Heat-resistant steel 20Х23Н18 is in high demand in the rapidly developing energy sector and for the manufacture of gas turbines. Interest has expanded in areas where it is possible to use elevated temperatures to produce certain parts.

Steel 20Х23Н18 is integral in the production of furnace equipment: muffles, screens, parts of burner devices with operating temperatures up to 1050 C and as a heat-resistant material up to 700..800 C. The grade is smelted in open electric furnaces.

The temperature range for forging stainless steel 20Х23Н18 is from 1220 C to ~ 900 C. Cooling is carried out in air if the steel cross-section is < 350 mm. For welding, electrodes are used, for example, TsT-19. Moreover, it is carried out without heating and further processing.

Which GOSTs regulate

Multifunctional steel 20x23n18 has a complex composition, which is regulated by a number of state standards.

The basis of the alloy is iron, and the remaining elements are necessary to obtain certain performance characteristics. Nickel, chromium, manganese, silicon, phosphorus and sulfur are used as alloying compounds. This composition gives the metal high strength characteristics, resistance to corrosion and increases heat resistance. In addition to the verified ratio of all elements, GOST regulates the technology for manufacturing raw materials and assortments.

Steel is smelted in an arc furnace in several stages, during which special attention is paid to temperature conditions. The generally accepted technological process consists of the following steps:

- at the initial stage of melting, the exposure temperature reaches 1180 degrees Celsius;

- upon reaching the highest melting point, the temperature begins to gradually decrease to a level of 900 degrees;

- after the main stage of deformation, the turn of hardening of the metal begins - for this, the workpiece is heated to 1150 degrees;

- at the last stage the alloy is cooled in water, oil or in open air.

Heat-resistant steel 20x23n18 according to GOST can only be produced on special steelmaking equipment, and only large production enterprises can guarantee compliance with all necessary requirements.

High-alloy heat-resistant steel 20Х23Н18

Substitute

Stainless steel grades – 20Х23Н13, 15Х25Т.

ASTM Standard: 310S AISI.

Application area

High-alloy heat-resistant steel 20Х23Н18 is used in the production of individual parts for combustion chambers, such as clamps, hangers, and fastening parts. This grade of steel is often used to produce seamless pipes, which are operated at high temperatures – up to +1100 °C.

Type of delivery

Stainless steel bars comply with GOST 5949-75, GOST 2590-71, GOST 2591-71, GOST 2879-69. Calibrated rods are made from stainless steel in accordance with GOST 7417-75, GOST 8559-75, GOST 8560-78, and ground rods - in accordance with GOST 14955-77.

Thick sheets produced from steel of this grade must comply with 7350-77, GOST 19903-74, GOST 19904-74, steel strips - GOST 4405-75, GOST 103-76, and strips - GOST 4986-79. When manufacturing forged blanks, there must be compliance with GOST 1133-71.

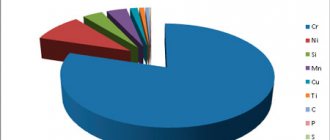

Chemical composition

| Chemical element | Silicon (Si), no more | Copper (Cu), no more | Manganese (Mn), no more | Nickel (Ni) | Titanium (Ti), no more | Phosphorus (P), no more | Chromium (Cr) | Sulfur (S), no more |

| % | 1.0 | 0.30 | 2.0 | 17.0-20.0 | 0.2 | 0.035 | 22.0-25.0 | 0.02 |

Mechanical properties

| Heat treatment, delivery condition | Rods. Quenching 1100-1150°C, air or water | Sheets are hot-rolled or cold-rolled. Quenching 1030-1130°C, water (transverse samples) | Cold rolled strip. Quenching 1050-1080°C, water or air | Cold rolled strip. Quenching 1050-1080°C, water or air |

| Section, mm | 60 | >4 | <0,2 | 0,2-2,0 |

| 0.2, MPa | 196 | 264 | ||

| B, MPa | 490 | 539 | 580 | 580 |

| 5, % | 35 | 35 | ||

| 4, % | 19 | 38 | ||

| , % | 50 |

Mechanical properties at elevated temperatures

| ttest, °C | B, MPa | KCU, J/m2 | 0.2, MPa | 5, % | , % |

| Rods with a diameter of 38-55 mm. Quenching 1180°C, water. Aging 800°C, 4 hours. | |||||

| 20 | 600-660 | 137-186 | 295-320 | 29-35 | 47-54 |

| 300 | 520-540 | 147-166 | 235 | 25-28 | 45-49 |

| 400 | 540 | 147-166 | 225 | 24-32 | 39-45 |

| 500 | 520-540 | 171 | 210 | 25-31 | 41-45 |

| 600 | 440 | 176 | 195 | 24 | 46 |

| 700 | 315-330 | 171 | 185-195 | 19-24 | 35 |

| 800 | 185-205 | 176 | 165 | 19-27 | 34 |

| Sample with a diameter of 10 mm and a length of 50 mm, rolled | |||||

| Deformation speed 20 mm/min. | |||||

| Strain rate 0.007 1/s. | |||||

| 800 | 255 | 215 | 24 | 67 | |

| 900 | 135 | 135 | 37 | 77 | |

| 1000 | 71 | 64 | 49 | 77 | |

| 1100 | 44 | 39 | 51 | 70 | |

| 1200 | 27 | 22 | 27 | 31 | |

Technological properties

Forging temperature

The initial temperature for forging stainless steel should be +1220 °C, and the final temperature should be about + 900 °C. If the cross-section of stainless steel is less than 350 mm, then cooling is carried out in air.

Weldability

Limited weldability.

Machinability

In the normalized and tempered state at HB 178 and B = 610 MPa, Ku b. Art. = 0.4.

Endurance limit

| Heat treatment, steel condition | Quenching 1100°C, water or air. HB 140-200 | |

| -1, MPa | 255 | 245 |

| B, MPa | 590 | 570 |

| 0.2, MPa | 290 |

Heat resistance

| Wednesday | Air | Air | Air |

| Temperature, °C | 650 | 750 | 800 |

| Test duration, h p> | 4500 | 1500 | |

| Depth, mm/year | 0,0027 | 0,01 | 0,044 |

| Strength group or score | 2 | 3 | 4 |

Physical properties

| Test temperature, °C | Modulus of normal elasticity, E, GPa | Density, kg/cm3 | Thermal conductivity coefficient W/(m °C) | Ud. electrical resistance (p, NΩ m) |

| 20 | 200 | 7900 | 14 | 1000 |

| 100 | 16 | |||

| 200 | ||||

| 300 | 182 | 19 | ||

| 400 | 176 | 7760 | ||

| 500 | 170 | 7720 | 22 | |

| 600 | 160 | 7670 | ||

| 700 | 150 | 7620 | ||

| 800 | 141 | |||

| 900 | 7540 |

| Test temperature, °C | Linear expansion coefficient (10-6 1/°С) | Specific heat capacity (C, J/(kg °C)) |

| 20-100 | 14.9 | 538 |

| 20-200 | 15.7 | |

| 20-300 | 16.6 | |

| 20-400 | 17.3 | |

| 20-500 | 17.5 | |

| 20-600 | 17.9 | |

| 20-700 | 17.9 | |

| 20-800 | ||

| 20-900 | ||

| 20-1000 |

Characteristics and properties

The metal composition is developed on the basis of heat-resistant alloys, but the presence of some additional components enhances the individual properties of the metal. Thus, nickel increases the heat resistance of the alloy, and chromium prevents oxidation. The presence of a small amount of carbon increases the permissible temperature range and increases the plasticity properties. Chromium forms a protective film on the metal surface and finished products are perfectly resistant to high humidity.

Steel has the following specific properties:

- high technology;

- increased plasticity;

- heat resistance;

- resistance to corrosion of any type;

- excellent weldability.

The main area of use of the alloy is the manufacture of various metal parts, and various mechanical and thermal methods are used to process metal blanks to create a specific shape. Steel lends itself well to forging, grinding, polishing and smelting. This property makes it possible to create monolithic parts with high tensile strength.

Chemical composition and analogues of steel 20Х23Н18

The properties and scope of application of various grades of stainless steel depend on the ratio of alloying elements. Chemical composition of steel 20Х23Н18 in% according to GOST 5632-72:

- iron (Fe) up to 54;

- chromium (Cr) 22-25;

- nickel (Ni) 17-20;

- manganese (Mn) up to 2;

- silicon (Si) up to 1;

- carbon (C) up to 0.2;

- phosphorus (P) up to 0.035;

- sulfur (S) up to 0.02.

Substitutes: 20Х23Н13, 15Х25Т. The main foreign analogues are brands AISI 310, AISI 310S and AISI 314 (USA).

Scope of application of stainless steel 20x23n18

The alloy, unique in its characteristics, is intended for the manufacture of parts that will be used under conditions of aggressive and extreme exposure. To obtain equipment parts, ordinary metal blanks are used, but there are also more attractive options, assortments with a ground surface. This assortment is used to create decorative interior elements. For example, furniture in the high-tech style necessarily contains several metal products that give it an original and modern look.

Steel 20x23n18 is purchased for the following purposes:

- creation of parts for heating systems and furnace equipment;

- aviation industry;

- production of parts intended for use in environments with increased radioactive background;

- creating kitchen utensils that are exposed to temperature;

- production of seamless pipes;

- construction of metal structures.

The heat-resistant alloy copes well with intense loads and withstands long periods of heating, which makes the metal indispensable in the manufacture of parts for certain equipment.

Material 20Х23Н18 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells material 20Х23Н18 in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, material 20Х23Н18 is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Stainless steel products 20x23n18

In you will find a wide range of steel 20x23n18 at the price from the manufacturer. Qualified consultants will help you choose an assortment option and calculate the required volume of rolled metal. Depending on your technical requirements, the following products can be purchased from the company:

- metal sheets of different thicknesses with subsequent surface treatment;

- finished pipes in a wide dimensional grid;

- calibrated metal rods;

- steel strips;

- wire of any diameter.

The company complies with all established regulations and carefully monitors the quality of each batch of products.

To select and purchase products made of stainless steel 20x23n18, go to the catalog.

Wire 20Х23Н18

Wire 20Х23Н18 is a product made of heat-resistant steel grade, obtained by drawing, drawing, rolling or pressing. Steel wire is used to make springs, ropes, fasteners, heating elements and much more. Winding occurs in coils or skeins. The wire is mainly made with a round cross-section, but square and rectangular sections are also possible.

Analogue 20Х23Н18

A foreign substitute for 20Х23Н18 in terms of properties and composition is AISI 310S stainless steel.

Scope of application of stainless steel 20Х23Н18

Corrosion-resistant steel 20Х23Н18 is widely used in mechanical engineering, architecture, energy, food and chemical industries. From it they produce:

- Working and guide vanes, forgings and bandages operating at temperatures of 650-700 °C.

- Furnace equipment operating at temperatures of 1000-1050 °C.

- Elements of combustion chambers.

- Medium-loaded parts and advertising structures.

- Pipelines and tanks for chemical reagents, liquid, bulk and vaporous food products.

In the domestic economy, the required material is in demand along with such well-known brands as 12Х18Н10Т and 08Х13.

Steel 20x23n18: characteristics, application, types

The fact is that recently interest in the industrial industry has grown significantly, and methods of high-temperature processing of steel have also begun to be used quite often.

Therefore, heat-resistant stainless steel 20x23n18, the characteristics of which are excellent for these purposes, has become popular.

General information about the material

If we take into account the characteristics, this steel boasts such advantages as: manufacturability of the material, increased ductility, high heat resistance.

What is important is that the weldability of this metal is quite high. It is also worth noting that steel 20x23n18 belongs to the austenitic class of metal.

The basis for this material is made up of two substances such as nickel and iron.

Sheet steel is made from a complex alloy and austenitic alloy. It must be highly resistant to any aggressive environmental influences. Atmospheric and soil moisture should also not have a significant effect on it.

The heat-resistant steel sheet of grade 20x23n18 itself is a very multifunctional and convenient material that allows it to be used in a variety of conditions.

Often used to make combustion chambers, the main requirement of which is high temperature resistance.

Steel classification

Most often, heat-resistant steels are used to produce parts that are simply impossible to obtain in any other way. One of these parts was a blade for gas turbine engines. Most often, st 20x23n18, the characteristics of which allow it to withstand high temperatures well, is ideal. Other important parts are also made from it.

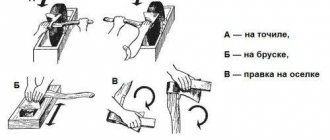

Operations for steel processing

In the industrial sector today, several operations are used to produce elements for gas turbine engines. These include forging, grinding, machining, polishing and precision casting. In order to go through all these stages of processing, it is necessary to use sufficiently high-quality steel.

You can use a large number of different materials, but the characteristics of steel 20x23n18 indicate that it is most profitable to use it, since it is most suitable for the job. It can also be used in almost any climatic conditions. Thanks to all these qualities, it has become the most common in this field.