- January 12, 2021

- Tools and equipment

- Valery Lysenko

Connecting a three-phase motor to a 220 V household network is in most cases required in the manufacture of various machines and devices. Usually the power of a single-phase electric motor is not enough, and not every home has a three-phase electrical installation. In this case, a diagram for connecting a three-phase motor to a single-phase network will come to the rescue.

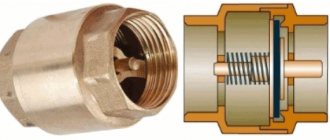

What is a starting capacitor

When the electric motor is in operating mode, its movement is provided by the windings. However, when at the moment of start you need to start rotating, the usual engine efforts are not enough. Without the use of additional means, it will only begin to tremble slightly.

Typically one of the engine elements is a run capacitor. It accumulates a charge that is capable of exceeding the operating voltage, and then releases it at the right moment. However, its work is not enough to start it. To do this, you need to connect another capacitor in parallel, which is called a starting capacitor.

Selection of a working capacitor Source sdelaysam-svoimirukami.ru

It is launched for a short time, which does not exceed a few seconds. Sometimes this is done by briefly pressing the start button, and sometimes the shutdown is done automatically after the engine begins to pick up speed.

The use of a starting capacitor is especially important in cases where the engine needs to be started under load. In this case, it will be necessary to increase the starting torque during the first seconds of operation.

In some cases, the engine is started with a light load. In this case, a starting capacitor may not be needed. This applies to motors whose power does not exceed 1 kW. Refusal to use it will simplify the scheme and reduce costs. Sometimes the load can be related to design features. In this case, you can take measures to reduce it, which will make it easier to start the engine in the future.

Various starting capacitors Source antemion.ru

A little history

Back in 1841, the English physicist Charles Winston introduced the first single-phase motor, which did not yet know how to spin on its own. This was done manually or using another engine.

In 1884-1885, a motor was developed that had armature windings and field windings and was called “universal”. This was done by Hungarian engineers, co-authors of the transformer Miksha Deri and Otto Blati, and independently of them Werner Siemens. Electric motors of this type are still used today.

In addition, Nikola Tesla was involved in the development of electric motors. The first capacitor motor was developed by French engineers Maurice Hitin and Maurice Leblanc in 1890. How to choose a capacitor for a three-phase motor in our time, we will understand further.

What is a capacitor

This part contains two metal plates, between which there is a dielectric layer. When voltage is applied to the plates, a charge accumulates on them. The electrical is inside the capacitor. The stronger the charge is on the plates, the stronger it is.

If you disconnect the voltage from the plates, the capacitor begins to release charge. If alternating current is used, the polarity of the voltage will periodically change. In this case, the plates will alternately have a positive and a negative charge.

The capacitance of a capacitor is its most important characteristic. It characterizes how much energy he is able to pass through himself. It is measured in farads. Since we are talking about a very large quantity, prefixes are usually used to indicate how small a part is used. The most commonly used is microfarads (this unit is equal to 0.000001 farads).

Motor connection procedure Source kabel-house.ru

There is a voltage rating for each capacitor. With it, this part is able to work for a long time and reliably. The maximum operating time value, which is expressed in the number of hours, must be indicated.

There are different types of capacitors:

- Polar are designed for use in DC circuits. An important feature is the need to connect in accordance with the polarity indicated on them. They are usually small in size and have a relatively large capacity.

- Non-polar ones can be connected regardless of polarity. They are used in alternating current circuits. They are larger in size than the polar ones.

- Electrolytic. They use sheets of foil as plates, and the dielectric is a thin layer of oxide.

Electrolytic ones are best suited for use as a starting capacitor. They are often used with an AC frequency of 50 Hz and a voltage of 220-600 volts. Capacitors can have a fairly high capacity; it can be hundreds of thousands of microfarads.

These parts are highly vulnerable to overheating. If the thermal regime is violated, they quickly fail. Non-polar capacitors do not have this disadvantage, but are several times more expensive.

Single-phase asynchronous motor Source asutpp.ru

When connected in parallel, the containers add up. In the event that it is not enough, you can connect an additional part in parallel to increase it. In this situation there is no need to reassemble the trigger circuit.

Other types of capacitors are also used. For example, these can be vacuum, liquid, gas and others. However, they are not used as starting capacitors.

Sometimes the capacitor that is included in the design fails to start. In this case, it is recommended to remove it and replace it with one that has a larger capacity. For low-power motors, it is permissible for one capacitor to perform the functions of working and starting.

The use of polar capacitors in alternating voltage conditions is possible when the connection is made through a diode. Now the polarity of the contacts will not change. However, if the diode is faulty, the part will fail.

Construction of an asynchronous motor Source elektrikexpert.ru

Use of asynchronous motors

Three-phase and single-phase asynchronous motors are actively used in various sectors of the economy. There are several reasons for this:

- Simplicity of design.

- Reliability and durability during use.

- In order to start the engine, there is no need to use expensive and scarce devices.

- The motor does not require too frequent maintenance.

By appearance, you can easily distinguish three-phase motors from single-phase ones. The former always have 6 terminals, while the latter have two or four.

For three-phase motors, the windings are connected in two ways: star or delta. They assume the use of a voltage of 380 volts. However, it is rarely used in everyday life. To use such a motor, you need to know how to connect it correctly.

This is done using a phase-shifting capacitor. This will allow the use of three-phase motors when connected to a single-phase network. In this case, the motor power will be equal to 50% -60% of the nominal.

Checking the starting capacitor Source antemion.ru

Optimal operation of a three-phase motor is ensured by using a variable capacitance. To do this, at the first stage, working and starting capacitors are used, and at the second, only the first of them.

Asynchronous single-phase motors are often used in everyday life. Additional winding is usually required to start.

When choosing the capacitance of a capacitor, it is necessary to take into account how the magnitude of the starting torque depends on it. As this characteristic increases, the force increases. At a certain value it becomes maximum. After a further increase, the starting torque will begin to fall.

Calculation of capacitor parameters Source uk-energotekhservis.rf

Indirect inclusion

Connecting a single-phase motor

The main component of the indirect connection circuit is a magnetic starter, which is connected to the gap between the power network output and the electric motor.

The power contacts of this block are designed as normally open. Based on the maximum current flowing through it, a magnetic starter belongs to one of seven standardized groups. Due to the low power of single-phase electric motors, a device of the first group is usually sufficient, the maximum switching current of which is 10 A.

The control part of the coil is designed for connection to networks with different voltages. The most convenient is a magnetic starter controlled from 220V AC.

What characteristics are taken into account when choosing

The installation of the capacitor must be done strictly according to the relevant regulations. Its selection is made based on the following information:

- Motor type (single-phase or three-phase) and winding connection method (delta or star).

- The power supply network used. In everyday life you can most often find 220 V. A supply voltage of 380 V is also used, provided that the network is three-phase. The latter option is often used in industrial settings.

- Engine power.

- The power factor in most cases is 0.9.

- Electric motor efficiency.

This data can be obtained from the operating instructions for the electric motor. Electrical grid data must be available from other sources. For calculations, you can use an online calculator or do the calculations yourself.

There are additional parameters that also need to be taken into account:

- Permissible deviation from the calculated value.

- The temperature range in which the part should operate. For some varieties, going beyond it may cause damage.

- The resistance level of the dielectric used.

- Loss tangent.

These parameters are not critical. Therefore, they are often forgotten. However, the more carefully the starting capacitor is selected, the more reliable and durable the operation of the motor will be.

Additionally, you need to pay attention to the size and location of the part. Typically, as the capacity increases, the dimensions of the part increase. Sometimes there may be a choice between brands from different manufacturers. You need to choose those that produce higher quality and more reliable parts.

Starting capacitor SVV-60 Source aliradar.com

How to choose a starting capacitor

For it to work most effectively, you need to choose the right container. To calculate it, various formulas are used, depending on the method of connecting the windings. The calculations are performed as follows:

- It is necessary to determine the operating current and voltage of the motor. When carrying out calculations, the designations I and U are used for them. The current value is taken from the operating instructions for the motor, and as U we take the one provided by the supply voltage.

- Capacity is determined by the formula C = (K x I) / U.

If the windings are connected in a triangle, K = 4800 is used, and when connected in a star, K = 2800 should be used. The result of the calculation is the capacitance expressed in microfarads.

Connecting a single-phase asynchronous motor Source sibay-rb.ru

When making calculations, the rated current must be taken into account. We are talking about the maximum permissible operating current under conditions when the engine is operating in normal mode. In practice, its value depends on the available load. If it is not there, then the value will be minimal.

This value is called no-load current. It is actually compensation for losses associated with energy losses in windings, dielectrics, friction and other similar reasons.

Connecting a three-phase motor to a single-phase network Source stroysvoy-dom.ru

If you gradually increase the load, the current will increase. Then it will reach the nominal value. With a subsequent increase, the current will continue to increase, but the speed will begin to fall. Prolonged stay in this mode will lead to increased wear of the equipment and possible breakdown.

You can determine the rated current not only from the operating instructions, but also measure it yourself. In the latter case, its value will be determined more accurately. This measurement can be done as follows:

- Disconnect the capacitors.

- Start the engine in operating mode.

- Using a current clamp, the current strength is determined.

Based on the obtained value, the required capacity is determined. Then they purchase the required part and install it. In this case, deviation from the calculated value is allowed by no more than 15%.

Schemes for connecting a three-phase motor to a single-phase network Source orenburgelectro.ru

When connecting a single-phase motor, the capacity of the working capacitor is determined as follows. You need to take 7 microfarads for every 100 watts of rated power. For starting, the capacity is chosen 2-3 times larger. Single-phase asynchronous motors are often used in home appliances.

For this purpose, capacitors of the following designs are usually chosen:

- metal-paper, high-frequency, which are designated MBGCH;

- heat-resistant paper type belonging to the BHT variety;

- paper in a sealed metal case - KBG-MN.

If the motor needs to rotate in the reverse direction, the connection to the capacitor will need to be changed. To do this, it will be enough to simply swap the terminals. If we are talking about replacing an existing part, then it is most convenient to choose it with the same characteristics as before.

As a working one, you must use a non-polar capacitor designed for use with alternating current. This is due to the fact that the polarity will constantly change during operation. However, it is permissible to use a polar one as a starter. In order to prevent the voltage sign from changing, it is necessary to connect this part via a diode.

Using starting and running capacitors for connection Source uk-parkovaya.ru

Condensate Pump – Types

Condensate pumps are produced in several versions, which differ in the number of stages, sections and installation option:

- multi-stage (2-stage and 4-stage) horizontal installation type;

- sectional single-casing devices of horizontal type (3- and 6-stage);

- sectional two-body vertical installation type;

- spiral type 1-stage devices with a 2-way input wheel.

In addition, devices can be segmented according to the following principles:

- direction of coolant flow: direct-flow, countercurrent and with transverse coolant flows;

- the number of changes in the possible directions of movement of coolants - one-pass, two-pass, etc.;

- design: shell-and-tube, plate, etc.

Condensate devices can be connected according to two schemes: open and closed . In closed piping circuits, a condensate trap must be installed behind the installation or directly inside the pressure installation itself. An open connection scheme implies that the device is connected to the external atmosphere. A closed scheme of communication with the atmosphere does not imply.

Installation check

Once a suitable starting capacitor has been selected, it must be tested. To do this you need to do the following:

- First you need to turn off the power from the electric motor.

- It is necessary to de-energize the capacitor, since a residual charge could remain on it. To do this, you need to short-circuit its windings.

- Now you need to remove one of the terminals and connect a device to measure capacitance.

- The probes are connected to the terminals of the capacitor. After this, the measuring device will show the exact capacitance value.

When using a multimeter, you must first set the main switch to capacitance measurement mode.

When carrying out calculations, you can use a simplified version. It is known that the starting current can exceed the rated current by 3-8 times. Therefore, you can simply use a capacity 2-3 times larger than that of the working capacitor. If the starting capacity is not enough, you can simply take a more suitable capacitor.

Detailed characteristics of the starting capacitor Source electrikexpert.ru

Difference between start and run capacitors

To better understand why a starting capacitor is needed and what the features of their application are, you need to know about their differences. The main ones are the following:

- They have different installation locations. The worker is part of the circuit of working motor windings. The starter is part of the motor starting circuit.

- Capacitors differ in exactly when they are supposed to work. The starter is connected to the circuit during the first few seconds after starting. Then it is turned off in manual or automatic mode. The worker performs his functions during the entire time the engine is running.

- Each of them has its own functions. The starting one provides a phase shift between the windings to provide the main force when initially starting the motor. The worker ensures the rotation of the phases necessary for normal operation of the electric motor.

- Each capacitor type has different operating voltage requirements. The starting unit must be designed for one that exceeds the supply by 2-3 times. The worker must be designed for one that is 1.15 times greater than the incoming one.

In both cases, capacitors of the MBGO and MBGCh types are most often used.

Methods for connecting three-phase electric motors

In electrical engineering, there are two types of power switching for a three-phase asynchronous motor:

- star method;

- using the triangle method.

The listed types of connections are used on all types of three-phase electric motors. The nature of the engine’s operation and its maximum load depend on which method is used. Thus, motors with a star connection have a smooth start, but cannot operate at the maximum load stated in the technical data sheet. Motors with a “triangle”, on the contrary, start quickly and can produce maximum power.

How does the load size affect the choice of capacitors?

If the part is selected in accordance with the calculations given here, then it will fit well under a uniform load. An example of such a situation is the operation of a fan.

If the load changes, then in this case you can use the following trick. For example, you can consider a circular saw, which is used to cut boards and logs. In the first case, it is obvious that the load is less, and in the second - more.

For example, if calculations were made based on the rated current and a capacitance equal to 10 microfarads was obtained, then you need to use such a working capacitor when sawing boards. It will most likely not be enough to work with logs. In this case, when performing work, two such parts are connected in parallel.

If this is not done, the engine will lose power. As a result, it will begin to overheat and to work on it you will need to take breaks to allow the motor to cool down.

To start the engine you need to connect a starting capacitor Source chipmaker.ru

Operating principle

The principle of operation of an electric motor demonstrates the simplest experiment that we were all shown at school - the rotation of a frame with current in the field of a permanent magnet.

The frame with current is an analogue of the rotor, the stationary magnet is the stator. If current is applied to the frame, it will turn perpendicular to the direction of the magnetic field and freeze in this position. If you force the magnet to spin, the frame will rotate at the same speed , that is, synchronously with the magnet. We have a synchronous electric motor. But our magnet is a stator, and by definition it is motionless. How to make the magnetic field of a stationary stator rotate?

First, let's replace the permanent magnet with a current-carrying coil. This is the winding of our stator. As is known from the same school physics, a coil with current creates a magnetic field. The latter is proportional to the magnitude of the current, and the polarity depends on the direction of the current in the coil. If we apply alternating current to the coil, we get an alternating field.

Magnetic field is a vector quantity. The alternating current in the supply network has a sinusoidal shape.

A very clear analogy with a clock will help us. What vectors constantly rotate before our eyes? These are the hour hands . Let's imagine that there is a clock hanging in the corner of the room. The second hand rotates one full revolution per minute. An arrow is a vector of unit length.

The shadow that the arrow casts on the wall varies as a sine with a period of 1 minute, and the shadow cast on the floor changes as a cosine. Or a sine phase shifted by 90 degrees. But a vector is equal to the sum of its projections. In other words, the arrow is equal to the vector sum of its shadows.

The most common models in Russia

Most often you can find the following brands on sale:

- Capacitors of the SVV-60 brand with a metallized polypropylene version. They have a relatively high price.

- HTC film brands have a fairly high level of quality, but cost a little less than SVV-60.

- E92 are a budget option for starting capacitors. They have a relatively low price, but are inferior in quality and reliability to the previous two options.

There are also a number of other models, but they are less common.

Procedure for connecting capacitors Source uk-parkovaya.ru

Tips for use

Determining the required characteristics and choosing a model usually requires considerable effort. In this regard, it makes sense to take into account a few tips:

- It is mandatory to use a starting capacitor when working with high-power motors or in cases where it is necessary to start rotation of the shaft with a load.

- Motors smaller than 1 kW can usually be operated without the use of a starting capacitor. Such motors are often used in household appliances.

When connecting the starting circuit, you must carefully follow all the necessary rules. An error can lead to a breakdown or emergency.

Features of device operation

When operating the device, you must take precautions, neglect of which can lead to rapid failure. Each pump must be checked for correct connections before initial start-up and the following requirements must be met during normal operation:

- If the supply of electricity to the site is accompanied by voltage surges, a stabilizer must be included in the assembly diagram illustrating the design of the Aquarius pump.

Starting capacitor https://m.st

- When the groundwater level fluctuates seasonally, it is necessary to control the elevation of the device. The housing must be completely submerged under water to avoid dry running.

- It is necessary to test the automation - how the device reacts to pressure drops during combined operation with a relay. Correct design and adjustment of smart systems for the Aquarius deep-well pump is the key to long-term trouble-free operation.

- If the water in the well is cloudy due to the presence of natural suspended matter, the equipment should be periodically removed to clean or replace filters.

- If the operation is slow (as evidenced by increased noise from the well), the device should be maintained by replacing bearings, seals and other consumables.

- When inspecting the device, you should check the smoothness of the speed increase and compensation of starting loads. When power surges occur when turned on, the problem is eliminated if you know how to correctly connect the capacitor to the Aquarius pump.

Carrying out repair work https://

With proper care and preventive maintenance, the device can operate for up to 10 years without serious breakdowns.