be included in the documents.

In addition to separating devices according to power supply from a three-phase or single-phase network, you should pay attention to whether there is such a good function as anti-sticking. If the electrode sticks to the surface, it will be extremely useful to automatically disconnect the device from the network.

“Hot start” also helps in operation. It allows you to quickly ignite the arc. And the presence of a display will help not to confuse operating modes and provide useful information. There are universal inverters in which the transition to argon arc welding is carried out in one touch.

The video will show what criteria to use to choose a welding machine whose power consumption will allow you to save:

Inverter device design

Familiarization with the structure and mechanism of operation of the inverter will not only simplify operation, but will also help prevent breakdowns and malfunctions. So, first of all, the voltage of 220V with a frequency of 50 Hz turns from alternating to constant, and then again into alternating, but at high frequency. Then this voltage again becomes constant and is transferred to the working arc. The quality characteristics of the arc are controlled automatically. A special microprocessor built into the control unit is responsible for this. There is practically no arc sticking in inverters, and this is its significant advantage over transformer-type models.

When a short circuit occurs, which lasts no more than 0.5 seconds, the electronics generate powerful impulses. Due to this, the molten metal bridges are destroyed, which avoids sticking. If the short circuit lasts longer, the equipment shuts down completely. The electrode does not stick to the workpiece, and the machine circuit does not overheat. This is a fundamental difference between inverter-type devices and units that operate on transformers. Characteristic features of welding machines manufactured using inverter technology:

- increased productivity rates – up to 95%;

- no inductive losses during welding;

- resistance to voltage surges and short circuits;

- possibility of precise adjustment of operating parameters;

- electrodes of different sizes made from various raw materials can be used as consumables;

- safe operation, the device is equipped with highly effective protective mechanisms;

- instant ignition of an electric arc;

- compact dimensions;

- light weight.

Another important feature of inverter devices is electricity consumption. Regardless of power consumption, all energy is spent only on the work process. The efficiency of inverters is 85-95%. These are quite high figures.

Rectifier

This device is a transformer type device that operates on the principle of converting alternating voltage into a constant value required for welding.

Unlike a standard converter device, when working with a rectifier, it is possible to obtain a more stable arc with good quality indicators and better characteristics.

Thanks to this, it is possible to weld not only ordinary steel products, but also non-ferrous metals, including workpieces of small thickness. When working with a rectifier, no special welding experience is required.

When determining the required power indicator of this device, they usually proceed from the value of the electric arc voltage (for a rectifier it is 24 Volts). This value is then multiplied by the operating current (usually 160 Amps), which results in the so-called “arc power”.

If it is necessary to accurately estimate the energy consumption of the purchased device, an adjustment is introduced into the calculations for unproductive heating of the equipment (efficiency indicator equal to approximately 0.65-0.7). For devices with transformerless output, the power factor must also be taken into account (usually it is 0.95...1).

Studying the technical specifications

To choose a suitable inverter device, you should definitely study the technical characteristics of the models in question and read reviews about them. The power consumption of 220V equipment is calculated taking into account the following parameters:

- input voltage (minimum and maximum);

- current range;

- working arc voltage;

- Efficiency of the welding equipment model under consideration;

- PV or continuous on time;

- maximum power.

These parameters are specified in the instruction manual. Before buying welding equipment, familiarize yourself with what each of them means and how it affects power consumption.

Bottom line

This article describes what parameters of the inverter operating mode determine the power; it is shown that it is influenced by the welding arc voltage, current strength, duration of activation, etc.

In addition, various classes of welding machines are considered, as well as their features and differences. This material will definitely be useful to novice welders who are still thinking about purchasing a welding machine.

Voltage

Let's start with the first characteristic - voltage range. This indicator is needed to determine whether the device can operate on the network to which you plan to connect it. If you buy a model for domestic use, choose from single-phase models; if for industrial use, choose from three-phase ones.

It is important that the equipment can operate at a lower voltage, because 220V is rare in household networks. In most cases, the voltage does not exceed 200V. Excellent power indicators are demonstrated by welding machines that function properly in a network with voltage from 150-170V to 220-250V.

Work without interruption

PV or on-duration is the time during which the welding machine is able to weld parts without interruption, determined as a percentage. Equipment operation is usually divided into cycles of 10 minutes each. But not all 10 minutes can be welded without interruption. If the duty cycle is 70%, then 7 out of 10 minutes can be worked continuously, then a stop should be made. As a rule, manufacturers designate different PVs for operation at different welding currents.

If you ignore the need to take regular breaks, the welding equipment itself will suffer. During prolonged operation without a break, the internal mechanisms overheat, the automatic relay is activated, and the unit turns off. Frequent operation in this mode negatively affects the condition and functioning of important components of the welding inverter.

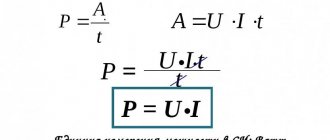

Calculation by formula

Now let's look at how to calculate the power factor. For this purpose, the formula is used: the duty cycle in minutes is divided by the sum of the operating time before and after stopping. We multiply the resulting number by 100. Let’s say the device welded metal regularly for 6 minutes without interruption. Then the protective mechanism was activated, it stopped the working process, the device “rested” for 4 minutes, after which it started working again. We calculate the coefficient using the formula:

6/(4+6) x 100 = 60%

The power factor for inverter devices of the amateur and semi-professional classes does not exceed 70%. As a rule, this figure is in the range of 60-70%. Data that may be required to calculate the power consumed by an inverter device is available in the technical documentation. The necessary information is posted on the manufacturer’s website, in the instruction manual, or directly on the page of the online store where you are going to buy the tool, in the Characteristics section.

Let's look at how to calculate power using the example of a unit with the following technical parameters:

- voltage MIN – 160V;

- voltage MAX – 220V;

- current strength – 160A;

- arc voltage – 23V;

- Efficiency – 0.89%;

- PV – 60%.

First, let's determine the maximum power. It is necessary to multiply the welding current by the working arc voltage. The resulting value is divided by the efficiency. Here's what happened:

160A x 23V / 0.89 = 4135 Watts

This is an indicator of the power required to power the unit directly during the welding process. To calculate the average value, you need to multiply the maximum power by the duty cycle and divide by 100%.

4135 x 60 / 100 = 2481 W.

The result is the nominal value of power consumption. Why is the rated power taken for calculations? The welding inverter will not operate at maximum current all the time. It stops welding at a lower current, so it is not advisable to buy a model with a power that is almost twice the required value.

By the way, you don’t have to calculate the power consumption yourself; the manufacturer has already done it for you. This characteristic is indicated in the technical documentation along with other indicators.

Selecting electrodes for a welding inverter

The power and current also determine which electrodes can be used with the unit. The range of consumables is very wide. Installing an unsuitable electrode leads not only to deterioration in welding quality, but also to breakdown of the inverter apparatus. We have compiled a table that will help you select electrodes.

| Thickness of metal workpiece (mm) | Current (A) | Electrode diameter (mm) |

| 1-4 | 20-90 | up to 2 |

| 5-7 | 90-130 | 3 |

| 8-12 | 140-180 | 4 |

| 12-16 | 180-220 | 5 |

| from 15 | from 220 | from 6 |

Consumable electrodes used for inverter welding must comply with the requirements of GOST 9467-75. Only such consumables can be considered safe to use; they ensure high quality of the welding process and leave behind neat, even seams. Electrodes are classified into those used for welding conventional (ANO) and critical (USSI) structures.

OZS-12 are popular electrodes that allow you to work at low currents. They can be used to work with low-carbon and carbon steels. ANO-36 is also often used; their surface is treated with a rutile cellulose coating. They light up easily and are recommended for those who do not yet have sufficient experience in using welding machines. Such electrodes are suitable for welding parts made of stainless and high-alloy steel. Consumables for welding aluminum sheets, cast iron and other metals are available for sale. The speed and efficiency of welding, as well as the quality of the seam, depend on the correct choice of electrode.

How to increase the power of a gasoline generator?

The power of generator sets can be increased by increasing the air pressure supplied to the cylinders. After all, the more oxygen there is, the easier and faster the fuel burns in the cylinders, and accordingly, the power of the generator increases. The supply of air under pressure above 1.3–2.5 kgf/cm2 is called supercharging.

Interesting materials:

How to stand in a plank for 5 minutes? How is the country vacationing in November 2022? How to mow the lawn in the fall? How does dry air affect the skin? How to sum up the capacitance of capacitors? How to dry figs at home? How to dry onions in the microwave? How to dry lemon balm? How to dry lemon balm in the oven? How to dry Ranetki in the oven?