21 22 .. 1.6. PLOW BODY

Plow body types

Based on the shape of the working surface, dump bodies are divided into cultural, semi-screw, screw and cylindrical. In our country, the first three types are used.

Cultural bodies (Fig. 1.5, a) wrap well and crumble the soil layer, so they are used for plowing old arable lands. Cultural bodies are produced for operation at speeds up to 7; 7…9 and 9…12 km/h. The permissible operating speed is indicated in the technical specifications of the plow.

Half-screw housings (Fig. 1.5, b) wrap the formation well, but loosen it worse. Such bodies are installed mainly on shrub-marsh plows, but they can also be used on general-purpose plows for plowing heavily turfy and virgin soils.

Screw housings provide a full rotation of the formation without loosening it and create the best conditions for the decomposition of crop residues and turf. They are used for plowing a layer of perennial grasses, radical improvement of forage lands and primary plowing of virgin lands.

Moldless plow body

(Fig. 1.5, c) is intended for loosening soil in wind-erosive and arid areas. The layer, cut by ploughshare 1 and raised by widener 8, falls over the upper edge of the widener and falls to the bottom of the furrow. As a result of the deformation of the formation by the ploughshare, the expander and the impact on the bottom of the furrow, the formation crumbles without significant mixing of the layers. Shield 7 protects rack 3 from abrasion.

Cut-out plow body

(Fig. 1.5, d) is used for moldboard plowing of podzolic soils and at the same time deepening the arable horizon by 4...5 cm. The body is equipped with two shares 1 and 10. The lower part of the layer, cut by share 1, passes into the gap between them without turning. The upper part of the layer , cut by ploughshare 10, goes to dump 9, turns around and falls onto the lower loosened layer.

Body with overlay chisel

(Fig. 1.5, e) is intended for plowing hard soils clogged with stones. A chisel 13 is attached to the toe of the share 1, the working end of which protrudes beyond the toe of the share by 3...4 cm. The chisel ensures good penetration of the body and protects the share from breakage when encountering stones. The worn bit is replaced with a new one. The body is equipped with an angle 11 and a vertical knife 12.

Housing with subsoiler

(Fig. 1.5, f) are used for moldboard plowing of podzolic, chestnut soils and thin chernozems with simultaneous deepening of the arable layer by 6...15 cm. The pointed deepening paw 14, installed behind the body and below the ploughshare, loosens the bottom of the furrow opened by the body, which eliminates mixing arable layer with subsurface. The holes in the stand allow you to rearrange the paw in height and change the depth of loosening. The gripping width of the subsoil paws is 26 or 30 cm. They are used with bodies with a working width of 30 and 35 cm, respectively. Bodies with subsoilers are installed on general-purpose and special-purpose plows.

Disk enclosure

(Fig. 1.5, g) are used for plowing heavy hard soils clogged with tree roots, as well as for waterlogged soils when cultivating rice. The body is equipped with a spherical disk 15 with a sharply sharpened cutting edge. The disk is attached to the flange of the spindle 16, which rotates freely on bearings. The rack 3 is fixed to the plow frame so that the plane of rotation of the cutting edge of the disk is inclined to the bottom of the furrow at an angle of 70°, and with the direction of movement of the plow it forms an angle of attack of 40...45°.

The disk, buried 25...35 cm, moves forward along with the unit and at the same time rotates under the influence of soil resistance. The layer cut off by the disk is shifted to the side and thrown into the furrow with a turnover. The disc housing does not compact the bottom of the furrow. The coarse-clump structure of the plowed soil promotes good aeration and rapid drying of the lower layers.

The working width of a disk housing with a diameter of 71 cm is 30 cm. Discs with a diameter of 76 and 81 cm are also used.

Combined body

(Fig. 1.5, h) is designed for plowing heavy soils with simultaneous intensive loosening of the soil layer. The body is equipped with a shortened blade 2 and a rotor 19 located in place of the cut-off wing of the blade. The shape of the rotor is a truncated cone, with the large base facing upward. Blades 20 are attached to the cone generatrices. The rotor shaft 18 rotates in the housing 17. The rotor speed is 268...507 min-1. The blades intensively crumble the layer of soil coming off the dump, and at the same time turn it over and throw it into the furrow. The surface of the field plowed by the combined hull is flat, well loosened and does not require additional processing.

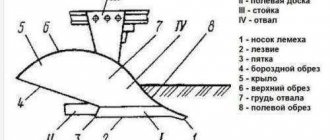

Rice. 1.5. Types of plow bodies: a - cultural; b - half-screw; c - dumpless; g - cut-out; d - with an overhead chisel; e - with a subsoiler; g - disk; z - combined; 1, 10 shares; 2.9 - dumps; 3- stand; 4 — blade feather; 5-field board; 6-blade chest; 7-shield; 8- extender; 11 - let’s find out; 12- knife; 13 - bit; 14 — deepening paw; 15 — disk; 16-spindle; 17- rotor housing; 18- shaft; 19- rotor; 20- blades

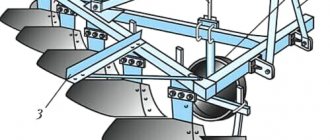

Let's look at the design of plows of the "PL" family using the example of the PLN-4-35 plow. The plow (Fig. 1) consists of working parts and auxiliary parts.

Main working bodies

plows are: bodies, skimmers

7

and disc coulter

2.

Each plow body consists of a ploughshare

8,

a moldboard

9

, a field board mounted on a shoe, which is attached to a stamped steel stand

10

.

The body stand is attached with three bolts to the plow frame 1

and a vertical bolt to the stiffener beam.

The skimmer, like the body, consists of a share, a blade and a stand. It is attached in front of the body to the frame strip on the left side with a holder and a bracket with nuts. The circular knife is installed in front of the last housing.

To auxiliary parts

mounted plow includes: frame

1

, suspension with automatic coupling lock

5

, support wheel

6

with screw

4

for installing the wheel at different heights relative to the supporting plane of the bodies.

In addition, when plowing with a plow with simultaneous harrowing, a hitch for harrows 12 with

a stretcher

11

.

All working and auxiliary parts are mounted on a plow frame made up of longitudinal bars, transverse struts and a stiffening beam.

The bodies are placed on the frame sequentially with an offset by the working width b

towards the non-arable field (Fig. 2) with some overlap ∆

b

= 25...75 mm, which contributes to complete cutting of the layer with small deviations of the plow from straight-line movement.

Distances l

between the bodies (along the course of the plow) must be such that it is possible to install skimmers and the plow is not clogged with soil and plant debris.

Usually they take l

= (2.0…2.2)

b

.

For plows with a body working width b =

35 cm,

l

= 75 cm, and for

b

= 40 cm,

l

= 80 cm.

Which plow should you choose?

| Be sure to take into account the features of the available equipment. Choose a plow for the tractor. |

Choosing a plow body

The main working elements of the plow are the bodies. The plow body consists of a ploughshare and a moldboard. The ploughshare cuts the layer of earth from below and directs it to the dump. The blade separates the layer from the unplowed canvas and turns it over. The number of plow bodies usually varies from 3 to 12.

Depending on the geometric shape of the plowshare-moldboard surface of the body, certain goals and features of plowing are achieved. The cultural body crushes the formation well, but does not completely turn it over. Such buildings, as the name implies, are used in constantly plowed fields. The half-screw body both turns over and crumbles the formation to a moderate extent. It is advisable to use it for cultivating fallow lands. The screw casing wraps the formation well without crushing it too much. This profile is used for the development of virgin lands.

Choosing a plow share

The geometric shape of the share also determines the plowing characteristics. Traditional are used to cultivate light old-arable fields . To ensure good penetration on heavy soils, chisel-shaped shares are used. On very heavy, rocky and uprooted areas, toothed shares and shares with a retractable chisel .

Choosing a plow moldboard

Depending on the geometry, blades are most often classic, screw and feather. Screw moldboards are effective in fields with a lot of crop residues. Feathers are used on wet soils: they have a striped rather than continuous surface, due to which less soil sticks to them. In other cases, you can use the classic blade profile.

| Feather blades save fuel when processing wet soils, and their repairs are cheaper: you can replace an individual part rather than the entire blade. |

Operating a moldboard plow

Plows with moldboard bodies have found the widest application in our latitudes. Such a plow provides plowing of the field with full or partial rotation, creating loosening of the formation. A moldboard plow is an indispensable unit on the field that is capable of embedding crop residues to a sufficient depth.

Among the known ones, this is the most environmentally friendly of all known methods of weed control, successfully replacing even the use of chemicals, the harm from which today is considered exorbitant in comparison with the benefits. Also, during plowing with a moldboard plow, larvae of insects - field pests, and spores of various crop diseases are destroyed. And all this without the use of herbicides.

It is worth adding that from the point of view of some experts, the use of a moldboard plow does not seem so clear-cut. The arguments include the deterioration of the fertile soil layer and its compaction, and the need to keep the land fallow. As an alternative, non-traditional methods of tillage are offered - gentle, minimal, no-moldboard. However, herbicide-free cultivation of crops without a moldboard plow is currently not possible, which means it will continue to be used.

Connecting the plow to the tractor

Depending on the method of connection to the tractor, trailed, semi-mounted and mounted plows can be distinguished.

The mounted plow is fully hydraulically lifted, ensuring mobility and ease of movement of the tractor. However, in this case, the load on the tractor increases, so mounted plows, as a rule, have no more than 8 bodies. The design of a semi-mounted plow allows the plow body to be lifted hydraulically separately from the frame, while the plow moves on a support wheel, reducing the load on the hitch. Trailed plows are not connected to the hydraulic drive of the tractor.

How are plows divided by purpose and design?

To plow large areas in a short time, it is necessary to choose the right plow design. It depends on the capabilities of the tractor, the planned crop, and plowing tasks. Based on the type of main tool, plowshare and disk models are distinguished. Depending on the type of hitch, there are mounted, semi-mounted and trailed designs. The device will work effectively if selected correctly.

According to plowing technology, plows are divided into: products for dump plowing and for smooth plowing.

More varieties are distinguished by the design of the body and units:

- reversible plows - differ from the classical design in the absence of a felling ridge, two sets of knives are used alternately, plowing time is reduced;

- moldboard - used to turn over the top layer of soil when plowing;

- non-mouldboard designs - used when there is no need to turn over the top balls of soil;

- disc - in this case, discs are able to cut roots and large weeds when plowing;

- cut - the plowing depth in this case is about 5 cm, this is necessary on soils with a thin fertile layer;

- combined systems - plowing and loosening the soil, preparing it for planting crops.

Modern tractor plows for plowing land work efficiently and do not require constant maintenance. It is necessary to monitor the condition of the working unit, as well as replace consumables after their service life has expired. The main advantage of the large number of types of equipment is the ability to choose exactly the option that is ideal for a specific soil type.

What is important to consider when choosing a plow?

There are various factors to consider when choosing a plow.

Tractor power . This parameter is one of the most important when selecting equipment. The type of connection and the number of plow bodies depend on it. The tractor's traction force must be sufficient to tow the available number of bodies and move the plow without excessive fuel consumption. The most popular are 7-8 furrow plows.

| Experts recommend determining the number of bodies when choosing a plow based on 40 hp. tractor power per body. |

Area of cultivated areas . The working width of the plow, which depends on the number of bodies, must optimally correspond to both the volume of plowing and the power of the equipment. The nature of the fields being processed . To correctly select the body and type of ploughshare, you need to take into account the degree of complexity of the terrain and the hardness of the soil, the moisture content of the field and the presence of residues on it.

What else you should pay attention to: protection systems and out-of-furrow operation

plow protection also depends on the complexity of the soil . Most often, plows are equipped with spring, hydraulic protection or shear bolts. On light soils, traditional shear bolt protection . When the plow hits an obstacle while plowing, the bolt is sheared off. The body rises and passes over the plow.

In fields with heavy soil with a lot of rocks or roots, frequent replacement of bolts can be inconvenient, so experts recommend using spring or spring protection . Having encountered an obstacle, the body rises and falls due to the operation of the shock absorber.

The most modern option is hydraulic protection . The housings are raised and lowered by a hydraulic cylinder. Of course, such a protection system is much more expensive and more difficult to repair than others.

There are also varieties of plows according to the location of the tractor during plowing . If the tractor moves with one wheel in a furrow, as happens in the traditional case, the strip under the wheel becomes compacted, and the tractor itself is always in a tilted state, which increases wear on parts and causes inconvenience to the driver. Some modern plows are equipped with on-land technology, which allows the tractor to remain entirely on the unplowed strip during plowing. But the most convenient are universal plows that allow both types of work.

| Tilt of the tractor while plowing in a furrow can lead to back pain and impaired driver posture. |

Operating principle of a moldboard plow

A general-purpose moldboard plow involves plowing the soil to a depth of 20-30 cm. The process itself is as follows: The upper part of the soil layer is cut off with a skimmer, turned over and placed back in the furrow.

The main body of the plow cuts off the layer from the side of the furrow and places it on the covered part previously laid by the skimmer. The knife installed in front of the rear body ensures the formation of a smooth furrow wall.

Prices for plows, depending on the model, can vary significantly - from $500 to $30,000. The market offers a wide variety of these irreplaceable agricultural units, for every taste and budget.

Arbitrary plowing of the steppes, deforestation, burning of vegetation, annual moldboard plowing, repeated disking, rolling and harrowing, as well as improper rotation of crops scatter the soil, expose it to ruthless gusts of wind.

Why is moldboard plowing harmful for agriculture in such vast areas as the North Caucasus, Northern Kazakhstan, the Volga region and the Siberian steppes?

The main harm is in soil turnover. It is known that after harvesting, the lower part of the stems remains unharvested on the surface - the stubble, which, together with the root system, firmly holds the top layer of soil together, forming reliable armor against erosion.

Plowing with a moldboard plow is accompanied by a complete revolution of the soil layer: the upper bound part falls down to the bottom of the furrow, and the lower unbound layer of soil turns out to the surface. In this case, the soil crumbles, and if there is insufficient moisture, it is sprayed.

Consequently, the moldboard plow is dangerous for agriculture in such vast steppe regions as the North Caucasus, Volga region, Northern Kazakhstan and Southern Siberia. People did not come to this conclusion immediately and not so long ago.

To deny the plow - a tool well known and familiar to every villager since childhood? Is this possible? How then to prepare the soil for sowing? These and other doubts have been expressed more than once and not in a friendly manner by many practitioners, and not only by them.

But farmers correctly assessed the harm of moldboard plowing and without a doubt abandoned the moldboard plow. They understood: if you don’t plow, you will be left without bread, and if you continue moldboard plowing, then in a few years you can lose the soil and bring the curse of your descendants.

In our country, the first to abandon the moldboard plow was T. S. Maltsev, now an honorary academician of the All-Russian Academy of Agricultural Sciences, a man of rare determination and devotion to his native land. He developed, tested in practice, non-moldboard cultivation and proved its advantage for areas with short summers and a relatively large amount of mineral nutrients in the upper horizon of the arable layer. Having abandoned the moldboard plow, T. S. Maltsev developed a system of soil-cultivating machines, the basis of which is a moldless plow, knife-shaped claw harrows and other implements.

The first moldless plow was manufactured in 1952 and outwardly differed little from its antipode - the moldboard plow. The same frame, assembled from separate rows, the same stiffening beam, the same support wheels, mechanisms for setting the plow to the required plowing depth and a towing device. Only all the accessories of a conventional plow were more delicate and had less strength, while those of a moldless plow were larger and stronger.

The main difference was in the design of the working bodies - the housings. The Maltsevsky plow had bodies without moldboards. A regular chisel-shaped ploughshare, a ploughshare extension and a protective shield protecting the body rack from abrasion were attached to the stand. Such a body uses a ploughshare to cut a layer of soil at a depth of 30 - 50 cm and raises it to a height of 10 - 12 cm onto an extender located above the ploughshare. From this height, the layer breaks off behind the body and crumbles. But crumbling occurs without noticeable mixing of the layers of the soil layer. True, a significant shift occurs at the moment the layer of the lower layers rises horizontally forward by 12 - 15 cm and to the right in the direction of movement of the plow by 20 - 25 cm. The overlying layers also shift horizontally forward and to the right, but to a lesser distance; forward no more than 10 cm, and to the right up to 15 cm.

It is interesting that T. S. Maltsev initially did not set in his system the condition of mandatory preservation of standing stubble for the winter to accumulate moisture and protect the soil from wind erosion. Therefore, at first, the moldless plow was used only for spring plowing of pure fallow. And only much later, in 1967, T. S. Maltsev began to widely use his plow during the autumn rise of plowland, as a result of which a lot of standing stubble remained on the surface. One detail is curious in this regard: T. S. Maltsev did not think about wind erosion at all when he rejected the moldboard plow. The moldless plow appeared as the fruit of many years of thinking about the widespread use of grass-based farming systems.

The fact is that in 1939, on the collective farm “Zavety Ilyich” in the Shadrinsky district of the Kurgan region, where T. S. Maltsev worked as a field farmer, they began to introduce a grass-based farming system. It was based on the teaching of V. R. Williams that only perennial grasses are naturally capable of restoring the structure of the soil and accumulating organic matter.

The farm's land mass was divided into ten fields. Eight of them were occupied by ordinary crops and fallows cultivated on the collective farm, and two fields were sown with perennial grasses. They were called upon to restore the fertility of the soil depleted by previous crops.

Only at the end of the 40s, when the grass-field system completed its first round on the collective farm, doubts arose: why can perennial grasses leave organic matter in the field, but annual grasses cannot?

After much thought, experiments and constant observations, T. S. Maltsev came to the conclusion: it is not the annual plant that is to blame, but the person who, through improper soil cultivation, creates conditions in which the role of annual plants turns out to be so unseemly. Plowing with a moldboard plow is the root cause of air penetration into the roots and other plowed parts of plants. This means that you need to plow so that the upper and lower layers of the soil do not change places for 4 - 5 years. Hence the conclusion - the moldboard plow must be replaced with a moldboardless one. However, the merit of T.S. Maltsev is not only and not even so much in the rejection of the moldboard plow.

To be fair, it should be noted that long before him, at the end of the last century, the famous Russian agronomist I. E. Ovsinsky, manager of the estates of the Bessarabia province, abandoned the conventional plow. The “new farming system” he proposed provided for surface tillage of the soil as weeds appeared to a depth of 5 cm. For this purpose, I. E. Ovsinsky used multi-body plows with small moldboard-less bodies. Initially, the “new farming system” was a resounding success, but then the brave experimenter was criticized by venerable professors, and his system was forgotten for a while.

Later, in 1913, the French farmer Jean completely abandoned the plow. He tilled the soil with a spring cultivator to a depth of 3 - 4 cm. The next time he increased the depth of cultivation by 1 - 2 cm, and so in several passes he brought the total depth of cultivation to 20 cm. By sowing one or two annual crops, he received consistently high yields - up to 40 centners of oats per hectare.

But the most vehement and convinced opponent of the plow was the American farmer E. Faulkner, who wrote and published the book “Ploughman’s Madness.” What unflattering epithets does he call the plow? “The plow is a tradition... The plow is the greatest curse on the earth... The use of the plow has virtually destroyed the productivity of our soils. But we can add that it destroyed, fortunately, temporarily... The moldboard plow is the villain in the world agricultural drama. The bigger and better the plow, the more devastating its effect.”

Faulkner, like Ovsinsky, believed that the soil in its natural state has fairly good permeability for air and water thanks to the passages and channels made by earthworms, insects and the remains of plant roots. Plowing, in their opinion, destroys this network of canals and turns the soil into a monotonous mass, drying out in dry weather and sticking together after rains. It should be noted that Faulkner harvested high yields of corn and vegetables on his plot of exceptionally heavy clay soil.

Faulkner suffered the same fate as his predecessor Ovsinsky. American scientists greeted his recommendations with hostility, despite the fact that Faulkner himself did not consider his proposals new. He wrote that his ideas are so old that they can rightfully be called new.

They are old because moldless plowing prevailed in the distant past, when in many countries farmers used omachis, plows and other tools that had only sharpened forms or did not have any devices for turning the formation. Therefore, there is no point in looking for a pioneer of moldless plowing.

After Maltsev, scientists and practical farmers in various regions of the country began to ask themselves the question: is a moldboard plow useful or harmful for their conditions? And in most cases they came to the conclusion: there can be no clear answer.

We now know that any weapon under certain conditions can cause colossal harm and, conversely, under other conditions it will bring great benefit.

The moldboard plow turned out to be two-faced, like the ancient Roman god Janus. He could become both the farmer's enemy and his friend. It all depends on the method and conditions of its use. It can be likened to a knife: in the hands of a surgeon, a knife is a means of healing, in the hands of a murderer it is a means of destruction.

In August 1954, an All-Union meeting on the Maltsev farming system was held in T. S. Maltsev’s native collective farm. Alexander Ivanovich Baraev, the future director of the All-Union Scientific Research Institute of Grain Farming in Shortandy (VNIIZH), was also there. Having familiarized himself with Maltsev’s experiments, he then said that “Kazakh farmers will follow Maltsev; that his research and the results he obtained now provide the basis for the widespread introduction of a new soil cultivation system not only in the Kurgan region, but also in areas with other soil and climatic conditions.”

What attracted the attention of Kazakh farmers in Maltsev’s system? Moldless plowing. And although the conditions here were different, plowing without rotation provided the basis for the development of a soil cultivation system in the virgin regions of Kazakhstan and Siberia. But under these conditions, it was also necessary to preserve standing stubble to accumulate the moisture that was missing here and to protect the soil from wind erosion.

Scientists at the All-Russian Research Institute of Agriculture under the leadership of A. I. Baraev, who became an academician of the All-Russian Academy of Agricultural Sciences and director of the All-Russian Research Institute of Agriculture, have conducted extensive experiments over the past 12 years and developed a system of non-moldboard erosion control soil cultivation in conditions of lack of moisture and wind erosion. They used everything valuable from T. S. Maltsev’s system and substantiated the basic principles of stubble conservation using a new system of machines.

Now this system is used in vast areas of steppe Siberia and Kazakhstan, over 15 million hectares. The farmers of the North Caucasus also look at this system with hope after the dust storms of 1969.

That is why T. S. Maltsev, addressing A. I. Baraev in a greeting address on the occasion of his sixtieth birthday, wrote: “Alexander Ivanovich, we are all very glad that our work on the development of moldless farming and sowing dates was reflected in the works the institute you head. You correctly understood our question, that no-moldboard tillage can be useful only if it is developed on site, taking into account all the features of natural conditions. And you successfully solved this at home by using flat-cutting implements and specialized seeders.”

Many institutes and design organizations participated in the development of equipment for this system: All-Union Institutes of Agricultural Mechanization and Agricultural Engineering, Kazakh Institute of Agricultural Mechanization and Electrification, plants: named after. October Revolution (Odessa), Sibselmash (Novosibirsk), Red Aksai (Rostov), etc.

In this system of machines there was no longer even a place for the name “plow”, the principles of soil cultivation had changed so much. New machines began to be called cultivators: deep-ripper cultivator, flat-cut cultivator, boom cultivator, heavy cultivator.

The new machines structurally had nothing in common with the old plow. They are nothing more than hybrids of steam cultivators with a Maltsev moldless plow. They received their form from cultivators, and their content from a moldless plow.

Autumn non-moldboard cultivation and loosening of fallows to a depth of 25 - 30 cm is carried out using cultivators-flat cutters-subsoilers KPG-250 and KPG-2-150. Their main working body is arrow-shaped flat-cutting paws with a working width of 250, 150 and 110 cm. At the lower end of the stand of such a paw, two plowshares are fixed, the cutting edges of which, thanks to surfacing of the sormite alloy, self-sharpen during abrasion with soil. On the frame of the KPG-250 cultivator you can install one flat-cutting paw with a width of 250 cm or two with a working width of 110 cm. In the first version, it is used for surface tillage of the soil to a depth of 16 cm, and in the second version for deep loosening of the soil to a depth of 30 cm .

Such implements, without damaging the stubble, loosen the lower layers of the soil, cut the roots of weeds and slightly puff up the soil. Up to 80% of stubble is preserved. It is damaged only where the paw stance moves.

Such a unit passes through the field, and you cannot immediately determine where the field has been processed and where it has not yet been touched. There are no usual furrows, and only barely noticeable narrow strips of loosened earth mark the cultivated field. It, like a well-graphed sheet of paper, is drawn with lines spaced 2.5 m apart, and between them lie strips of earth covered with untouched stubble. And this unusual and inconspicuous cultivation of arable land more than once caused the notorious peasant conservatism to manifest itself, the origins of which go back to the distant past, when what was visible to a person on the field often seemed real. He looked at the field cultivated with flat-cutters, completely covered with untouched stubble, and anxiety tore his heart: is it conceivable that such a strong soil covered with stubble would be able to accept the seed and give it everything for a good harvest?

He knew that his father and his father's father had persistently loosened the soil and rejoiced at the sight of a well-plowed field. He, too, plowed deeply with ecstasy, clearing the soil, sowed early, was glad that he had thoroughly loosened the soil, and was confident that he was doing a good job. And now it turned out: bad. The farmer did not immediately accept the new machines. But when I saw and understood the protective properties of untouched stubble against wind and drought, I abandoned the plow and began to use subsoilers and flat cutters.

In recent years, the new processing system has been supplemented with a number of machines and tools. Scientists and designers have created not only tillage machines, but also seeding machines capable of sowing grain crops on stubble backgrounds that have been treated and not treated since the fall. The industry has launched the production of SZS-9 stubble seeders; cultivator seeders and cultivator seeders. The latter perform pre-sowing cultivation, sowing of grain crops and light compaction in one pass.

The work of the creators of the system of anti-erosion measures was highly appreciated. In 1972, A. I. Baraev, E. F. Gossen, I. I. Khoroshilov, A. A. Zaitseva, G. G. Berestovsky, A. A. Plishkin were awarded the Lenin Prize for the development and implementation of a system of measures for protection of soils from wind erosion in the steppe regions of Kazakhstan and Western Siberia.

PLOW Moldboard

working part of the plow body,

intended for lifting a layer of soil cut with a ploughshare, deforming it, wrapping it with the top layer down and falling into the furrow. According to the shape of the working surface, O. items are divided into cylindrical, cultural, half-screw and screw (see Fig.). According to the design of plows, there are solid, composite (of two parts), plate, rod, roller, etc. On plows produced in the USSR, cultural and semi-screw moldboards are most widely used. O. p. are made of 3- or 2-layer steel and subjected to hardening. On plows for high-speed plowing (up to 12 km/h), special moldboards are used. the shape of the working surface, the edges ensure the standards. formation turnover, good application and continuous plowing surface.

Big Encyclopedic Polytechnic Dictionary. 2004.

See what “PLOW Moldboard” is in other dictionaries:

- snow plow blade with sectional blade

— blade with sectional blade A continuous blade of a snow plow, the blade of which consists of separate sections. [GOST 15840 70] Topics snow blowers General terms components and parts of snow blowers Synonyms blade with sectional blade ...

snow plow blade

- blade Part of a snow plow with a knife (with knives), cutting snow from the surface being cleared and moving it to the side. [GOST 15840 70] Topics snow plows General terms components and parts of snow plows Synonyms plow ... Technical translator's reference

moldboard (part of the plow)

- moldboard The part of the plow body that wraps and crumbles the formation. Plow body parts 1 stand; 2 body shoe; 3 ploughshare; 4 dump; 5 dump chest; 6 blade wing; 7 blade feather; 8 field board; 9 heel of the field board; 10 let's get it out of the way. [GOST R 50694... ... Technical Translator's Handbook

Blade

— 34. Dump An artificial embankment made from dump soils or substandard minerals, industrial, municipal waste Source: GOST 17.5.1.01 83: Nature conservation. Land reclamation. Terms and Definitions …

Snow plow blade

— 16. Moldboard of a snow plow Moldboard Part of a snow plow with a knife (with knives), cutting snow from the surface being cleared and moving it to the side Source: GOST 15840 70: Snow blowers. Terms and definitions... Dictionary-reference book of terms of normative and technical documentation

Snow plow blade with sectional blade

— 19. Moldboard of a snow plow with a sectional blade Moldboard with a sectional blade Solid blade of a snow plow, the blade of which consists of separate sections

Setting up a plow: advice from experienced machine operators

- Always start setting up the implement with the tractor, then adjust the plow.

- Equalize the tire pressure on all wheels of the tractor and the length of the hitch arms: these little things will allow the tractor to run smoother and save effort and money.

- The width between the front and rear wheels of the tractor should be the same.

- The plow will be able to adjust its direction if you leave about 10 cm of horizontal play in the lower hitch arms. The upper arm should rest against the frame at an obtuse angle to apply pressure and prevent the plow from digging out.

- The working depth of the skimmers should be 5-7 cm less than for the main buildings.

- The optimal ratio of body working width to plowing depth, which will ensure minimal wear of parts and maximum operating efficiency, is approximately 1:4.

- Observe the speed limit: the optimal tractor speed when plowing is 7-8 km/h.

| When plowing at speeds over 9 km/h, wear of parts increases by 15%. |

The plow is the oldest invention of mankind. Improving along with progress, the plow remains an indispensable tool for tillage today.

Improve your agricultural business and you - purchase an ASM-AGRO conveyor grain dryer and save up to 99.9% of the grain harvest.

View the catalog of grain dryers

Plow manufacturing quality

Agricultural equipment must be as reliable as possible. A broken plow blade during plowing can stop work for several hours. Sometimes getting to a warehouse with components for agricultural equipment is quite difficult, since the fields are located far from large cities. Therefore, you should give preference to plows and other attachments from trusted manufacturers who carry out certification, testing and quality control at every stage of production.

GC "Lida-Region" offers plows and other equipment for agricultural companies of guaranteed high quality. The catalog presents products that are used by leading enterprises in the CIS. Take advantage of the convenient selection and buy reliable equipment with a guarantee - call the managers to order products with convenient delivery.