Steel 09G2S

| Profile | Size(mm) | NTD |

| Circle | GOST 19281-73, GOST 2590-2006, GOST 2591-2006 | |

| Calibrated circle | GOST 19281-73, GOST 2590-2006, GOST 2591-2006 | |

| Square | GOST 19281-73, GOST 2590-2006, GOST 2591-2006 | |

| Forging | GOST 1133-71 |

Characteristics of steel 09G2S

The operational and technical characteristics of products made from steel 09G2S are regulated by GOST 19281-73.

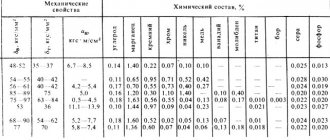

This alloy contains 11 elements. The percentages of all components of the substance are presented in the table below and in the diagram.

| Cr | Mn | Ni | Mo | C | Fe | P | S |

| up to 0.3 | 1,3 – 1,7 | up to 0.3 | 0,25 – 0,4 | up to 0.12 | 96-97 | up to 0.035 | up to 0.04 |

Steel 09G2S , whose Brinell hardness is 450-490 MPa, is one of the most popular grades of steel for buildings in construction. But this is not the only advantage of steel. With a specific gravity of 7.85 g/cm3 after processing and obtaining a 2-phase structure, the steel acquires a high level of endurance limit while simultaneously increasing (3.0-3.5 times) cycles until structural failure.

Structural steel 09G2S is capable of maintaining its original characteristics at high pressure in the temperature range from -70 ˚С to +425 ˚С. Steel 09G2S is resistant to loads with a variable force vector, durable and responds well to heat treatment.

Steel 09G2 is divided into categories depending on the requirements for impact bending tests. The characteristic is the impact strength of KCU - the ability of the material to absorb mechanical energy during the process of deformation and destruction under the influence of load.

The category is indicated along with the steel grade. For example, steel with category 12 is designated as 09G2S-12 . Category 15 - 09G2S-15. The difference between them is the impact strength temperatures.

Strength class 09G2S is described by GOST 19281-2014.

Interpretation of steel 09G2S

- 09 – quantitative fraction of carbon content in the alloy (0.09%);

- G2 is manganese and its part in the entire volume fluctuates around 2% (the exact figure ranges from 1.3 to 2%);

- C – denotes silicon, the absence of numbers after the symbol indicates that it is less than 1%.

Advantages of steel 09G2S

- High mechanical strength

- Durability – the service life of parts made from this steel is more than 30 years

- Wide operating temperature range – from -70°С to +425°С

- No tendency to temper brittleness

- After tempering, the viscosity of steel does not decrease

- Does not lose ductility and does not change grain size when welding elements

Application of steel 09G2S

- Heating and steam boilers;

- Welded complex structures

- oil industry - pipe laying in the far north of Russia, installation of complex welded parts;

- mechanical engineering – production of steam boilers and other equipment for working at high temperatures;

- In simple street structures

The specific gravity of this alloy is 7.85 g/cm3. The weldability of this steel is not limited.

Welding methods:

- manual arc (RDS)

- argon-arc (AS) submerged arc and gas protected

- electroslag (ESS)

The critical point temperature is:

- Ac1 = 725°

- Ac3(Acm) = 860°

- Ac3(Acm) = 860°

- Ar1 = 625°

The material has no flake sensitivity and no tendency to temper brittleness.

Forging temperature:

- start – 1250°С

- end – 850°С

Cutting machinability is available in the normalized tempered state δB = 520 MPa, Kυ b.st = 1.0 K υ tv. spl=1.6

Analogs

Using low-alloy steels grade 09g2s, like other Russian-made metals containing carbon and manganese, it is possible to produce various types of rolled products and pipe products.

Class. Low-alloy structural steel for welded structures.

Some foreign analogues: 9MnSi5, 09G2S, 9SiMn16.

The offered metal meets both the requirements of GOST and international standards. Before shipment, each batch of goods undergoes a thorough check for defects, as well as compliance with the declared chemical composition. We are ready to provide all the necessary documents for rafting.

Material 09G2S - exact and closest foreign analogues

Bulgaria

Hungary

Germany

China

Romania

Japan

| BDS | MSZ | DIN, WNR | G.B. | STAS | JIS |

| 09G2S | VH2 |

| 9MnSi5 |

Steel 09G2S - domestic analogues

| Rolled metal grade | Substitute |

| 09G2S | 09G2, 09G2DT, 09G2T, 10G2S |

The difference between the manufacturing technology of bolts of classes 6.6, 5.6 and 4.6 from class 5.8.

Bolts of classes 6.6, 5.6 and 4.6 are made by hot stamping. To ensure mechanical properties in strength classes 6.6 and 5.6, special heat treatment is required to increase the ductility and toughness of steel.

Cold heading of bolts, used in mass production at large factories, leads to the effect of hardening of the metal and a decrease in ductility and toughness. It is as a result of this that large hardware plants equipped with cold heading machines produce fasteners of classes 4.8 and 5.8.

Purpose

Structural low-alloy silicon-manganese steel 09G2S is used for the manufacture of elements and parts of welded structures operating under pressure in the temperature range -70 +4250C.

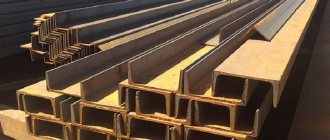

Almost the entire line of metal products is made from steel 09G2S, namely steel I-beam, hot-rolled steel sheet, used and unused pipes, strip, circle. St 09G2S has received such widespread use due to its mechanical, chemical and physical properties. Such as good weldability, exposure to external environments, high strength under load.

Use of bolts of strength classes 6.6, 5.6 and 4.6

Bolts of strength classes 6.6, 5.6 and 4.6 are used in mechanical engineering and construction in units that require increased ductility and reliability of fasteners.

The main purpose of bolts of strength classes 6.6 and 5.6 are structures and objects for which the integrity of the fastener is an important factor, even with significant deformations of the fastened elements and vibration effects.

For example, such fasteners are used in the nuclear industry, shipbuilding, defense engineering, and carriage building.

Bolts of strength classes 6.6, 5.6 and 4.6 in accordance with GOST must have a strength class stamp and a manufacturer's mark on the head. The photo above shows bolts 2M20x180.46 GOST 7795-70 strength class 4.6, below is a photo of bolts of strength class 6.6. The letter “C” around the strength class is the trademark of Spetsmashmetiz.

Modulus of elasticity of steel

Editorial team E-metall Published 2021-03-27

When designing steel products or structural elements, the ability of the alloy to withstand multidirectional types of loads is taken into account: impact, bending, tensile, compressive. The value of the elastic modulus of steel, along with hardness and other characteristics, shows resistance to these influences.

For example, in reinforced concrete construction, longitudinal and transverse reinforcing bars are used. In the horizontal plane they are subject to tension, and in the vertical plane they are subject to pressure from the entire mass of the structure. In places where stress is concentrated: corners, technological openings, elevator shafts and flights of stairs, more reinforcement is placed. The ability of concrete to absorb water causes constant changes in compressive and tensile loads.

Let's look at another example. During wartime, many developments in the field of aviation were created. The most common causes of accidents were engine fires. Taking off from the ground, the plane enters atmospheric layers with rarefied air and its body expands; the reverse process occurs during landing. In addition, the structure is affected by the resistance of air flows, the pressure of curved layers of air and other forces. Despite their strength, the alloys existing at that time were not always suitable for the manufacture of critical parts; this mainly led to ruptures of fuel tanks.

In various types of industry, parts of moving mechanisms are made from steel: springs, leaf springs. The grades used for such purposes are not prone to cracking under constantly changing loads.

Mechanical properties

The mechanical properties of steel 09G2S describe the following characteristics for long and shaped rolled products with a cross section of up to 10 mm:

| Type of mechanical characteristics | Testing temperature, ºС | Meaning | ||

| Temporary resistance | Ϭ0.2, MPa | +20 (room) | 345 | |

| Tensile strength | ϬV, MPa | 490 | ||

| Elongation | δ5, % | 21 | ||

| Impact strength | KSU | 64 | ||

| KSU-40 | -40 | 39 | ||

| KSU-60 | -60 | 34 | ||

In order to determine the strength class (ST) of the test sample, you should refer to GOST 19281-2014, which shows in detail all the key characteristics that should be relied upon when conducting tests or assessing the finished protocol for the strength category.

It is worth remembering that this mechanical indicator directly depends on the chemical set of the corresponding components, and the presence of a higher percentage of any element can play a key role in the formation of strength indicators when processing this steel.

Mechanical properties of steel 09G2S

Depending on the strength class, such an indicator of mechanical characteristics as hardness also changes. The relationship between these two indicators is direct: the higher the strength category of the material, the higher the hardness value. Typically, the hardness of low-alloy alloys is measured using the Brinell method, and the hardness indicator is indicated in HBW units, but depending on the requirements for the product and the place of inspection (base material or weld material), the hardness measurement method may change. In this case, the hardness of the material can be expressed in units on the Rockwell, Vickers, etc. scale.

The steel heat treatment mode is assigned according to critical points:

| Critical point | Ac1 | Ac3 | Ar3 | Ar1 |

| ºС | 725 | 860 | 780 | 625 |

Depending on the required mechanical properties, the heat treatment mode is assigned. Normalization and hardening of 09G2S steel takes place at high temperature heating from 930 to 950 ºС. The dependence of mechanical properties on the tempering temperature is given below:

| Temperature, °C | Yield strength, δ0.2, Pa | Tensile strength, δB, Pa | Elongation, δ5, % | Relative narrowing, ψ, % |

| 20 | 295×106 | 405×106 | 30 | 66 |

| 100 | 270×106 | 415×106 | 29 | 68 |

| 200 | 265×106 | 430×106 | — | — |

| 300 | 220×106 | 435×106 | — | — |

| 400 | 205×106 | 410×106 | 27 | 63 |

| 500 | 185×106 | 315×106 | — | 63 |

As follows from the table, the higher the temperature of the accompanying tempering, the lower the tensile strength of the alloy.

Heat treatment promotes the formation of an alloy with a two-phase structure, the grain dispersion of which determines the main indicators of the mechanical properties of the material.

The difference between strength classes 6.6, 5.6 and 4.6 from class 5.8.

According to GOST 1759.4-87, for bolts of strength classes 6.6 and 5.6, in addition to strength properties, impact strength is also standardized (unlike the widespread bolts of classes 5.8 and 4.8, for which these parameters are not standardized). Impact strength values are also standardized for high-strength bolts of classes 8.8-12.9.

The relative elongation of bolts of classes 6.6, 5.6 and 4.6 is one and a half to two times higher than for fasteners of classes 5.8 and 4.8. Relative elongation characterizes the ductility of steel.

Replacing bolts of strength classes 4.6 and 5.6 with common bolts of classes 4.8 and 5.8 is not permissible without agreement with the structural designer. The assumption “the higher the strength class numbers, the better the bolt” is not appropriate in this case, although it is a common misconception .

The tensile strength values for bolts 5.6 and 5.8 (4.6 and 4.8) are the same, but the ductility values are different: 20% versus 10% (22% versus 14%).

In addition, for classes 6.6, 5.6 and 4.6, impact strength is standardized, while for classes 5.8 and 4.8 it is not controlled by the Manufacturer at all.

Replacing bolts of class 6.6 with class 5.8 is a gross violation of technical requirements. However, due to the rarity of bolts of strength class 6.6, some Suppliers neglect this and offer the Customer replacement bolts of class 5.8 from stock.

Modulus of elasticity of steel

The elasticity of solids is the ability to return to its original shape after the cessation of deforming influences. For example, a block of plasticine has zero springiness, while rubber products can be compressed and stretched. When various forces are applied to objects and materials, they become deformed. Depending on the physical properties of the body or substance, two types of deformation are distinguished:

- Elastic - the consequences disappear after the action of external forces ends;

- Plastic - irreversible change in shape.

The modulus of elasticity is the name of several physical quantities that characterize the tendency of a solid body to deform elastically.

The concept was first introduced by Thomas Young. The scientist suspended weights from metal rods and observed their elongation. Some samples doubled in length, while others were torn during the experiment.

Today the definition combines a number of properties of physical bodies:

Young's modulus : Calculated by the formula E= σ/ε, where σ is the stress equal to the force divided by the area of its application, and ε is the elastic deformation, equivalent to the ratio of the elongation of the sample from the beginning of deformation and compression after its cessation.

Shear modulus (G or μ) : the ability to resist deformation while maintaining volume when the direction of loads is tangential. For example, when hitting the head of a nail, if it was not made at a right angle, the product becomes distorted. In sopromat, the value is used to calculate shifts and torsion.

Bulk modulus or bulk modulus (K): changes caused by the action of a confining stress, such as hydrostatic pressure.

Punch ratio (Ⅴ or μ) : the ratio of transverse compression to longitudinal elongation, calculated for material samples. For absolutely fragile substances it is zero.

Lamé's constant : the energy that provokes a return to its original form, calculated through the construction of scalar combinations.

The modulus of elasticity of steel is correlated with a number of other physical quantities. For example, when conducting a tensile experiment, it is important to take into account the tensile strength, exceeding which results in destruction of the part.

- Ratio of rigidity and ductility;

- Impact strength;

- Yield strength;

- Relative compression and tension (longitudinal and transverse);

- Strength limits under shock, dynamic and other loads.

The use of a number of approaches is determined by the requirements for the mechanical properties of materials in various industries, construction, and instrument making.

Recycled raw materials

The variety of products is great, the entire range is easy to see simply by “Googling” or visiting any pipe bulletin board or for rolled metal products. A huge number of channels, corners, etc. Moreover, it is not always clear how the authors set the cost.

For example, the question with the content: “steel 09g2s price per ton” is simply baffling. After all, the decoding does not speak about the type of rental, nor about its other properties and qualities.

By the way, we have already written an article about scrap steel 09g2s - it describes in more detail the recycling of this steel.

Moreover, there are excellent categories when they want to sell old scrap 09g2s, new products, or simply materials that have already become unusable. Therefore, the price for this type of metal is rarely fixed. Only what is recycled is taken by weight. Channels and other items are accepted individually as business scrap with a price. Rolled sheets are measured by footage. But in principle, these data can also be calculated by weight, subject to the purchase of large quantities. But then both parties run the risk of cutting prices, because the number of products may differ slightly with this method.

Source

Strength classes 6.6, 5.6 and 4.6. Technical requirements

Technical requirements for bolt strength classes are standardized by the canceled GOST 1759.4-87, GOST R 52627-2006 and the current GOST R ISO 898-1-2011. More detailed properties of fasteners of various strength classes are presented on the page of the same name on our website.

The fundamental feature of bolts of strength classes 6.6, 5.6 and 4.6 are the values of impact strength and ductility, standardized by GOST 1759.4-89.

The impact strength of bolts is an indicator of the steel's resistance to brittle fracture under shock loads and vibrations. Elongation at break is an indicator of the ductility of steel. The higher the relative elongation, the higher the ductility. In particular, the relative elongation for class 4.6 must exceed 22%, for class 5.6 - at least 20%, for class 6.6 - at least 16%.

Comparison with another steel grade

For example, for 09g2s and st3 the difference is determined primarily by the carbon content. For St3sp it is 10-20 times higher than what is found in the low-alloy alloy.

St3sp – refers to carbon alloys. This grade of steel is characterized by high brittleness and rapid destruction at low temperatures. If the brand being described has a lower limit of -70 degrees, then the object of comparison is only -20.

The quality of St3sp is ordinary, which indicates a likely high presence of sulfur and phosphorus. Then, like 09g2s is high quality. All other advantages are already in the previous description. It only remains to note that the cost of this brand is significantly higher than the price of St3sp.

Video about low alloy steels:

Which is better: galvanized or stainless steel?

In order to successfully solve various technological problems and not get confused: buy a galvanized sheet instead of a stainless steel one, contact a trusted, reputable supplier. Although both metals are corrosion-resistant, and when constructing structures with a service life of no more than 10 years, it is quite possible to get by with cheaper galvanized steel, for critical objects it is still not worth skimping on quality.

A guarantee that you are purchasing a certified product will be choosing as a partner a reliable supplier with attractive market offers. Today we are the best and are ready to supply any volumes of highest quality metal products in the shortest possible time.

Assortment of bolts of strength classes 6.6, 5.6 and 4.6

The range of sizes of bolts of classes 6.6, 5.6 and 4.6 is determined by standards and drawings:

The range is not limited to the first version according to GOST; we also produce bolts with holes of the 2nd and 3rd versions.

We accept orders for bolts of classes 6.6, 5.6 and 4.6 with rod or thread lengths not specified in GOSTs, or with head sizes not according to standards.

Technical requirements for non-standard bolts are determined by the Customer’s drawings or SMM drawings, developed according to the Customer’s technical specifications (TOR) by our designers.

Characteristics of the steel in question

Due to the inclusion of certain impurities in the composition, st 09g2s acquires the following type of characteristics:

- Increased mechanical strength.

- Resistance to high temperatures.

- Possibility of heat treatment to improve performance. For example, hardening significantly increases surface hardness.

- The density or specific gravity is 7.85 grams per cubic centimeter of material. This moment determines the possibility of obtaining lightweight products.

In addition, welding can take place without preheating the structure. Therefore, the process of welding individual parts made from the material in question is significantly simplified. Good weldability is determined by low carbon concentration.

The demand for o9g2s is due to the fact that practically no analogue has similar mechanical properties. Products made from the metal in question can be used at temperatures from -70 to 450 degrees Celsius.