What is it and what is it for?

A check valve is one of the elements of protective pipeline fittings.

The main purpose is to prevent changes in the direction of water flow. It automatically closes the pipeline if the flow direction changes in the opposite direction.

Water check valve

Also performs the following functions

- When the water supply is turned off, it prevents its outflow through the riser

- Blocks hot water from entering the cold water supply system and vice versa

- Significantly reduces the likelihood of water hammer

- Increases the operating time of equipment (pumps, meters, etc.)

- Reduces the risk of broken connections in the plumbing system

Classification of fittings depending on temperature

Cryogenic fittings, for liquefied gases - temperatures below minus 153°C (valves, regulators, shut-off devices made of special steels and alloys)

Refrigeration unit fittings - temperatures from minus 153°C to minus 60°C (Danfoss refrigeration equipment, shut-off and control valves made of special and non-metallic alloys)

Fittings for low temperatures - from minus 60°C (special Danfoss equipment, valves, regulators, gate valves made of alloy steel grades 20ХН3Л, 09Г2С, etc.)

Fittings of medium parameters - temperatures up to plus 450°C (pipe fittings made of carbon steels 20L, 30-35L, 45L, etc.)

Valves of high parameters - temperatures up to plus 600°C (pipeline fittings made of special, stainless and molybdenum steel grades KhMF, 12Х18Н9ТЛ, 12Х18Н12М3ТЛ, etc.)

Heat-resistant fittings - temperatures above plus 600°C (materials used, depending on individual operating conditions - nickel, molybdenum, titanium containing alloys)

Where is it used?

A non-return valve is very useful in the water supply of a private home.

If for some reason the pump stops, it prevents water from flowing back into the well or borehole. In the event of a power outage or pump shutdown, there is no need to refill the system with water.

On water pipes.

The supply of hot and cold water in private and apartment buildings is carried out through different pipes. Sometimes different water pressure causes hot water to fill cold water pipes. The valve allows you to bring the pressure back to normal.

In front of the cold and hot water meter.

Helps protect against damage in the event of a water hammer.

At the inlet to the water heater.

The boiler is filled under pressure. When warming up and pressure increases, the displaced coolant will be directed back into the cold pipe. Prevents churn

Product sizes

Speaking about the dimensions of a check valve, first of all, the nominal bore and nominal pressure of the device are distinguished. The nominal diameter is fixed at values from 10 to 400 mm, inclusive. There are models of 15, 20, 25, 65, 80 mm, and with other passage diameters. Conditional pressure refers to the amount of water pressure in the circuit at which the check valve opens. Here the values range from 0.25 MPa to 2580 MPa. Among the intermediate values, there are: 6.3 (MPa), 10 (MPa), 16 (MPa). It is worth noting that check valves differ in the range of operating temperatures, among which there are models capable of operating with liquid from -60 to 600 degrees Celsius.

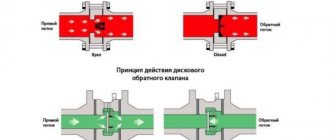

Operating principle of a check valve

- The flow of water flowing through the pipes under pressure acts on the shut-off element and presses out the spring, which keeps the valve closed.

- After the spring has compressed, the valve opens and water flows freely through it in the desired direction.

- When the pressure in the water supply drops or when water moves in the opposite direction, the spring mechanism of the device moves the valve to the closed state.

- All the actions of the shut-off valve prevent the formation of backflow in the water supply system.

Operating principle of a check valve

Description of devices

The check valve looks pretty simple. Inside the structure there are the following main elements:

- a small spring that functions as a delay mechanism for the bolt mechanism;

- shutter with seal - can be made of durable plastic or steel;

- a metal body (usually dismountable for ease of maintenance), consisting of two threaded parts.

Today there are a large number of locking mechanisms. Taking into account the design, the device can be supplemented with the following auxiliary elements:

- stem;

- pin on hinges;

- ball bearings;

- springs;

- elastomers;

- disc levers.

To choose the right locking element, you need to take into account the design of the system and the main purpose of the installation.

Design Features

Housing material

The most common material used to make a check valve body is brass. This material is highly resistant to chemicals that may be present in water (mineral salts, oxygen, iron compounds, manganese, sulfur and others).

titanium, cast iron, steel, bronze mainly used in industrial systems

Plastic is used in polypropylene pipelines with water temperatures up to 90 degrees

Rubber or silicone sealing gasket.

Check valve device

Shutter element

It comes in the shape of a ball, cone, or “plate”. Double-leaf check valves are also used in pumping stations and water supply systems. They have a shutter in the shape of two semicircular fragments. Most often made of brass

Return mechanism.

To return the shutter to the closed state, the device has a spring. Stainless steel is most often used to make the spring (an important element of the shutter). But there are also models where, under pressure, the shutter rotates on hinges.

Manufacturing materials

Check valves are made from a variety of materials, which must be selected based on the valve's operating conditions, the type of operating environment, and other requirements placed on them in specific industries.

The most popular materials for check valves are:

- Stainless steel;

- Various steel alloys;

- Brass;

- Plastics, mainly polypropylene.

What a check valve must be made of is largely determined by the type of fluid flowing through it, including its physical condition, level of corrosiveness, and required opening pressure and flow rate.

Types of check valve

Spring (lifting)

Its design is similar to a shut-off valve. With sufficient pressure, the valve rises up, opens the hole, allowing the flow to circulate. At low pressure it falls down onto the seat and the water path is blocked. All this happens automatically.

It is used only on horizontal pipes, with mandatory vertical axial installation.

Advantages of a spring valve. Repair is possible without dismantling, as it has a removable cover. Plus it can be used at high temperatures.

High tightness. Versatility, can be used in both private and industrial water supply systems.

One of the disadvantages of spring valves is sensitivity to dirt and mineral impurities contained in water, which can damage them. But this can be solved by installing a filter.

Ball valve

The locking element in this device is a metal ball. Sometimes the ball is covered with rubber for reliability.

If there is no pressure in the water supply, the ball, under its own weight, tightly blocks the passage hole and prevents the liquid from moving in the opposite direction. When water is supplied, the resulting pressure lifts the ball, opening the way for the water flow.

Ball check valve

Pros. Ball check valves can be installed in vertical and horizontal pipes

Simple design and absence of mechanical components increases service life.

However, it should be remembered that with an equal internal cross-section, the outer dimensions of a ball valve are larger than that of other types of valves.

Rotary or paddle

The valve received this name because of its design.

It is based on a metal disk (“plate”) and an axis with a spring. The axis of rotation is located above the through hole. When open, the disc is parallel to the movement of water; when closed, it is perpendicular. Under fluid pressure, the disc opens. When the pressure drops, the spring is activated, the disk turns and blocks the flow. rotates under fluid pressure. If the pressure drops, the spring is activated and the disk blocks the path of water

The disadvantage is that in valves of large diameter there is a strong impact when slamming, which can lead to rapid failure of the structure.

Rotary check valves are divided into two groups:

Simple - with a small diameter of up to 400 mm. Used in systems where shocks cannot greatly affect the operation of the hydraulic system and the valve itself

Impactless - valves with a special mechanism that ensures smooth closing of the disc. The downside is that they are more expensive.

Double check valve

This device has two locking segments, which are located on a rotating axis. The plates are located in the center of the passage hole.

Water moving in the right direction opens the doors. If the direction of flow changes, the plates, under the action of springs, close the passage of the liquid.

Butterfly valves come in a wide range of sizes so they can be installed on pipes of various diameters.

They are also recommended for installation in systems where high pressure is present.

Why is the device needed?

A sewer check valve is a device that is designed specifically to prevent leaks and backflow of water due to clogged sewer lines. Sometimes even a package that accidentally gets into the pipeline leads to blockages and flooding of the apartment.

To protect the room from the reverse movement of sewer system waste, a special valve is installed that operates automatically. A similar mechanism is used not only in offices, cottages, residential buildings and industrial premises, but also in heating and water supply systems (for the pump).

Their operating principle is quite simple: if the waste liquid begins to move in the opposite direction, the locking mechanism stops this movement, as a result of which flooding does not occur.

In most cases, the need to install the device arises in the following situations:

- regular entry of debris and large objects into the sewer system, as well as other violations of operating rules;

- a long period of use of the pipeline, during which a layer of grease with dirt particles has formed on the inner surface. This significantly increases the likelihood of clogging;

- the slope of the sewer pipeline is too large or small, because to ensure free gravity flow of liquid, it is important that a certain speed of movement of the wastewater be maintained;

- bends located at a perpendicular angle to the sewer pipe. As a result, the speed of water movement changes sharply and a water blockage may occur.

If in a multi-storey building with a single riser, residents of first-floor apartments installed a check valve for the sewer system at 50 or 110 millimeters, then flooding with drainage can occur even on the 2nd floor. The liquid will not get further up, because... pressure will most likely cause the blockage to clear.

In country houses, similar locking mechanisms are also often installed. However, then it is recommended to install them on the street, after collecting all the branches of the sewer pipes into a single one.

Classification by installation method

Flanged valve

With this type of device, the return flange and the supply flange are welded to the valve body and a single structure is obtained.

This type of valve is mainly used in industrial systems for large diameter pipes.

Due to its large size, it can cause water hammer, since at the moment of closing, increased pressure is created in the system. To avoid this, systems use shock-free shutters with soft closing.

Advantages: ability to work in systems with water pollution. Application on main pipelines with large pipe diameters.

Wafer

These devices have virtually no mounting hardware. The valve itself is mounted between two flanges, at the ends of the connected pipes. A special seal is placed at the installation sites. After this, the flanges are tightened together with threaded connections (bolts or studs).

If installed correctly, the valve will be securely fixed. In terms of reliability, this type of connection is almost as good as a flange connection.

Coupled

The most common in household plumbing.

With this connection, the valve is connected to the pipe using a threaded coupling.

Pros: No need to use additional fasteners. Not suitable for large diameter pipes.

What to look for when choosing?

Installation method:

- Flanged. Ball valves are most often mounted using welded flange disks at the edges. This is a very durable connection, in demand on large diameter highways.

- Wafer. Rotary valves are usually produced in this design. The product is placed between the flanges and tightened with threaded rods. This installation method may seem unreliable, but in fact it is not inferior in strength to others.

- Coupling. Installation of a coupling check valve in a pipeline is carried out using a thread. These models simply screw onto the ends of the pipes and seal. They are not suitable for industrial highways, but they take root well in everyday life.

Size

The diameter of the passage hole must match the diameter of the pipeline. To correctly install a check valve on a pipe, find out its actual size and round the number to the nearest standard range: (6, 8, 10 (3/8”), 15 (1/2”), 20 (3/4”), 25 (1”), 32 (1 1/4”), 40 (1 1/2”), 50 (2”), 65 (2 1/2”), 80 (3”), 100 (4”), 125, 150, 200 and so on).

Material

If you are looking for a hot water valve, purchase a nickel-plated brass product or a steel one. Valves made of PVC or polypropylene will last less than the stated period in conditions of extreme temperatures. However, don’t write them off: they are a practical solution for other everyday tasks.

Operating pressure

It is better if the valve pressure rating is twice the actual load. This is a guarantee that the device will work properly for many years.

Do I need a check valve for a water meter?

If you turn on several taps at the same time in an apartment building, pressure drops will occur in the water supply system. To avoid this, it is enough to install a check valve on the water meter, which will equalize the pressure drops.

The internal space of the meter must be constantly filled with water. This requirement allows the hydraulic check valve to be fulfilled. This will allow the meter to not fail for a long time.

If the pressure in the cold water pipe is greater than in the hot one. The meter will also start counting cold water. This will result in an increase in your utility bill accordingly. The check valve prevents cold water from entering the hot water system.

Valves that reliably block the water flow and prevent movement in the opposite direction. They will help prevent the consequences of water hammer for the water meter. This significantly increases the service life of the device.

Is it really necessary?

Installation of a sewer check valve 50 or 110 is not always required; there are certain situations when installing this device does not make much sense. For example, residents of apartments on the 6th floor of an apartment building do not have to worry about possible sewer flooding through the central blockage, because... the pressure of waste fluids will not maintain a high level when rising to the 6th floor.

In general, there are situations when it is strongly recommended to install the device:

- location of the apartment on the first/second floor of a multi-storey building;

- location of office space on the first two floors;

- private 1-storey house;

- cottage-type country house with 2-3 floors.

In the above situations, it is financially more profitable and easier to install a valve on plumbing fixtures in advance than to later repair the premises and deal with the negative consequences of a clogged and broken sewer. It is especially important to install the mechanism in houses with old pipelines. Pipes in such buildings usually have a layer of sediment on the inner walls, resulting in a smaller working area and an increased likelihood of clogging.

Where to install

- If necessary, a check valve is installed where it is necessary to ensure flow movement in one direction.

- After the water meter, to protect against water hammer

- On hot and cold water pipes when used simultaneously. Due to the pressure difference, overflow through the mixer is possible

- At the water heater inlet to prevent heated water from escaping into the cold water supply system

- In front of the pump or pumping station to prevent the outflow of water in the event of a power outage or breakdown

- At the very inlet of the suction pipe

- In the anti-drip protection system of the dishwasher and washing machine

Where in the apartment should I install a check valve - video

How to install correctly

The easiest way to install a check valve is through a threaded coupling. Suitable for installation in the water supply system of an apartment or private house.

Work order (step by step instructions)

Select location, see above

Prepare fittings of the required diameter.

Wrap a sealant around the thread (linen, fum tape, thread)

Use a fitting to secure the check valve

Open the tap and check for leaks

If you are unsure or doubt your capabilities, call a plumber

It is important! There is an arrow on the valve body. The direction of the arrow must coincide with the direction of water flow in the pipeline

Even the most reliable shut-off valves fail over time. Therefore, you need to know how to remove the check valve yourself.

- First you need to turn off the water flow with taps

- if necessary, drain from the system

- Then unscrew the nuts.

- Dismantling flanges or fittings

- Remove the check valve.

- If possible, replace failed parts (for example, a spring)

- Reassemble in reverse order.

.

Attention! If the valve is installed near the water meter. You must act carefully so as not to damage the seal installed by the management company.

Main tasks of the device

It stabilizes the pressure in the system, protects against water hammer, and prevents reverse fluid circulation. If the valve is installed in a submersible pump in front of a well in a summer cottage, it allows the pump to operate without failures or breakdowns.

Possible errors and problems during installation

The device may fail due to installation errors.

During the installation process, be sure to follow the instructions

It is advisable to inspect for problems once a month.

Possible problems:

No water flow

Incorrect installation. The arrow shows the direction of flow.

What to do: Disassemble and unfold the valve

During installation, the plug or the shutter retainer was not removed. This will result in the device not allowing liquid to pass through.

Solution: Dismantle, remove plug or retainer

The valve does not hold well

does not seal tightly.

A solid particle may enter and prevent the passage from being completely blocked.

What to do: First, try to wash off the trapped debris with a stream of water. You need to open and close the nearest shut-off valve several times. If this does not help, disassemble the check valve, rinse it well and reinstall it

The threaded coupling has burst.

This happens when there is a heavy load in the pipeline, a defective product, or too much sealing material is wound.

What to do: Can only be fixed by replacing the product

Tapping

After installing the check valve, knocking noises are heard. This can happen due to the larger valve diameter. Another option: installed too close to the pump.

Solution: in the first case, purchase a device with a smaller diameter. In the second, rearrange it to a more suitable place.

Advice and recommendations from experts

To avoid mistakes during installation, we recommend reading expert advice:

- The direction of the arrow on the valve body and the direction of fluid flow in the water supply must match.

- The device must be installed in places where there is easy access. This is necessary so that the check valve can be inspected or repaired in the future.

- Before installation, check the device for leaks.

- Valves made of steel and brass have a longer service life. Since they are more resistant to corrosion and pressure changes.

- It should be installed after the metering device.

So that the water check valve installed in the water supply system can function correctly for a long time. It is necessary to carry out installation according to the rules specified in the instructions

Why is the valve not working?

A sign that the check valve is broken - the system cannot maintain the accumulated pressure. Or rather, a broken valve is only one of the reasons. The second is a leak in the supply pipeline. So you'll have to check both options.

What does a water check valve look like in cross section?

If you look carefully at the check valve device, you will understand that there is nothing to break. Possible breakdowns include a wedge on the rod and debris that prevents the disc from pressing tightly. The locking plate may also be worn. The latter is incurable, we change it immediately. Wear also includes pressed grooves from the seat on the sealing ring. So having a seal is a mixed advantage. The rubber is pressed through and the valve begins to “etch”.

This is what a blockage looks like on a small diameter OK

If the stem is lopsided or jammed, in some cases you can correct it. As a rule, this does not last long, and it will jam again quite soon. If the locking plate is clogged, it can usually be cleaned. To prevent this situation from happening again, place a filter in front of the check valve. If it is already there, and the water is still too dirty, there are several options:

- install a second, smaller filter;

- or raise the end of the pipeline from the bottom level;

- clean or deepen the well or borehole.

If we are talking about a submersible pump of the “Kid” type, dampening the vibrations that occur during its operation will help reduce the amount of turbidity. There are different methods - from the use of springs in suspension, to rubberized suspension. This really helps. Another option is to place a barrel with a wide neck in the bottom of the well, and a pump in it. Less silt and sand will rise.

You can see this picture

Next note. If, after a long period of operation without breakdowns, the check valves begin to “fly” one after another, the water level may have changed and you need to move the suction point. The second option is that the pipes are clogged with sand or silt and the pipeline needs to be simply flushed. Well, check it for leaks. By the way, if the station does not gain pressure, then the problem is most likely not in the check valve, but in the bulb, its fastening, nipple, etc.

Source