Despite the proliferation of power tools, hand tools are still necessary and have their uses. The advantages are obvious - no electricity or batteries are required for operation, hand tools are usually compact and lightweight. Such tools include a rasp. Construction portal Firststroy.ru will tell you what a rasp is, how to work with it, its types and recommendations for choosing a tool.

Operating principle

The principle of operation of a file is to remove the top layer from the workpiece by means of friction.

The teeth of the bar determine the quality of the cut, and the depth depends on the effort applied by pressing the tool and the speed of movement.

A coarser and larger notch allows you to work much faster, but at the same time the quality of processing decreases.

Fine or diamond edges provide an almost perfect surface.

In many ways, the results of the work depend on the characteristics of the material and the correctly selected type of file.

What is it and why do we need it?

A rasp is a cutting tool with a large number of blades. This device may have sharp and large notches. It has found its application in the elimination of rough wood layer with its subsequent leveling, as well as in filing products and giving them a certain shape. This product is found both in garages and in locksmith shops. It is considered universal, as it can be useful for rough and primary work with wood.

The rasp can be used for processing wood, soft and finishing sheet materials. Due to the practicality of use in many technological procedures, this carpentry attribute has gained popularity among craftsmen. Its main purpose is considered to be filing, that is, the elimination of the surface layer from the workpiece in order to subsequently give it the desired shape, size, and roughness. The tool is necessary for quick, high-quality and simple removal of irregularities from any surface.

When using such a carpentry attribute, the processing accuracy can be about 0.05 mm.

Despite the fact that filing is considered a labor-intensive process, the use of a high-quality rasp can make the work easier, faster, and also eliminate the formation of defects. The main part of the tool’s design is considered to be metal teeth, which have some resemblance to a grater. The working part of the device is made of steel, and the surface is produced by stamping notches and teeth. The latter are located towards the long side, overlapping each other.

To make the tool easy to use, it has a handle. It is usually made of hard wood or plastic.

Thanks to the structural features of the handle, the master is protected from injury and deformation of products.

Form

The standard tool is a flat rasp. It is used when it is necessary to trim workpieces, remove burrs from the surface of metal or wooden products. Rasps of the presented shape are made from the strongest tool steel. What is a round rasp? Devices with a rounded working surface open up the possibility of processing all kinds of holes, uneven surfaces of non-solid materials. Often, such tools are used when performing plumbing work.

Read also: What is depopulation?

As for semicircular rasps, the latter can be used when processing not only concave, but also flat workpieces. They are used when cleaning the surfaces of large diameter holes.

Literary significance and criticism

Anthony Getrin is one of the first examples of the amateur detective, an idea that soon became popular in detective literature. The focus on breaking an elaborate alibi is similar to the work of Freeman Wills Crofts, A Contemporary of MacDonald. “The story is an ordinary body in research, with enough obvious findings... The killer's fakery is obvious from the very beginning. Despite all this, it has been declared several times a “classic” and “epoch-making work” by disciples of the genre.[1]

What should a set of rasps consist of?

It is worth considering that for high-quality work, a whole set of rasps is required. The classic set is represented by a combination of the following options:

- Flat.

- Round.

- Semicircular.

Classification is also carried out according to the type of notches applied into two classes, only if both are available it is possible to carry out work with high accuracy. The semicircular rasp of the second number has more notches on the surface, which ensures higher efficiency in use.

Most often, a metal rod is made using steel grade U7, in some cases U8 and U10. By increasing the hardness and sharpness of the cutting edge, the degree of engagement with the surface being processed significantly increases at the time of processing.

Only two types of tools are produced abroad: regular and grooved. The teeth of such designs, as a rule, have standard sizes.

Manufacturing materials

Metal rasps, like files, are made from steel. In some cases, products are made from tool carbon steel, such as U10, U11, U12, U13. In addition, the basis of rasps is often alloy steel - ШХ6, ШХ9, ШХ15.

To understand how much carbon is in the rasp steel, it is worth observing the nature of the sparks.

A small amount of C2 will be expressed as sparks from the abrasive disc, which are straw-yellow in color and fan out.

Steel with a high carbon content promotes the appearance of sparks, which separate a small number of stars from the thickening point. The abundant production of many sprockets comes from a high-carbon type of tool steel.

Long orange-red sparkles appear from the chromium metal.

If high-speed steel with chromium and tungsten was used in the manufacture of the rasp, then at the same time both short and elongated sparks appear, which have a dark red color and thickening at the end.

Types of rasps

There are quite a large number of different types of such instruments. Classification is carried out according to various criteria, the most important being the type of working part:

- Flat rasps are much more common than other options and are usually included in standard sets. A similar working surface can be used for finishing flat surfaces; the tip can be tapered or straight.

- There is also a semicircular rasp. In most cases, a tool with a similar surface is used for processing semicircular workpieces. The degree of rounding of the main part of the product may vary significantly.

- To work with products that have an unusual shape, versions with a triangular or other complex cross-section are often used. The special shape allows material to be removed from corners and other complex geometries.

There is a roughing rasp with a different working surface, which is made using structural or tool steel. The type of alloy used largely determines the performance characteristics of the product.

Tool Features

The use of rasps requires subsequent finishing of the workpiece. This is due to the high surface roughness after completion of the work. The process of removing chips using such tools is greatly simplified due to the presence of a special groove in front of each notch or protrusion.

When processing parts of unusual shapes, rasps with a triangular cross-section are often used. This allows you to remove material from difficult surfaces and angles. The degree of engagement with the workpiece depends on the sharpness of the cutting edge and the hardness of the steel used to make the tool.

Subtleties of work

Finding out what a rasp is used for and learning how to work with it, you should gradually learn specialized subtleties that allow you to achieve much better results.

- Having already completed work on the part, it is necessary to ease the pressure on the rasp so that the work turns out softer and more delicate. The fact is that the pressure force affects the depth of the recesses left by the tool on the surface.

- When working with wood, wood dust always remains on the tool. It needs to be brushed off. It is also recommended to fan the surface being treated as often as possible. This way it will be much clearer how the work is going, what needs to be faked or corrected, where you can use the rasp one more time.

- If you have to work on a thin or too small area, it is better to take not an ordinary rasp, which is useless here, but a miniature corrugated one. With its help you can easily reach the most difficult places.

The main differences between a rasp and a file

A rasp is a type of file. Features are as follows:

- The rasp is intended for rough processing; after its use, finishing files (with finer notches).

- Due to the large cutting edge, productivity is significantly increased. In other words, this tool takes much less time to remove material.

- If you pay attention to how the notches are located, the differences are almost immediately evident. In the case of a rough instrument, they look like large cells arranged in a checkerboard pattern.

- The product in question is designed to transmit high force. That is why the main part is more massive and is made using a thicker layer of material.

The file is characterized by the fact that it allows you to obtain a better quality surface in comparison with the case of using a rasp.

In most cases, the technological map provides for a combination of several similar tools, thereby increasing the productivity and quality of the resulting product. That is why the set is often represented by a combination of several types of products, which can have different shapes.

What is a wood file

Structurally, the tool looks simple. This is a steel plate with multiple notches, which vary in depth and profile.

The wooden or composite handle is designed for ease of holding while performing work.

- The main purpose of a wood file is to perform rough rough work.

- Removing a thin layer with a tool allows you to speed up the process of preparing the surface for the main work.

- A grinding machine can replace a wood file. However, not every master can afford it.

Therefore, most specialists trust and work with old, reliable files.

Blade plastic cutter for metal

Another device will help you deal with plastic quickly and easily.

To do this, you should cut the file with the same grinder according to the same pattern as in the photo. The head angle should be approximately 45°

After trimming, the head needs to be sharpened on both sides and the handle wrapped with heat shrink or, as in this case, electrical tape

If you need to cut a sheet of plastic straight, draw a line along the ruler with force

After such manipulation, the plastic will easily break along the drawn line, leaving a smooth edge.

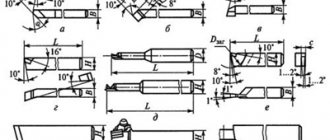

Types of files

The industry offers various types of this tool, most of which are universal and can be used with equal success for fine processing of wood and metal. The tools are classified according to the type of cutting part:

- with a single notch;

- with double cross notch;

- for wood with an arc notch;

- with rasp notch;

- stamped file.

Separately, it is worth noting a tool designed for delicate work with miniature parts. A wood file is the same file, but smaller in size, which makes it indispensable for making small crafts from wood and other soft materials. For the same purposes, a type of needle file is used - riffles. Their working part is curved, which significantly facilitates the production of small parts of complex shapes.

All files, regardless of their purpose, are classified according to the cross-section of the working part. The most popular tool is the following profile:

- flat (rectangular);

- square and round section;

- triangular;

- semicircular;

- rhombic.

The shape of the tool, size, depth and type of notch are selected depending on the type of work performed. The rougher the processing, the larger the notch should be and the larger its pitch. From this we can conclude that a home workshop should have not just one file, but a whole set of similar tools with different characteristics.

Features and scope of application of the rasp

In carpentry, a separate type of file called a wood rasp is often used. At first glance, these two tools are similar, but there are serious differences between them. The fact is that the notch of the rasp is made in the form of separate burrs of different shapes. Thanks to this configuration, the tool does not clog and can quickly process a large surface.

Note! A rasp is indispensable in cases where it is impractical to use other methods of surface treatment (saw, plane).

For example, you need to remove a few millimeters from the end surface of a small board. The saw will most likely ruin the workpiece, it is impossible to use a plane due to the short length of the board, a simple file will take a long time to work, and besides, it will constantly become clogged with sawdust.

Proper use of the rasp

Proper use of a rasp file eliminates the occurrence of defects on the surface of the wood being processed, and also protects the carpenter from injury and damage to the tool. Technological features of the design of the working part of the tool require compliance with certain rules when working with it:

- Products must first be thoroughly cleaned of wood sanding dust and shavings. This can be done using brushes with different bristles softness. This is important for the carpenter to correctly visually assess the degree of required polishing of the product.

- For convenience, a wooden workpiece is often clamped in a vice. This ensures the correct angle of the fixture. For quality work, it is important to maintain a 90° angle between the tool and the arm bent at the elbow.

- During the filing process, a balance of forces applied when pressing with the right and left hands during the working stroke must be maintained. Thus, during the grinding process, the wood will not receive new defects: chips, cuts and burrs.

- Surface treatment is carried out diagonally to the wood fibers. This is due to the peculiarities of the macroscopic structure of wood.

How to restore a file at home?

Many novice craftsmen believe that a tool with traces of paint or covered with rust cannot be restored, and they throw it away. Any metal files can be cleaned, sharpened and used for a long time. After work on restoring the metal rod, you can also update the handle; it is recommended to carefully remove the old one if it is cracked and has defects. A new one will last a long time if it is treated with special wood products, varnished or painted.

How to clean a file?

Many craftsmen have encountered a problem when files become covered with rust and cannot be used. You can clean both straight and triangular files, as well as other options, using improvised materials at home.

- Pour hot water into the container where the entire file is placed and clean the surface of the tool with an old toothbrush and dishwashing detergent.

- Drain the soap solution, dry the file, prepare a liquid for cleaning the surface of the tool, consisting of 1 tbsp. hot water and 2 heaped teaspoons of citric acid. Pour the prepared solution into the file and leave it in it for 12 hours.

How to sharpen a file?

Frequent use of a file can cause the tool to become dull. Working with copper, aluminum and stainless steel often causes small metal particles to get stuck between the teeth. A rough file becomes clogged, its surface loses its functions, and its cutting part needs to be sharpened. There are several options that can return the file to its original appearance.

- The chemical method

is fast and effective. Before sharpening, the tool must be cleaned, degreased and dried. The solution into which the file is then placed consists of water (86%), nitric acid (8%) and sulfuric acid (6%). In 10 minutes. After immersion, the instrument must be removed and washed thoroughly. - The electrochemical method

is similar to the previous one. The proportions of the solution in it are slightly different; water (80%), nitric acid (9%) and sulfuric acid (11%) are taken. The file must be dipped into the prepared mixture and a low frequency current must be passed through using aluminum plates. - The mechanical method

of sharpening tools requires a special device - a milling machine. First, the file is fired in a special furnace at a temperature of about 800°C, after which its surface is ground on a machine. Using a chisel, notches are formed on a smooth file. To harden the tool, place it in a solution consisting of water (50 l), salt (2 kg) and hydrochloric acid (1 l). For hardening small instruments, the proportions are reduced. - The sandblasting method

of sharpening files requires the ability to work with special tools. The cutting surface is restored using fine sand, which is passed through a nozzle under pressure. - Folk methods of sharpening

tools are widely used by home craftsmen. Experts recommend using different compounds to restore the working surface of files: citric acid, ferric chloride, vinegar.

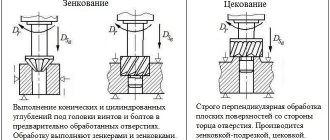

Purpose of some types of rasps

Perhaps the first thing you should pay attention to when choosing a rasp is the profile of its working part. The list of works that can be performed with its help depends on this characteristic. With all the diversity of the instrument, four of its varieties are most common: flat, round, semicircular, triangular.

Flat

This tool is convenient for processing smooth surfaces and recesses with a large radius of curvature. It can also be used to form the inner surface of grooves and cuts in wood.

Round

First of all, a round rasp is used to develop holes in the wood and the end surfaces of curved cuts. In addition, this tool will help smooth the ends of wood-based boards and slabs.

Semicircular

A rasp with a semicircular working part is advantageous in its versatility; one side of it performs the work of a flat rasp, the other - a round rasp. It can be used with equal success for leveling flat and curved cuts.

Triangular

This tool has three planes at once, which determines the scope of its use. It can level small flat parts, develop the inner surfaces of polygonal shaped holes. It is also used to make shaped cuts when creating tenon joint elements.

Tool care tips

Only with proper care of the tool can you significantly extend its service life. Among the features of care, we note the following:

- At the time of work, there is a possibility that the recesses and notches will become clogged with material. This is manifested by the fact that when performing movements, the proper layer of material is no longer removed from the surface, and the instrument begins to move without significant effort. Cleaning can be done by lightly hitting the surface. You need to be careful when doing this, as too much force can cause damage to the tool.

- If the notches become clogged with chips, it is possible to clean them using a standard brush.

- Before using the rasp directly, it is prohibited to place it on metal surfaces. Such long-term operation causes rapid wear of the cutting edge.

- Contact of the tool with various lubricants is not allowed. Even a small amount of such a substance can cause a significant reduction in the performance of the product.

Upon completion of work, you should check the condition of the tool. The appearance of minor defects indicates that the tool will have to be replaced in the near future, as it will lose its basic performance characteristics.

Rasp - all about the tool, where and how it is used

Despite the proliferation of power tools, hand tools are still necessary and have their uses. The advantages are obvious - no electricity or batteries are required for operation, hand tools are usually compact and lightweight. Such tools include a rasp. The construction portal Firststroy.ru will tell you what a rasp is, how to work with it, its types and recommendations for choosing a tool.