Which GOSTs regulate

High-alloy steel 12x18n9t is produced in accordance with GOST 5632-72, which contains all the necessary information about the percentage of different compounds and manufacturing technology.

The chemical composition of steel includes the following elements:

- carbon – 0.12%;

- silicon – 0.8%;

- manganese – 2%;

- sulfur – 0.02%;

- phosphorus – 0.035%;

- chromium – 19%;

- nickel – 9.5%;

- titanium – 0.8%.

Depending on the manufacturer, the composition of the alloy may vary slightly, but these changes should not exceed the specified content of certain elements in the composition.

Since metal blanks are produced in different forms, depending on the category, one of the following GOSTs is used:

- long products - GOST 5949-75;

- forgings – GOST 25054-81;

- thick sheet - GOST 7350-77;

- wire – GOST 18143-72;

- rods - GOST 189087-73.

The main area of use of 12x18n9t steel according to GOST is the production of various parts, therefore, the most convenient type of workpiece is selected for each production task. For example, in the manufacture of pipes, a metal sheet is used, and depending on the category of the pipe itself, the raw material has different thicknesses and surface types.

12Х18Н9Т (Х18Н9Т)

- Products made of steel 12Х18Н9Т (Х18Н9Т) in stock:

Circle - Sheet

- Wire

- Hexagon

to make a request

Steel 12Х18Н9Т (Х18Н9Т) corrosion-resistant chromium-nickel austenitic class

Substitutes: Steel 08Х17Т, Steel 08Х18Т1, Steel 10Х14Г14Н4Т, Steel 12Х18Н10Т, Steel 12Х17Г9А4, Steel 03Х23Н6

Steel 12Х18Н9Т is used: for the manufacture of welded equipment, pipes, furnace fittings parts, heat exchangers, muffles, exhaust system parts, sheet and section parts; devices and vessels operating at temperatures from -196 to +600 °C under pressure, and in the presence of aggressive media up to +350 °C; aircraft manufacturing parts; powder used in the production of permeable products and porous rolled and sintered tape, filters for the purification of lubricating oils, fuel, alkalis, air and other gases and technical liquids, as well as for the production of flame arresters, porous coolers; wire woven mesh of twill weave, used as a reinforcing material in the manufacture of asbestos steel sheets, for separating bulk solids by grain size, filtration and other purposes; double and triple lay ropes for special working conditions. Steel grade 12Х18Н9Т is recommended to be used in the form of long metal and hot-rolled sheets not produced in continuous rolling mills. Recommended maximum operating temperature for a long time is +800 °C, for a very long time +600 °C. The temperature of intensive scaling in air is +850 °C. The steel is unstable in sulfur-containing environments and is used when nickel-free steels cannot be used.

Specifications

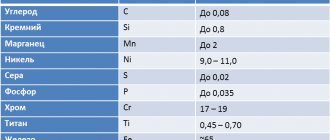

| Chemical composition in% |

| NTD | C | S | P | Mn | Cr | W | V | Ti | Si | O | Ni | Mo | Cu | Ca |

| TU 14-1-748-73 | ≤0,12 | ≤0,020 | ≤0,040 | ≤2,00 | 17,00-19,00 | ≤0,20 | ≤0,20 | — | ≤0,80 | — | 8,00-9,50 | ≤0,50 | ≤0,40 | — |

| GOST 13084-88 | 0,05-0,12 | ≤0,020 | ≤0,030 | ≤0,35 | 16,0-20,0 | — | — | 0,50-0,80 | ≤0,10 | ≤0,35 | 7,0-10,0 | — | — | ≤0,15 |

| GOST 5632-72 | ≤0,12 | ≤0,020 | ≤0,035 | ≤2,00 | 17,00-19,00 | ≤0,20 | ≤0,20 | — | ≤0,80 | — | 8,00-9,50 | ≤0,50 | ≤0,40 | — |

According to GOST 5632-72 and TU 14-1-748-73 Ti% content = 5C% - 0.8%. For aircraft parts, Mo% content ≤ 0.30%. According to GOST 13084-88, the chemical composition is given for powder of the PKh18N9T brand.

| Mechanical properties |

| Mechanical properties at 20°C |

| Delivery status | Section (mm) | t test (°C) | holiday temperature (°C) | sТ | s0.2 (MPa) | sB (MPa) | d5 (%) | d4 | d | d10 | y (%) | KCU (kJ/m2) | HB | H.R.C. | HRB | H.V. | HSh |

| Gradation of property indicators of finished heat-treated parts according to OST 1 90005-91 | ||||||||||||||||

| 540-800 | ||||||||||||||||

| Blanks (forgings and stampings) according to OST 95-29-72 in delivery condition: Austenization at 1020-1100 °C, cooling in water or air | ||||||||||||||||

| Sample | 20 | ≥246 | ≥520 | ≥37 | ||||||||||||

| Sample | 350 | ≥186 | ≥372 | |||||||||||||

| Blanks for pipeline fittings according to ST TsKBA 016-2005. Hardening in water or in air from 1020-1100 °C (holding time 1.0-1.5 min/mm of largest cross-section but not less than 0.5 h) | ||||||||||||||||

| ≤60 | ≥196 | ≥510 | ≥40 | ≥55 | 121-179 | |||||||||||

| 100-160 | ≥196 | ≥510 | ≥37 | ≥45 | 121-179 | |||||||||||

| 160-500 | ≥196 | ≥510 | ≥37 | ≥44 | 121-179 | |||||||||||

| 60-100 | ≥196 | ≥510 | ≥39 | ≥50 | 121-179 | |||||||||||

| Quenching in water or air from 1050-1100 °C | ||||||||||||||||

| Forgings | 300-500 | ≥216 | ≥510 | ≥35 | ≥40 | |||||||||||

| Wire | 1,0-6,0 | 540-880 | ≥20 | |||||||||||||

| Hot rolled sheets (4.0-50.0 mm) and cold rolled sheets (4.0-5.0 mm) according to GOST 7350-77. Hardening in water or air from 1030-1080 °C | ||||||||||||||||

| ≥215 | ≥530 | ≥38 | ||||||||||||||

| Forgings for parts resistant to MCC. Quenching from 1000-1050 °C in oil, water or air | ||||||||||||||||

| 100-300 | ≥196 | ≥540 | ≥38 | ≥45 | 121-179 | |||||||||||

| 60-100 | ≥196 | ≥540 | ≥39 | ≥50 | 121-179 | |||||||||||

| <60 | ≥196 | ≥540 | ≥40 | ≥55 | 121-179 | |||||||||||

| Heat-treated wire as delivered in accordance with GOST 18143-72 (relative elongation, % with an estimated sample length of 100 mm is indicated for wire of the 1st class, in brackets - for the 2nd class) | ||||||||||||||||

| 0,2-1,0 | 590-880 | ≥25 (≥20) | ||||||||||||||

| 1,1-7,5 | 540-830 | ≥25 (≥20) | ||||||||||||||

| Cold-drawn wire as delivered in accordance with GOST 18143-72 | ||||||||||||||||

| 0,2-3,0 | 1130-1470 | |||||||||||||||

| 3,4-7,50 | 1080-1420 | |||||||||||||||

| Cold-hardened rolled products. As delivered, without heat treatment | ||||||||||||||||

| Wire | 1,0-6,0 | ≥1080 | ||||||||||||||

| Rods | ≤3,9 | ≥935 | ||||||||||||||

| Ground rods, processed to a specified strength (TS) according to GOST 18907-73 | ||||||||||||||||

| 1,0-30,0 | 640-880 | ≥20 | ||||||||||||||

| Hot-rolled and forged long products according to GOST 5949-75 and stampings according to OST 1 90176-75. Quenching in air, oil or water from 1020-1100 °C | ||||||||||||||||

| Sample | ≥196 | ≥540 | ≥40 | ≥55 | ||||||||||||

| Hot-rolled and forged long products according to STP 26.260.484-2004. Quenching in water or air from 1050-1100 °C | ||||||||||||||||

| Sample | ≥200 | ≥450 | ≥25 | ≥35 | ≥1960 | |||||||||||

| Hot-rolled and forged long products according to STP 26.260.484-2004. Stepwise processing according to the mode: heating to 1050-1100 °C; holding time when heating for products with a wall thickness of up to 10 mm - 30 minutes, over 10 mm - 20 minutes + 1 minute per 1 mm of maximum thickness; cooling at the highest possible speed up to 870-900°C; exposure at 870-900 °C for 2-3 hours; cooling with a furnace to 300 °C (speed - 50-100 °C/h), then in air | ||||||||||||||||

| Sample | ≥200 | ≥520 | ≥35 | ≥50 | ||||||||||||

| Mechanical properties at elevated temperatures |

| Delivery status | Section (mm) | t test (°C) | holiday temperature (°C) | sТ | s0.2 (MPa) | sB (MPa) | d5 (%) | d4 | d | d10 | y (%) | KCU (kJ/m2) | HB | H.R.C. | HRB | H.V. | HSh |

| Sheet 2 mm. Cold hardening with a degree of cold plastic deformation of 60% | ||||||||||||||||

| 20 | ≥1290 | ≥1330 | ≥10 | |||||||||||||

| 300 | ≥970 | ≥1080 | ≥6 | |||||||||||||

| 500 | ≥780 | ≥870 | ≥10 | |||||||||||||

| 700 | ≥360 | ≥420 | ≥29 | |||||||||||||

| Sample 10 mm in diameter, 50 mm long, rolled. Deformation speed 20 mm/min. Strain rate 0.007 1/s | ||||||||||||||||

| 800 | ≥155 | ≥200 | ≥27 | ≥57 | ||||||||||||

| 900 | ≥110 | ≥120 | ≥41 | ≥90 | ||||||||||||

| 1000 | ≥58 | ≥66 | ≥50 | ≥95 | ||||||||||||

| 1100 | ≥35 | ≥38 | ≥66 | ≥99 | ||||||||||||

| 1200 | ≥22 | ≥26 | ≥79 | ≥100 | ||||||||||||

| Rods with a diameter of 18-25 mm. Quenching in water at 1050 °C | ||||||||||||||||

| 20 | ≥280 | ≥620 | ≥41 | ≥63 | ||||||||||||

| 300 | ≥200 | ≥460 | ≥31 | ≥65 | ||||||||||||

| 400 | ≥180 | ≥450 | ≥31 | ≥65 | ||||||||||||

| 500 | ≥180 | ≥450 | ≥29 | ≥65 | ||||||||||||

| 600 | ≥180 | ≥400 | ≥25 | ≥61 | ||||||||||||

| 700 | ≥160 | ≥280 | ≥26 | ≥59 | ||||||||||||

| 800 | ≥100 | ≥180 | ≥35 | ≥69 | ||||||||||||

| Mechanical properties depending on the degree of plastic deformation |

| Delivery status | Section (mm) | t test (°C) | holiday temperature (°C) | sТ | s0.2 (MPa) | sB (MPa) | d5 (%) | d4 | d | d10 | y (%) | KCU (kJ/m2) | HB | H.R.C. | HRB | H.V. | HSh |

| Sheet. Quenching in water from 1050 °C (the degree of compression is indicated in%) | ||||||||||||||||

| 0 % | 280-400 | 550-650 | 40-50 | |||||||||||||

| 30 % | ≥900 | ≥950 | ≥12 | |||||||||||||

| 70 % | ≥1150 | ≥1250 | ≥3 | |||||||||||||

| Mechanical properties during long-term strength testing |

| Creep limit, MPa | Rate of creep, %/h | Test temperature, °C | Long-term strength limit, MPa | Test duration, h | Temperature, °C |

| 74-78 | 1/100000 | 600 | 186-235 | 10000 | 550 |

| 132-167 | 10000 | 600 | |||

| 137-196 | 100000 | 550 | |||

| 98-127 | 100000 | 600 |

| Technological properties |

| Machinability | In the hardened state at НВ 169 and sВ=610 MPa Kn tv.all.=0.85 Kn b.st.=0.35. |

| Features of heat treatment | Depending on the purpose, operating conditions, and aggressiveness of the environment, the products are subjected to: a) hardening (austenitization); b) stabilizing annealing; c) annealing to relieve stress; d) stepwise processing. Products are hardened in order to: a) prevent the tendency to intergranular corrosion (products operate at temperatures up to 350 °C); b) increase resistance to general corrosion; c) eliminate the identified tendency to intergranular corrosion; d) prevent the tendency to knife corrosion (welded products work in nitric acid solutions); e) eliminate residual stresses (products of simple configuration); f) increase the ductility of the material. Hardening of products must be carried out according to the following regime: heating to 1050-1100 °C, parts with a material thickness of up to 10 mm should be cooled in air, over 10 mm - in water. Welded products of complex configuration should be cooled in air to avoid leakage. The holding time when heating for hardening for products with a wall thickness of up to 10 mm is 30 minutes, over 10 mm - 20 minutes + 1 minute per 1 mm of maximum thickness. When hardening products intended to work in nitric acid, the heating temperature for hardening must be kept at the upper limit (the holding time for welded products must be at least 1 hour). Stabilizing annealing is used to: a) prevent the tendency to intergranular corrosion (products operate at temperatures above 350 °C); b) relieving internal stress; c) eliminating the detected tendency to intergranular corrosion, if for some reason hardening is impractical. Stabilizing annealing is permissible for products and welded joints made of steels with a titanium to carbon ratio of more than 5 or niobium to carbon of more than 8. To prevent the tendency to intergranular corrosion of products operating at temperatures above 350 ° C, stabilizing annealing can be applied to steel containing more than 0.08% carbon. Stabilizing annealing should be carried out according to the following regime: heating to 870-900 °C, holding for 2-3 hours, cooling in air. When heat treating large-sized welded products, it is allowed to carry out local stabilizing annealing of the closing seams according to the same regime, and all welded elements must be subjected to stabilizing annealing before welding. When carrying out local stabilizing annealing, it is necessary to ensure simultaneous uniform heating and cooling along the entire length of the weld and adjacent zones of the base metal to a width equal to two to three times the width of the weld, but not more than 200 mm. Manual heating is not acceptable. To more completely remove residual stresses, annealing of products made of stabilized chromium-nickel steels is carried out according to the following regime: heating to 870-900 °C; holding for 2-3 hours, cooling with a furnace to 300 °C (cooling rate 50-100 °C/h), then in air. Annealing is carried out for products and welded joints made of steel in which the ratio of titanium to carbon is more than 5 or niobium to carbon is more than 8. Stepwise processing is carried out to: a) relieve residual stresses and prevent the tendency to intergranular corrosion; b) to prevent the tendency to intergranular corrosion of welded joints of complex configuration with sharp transitions in thickness; c) products with a tendency to intergranular corrosion, which cannot be eliminated by any other method (quenching or stabilizing annealing). Stepwise processing must be carried out according to the following mode: heating to 1050-1100 °C; holding time when heating for hardening for products with a wall thickness of up to 10 mm - 30 minutes, over 10 mm - 20 minutes + 1 minute per 1 mm of maximum thickness; cooling at the highest possible speed up to 870-900°C; exposure at 870-900 °C for 2-3 hours; cooling with a furnace to 300 °C (speed - 50-100 °C/h), then in air. To speed up the process, stepwise processing is recommended to be carried out in two-chamber or two furnaces heated to different temperatures. When transferring from one oven to another, the temperature of the products should not be lower than 900 °C. Step processing is permitted for products and welded joints made of steel with a titanium to carbon ratio of more than 5 or niobium to carbon of more than 8. |

| Weldability | Weldable without restrictions. Welding methods: RDS electrodes TsL-11, TsL-15 (providing corrosion resistance), TsT-26 (used as a heat-resistant electrode without MCC requirements), ESW. Subsequent heat treatment is recommended. To prevent the tendency to knife corrosion of welded assemblies operating in nitric acid, welded assemblies are hardened in air from 970-1020 °C; in this case, the heating temperature should be kept at the upper limit (holding time for at least 2.5 min/mm of the largest wall thickness, but not less than 1 hour). In the case of welding with wire St. 04Х19Н11М3 or electrodes type E-07Х19Н11М3Г2Ф (grades EA-400/10U, EA-400/10T, wire St. 04Х19Н11М3, etc.), hardening in air from 950-1050 °C is used (holding time not less than 2 .5 min/mm of greatest wall thickness, but not less than 1 hour). In the case of welding with electrodes of type E-08Х19Н10Г2МБ (grades EA 898/21 B, etc.) to relieve residual stresses in welded assemblies: a) operating at temperatures of 350 °C and above; b) working at a temperature not higher than 350 °C, if hardening is not practical, use stabilizing annealing at 850-920 °C (holding time after heating the charge for at least 2 hours). To relieve residual stresses of welded assemblies operating at a temperature not exceeding 350 °C, after final mechanical treatment (before lapping), if other types of heat treatment are not practical, tempering at 375-400 °C (holding time 6-10 hours), air cooling is used . In the case of welding of pipes with an internal diameter of at least 100 mm or more to the body (without guy wire), according to the design documentation, stabilizing annealing at 950-970 °C and air cooling are used. |

| Forging temperature | Start - 1200 °C, end - 850 °C. Sections up to 350 mm are cooled in air. |

| Endurance limit |

| Heat treatment, steel condition | s-1 (MPa) | t-1 (MPa) | n | sB (MPa) | s0.2 (MPa) |

| 279 | 1E+7 | ||||

| 196-235 | 132 |

| Heat resistance |

| 0,0018 | 2 | ||

| Air | 650 | 0,0022 | 2 |

| Air | 750 | 0,013 | 4 |

| Physical properties |

| Test temperature, °C | 0 | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| Modulus of normal elasticity (E, GPa) | 195 | 195 | 189 | 182 | 175 | 167 | 180 | 153 | 143 | 135 | ||||

| Modulus of elasticity under torsional shear (G, GPa) | ||||||||||||||

| Density (r, kg/m3) | 7900 | 7900 | 7860 | 7820 | 7780 | 7740 | 7690 | 7650 | 7600 | 7560 | 7510 | |||

| Thermal conductivity coefficient (l, W/(m °C)) | 16 | 18 | 20 | 21 | 23 | 25 | 26 | 28 | 29 | |||||

| Ud. electrical resistance (R, NΩ m) | 725 | 725 | 792 | 861 | 920 | 976 | 1028 | 1075 | 1117 | 1149 | 1176 | |||

| Linear expansion coefficient (a, 10-6 1/°С) | 16 | 17 | 17,6 | 18 | 18,3 | 18,6 | 18,9 | 19,3 | 19,5 | 19,5 | 20,1 | |||

| Specific heat capacity (C, J/(kg °C)) | 469 | 486 | 498 | 511 | 519 | 528 | 532 | 544 | 544 | 548 |

| Sensitivity to embrittlement |

| Time, h | Temperature, °C | KCU, J/cm2 |

| 0 | 245 | |

| 10000 | 500 | 186 |

| 20000 | 550 | 220 |

| 10000 | 600 | 215 |

| Designations |

Mechanical properties:

|

Characteristics and properties

Corrosion-resistant steel is used for the manufacture of parts that are used in complex and aggressive environments, so the metal has the following characteristics:

- Mechanical strength. Steel grade 12x18n9t is used to produce elements of machinery that remain operational under prolonged shock and vibration loads.

- Heat resistance. Metal products can operate in temperatures from – 196 degrees to +600 degrees Celsius.

- Corrosion resistance. The alloy retains its crystalline structure while being exposed to high temperatures and aggressive acidic environments.

Steel does not oxidize when directly exposed to atmospheric factors and when there is a sudden change in temperature.

The main advantage of this alloy is its excellent manufacturability. Metal products can be produced by hot plastic deformation. Deep-drawn steel 12x18n9t retains high ductility during cold deformation, which makes it possible to manufacture parts with complex configurations. Manufacturability parameters are also expressed in the ability to accept welding well by any means. To connect metal elements, manual and automatic welding is used, the seam is smooth and airtight.

Stainless steel 12Х18Н9Т: where the alloy is used

Steel grade 12Х18Н9Т is a very popular alloy due to its versatility of use. Today, pipes, welded equipment, parts of energy, heat exchange equipment, and furnace fittings are made from stainless steel of this grade. Welded steel structures are designed for operation in a wide temperature range: from -269 to +600°C. The material retains its working properties in an aggressive acidic environment when heated to 350°C.

Stainless steel 12Х18Н9Т is the basis for the manufacture of rolled metal products:

- wires;

- rods;

- thin and thick rolled sheets;

- ribbons;

- seamless hot- and cold-formed pipes;

- calibrated rolled products.

Various types of metal mesh are made from stainless steel grade 12Х18Н9Т: woven, welded, wicker. Steel sheets are used for the manufacture of all-metal expanded metal mesh (CPVA).

Are you interested in rolled metal products made from steel of this brand? GRID TRADING HOUSE offers mesh and wire; you can select, order and buy (stainless steel 12Х18Н9Т based) rolled metal products on our company’s website.

Scope of application of stainless steel 12x18n9t

Steel 12x18n9t according to GOST 5632-72 is used in the manufacturing industry and construction. This alloy is used to produce the following products:

- welded structures of any type;

- metal products that come into contact with nitric acid;

- parts of equipment operating under increased exposure to atmospheric factors;

- cryogenic technology;

- capacitive and heat exchange equipment.

The main advantage of this alloy is that the workpieces are easy to process. To preserve the characteristic characteristics of the metal, there is no need to resort to special metalworking technologies. Steel retains high strength, corrosion resistance and ductility both during mechanical and thermal processing.

The main area of application is related to mechanical engineering, which specializes in the creation of heavy equipment. Units that are operated in extreme conditions, exposed to heat and in contact with acid-containing environments necessarily consist of metal parts of this category.

Properties of stainless steel

How are corrosion-resistant properties achieved? — Thanks to the addition of additional chemical elements at the metal production stage, an oxide film is formed on the surface, which does not dissolve, but, on the contrary, protects the alloy itself from the effects of corrosion.

The main properties of stainless steel also include:

- high strength

- high quality welded joints

- plastic

- long service life with preservation of its properties

Nickel (nickel-based alloys) and iron-nickel (iron-nickel-based alloys) can be used as the base metal.

The introduction of various alloying elements adds certain properties to the original metal:

- chromium increases the corrosion resistance, hardness and strength of the alloy; reducing the linear expansion coefficient simplifies the welding process

- Nickel additionally increases viscosity, ductility, hardenability and reduces the coefficient of thermal expansion, which allows the use of a product made from such an alloy with sulfuric, hydrochloric and phosphoric acids

- manganese in a percentage of more than 1% helps to increase durability, hardenability, hardness and wear resistance (can be partially replaced with nickel)

- titanium increases the strength of steel and its density, which provides high corrosion-resistant properties

- molybdenum increases elasticity, anti-corrosion properties, increases tensile strength and resistance to high temperatures

- Niobium provides low corrosion in welded products

- vanadium increases the strength, density and hardness of the alloy

- tungsten increases hardness and reduces brittleness during heat treatment (tempering) due to the formation of hard carbide compounds with other elements

- silicon in a percentage of more than 1% increases heat resistance, elasticity, scale resistance and acidity, and also increases electrical resistance and strength with the same viscosity parameters

- cobalt helps to increase impact resistance and improve heat-resistant properties

- copper gives the alloy high resistance to atmospheric corrosion

- aluminum helps reduce metal aging and also increases impact strength and fluidity

Stainless steel products 12x18n9t

Corrosion-resistant steel is prepared in arc furnaces, and to strengthen the crystalline structure, the workpiece goes through a stage of hardening and gradual cooling.

The company complies with all established standards and requirements, closely monitors product quality and can produce any type of assortment.

The company’s catalog presents all types of assortment of alloys of this brand:

- metal sheets of different thicknesses and overall dimensions;

- pipes of different diameters with machined and rough surfaces:

- steel flanges;

- wire;

- rods, circles and hexagons.

To select and purchase products made of stainless steel 12x18n9t, go to the catalog.

Main characteristics of 12Х18Н12Т

Alloy 12Х18Н12Т

low-magnetic, characterized by high resistance to corrosion damage, neutral when exposed to chemically aggressive gas environments (with the exception of sulfurous acid vapors).

Products made from this steel can be used without loss of original properties in a lightly or unloaded state under conditions of temperatures of 550–800°C

.

Another advantage of 12Х18Н12Т

– heat resistance.

Elements and structures made from this steel work perfectly at temperatures from -196°C to +600°C

under the influence of aggressive chemicals.

Due to the fact that stabilized austenitic chromium-nickel steel is cold-resistant, it can be used for the manufacture of structures for use in northern cold regions.

Resistance to mechanical stress, high levels of strength and reliability ensure this steel is in great demand in various industries.

Scale on the surface of products made of 12Х18Н12Т

begins to form only at temperatures of

850°C

or more.

Long-term operation of products without compromising performance characteristics is possible up to temperatures of 600°C

, and the maximum temperature regime for long-term operation of products made from this alloy is

800°C

.

Parts and elements made of steel 12Х18Н12Т

are characterized by low antifriction properties (have a low coefficient of friction), and, accordingly, a reduced ability to resist wear. When friction acts on such products, scuffs may form on their surfaces, scratches may appear, and metal envelops.

Based on this, alloy 12Х18Н12Т

not suitable for the production of parts that may be subject to friction during operation.

Increased antifriction properties are facilitated by nitriding, carried out in special modes using ammonium chloride.

Description

Steel 12Х18Н12Т is used : for the production of sheet and long products; pipes and various parts operating at temperatures from -196 °C to +600 °C in aggressive environments; pipe blanks intended for the production of seamless cold-deformed, heat-deformed, hot-deformed, including hot-pressed, and hot-pressed reduced pipes intended for steam boilers and pipelines of installations with high and supercritical steam parameters; welded equipment operating in highly aggressive environments (solutions of nitric, acetic acids, solutions of alkalis and salts); structures welded by spot welding; connections of equipment operating in radioactive environments and in contact with aggressive environments; structures of ship hulls, vessels, products of marine equipment and shipyards (pipelines, fittings, fairings of various equipment).

Note

The steel is low-magnetic, corrosion-resistant, heat-resistant and heat-resistant. Stabilized chromium-nickel steel of austenitic class. Magnetic permeability μ ≤ 1.01 gs/e. Steel usually does not contain an α phase. With an unfavorable ratio of alloying elements and carbon, the magnetic permeability can be up to 1.50 gf/e. Heat treatment - austenitization or stabilization, hot forming and bending at temperatures used for hot deformation do not change the magnetic permeability, and hardening above 5-10% at room or low temperatures significantly increases it. Steel 12Х18Н12Т has a lower ferrite phase content than steel 12Х18Н10Т. Recommended maximum operating temperature for a long time is +800 °C, for a very long time +600 °C. The temperature of intensive scaling in air is +850 °C. Steel has low antifriction properties and is prone to scuffing, so it is usually not used in friction pairs. To improve anti-friction properties, nitriding is carried out according to special modes using ammonium chloride to remove the oxide film.

physical characteristics

| Temperature | E, GPa | G, GPa | r, kg/m3 | l, W/(m °С) | R, NOM m | a, 10-6 1/°С | C, J/(kg °C) |

| 0 | 210 | 77 | 7950 | 15 | 725 | — | — |

| 20 | 205 | — | 7900 | 151 | 761 | — | — |

| 100 | 198 | — | 7870 | 1633 | 792 | 166 | 460 |

| 200 | 193 | — | 7830 | 1758 | 861 | 17 | 482 |

| 300 | 186 | — | 7780 | 1884 | 920 | 172 | 507 |

| 400 | 177 | — | 7740 | 2135 | 976 | 175 | 525 |

| 500 | 170 | — | 7700 | 2303 | 1028 | 179 | 545 |

| 600 | 157 | — | 7850 | 2470 | 1075 | 182 | 563 |

| 700 | 147 | — | 7610 | 2680 | 1117 | 186 | 579 |

| 800 | — | — | 7560 | 2800 | 1155 | 189 | 590 |

| 900 | — | — | 7510 | 291 | 1210 | 189 | 603 |

| 1000 | — | — | — | 308 | 1245 | — | 616 |

| 1100 | — | — | — | 323 | 1275 | 193 | 625 |

| 1200 | — | — | — | 341 | 1315 | — | 637 |

Chemical composition

| Standard | C | S | P | Mn | Cr | Si | Ni | Fe | Cu | V | Mo | W |

| TU 14-1-1529-2003 | ≤0.12 | ≤0.02 | ≤0.035 | 1-2 | 17-19 | ≤0.8 | 11-13 | Remainder | ≤0.3 | ≤0.2 | ≤0.5 | ≤0.2 |

| TU 14-3R-55-2001 | ≤0.12 | ≤0.015 | ≤0.03 | 1-2 | 17-19 | ≤0.8 | 11-13 | Remainder | ≤0.3 | — | — | — |

| GOST 5632-72 | ≤0.12 | ≤0.02 | ≤0.035 | ≤2 | 17-19 | ≤0.8 | 11-13 | Remainder | ≤0.4 | ≤0.2 | ≤0.5 | ≤0.2 |

| TU 14-158-137-2003 | ≤0.12 | ≤0.02 | ≤0.035 | ≤2 | 17-19 | ≤0.8 | 11-13 | Remainder | — | — | — | — |

| TU 14-3-460-2003 | ≤0.12 | ≤0.025 | ≤0.035 | 1-2 | 17-19 | ≤0.8 | 11-13 | Remainder | ≤0.3 | ≤0.2 | ≤0.5 | ≤0.2 |

Fe is the basis. According to GOST 5632-72, TU 14-1-1529-2003 and RD 9257-76 Ti content % = 5С% - 0.7%. For aircraft parts, Mo content % ≤ 0.30%. According to TU 14-1-1529-2003, the mass fraction of residual elements: tungsten, vanadium, molybdenum must comply with the requirements of GOST 5632. For steel 12Х18Н12Т-Ш, the sulfur content should be ≤ 0.15%, the phosphorus content ≤ 0.30%. According to TU 14-3-460-2003 Ti content % = 5·(C-0.2) % - 0.7%. The mass fraction of residual elements: tungsten, vanadium, molybdenum must comply with the requirements of GOST 5632. According to TU 14-158-137-2003, the content of Ti% = 5C% is 0.7%. It is allowed to introduce cerium and other rare earth metals at a rate of 0.2-0.3%, which are not determined by chemical analysis. According to TU 14-3R-55-2001, the technological addition of rare earth elements is allowed to improve the quality of the metal. The content of residual elements is in accordance with GOST 5632. The content of Ti% = 5·(C-0.02)% - 0.7%.

Designations

| Name | Meaning |

| Designation GOST Cyrillic | 12Х18Н12Т |

| Designation GOST Latin | 12X18H12T |

| Translit | 12H18N12T |

| By chemical elements | 12Cr18Н12Ti |

| Name | Meaning |

| Designation GOST Cyrillic | Х18Н12Т |

| Designation GOST Latin | X18H12T |

| Translit | H18N12T |

| By chemical elements | Cr18H12Ti |