In the production of cabinet furniture, it is impossible to do without a machine for cutting material. Furniture structures such as kitchen walls, computer tables and even beds will require parts with high dimensional accuracy. Make no mistake, you can start making furniture using just a circular saw for cutting. You will have to resort to making a format-cutting machine with your own hands.

The fact is that a circular saw can cut at a low speed, while the quality of the finished part depends entirely on the craftsman. Thus, the production of furniture will not only be slow, but also possibly unprofitable, because there is a high possibility of producing defective products.

A vertical format-cutting mechanism for slab material allows you to remove responsibility from the master and make precise linear movements during cutting.

Furniture blanks turn out to be accurate, and their production speed reaches 15 parts per minute.

Cutting parts in a sheet of chipboard using online and offline computer programs

On the Internet, in the public domain, there are many chipboard cutting programs that offer several cutting options at once.

You can search for such programs on specialized furniture forums or simply by entering the request into any search engine: “Free chipboard cutting program.”

The search will return three main options:

1 Download the cutting program to your computer - the most common and most convenient program for cutting laminated chipboards for beginners is Cutting. A simple interface, clear layout and many options for cutting sheets.

2 Create chipboard cutting online - here you won’t need to load your PC with programs that may not be useful in the future.

3 Cutting and ordering chipboard cutting online on the furniture company’s website is an ideal option if the production workshop is geographically convenient for you.

In this way, you will “kill two, or maybe more, birds with one stone” - you will select chipboard on the website, which is available in the required quantity, make economical cutting, see the cost and immediately, sitting at home, order chipboard cutting in a furniture workshop.

I will repeat the important points once again.

Sawing rules

First you need to choose a cutting method.

Be sure to carry out the following preparation (cutting):

- To protect the laminated surface of the board from damage during operation, you need to prepare masking tape or tape;

- for marking workpieces - a ruler and a pencil;

- From the ends of the slab, mark future cutting points with a pencil;

- in order to prevent chips from appearing, you need to stick masking tape or adhesive tape to the cut area;

- after gluing the tape, connect the preliminary marking points with a pencil;

- prepare sandpaper to finalize the cut lines.

The following rule applies not to preparation, but to actions after cutting, but is general for any method: if irregularities are found on the edges, then they need to be processed with a file or rasp. The ends resulting from cutting are covered with veneer with a pattern similar to the pattern of the laminated coating.

What not to saw

Chipboard cannot be sawed using an angle grinder, which is also called a grinder. When working with this tool, there is a high risk of injury, especially when using large diameter discs. Injury can also occur when the tool guard is removed from the tool.

To make a format cutting machine with your own hands you need:

First of all, bolt the 600 mm long folding stops to the lower ends of the racks with a cross section of 40x90 mm. At the bottom of the racks, make 12 mm holes with a pitch of 200 mm for the dowels that secure the adjustable stop blocks. At the top ends of the posts and in the three wall brackets, drill 38 mm holes for 1 inch steel pipe. Make holes for cotter pins at the ends of the pipe. The pipe is threaded through the holes of the brackets and racks, and then secured with cotter pins. To work, position the stands to provide support for the outer edges of the workpiece. If you need to cut a whole sheet crosswise, place it with its end on the floor and press it with clamps to the posts above the cutting line so that the clamps do not interfere with the saw. To cut a smaller piece, or when you need to saw a whole sheet lengthwise, place it on stop blocks to position it at a convenient height, and secure it to the posts with clamps.

To accurately install the guide bar for a circular saw, secure a clamp at one end below the marking line and place one end of the guide on it, fixing the second end, move on to the first and finally align it.

For this purpose, you can even assemble industrial equipment yourself - a cutting machine.

Useful tips

To ensure safe operation, it is recommended to have good exhaust ventilation in the room where it is installed. In this case, wood particles will not be able to accumulate and ignite from an accidental spark that may arise from a working motor.

It should be remembered that the rotation speed of the saws is quite high, so you must act carefully when working

It is best to press the sheet material with a special paw, turning the eccentric, which is moved manually by the operator. Instead of a measuring scale, you can use a ready-made ruler from old equipment or a tape measure. The stop is fixed with an eccentric or a screw with a large thread. To comply with safety regulations, all moving parts of the equipment must be covered with removable steel shielding. The saw unit must be located at a safe distance from the operator's location.

Exploitation

We used the same principle in this design. The saw blade comes close to the carriage plate

The gap between the plywood of the carriage and the disk is minimal - this way we avoid large chips

The back side of the sheet will definitely have a perfect cut, but the front side may chip. The task is simple - the sheet that we will cut must be pressed against the sheet of the formatter carriage. We will cut plywood 4, 6 and 10 mm. Therefore, we set the gap between the plane of the inclined “table” of the formatter and the carriage itself to 20 mm, so that several sheets could be cut simultaneously (5 sheets of 4 mm, three sheets of 6 mm, or 2 sheets of 10 mm).

Therefore, when you need to saw off only one sheet, we place a piece of the required thickness under it.

The material must be pressed against the carriage sheet to prevent chipping. We use linings from scraps

Also on the inclined table I made markings and stops for standard plywood sizes for us.

Now the process of dissolving the plywood has noticeably accelerated, and the cut turned out to be very good

Manufacturing stages

Frame

First I assembled the frame from blocks. In fact, there is nothing complicated here - the design is as simple as felt boots. At first, it was used as a stand for unraveling sheets manually using the same circular saw. We also waited for the components to arrive and for free time to assemble.

The frame must be attached to the floor and wall. Otherwise, you can be tormented with its geometry later.

Mechanics

The vertical format machine is convenient because you don’t need to make a lot of effort to hold the saw itself, since the carriage with the saw (which moves up and down) is balanced with a counterweight through a cable.

The carriage with a circular drive rides on solid polished 20 mm shafts

The cable goes through 2 rollers installed in a box above the entire structure. I made the rollers myself from a 20 mm thick polypropylene sheet. The rollers are mounted on a bronze bushing, which rotates on polished 8 mm shafts. Its advantage is that there are no bearing balls, so it is not afraid of sawdust. But if I were assembling it now, I would buy a ready-made roller block. Under load, the roller still creates decent resistance to movement, so you have to apply a little more force to move the carriage.

The cable goes through two homemade polypropylene rollers to the counterweight

The entire structure with the blocks had to be tightly screwed to the wall, because it carries a large load (the weight of the carriage with the circular saw, the effort of the machine operator and the weight of the counterweight).

The counterweight moves along its shafts. It's a small plywood box that looks like a mailbox to me.

Counterweight - a box with a load (metal scraps)

As the counterweights themselves, I used scraps of pieces of iron that were lying idle. These are pieces of shafts of short length that will no longer be used. I wrapped small bundles with stretch and tape. This makes it easier to select the appropriate weight needed for the counterweight.

A weight is a set of bundles made from production scraps

There is no load on the shafts themselves - the shafts essentially simply direct the movement of my counterweight. Therefore, I used fairly thin shafts with a diameter of 10 mm. On the cargo box itself, bushings are made of sheet high-molecular polypropylene (in terms of the coefficient of sliding friction, it is quite close to the caprolon from which bearings are made). Here I also did not use linear bearings with balls, since they easily become clogged with dust and then crunch a lot and do not roll well.

Bushings made of high molecular weight polypropylene with a low coefficient of friction. This is not a bearing - there is nothing to break or become clogged

The 20 mm drive shafts are mounted on plywood stands. I had 20mm scraps. I milled them on a CNC machine. The holes for the shafts are not through - they are just recesses into which the shafts are inserted.

Adjustment right-left and back-and-forth helps align the shafts vertically to the desired plywood thickness

These shaft mounts in the upper and lower parts of the formatter are attached to the bars with M10 bolts and nuts. I made the holes not round so that it would be possible to adjust the distance between the surface for sheets and the carriage. I also made cuts in the bars for adjustment (I don’t have a hand router as it is unnecessary, so I had to bore the holes with a drill on a drilling machine - it didn’t turn out very nicely, but they perform their function).

Using these holes, you can move the upper and lower shaft support to the right or left. This helps to set the cut strictly vertically. As it turned out, this was the right decision, since the first test cuts were not at 90 degrees. A little adjustment helped achieve the perfect saw.

The carriage with the circular is just a sheet of 10 mm plywood. The shafts slide in homemade bushings made of the same high molecular weight polypropylene 20 mm thick.

Sleeve made of high molecular weight polypropylene. Ball bearings are not suitable, otherwise they will clog instantly

There are 4 holes in the base of the circular saw, through which the circular saw is attached to the carriage with M5 screws with hex cylinders. Tightening with a hexagon allows you to tighten the screws much stronger than with a simple screwdriver and does not strip the threads. There are holes made in the carriage into which the busols are screwed (another name is “formattka”) - this is a furniture nut with external and internal threads. The external thread allows the busola to be screwed into wood, while the internal thread allows ordinary screws or bolts to be screwed into it. This way we can quickly screw and unscrew the circular saw if we need it as a hand tool (this has already come in handy more than once).

The circular saw base is screwed to the carriage

The bead nut is screwed with a hexagon into a wooden surface

Busola nuts are driven into the carriage. So the circular can be quickly removed at any time

Everything is tightened with a hexagon, so it holds tightly and does not break the thread

A cut was made in the plywood of the carriage close to the disk. This allows you to avoid chipping when sawing if the material is pressed against the carriage sheet from below.

Electrics

It quickly became clear that using the standard button on the circular saw is very inconvenient - you need to press two buttons at the same time for the saw to turn on. Considering that we turned the saw upside down, it became very unergonomic. Again, as soon as you release one of the buttons, the saw stops.

A relay is hidden in the HDPE pipe above the push-button post

Therefore, we decided to connect a simple push-button post. This is a simple box with two buttons, On and Off, that can be seen on most types of stationary (non-handheld) equipment. The convenience is that once turned on, the engine will not stop until you press the Off button. Yes, it’s elementary simple, but in fact it’s very convenient - your hands remain free.

When connecting, however, it became clear that the post alone was not enough - it needed to be connected to a magnetic switch so that the on position was fixed and turned off when the second button was pressed. A magnetic switch costs more than 1 tr. The toad was crushed by paying so much just for a button. Moreover, the magnet is important on powerful equipment, and here we have only 1 kW. We found another simple solution - connect the post to the relay for 200 rubles. You can search for the connection diagram on the Internet.

Relay for fixing the position of the buttons of the push-button post I brought the voltage to the socket, since I did not want to bite off the fork from the circular saw (as I said, I sometimes need it as a hand tool). I hid the relay and wires in a piece of sewer pipe. I filled the ends with hot glue to prevent a lot of dust from getting in there.

I secured the circular saw button with plastic zip ties.

In order not to hold the two start buttons on the circulars with your hands, they were secured with clamps in the pressed state

Types of machines

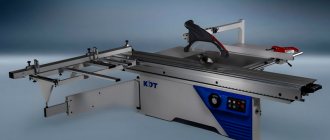

All types of format-cutting machines are professional woodworking equipment, differing in both production capacity and design features. The accuracy and high quality of their work is ensured by the complex design of the units, the professional adjustment and calibration of which guarantees high profitability.

Classification by production capacity

Different types of formatters differ not only in technical characteristics, but also in production capacity. According to this parameter, the machines can belong to both economy and business class.

Small-sized economy-class format-cutting machines have a minimal set of additional equipment and are characterized by a simple design. They are used where the duration of continuous operation does not exceed 5 hours/day.

Business class formatters are used in workshops where the duration of their daily operation does not exceed 10 hours. Machines in this category are usually equipped with a movable table and are equipped with a minimum functional set.

Almost all format manufacturers also produce top models designed for use in large-scale or mass production. Structurally, they are large-sized automatic centers for batch cutting, equipped with CNC systems with the ability to perform pre-programmed operations.

Constructive classification

According to their layout, format cutting machines are:

- horizontal;

- vertical.

Enterprises produce horizontally oriented machines of two types:

- with movable saw;

- with a moving table.

Machines with a horizontal movable saw are designed for work in small production workshops. They are equipped with a movable carriage with a circular saw, and the horizontally mounted table is fixed permanently.

For formatters with a moving table, the saw is mounted motionless on the bed, and the table with the workpiece attached to it is slid onto the saw. The table moves on special rollers using an electric drive or manually.

The overall dimensions of vertical FRSs are significantly smaller than horizontal ones. This is due to the fact that the processed materials are arranged vertically. In turn, this makes it possible to easily cut large-sized sheet and slab materials, even in cramped conditions of small production areas.

In such machines, the workpiece is fixedly fixed, and the sawing device is moved manually or using an electromechanical drive.

Recommendations from professionals

Now you know how to make a machine from a hand-held circular saw, so let’s consider the advice of the masters:

- Before using an electric saw on a machine, check the saw blade with a square, because some unscrupulous manufacturers do not place the blade exactly at a 90-degree angle, which causes the cuts to be beveled.

- If during work you plan to use a table to store tools on it, then the size of the tabletop should be larger than 1 m2.

- To create the machine, use durable and high-quality materials, because otherwise it will not last long.

- The table can be supplemented, for example, craftsmen sometimes manage to attach a special vacuum cleaner or a riving knife with protection for disks to it so that the remains from cutting wood and shavings do not fly all over the place.

- You should choose a place to mount the table in advance, and also make sure that the floor where the table will stand is perfectly level.

- If you have the skills and desire, you can make a folding tabletop, but this will require spending more effort, time and materials.

- If the table vibrates or sways during operation, you should adjust the height of the legs using rubber.

Since the circular saw is an electrical device, it should be operated by specialists. Moving the switch to another location should also be trusted only to specialists.

Design Features

In order to make a cutting machine with your own hands, you need to understand its design features. It should be noted that the standard design is represented by the following components:

- The bed is an element that serves as the basis for the entire structure. The frame is also designed to dampen some of the vibration.

- Working movable and fixed table.

- The saw unit, which consists of 2 saw blades, adjustable with a clamp.

Main equipment components

The movable table has a rather complex structure, which consists of a trolley, a support frame, a ruler, a separator, and a carriage. Almost all components are made of metal.

Saw unit

An important design element can be called the saw unit. A homemade version is often represented by a welded structure, since this method of connecting elements can effectively combat vibration that occurs during sawing. The main problem of the technological process under consideration is the formation of chips on the lining, which reduce the quality of the resulting material. That is why the saw unit has two saw blades, which eliminates the possibility of a problem.

The device of the saw unit

The features of the saw unit include:

- The assembly is solid, often cast from cast iron.

- Some models may have one electric motor, but often two are installed for each saw.

- A belt drive is used to drive the scoring disc. Note that the presence of a belt drive is a prerequisite for ensuring long-term operation of the electric motor, since this method of transmitting force allows you to smooth out the load exerted on the output shaft of the electric motor.

- The diameter of saw blades can reach 120 millimeters. They are made from tool steel, as it is more resistant to abrasion.

- The electric motor, through a belt drive with various pulleys, must provide up to 8000 rpm. Note that the higher the indicator, the better quality the surface can be obtained. However, increasing the frequency leads to a decrease in the feed rate and the emergence of structural problems due to the heavy load on the unit.

It is important to note that a self-made vertical format machine can have a rotating saw unit. It is quite difficult to make, it is necessary for cutting at an angle

Main saw

When developing a format cutting machine at home with your own drawings, you should take into account that the rotation of the main saw should be at a frequency of 4-6 thousand revolutions per minute. If the indicator decreases, there is a possibility of damage to the edge. If you use a modern electric motor when creating a structure, then it is possible to regulate the purity of rotation according to the characteristics of the material being processed. The power of the electric motor should vary from 3 to 5 kW. As the power rating increases, productivity increases significantly, but also costs due to the consumption of more electricity. The adjustment can also be made by selecting the belt drive pulleys, however, such a reconfiguration of the format-cutting machine requires some time and calculations.

In most models, the cutting height and saw position are adjusted by moving the entire saw unit. In this case, such adjustment can be achieved in two main ways:

- along vertical guides;

- due to rolling around a horizontal axis.

Another important parameter is the height to which the saw rises relative to the table, since this indicator determines the maximum thickness of the cut.

In many cases, a roller carriage is used to move the workpiece. The trolley moves along steel guides, for which a separator with balls or rollers is included in the design. Compensators and regulators can look different, it all depends on the accuracy and quality achieved during processing.

Personal experience

As the Pyroprinter project develops, our team has to optimize some processes.

We have long needed to make some kind of machine or device for quickly and accurately dismantling plywood for subsequent milling. I won’t bore you, I’ll immediately show you the result we got:

We made such a format-cutting machine with our own hands. Let me clarify right away - we are not a furniture manufacturer, where the format machine is one of the main tools. And it comes with the requirement to have a scoring saw blade for cutting without the slightest chips and high productivity. For us, cutting plywood (and other sheet materials) is an auxiliary production process that does not require high quality cutting.

Those who have ever encountered cutting sheets of plywood (1.5 * 1.5 m) know that sawing is accompanied by a number of difficulties:

- The sheet is bulky and requires a lot of space if cut horizontally;

- When cutting across the grain, many chips appear;

- Maintaining an even line from edge to edge by simply sawing along the drawn line is not easy - the cut floats a little.

The initial requirements were simple: you need a budget version of a format-cutting machine that you can assemble with your own hands. The cut should be straight and without chips. When cutting, spend a minimum of time setting dimensions. The formatter should take up minimal space.

How to install the saw correctly

The next step is to properly position the saw on the top surface of the saw table. To do this, the contractor must perform the following actions:

The work of making a machine requires great concentration and concentration. The slightest mistake can lead to having to start all over again.

After securing the structure to the table, you need to install a block to turn the circular saw motor on and off. A hole is cut in the housing, the switch is secured with bolts and universal glue. There should be two separate cables coming from the unit. One - to the instrument, the second - to the nearest electrical outlet.

When assembling such a unit yourself, it is worth taking into account the performance of the motor, as well as the highest power of the electric motor. In this case, experts recommend suspending your choice on an engine whose power does not exceed 1000–1200 W; otherwise, operation can be dangerous. Well, a more powerful saw requires a heavier and more stable table.

Chip removal

After the first launches, another unpleasant feature was revealed - when you start cutting the sheet from above, all the shavings fly in a beautiful fountain directly onto the operator’s head. Therefore, they quickly began to solve the issue of chip removal, while the operator had to wear a technical jacket with a hood and glasses.

By that time, it was time for us to purchase a chip extractor in order to extract dust from 2 CNC milling machines, a circular machine, a sanding area with a sander, and from the future format machine. Since there are a lot of devices, we took a Jet 2300 2.2 kW chip ejector with 2 bags for 35 tr (a similar one for 1 bag costs 25 tr).

Chip ejector, without which the worker’s head was constantly covered in sawdust from sawing

In principle, if I had only one format machine, I would attach a vacuum cleaner with a long hose to it. In this option, it makes more sense to choose a circular saw with a connection for the vacuum cleaner hose. It’s better to take a vacuum cleaner with a large bag and a built-in socket for hand tools (connect the formatter through it). Then, when you turn on the formatter, the vacuum cleaner will turn on automatically and also turn off after turning off the saw (I use a Karcher vacuum cleaner with fabric bags, but I would prefer a larger bag). But in my case, the choice in favor of a chip extractor was obvious - you can’t install a vacuum cleaner on every machine (the money will be the same, but it will be very noisy and there will be a large load on the network). I assembled air ducts under the ceiling from sewer pipes, taped them inside with aluminum tape to remove static, and routed them to all the machines.

This is not a sewer under the ceiling))), but air ducts for removing chips to the chip suction

In order not to have to run to the chip ejector every time to turn it on, the power button was taken out and hung from the ceiling in the middle of the room.

To connect it to the formatter, I made a small casing from the same plywood and a small casing from the air duct (bought at a hardware store), which fits over the circular. It fits tightly, so no fastenings were required. You can easily remove it at any time to change the disc. I admit, it looks collective farm, but I had no time for beauty - I needed to resolve the issue as quickly as possible, and there was no time for beauty. As usual, everything temporary becomes permanent. Maybe I'll change it somehow.

The nozzle was made by the collective farm in a hurry, but it was necessary to quickly resolve this issue

The nozzle fits elastically, so there was no need to come up with any fastenings

By the way, regarding changing the disk, my circular saw has a submersible design, that is, the disk can be pulled out completely without removing the circular saw from the machine. This again simplifies operation.

Features of furniture additive machines, their types and use

If you are already engaged in or just want to start producing furniture, then you will certainly need a drilling and attachment machine. It will help you accurately drill the required holes with which the elements will be connected.

If an additive machine for furniture produces parts according to pre-drawn drawings, then you will get a better result, the work will require less time and effort, and the manufactured furniture will be reliable and beautiful. Such a machine, of course, is expensive.

This is a high-tech unit; it is not needed for one stool or table, but for small production it is extremely necessary.

Scope of use

You need DIY additives to drill neat and precise holes at specific points. There will be no torn wood fibers or any chips. High-quality equipment samples allow this process to be carried out as quickly as possible and almost completely eliminate the possibility of obtaining low-quality workpieces. When designing furniture, any of its parts are calculated so that they are in a place previously intended for them; any deviations make it difficult to assemble the finished product, and sometimes make it impossible.

The operation of the additive machine occurs according to the aggregate principle. This means that several similar devices mounted on the head operate simultaneously.

The permissible error for this equipment is 0.4 mm at 64 cm.

Types of models

On an additive machine, several similar tools simultaneously perform their functions - drilling units, countersinks, which are mounted in a head with several spindles.

According to purpose, this equipment is divided into:

- Universal furniture machines;

- Specialized equipment;

- Special mechanisms.

Universal equipment - designed for complete hole preparation, from drilling to full processing with other devices. They are often used in the serial production of furniture; they are capable of performing many functions. Small models with low energy consumption are suitable for beginner amateurs.

Specialized devices - designed for conveyor processing of necessary parts. They are capable of processing a certain number of holes at the same time. Can be customized for different operations. Most of the additive equipment falls into this category. Special mechanisms are intended only for processing workpieces of a certain configuration.

What shortcomings were discovered and what would I change?

- Shaft diameter 20 mm. Professional formatters use 40 mm shafts, so it is difficult to bend them when cutting. Why didn't they take 40 mm? To be honest, it was strangled by a toad - one shaft 2 meters with a diameter of 40 mm costs almost 10 thousand rubles. And you need 2 of them (let me remind you that the entire format set cost 10-11 thousand rubles, including the circular). If you decide to assemble it on a furniture rod (for hangers), I don’t recommend it right away - our solid 20 mm shafts bend a little, and the rods will simply bend.

- Wooden frame. The tree tends to “walk” and dry out. Therefore, some bars may bend a little due to changes in humidity. An aluminum frame made from a machine-made profile would cost 30-40 thousand rubles. Simple square aluminum tubes are about half the price, but their bending rigidity is lower than that of a machined profile. In theory, key places can be strengthened with metal corners (we are talking about molded products, not corner fastenings of parts at an angle of 90 degrees). But again, the frame is attached to the floor and wall, and the problem of bending is solved by periodically adjusting the position of the shafts.

- It is still preferable to take laminated plywood rather than simple FC. This will make the sheets travel more fun. Why didn't we use laminated? Because in our warehouse there was only FC, and there was no desire or time to order a laminated sheet separately. Perhaps we will fix it in a future modification.

- The polypropylene bushings for sliding the movable carriage sometimes jam a little and they whistle. Now I would do it a little differently, but I’m showing you exactly how it was during the manufacturing process.

- Instead of shafts with a counterweight, it’s better to look for a cable with a “reverse traction tape measure” (I’m sorry, I didn’t look for the exact name of this unit). It should be no more expensive than my version, but it will be easier to assemble such a design. Plus, the extra resistance in the rollers that I used above the machine will disappear.

PS If you are new to our website and are interested in carpentry, then take a look at what cool things our CNC burner machine Pyroprinter does (this is not paint - it is BURNING):

This is what the burning process looks like:You can read about the PYROPRINTER machine itself here

Sequence of work

First, a strong metal frame is prepared that can serve as the basis of the machine. For this purpose, it is best to use a channel. The blanks are selected so that the result is a unit 6.5 - 6.7 m long, 2.5 m wide, and a height of eighty to one hundred and ten centimeters.

The main guide of the cutting equipment and the floor guide are designed and mounted on the bed. For them, it is best to use pipes whose dimensions are 6 cm in diameter, 6.5 m in length, and wall thickness - 5 mm. The moving part of the desktop should be made movable along guides. During the work process, it will be used to feed sheet material. This section can be moved manually or an additional CNC motor can be installed. Cutting lines along the length should be provided from three meters. This parameter can be increased or reduced by simply changing the size of the guides.

Read also: Screwdriver attachment for drywall screws

A pair of saws are hung on the bed - for the main cut and trimming. They are mounted on a saw unit so that rotation occurs in the opposite direction from the movement of a pair of asynchronous motors. It is recommended to provide the ability to tilt the block by forty-five degrees, for which you should use a rotating device on the sawing block.

You should choose electric motors carefully, because they will be intended to rotate the saws. Their power must be at least 2.9 kW. The motor must rotate the main saw at a speed of at least 5,000 revolutions per minute, and the scoring saw must produce three thousand revolutions more.

When creating equipment, it is best to use saw blades with a diameter of twenty-five centimeters, which will make it possible to cut not only laminated chipboard and trim sheets, but also to use a machine for sip panels.

Computer numerical control

Before processing, a 3D model of the future furniture is loaded into the program. CNC models equipped with a laser beam function are able to show the route of the unit's cutter. Unlike the operator, the presence of a CNC system makes it possible to speed up production and improve quality:

- thanks to the program, there is no need to set up the machine to produce each part;

- utilities ensure savings in material used;

- optimizing the movement of the working tool reduces the time required to complete a task.

The product layout is presented as a file. The files are loaded into the device memory. Depending on the contents of the file, the device is configured. The person is required to download the files and start the unit, after which the production of components will begin.

The best panel saws

Filato FL-3200B

Country of origin: Italy. The model is designed for longitudinal, transverse and angular cutting. It cuts sheet blanks of varying texture densities equally well. The metal frame of the machine is welded from rectangular pipes. It has increased strength and is resistant to deformation.

To dampen equipment vibration during operation, the body of the Filato FL-3200B is reinforced with steel sheets having a thickness of 3-4 mm. The cylindrical type guides are also made of steel. An aluminum carriage moves along them. The machine control buttons are located in the electronic unit, located in a convenient place for access.

Characteristics:

- overall dimensions – 3300x3100x900 mm;

- weight – 1050 kg;

maximum cutting height – 110 mm.

Advantages:

- the presence of an electronic display and an emergency stop button for the machine;

- reliability;

- durability;

- ease of maintenance and operation.

Flaws:

- high price;

- Difficulties in setting up the carriage.

Bosch GTS 10 XC

Country of origin: China. The model is equipped with a braking function, has a starting current limiter and an overload lock. Designed for small furniture production. The work table has retractable elements that allow you to cut large sheets of material of varying densities.

The design has a well-thought-out slab feeding system, which ensures accuracy and ease of cutting the material. Reliability of sheet fixation is ensured by a parallel stop. The maximum tilt angle is 47 degrees. The machine can produce clean and even longitudinal and transverse cuts. The machine can cut plastic and aluminum profiles.

Characteristics:

- overall dimensions – 635x343x768 mm;

- maximum cutting depth – 79 mm;

weight – 35 kg.

Advantages:

- smooth start;

- structural strength;

- reliability in operation;

- capacious corner stop;

- the presence of a dust collector and an adapter for connecting a vacuum cleaner;

- ease of setup and maintenance.

Flaws:

- the possibility of backlash;

- high price.

Holzmann TS 315VF-2000

Country of origin: Austria. The model is considered the best professional machine in its class. Designed for longitudinal and cross cutting of slabs. The design of the machine allows you to cut complex configurations from sheets. It features fast, accurate and neat cutting of material.

The machine is intended for equipping furniture and carpentry shops. Can cut chipboard, MDF, fiberboard, plywood, acrylic, composite and other materials. The aluminum carriage has high adjustment accuracy. The stops and marking rulers are made of the same material. The work table is made of vibration-damping cast iron. The body has a welded structure.

Characteristics:

- overall dimensions – 910x741x104 mm;

- maximum cutting depth – 100 mm;

weight – 263 kg.

Advantages:

- increased security;

- effective cleaning of the working area from dust and chips;

- fine adjustment;

- high quality cut.

Flaws:

- high price;

- Can only saw small slabs.

ZENITECH FR 1800

The country of development is Switzerland, the manufacturer is China. The model is designed for longitudinal, transverse and angular cuts. The machine is professional equipment. Equipped with a powerful three-phase motor. Provides high cutting accuracy. Can cut wood-based materials of various densities, as well as plastic and composite materials.

The desktop has a sliding structure made of cast iron. The frame is made of the same material. Despite the powerful engine, the machine is quiet in operation. The carriage is made of aluminum. The air cooling system prevents equipment from overheating during operation.

Characteristics:

- overall dimensions – 936x756x1040 mm;

- maximum cutting depth – 100 mm;

weight – 300 kg.

Advantages:

- high power;

- cutting accuracy;

- high quality cut.

Flaws:

- high price;

- You can only cut one slab.

Options for using the cutting mechanism

There are 3 options, thanks to which the vertical sawing machine cuts materials:

- feeding the saw onto the material – the saws are located under the table;

- feeding the saw onto the material – the saws are located above the table;

- feeding material to the saw – the saws are located under the table.

In the case of feeding the saw onto the material, which is located above the table, the motor and cutting discs are fixed to the carriage. The carriage is mounted on skids placed at the required height, which allow the entire cutting structure to be held and moved along the plane of the table. Skids or guides can be made of channel or powerful pipes.

The location of the saw under the table, which feeds the material, also assumes the presence of guides and a carriage moving along them. The difference between this arrangement is that the dust collector system is hidden under the table and does not interfere with the movement of large objects.