For narrow through parts (pipes, various workpieces), a special processing method is used, which is called mandreling. But what exactly is burnishing of holes and pipes? What are the different burnishing methods depending on certain parameters of the operation? Why would such technology be needed at all? In our article below we will give detailed answers to all these questions.

Burnishing technological process

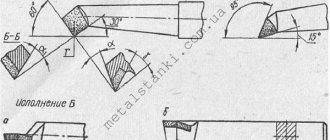

This process gets its name from a tool called a mandrel. Structurally, it is made in the form of a rod with one or several teeth. Depending on the method of application, mandrels are divided into sliding and rolling tools.

The technological process consists of cold deformation (compaction) of the surface of the part through the movement of the mandrel. Typically, this technology is used to burn holes. In this case, the tool moves along the bore. Due to the created effort, it provides:

- compaction of the internal surface layer along the entire hole;

- improving the quality of the workpiece (remaining roughness is removed);

- The diameter of the hole increases with increasing its accuracy class.

The quality assessment of the technological process is carried out by monitoring the following parameters:

- the magnitude of the tension created;

- speed of tool movement inside the hole;

- values of the force created;

- parameters of the resulting deformation.

The value of the first parameter affects the quality of the resulting surface. It is calculated as the difference between the internal diameter of the workpiece and the diameter of the mandrel used. If the difference is too large, it will not allow you to obtain a high-quality seal and get rid of roughness.

In practice, the maximum interference when mandrating the connecting rod bushing is necessary to obtain the required surface quality of the connecting rod.

Too little tension reduces the speed of work, leads to unnecessary deformation of the treated surface, and the appearance of excessive internal stresses. Therefore, the value of this parameter is calculated taking into account the plasticity indicators of the part and mandrel.

The force required to carry out the work is divided into two components:

- axial (directed along the line of movement);

- radial (acts perpendicular to the axial).

The first ensures the movement of the tool along the hole, and thereby increases the internal diameter. The second determines the quality of the surface being machined (accuracy class after processing)

In some cases, to reduce the friction force, especially in the non-contact deformation zone, mandrel grinding with lubricant back pressure is used.

The burnishing method is used to refine welded pipes. When processing welds, it is necessary to take into account the physical properties of the metal and the wall thickness. Such pipes are used, for example, for hydraulic cylinders. Therefore, after burnishing, strength tests must be carried out. As an indicator, you can use the ultimate strength indicator or the degree of expansion.

This is interesting: Electroplating and electroplating: equipment, types, purpose

4.2. Burning effort

The mandrel forces were measured using a dynamometer on an IR 5057-50 testing machine. In addition, a number of experiments were performed using a single-component elastic dynamometer with foil strain gauges. Electrical signals coming from the dynamometer were recorded through a TA-5 amplifier using a NO71.5M loop oscilloscope. The accuracy of measuring the mandrel forces in all cases was not lower than ±1%.

The experimentally established dependences of the hole mandrel forces on the amount of interference are shown in Fig. 4.1. It shows that the forces generated when mandrating deep holes of small diameter in thick-walled workpieces are small. The process of mandating holes can be carried out on almost any press or even manually, for example, on a vertical drilling machine. That is, from the standpoint of choosing the power of the equipment, these efforts are not of particular interest, but they need to be known to assess the stability of the firmware pusher, calculate the pusher and firmware for strength, and some other purposes.

| A | b |

| Rice. 4.1. Dependences of the forces of burnishing holes in workpieces made of steel 45 ( A ) and steel 20 (b ) when using steel and carbide tools: – |

The experimental results (Fig. 4.1) showed that the mandrel forces with steel tools are generally somewhat (about 10%) less than with carbide tools. This is obviously a consequence of the lower friction coefficient for steel tools

In Fig. 4.2 and fig. 4.3 the results of experimental studies of mandrel forces when using carbide tools are compared with the results of calculations, which were carried out using an empirical relationship obtained at the Institute of Superhard Materials of the National Academy of Sciences of Ukraine. As follows from Fig. 4.2 and 4.3, in the region of small interferences (a ≤ 0.03 mm) there is a satisfactory agreement between the calculated and experimental values of the mandrel forces. With increasing interference, the calculation error also increases at interference a

=0.09 mm it becomes more than 100% (see Fig. 4.2 and 4.3).

| A | b |

| Rice. 4.2. Dependence of hole mandrel forces ( d = 1.2 mm) with carbide (VK8) interference tools:A – steel 45; | |

| A | b |

| Rice. 4.3 Dependencies of hole mandrel forces ( d =3 mm) with carbide (VK8) interference tools:A – steel 45; — experimental data; - calculation according to the equation |

Based on processing the results of single-factor experiments, the following empirical dependencies were obtained for calculating the mandrel forces:

when using steel tools

; (4.1)

when using carbide tools

. (4.2)

In equations (4.1) and (4.2): P

– mandrel force (N); NV

– Brinell hardness (MPa);

d

– hole diameter (mm);

a

– burnishing tension (mm).

In Fig. 4.4 and 4.5 provide a comparison of the results of experiments and calculations performed using formulas (4.1) and (4.2). As you can see, the greatest error in determining the burnishing forces using these formulas for steel blanks does not exceed 20%. For copper workpieces it increases to 30%.

| A | b |

| V | G |

| Rice. 4.4. Dependence of burnishing forces with steel tools on tension: A – steel 45,d = 1.2 mm; |

| A | b |

| V | G |

| d | e |

| and | Rice. 4.5. Dependence of the mandrel forces with carbide tools on the tension: A – steel 45,d = 1.2 mm; |

What is burnishing?

During operation, the surfaces of metal parts experience severe loads that are practically not perceived by the internal layers of the products. It is the layers on top that counteract a variety of negative influences, ranging from thermal effects and corrosion to wear of parts.

Burnishing, as a process of effective surface treatment, was created precisely in order to level out all of these manifestations, thereby increasing the level of wear resistance and reliability of metal products.

Mandrelization is an innovative option for processing the holes of parts using the method of local cold deformation, performed using plastic technology. Its essence is as follows: the mandrel (a special working device) moves inside the barrel of the product and, due to tension, provides:

- modification of the geometric parameters and shapes of the part in general and its cross section in particular;

- high-quality leveling of existing roughnesses;

- strengthening the surface layer of the metal.

The value of the transverse diameter of the hole of the workpiece is always less than the cross-section of the mandrel by the interference index.

Trunk mandrelization – volumetric and superficial

The process of machining holes without removing chips can currently be performed volumetrically or superficially. In the first case, the procedure is carried out over the entire cross-section (transverse) of the workpiece. It allows you to obtain, in one pass of a working tool equipped with several teeth, a roughness value from 0.04 to 0.63 micrometers with a hole accuracy of 11 units on the IT scale.

Volumetric burnishing is recommended for processing long cylinders and tubular products made in the form of sleeves. It successfully replaces the less efficient operation of rough boring of such parts. Volumetric deformation makes it possible to work with pipes of any length, providing the necessary indicator of their straightness.

Surface-type burnishing guarantees a roughness in the range of 0.04–0.32 micrometers with an accuracy of no less than 6 and no more than 9 grades. With this method of deformation, a durable layer is created on the surface, so this technique can replace a number of complex procedures, in particular:

- metal grinding;

- deployment;

- honing;

- ironing.

Varieties

The types of mandrelization mean the free and non-free process of carrying out the operation.

When the mandrel is free, the product, namely its surface, is not limited in the possibility of deformation. This type of process is acceptable for large-scale work with electric-welded pipes or for seamless casting, where the thickness of the barrel wall is determined as an average value. Free mandrel is not suitable for workpieces such as pipes with thin barrel walls. Here, non-free blowing is used, which avoids the following consequences:

- axial displacement of the workpiece;

- decreased stability along the direction of the trunk;

- smoothing metal of insufficient quality.

To implement the non-free mandrel operation, the part is secured in special cages of a rigid and elastic structure before passing through the mandrel.

The use of any of the burnishing methods requires the use of lubricants to reduce friction, speed up the processing process, and avoid damage to the workpiece or tool.

Volumetric and surface burnishing

Mandrelization as a method of processing the bore of a hole, when there is no chip removal process, can be performed superficially or volumetrically.

With the volumetric method, the operation involves the entire workpiece (meaning the cross section). By making one pass with a tool, the working part of which is equipped with several teeth, an actual roughness in the range of 0.63–0.04 microns is achieved with great hole accuracy. Due to its effectiveness, volumetric burnishing is intended to replace a less effective method when workpieces are subjected to rough boring. Volumetric deformation is used to process any types of pipes and cylinders with a long barrel, while the straightness of the products is maintained within the required limits.

The use of surface burnishing makes it possible to obtain a roughness in the bore within the range of 0.32–0.04 microns. The main purpose of the method is to strengthen the surface layer and, possibly, to avoid complex technological techniques: reaming, grinding, smoothing and honing the metal.

Plastic deformation and sizing

The essence of plastic deformation is that a mandrel with a diameter of the working part larger than the bore of the hole is pressed into the latter under the influence of the force of the machine. Calibration of the inner surface of the pipes occurs when the area being treated is exposed to a source of thermal energy for heating and subsequent introduction of the mandrel into the area of the tool. The disadvantage of calibration is the possible change in the parameters of the workpiece and the greater complexity of the process regarding plastic deformation.

Shock pulse method

The method in which the mandrel tool is fed along the bore of the barrel not in a constant translational mode, but in shocks with the same frequency, is called the shock pulse method. This process is very effective, as it reduces the load on the tool and the channel and allows for maximum processing accuracy.

Practitioners in the field of metal processing and anyone who has direct experience with the process of mandreling holes, support the topic in the comments. For beginner craftsmen, your knowledge is invaluable!

Purpose and scope of application of burnishing

As briefly mentioned above, burnishing is necessary to strengthen the surface of the hole shafts, giving them greater strength, thus increasing the wear resistance of the product. All this is accomplished due to the ability to plastically deform the metal throughout the contact zone using a mandrel. There are two types of mandrels: sliding and rolling. Most often, the process occurs when the workpiece is cold.

When the mandrel tool moves along the barrel with a certain level of tension, other problems are solved along with strengthening the walls:

- adjusting the diameter of the hole to the required parameters, the trunks of rectangular holes to the required dimensions;

- getting rid of irregularities and any roughness that were caused by the previous processing of the trunk;

- the ability to form a certain cross-sectional shape, for example, to create slots, grooves or an original pattern on the inner surface.

Mandrelization is used not only in civil engineering, but also in weapons production. With its help, gun barrels of tanks and other vehicles are strengthened and used in the manufacture of cartridges.

When it is planned to apply mandrel to a particular hole, it is important that the mandrel has a diameter larger than the cross-section of the hole's barrel by the tension thickness. All this is calculated very accurately so that there is no rupture of the workpiece.

Types of equipment

The equipment that is used to make holes can be divided into “conditionally manual” ones, that is, those that require the constant presence of an operator - a machine operator, and automated ones, which work with minimal human intervention. As a tool for punching holes in metal, various types of punches, stamps and some others are used.

The first group includes equipment operating from a mechanical, hydraulic or other type of drive. The second are fully automated machines operating under CNC control, for example, coordinate punching presses or a hole punching machine.

Manual process

Manual methods for making holes in metal include drilling and punching. Drills and related equipment - drilling machines or hand drills - are used as tools for punching holes in metal. For manual punching of the tool, a bit and a percussion tool (hammer, sledgehammer) are used. This punch can be installed on hand presses.

Manual punching process

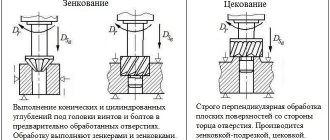

Drilling of holes is carried out on drilling, milling or lathes. Drills are used as a working tool. For final shaping of the hole, countersinks, counterbores, and reamers are used. With their help, ovals are eliminated, chamfers are formed, and the hole accuracy and surface cleanliness are increased.

To punch holes in metal, different presses are used - pneumatic, hydraulic, etc. The forces developed for the effective operation of a stamp, consisting of two parts (a punch and a matrix), range from several kilograms to hundreds, or even thousands of tons.

Punching holes on combined press shears

Often in production, combined presses and shears are used to produce holes.

Punching holes on combined press shears

This device consists of several mechanisms that allow you to process a metal profile, for example, a corner, cut strips of metal, cut in the shape of straight or triangles and, of course, a tool for punching holes in the metal is installed on these scissors. As a rule, it consists of a punch and a matrix. The punch has the diameter of the hole to be punched. The matrix has a hole in its body corresponding to the size of the punch. Through it, cutting waste is removed.

It should be noted that the above methods for producing holes are not characterized by high productivity, especially in conditions of large-scale or mass production. The advent of automated equipment eliminates this problem.

Punching holes on presses

The use of equipment operating under the control of a CNC system has led to a reduction in the labor intensity of production processes, which has a positive effect on the cost of the finished product. The fact is that the control program, which is entered before starting work, contains accurate data regarding the location of the holes on the sheet.

Punching holes on presses

For example, a revolving punching machine is equipped with a drum on which punches (tools for punching holes in metal) of different sizes and shapes are installed. When working, the program automatically selects the required tool. This engineering solution allows you to change the tool without stopping the operation of the machine, and increase the speed of obtaining the finished product. With equipment of this type, it is possible to produce up to 1,500 holes per minute. Obtaining the finished product consists of several operations. The first is to lay the sheet of metal on the workbench. To secure it on it, different types of clamps are used. Once installed and secured, the operator launches the control program. After this, the movement of the workpiece begins. According to the coordinates specified in the program, at the required point, the clamping device is lowered, fixing the sheet in the right place. After pressing, a blow is applied by a punch (punch).

A rotary tool can be installed on the tool drum, which significantly expands the capabilities of the machine and allows cutting contours of complex shapes. A press for punching holes in metal allows you to perform, in addition to puncture, the following operations:

- bullet - extrusion, obtaining edges of different directions;

- molding;

- incomplete punching.

The main indicators of the procedure for plastic deformation of workpieces

The main parameters of this processing include the following values:

- relative tension;

- interference;

- speed;

- force;

- relative deformation.

By interference, as mentioned above, we mean the difference between the nominal sections of the hole and the mandrel. An excessively high interference can cause a decrease in the final roughness index, which, of course, is undesirable. Therefore, the choice of the tension value is taken as responsibly as possible, taking into account the characteristics of plasticity and initial strength of the parts.

Relative interference is a dimensionless parameter. It means the ratio of the size of the machined or initial hole to the indicator of the mandrel tension.

The strength of the hole making process is divided into two components:

- radial;

- axial.

The first is required to increase the cross-section of the workpiece, which is subject to deformation. This component provides volumetric processing. But the axial force removes the smallest irregularities. It is needed for friction to work.

Relative deformation is an indicator that determines the real deformation of a part along its outer section. This parameter is expressed as a percentage.

The last indicator of the process is the burnishing force. It does not have a significant impact on the amount of wear of the working tool and the quality of the operation.

This is interesting: Chemical chrome plating: technology and implementation at home

Practical work

The method of practical work differs from the laboratory method by the predominant use of theoretical knowledge to solve practical problems. It is the skills of applying theory to practice that are fundamental.

The practical method helps to deepen knowledge and hone skills, stimulate cognitive activity and solve problems of a controlling and corrective nature.

One of the outstanding Soviet psychologists, E. Ya. Golant, identified five stages of students’ cognitive activity in the process of practical work:

Theoretical understanding of the work, when the teacher explains its meaning Instruction, in which the teacher explains the technical side of the work Trial stage, where several students perform practical tasks, and everyone else observes the process and, if the trainees make mistakes, make comments under the supervision of the teacher Execution stage, where all students solve the task assigned to them (the teacher pays the greatest attention to those who make mistakes) The control stage, where the teacher accepts and evaluates the students’ work, taking into account the quality of work, speed of completion, accuracy and correctness

The practical work method can be used in teaching students of any age, but it is important that the tasks correspond to the abilities and age characteristics of the students

Purpose and technological features

During the operation of any product, including those made of metal, the main load is taken by its outer surface, while the inner layers remain practically untouched. Such a load, in particular, can be thermal effects, as well as external factors leading to corrosion or intense wear of the metal.

The main task that burnishing, which is a method of processing a metal product, solves is to ensure its reliable protection from the above negative factors. Burnishing is an innovative technology, the essence of which is that the inner surface of holes made in metal parts is subjected to plastic deformation in a cold state, due to which a layer is formed on them, characterized by exceptional mechanical characteristics.

Morn is a tool for burnishing. There are rolling mandrels and sliding mandrels.

Burnishing, performed using a special tool that moves along the inner surface of the hole with a certain degree of tension, allows you to solve the following problems:

- bringing the dimensions of the internal section of the processed product into accordance with the required values;

- elimination of roughness existing on the inner surface of the hole being machined;

- improving the strength characteristics of the metal forming the inner surface of the hole.

If you plan to perform a mandrel, you should keep in mind that the diameter of the hole being machined should always be less than the cross-section of the tool used by the amount of interference.

Examples of parts after burnishing

Why is it necessary?

When operating any parts, devices or devices, it is mainly the outer layers that bear different loads. While the inner layers maintain a constant structure and do not deform. The rule applies to products made of any materials - wood, stone, ceramics, metal.

A negative impact can be exerted not only on the surface of the object, but also on any of its internal elements - holes, cuts, recesses.

Mechanical damage

A strong impact can seriously damage the outer surface of the part, which can lead to cracking (internal holes and various recesses can be damaged). Also, internal elements and surfaces can be damaged naturally. A simple example: Some pipes are used to dispose of heavy industrial debris, which can leave small damage and dents on the inside of the pipe, which will eventually cause the pipe to crack and even collapse.

Corrosion

When water comes into contact with some metals, corrosion can form, which negatively affects the quality of parts. The duration of contact is also of great importance - most modern alloys tolerate short-term exposure to water, whereas with prolonged contact, water can enter into a chemical reaction with the metal, leading to corrosion. In addition to its unpleasant appearance, corrosion negatively affects the hardness of the material, which makes the metal brittle.

Sudden temperature changes

Most modern alloys melt at very high temperatures, but it must be borne in mind that in the event of sudden cooling or heating, some metals become quite brittle. Also, in most cases, only the outer surface is seriously damaged, while the internal structure is preserved. This is especially critical in the case of metal parts with holes of non-standard shape (threaded, with various locking elements).

- Aggressive external environment. Many chemically active substances can seriously damage the outer layer of metal upon contact. Examples of chemicals are various alkalis, acids, and explosives. Also, the danger of a particular compound is determined by the degree of toxicity - some chemicals only slightly corrode the outer shell, others create cracks in the material, and so on.

Volumetric and surface burnishing

There are two types of mandrelization of trunks and pipes, in which no chips are formed - volumetric or surface. When performing volumetric burnishing, processing is carried out over the entire cross-section of the workpiece. As a result of such a technological operation, performed using a tool equipped with several teeth, it is possible to form a surface whose roughness will be in the range of 0.04–0.63 microns, and the accuracy will correspond to 11 units on the IT scale.

Volumetric burnishing scheme for small diameter holes

Using volumetric mandrel, long holes, pipe blanks or products made in the form of sleeves are processed. This operation, which can be used to make holes of almost any length while maintaining their straightness, is a good alternative to rough boring.

Scheme of processing a part by surface burnishing

When performing surface burnishing, you can obtain an internal surface whose roughness will be in the range of 0.04–0.32 microns, and the accuracy will correspond to 6–9 units. When surface grinding a hole, a hardened layer of metal is created on the inner surface of the hole, so this processing technology can be successfully used as an alternative to such complex operations as:

- grinding;

- honing;

- deployment;

- ironing.

Main settings

Experts are guided by the following burnishing parameters:

- normal and relative interference;

- execution speed;

- execution strength;

- relative deformation.

For normal burnishing, the tolerance on the dimensions of the hole being machined should be several times less than half the interference

The interference, which is one of the main parameters of mandrel, is the difference between the diameters of the hole being machined and the cross-sectional size of the tool used. If this indicator is too high, then during the processing it will not be possible to form a surface with the required level of roughness. When choosing this parameter, you should take into account both the degree of plasticity of the product being processed and its strength characteristics. The relative mandrel interference is understood as the value obtained by the ratio of the size of the machined or unprocessed hole to the value of the usual interference.

When mandrating, the force applied to the tool is divided into axial and radial components

The force with which mandrel is performed refers to the forces that the tool exerts on the walls of the hole in the radial and axial directions. With the help of the force exerted by the tool in the radial direction, the cross-section of the hole being processed increases, and the force created by the mandrel in the direction of the axis of the workpiece makes it possible to remove the smallest irregularities from its inner surface.

Relative deformation, measured as a percentage, makes it possible to determine how much the outer diameter of the workpiece has changed during mandreling.

When to start delegating

Focus on your schedule.

If work begins to take up too much time and personal resources and steals vacation days, it is worth redistributing the load. You can delegate some tasks to current employees or hire a personal assistant, including a remote one. Miller's law will help determine the amount of load. In his article “The Magic Number Seven Plus or Minus Two,” American psychologist George Miller noted that a person can retain no more than 7 ± 2 elements in short-term memory []. If during the day the number of things that need to be constantly remembered approaches or exceeds this value, this is a signal to change the schedule.

Five Questions to Help You Choose the Task to Delegate

Features of plastic deformation and calibration

There is a method of influencing the product by plastic deformation, when the mandrel is pressed into the product. Another popular method is to calibrate the inner surface of pipes by heating the product with an external source in the area affected by the mandrel. However, this method does not simplify, but complicates the process, and does not guarantee the accuracy of the product size upon completion of processing. The technical parameters of the outer surface of the part may be violated.

Drawing

Burnishing is a progressive chipless precision method of metal processing. It is based on the ability of ductile metals to acquire large residual deformations under the influence of internal pressure without destroying the metal of the workpiece, but with a significant change in their original dimensions. In addition, this method reduces metal consumption, the number of operations, and the volume of cutting.

Using burnishing (Fig. 91), you can process holes in parts such as bushings and sleeves made from seamless pipes. The processing consists of the following: a mandrel 1 with increasing diameters of working and calibrating teeth is pulled through a hollow workpiece 2 with an internal surface previously cleaned of corrosion. Under the influence of internal pressure, the part is plastically deformed to the desired size.

Rice. 91

This method eliminates pre-processing. In one or two passes you can get very precise and clean holes. At the same time, the metal is strengthened. This gives burnishing an important technical and economic advantage over other technological processes.

Burnishing reduces the labor intensity of hole processing by approximately 2...4 times, reduces material consumption (seamless pipes) by 15...30%, and increases the durability of processed parts.

The processing process is carried out either on broaching machines or on hydraulic presses.

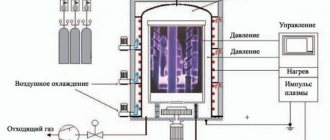

Shock pulse method

A widely used method is the application of axial vibration to the product using shock pulses. This method reduces mandrel forces and increases the accuracy of hole dimensions; pulses make the tool advance inside the part easier, especially in long pipes.

The essence of the method is that the product processing process occurs when a lubricant is applied to the inner walls of the pipe:

Shock sensors

- the workpiece moves cyclically in pulsating movements;

- when using shock pulses, lubricant is not supplied continuously, but in small portions;

- At the same time, an additional force acts in the opposite direction of mandrel movement at the moment when the lubricant layer on a local section of the workpiece decreases.

If you apply lubricant to the walls of the product in advance, the moving tool will displace the lubricant and dry friction of the contact surfaces will occur. This will lead to the appearance of unnecessary build-up on the tool and scratches, which will significantly reduce the quality characteristics of the workpiece after processing.

It is worth noting that the proposed method of drilling a hole significantly improves the quality of the internal surface of the workpiece and reduces the possibility of sample deformation due to the supply of lubricating fluid to the contacting elements. As a result, a protective film is created on the surface, which ensures the strength and reliability of the part.

How to lubricate the parts being processed

Spindle oil

Spindle oil with the addition of oleic acid is used as a lubricant. The composition has good performance characteristics, such as fluidity and penetrating ability, necessary for contacting surfaces. Oleic acid is a type of surfactant and, when exposed to a metal coating, reduces the hardness of the metal and the frictional force that occurs when the mandrel and the surface of the hole come into contact.

The heating temperature of the contacting bodies decreases, as a result, the treated coating is less rough and no growths remain on the edge of the deforming mandrel.

The amount of acid in the lubricant should not exceed 10 percent. Excellent quality characteristics are achieved precisely at this concentration. Exceeding this figure will be inappropriate and will not give a better effect.

The method of burnishing using shock pulses is the most advanced and widespread, compared to other schemes for deforming the internal surface of a part.

Burning schemes

There are the following schemes for metal processing of workpieces by mandrel:

- by stretching;

- compression method;

- combined application of tension and compression of the sample.

It is important to choose the right workpiece processing scheme. The circuit will determine the axial stress values of the product.

Using a scheme based on tension or compression, a force is applied to the workpiece over a certain segment. The mixed burnishing scheme distributes the load over the entire inner surface of the workpiece.

Volumetric processing of a part is carried out according to other schemes:

- passive;

- neutral;

- active.

The listed mandrel schemes influence the value of the axial stress and require special mechanisms - movable supports that make it possible to limit the shortening of the part when exposed to the mandrel. As the interference value increases, the degree of roughness of the inner surface of the workpiece will decrease. This technique involves pre-machining the hole before using the mandrel.

Dorns use two types of movement:

- rocking;

- slip.

The tool moves inside the workpiece with a given tension value using lubricant. To improve the processing result and reduce the mandrel force, lubricant is supplied inside the hole towards the movement of the mandrel by spraying.

The device for performing vibration processing of metal products consists of:

- dorn;

- a vibrating support, which allows you to fix the sample on it;

- hydraulic drive;

- piston

Dorn - device

The device effectively processes the inner walls of bushings, liners and cylinders.

Pipe burnishing method

(51)5 V 24 V 39 02 RESEARCH INVENTED machining Pinkovsky woman-d time hole outer bone selecting processes with varitel etc. Volumetric Mechanical Engineering IA PIPES for processing volumetrically produced on made of steel, = 33 MPa) and C Prelimin ohm, Pipe 5 is placed with lid 2. Liquid of the given value is poured into it and mandrel 6 is poured into the channels 7. Upon completion, stop submitting with the STATE COMMITTEE FOR INVENTIONS AND DISCOVERIES YAMPRI SCST USSR AUTHOR'S CERTIFICATE (57) The invention relates to metal pressing, in particular The invention relates to the processing of metals by pressure, in particular to volumetric burnishing, and can be used in mechanical engineering. The purpose of the invention is to reduce energy intensity and improving the quality of processing by changing the stress-strain state scheme. In FIG. 1 shows a device for implementing the proposed method; in Fig, 2 is a diagram of internal stresses in the pipe. The device contains a container 1, in the upper part of which a cover 2 with a seal 3 is installed coaxially. A blank 5 is installed in the cavity 4 of the container 1, a mandrel 6 with internal channels 7 is placed inside it. the next container 1, sealing 4 containers of 1 pressure up to the same time as processing 5, into which the lubricant under the pressure process of the burnishing smear is dumped. 801551527 A 1 new. The purpose of the invention is to reduce energy intensity and improve the quality of energy by changing the scheme of the directly formed state. One by pushing the mandrel through the pipe being processed, high pressure liquid is applied to its surface. The pressure is 0.45 - 0.62 of the yield strength of the material being used. This is to smooth the scallops after pre-processing the pipe. 2 ill. Pressure in the cavity 4 containers 1, Process is completed. Example, Dor nova Niesse DB 2432, workpiece B50 (yield strength has the following dimensions. length 200 mm, outer diameter 30 mm, inner diameter 10 mm. A pipe is placed in the container and sealed with a lid , then liquid (industrial oil) is supplied into the container cavity under pressure and the pressure is increased to 300 MPa. At this pressure, the mandrel is pushed into the workpiece, into which lubricant is supplied through the channel. At the end of the mandrel process, the pressure in the container cavity is released, and the mandrel stops through the channel lubricant is supplied, the degree of deformation into the pipes is 1700, after processing the internal diameter of the pipe is 11 mm, which corresponds to 7 - 8 quality, and the roughness of the treated surface is K = 0.16 0.08 microns. The use of the proposed method allows you to improve the quality of the internal surface and reduce the energy consumption for mandrel pipe by 2 - 3 times. Formula of the invention: A method for mandrel pipes, in which a pipe is processed with a mandrel while simultaneously exposing it to a high-pressure liquid, characterized in that, in order to reduce the energy consumption, the author S. Chukkhred I. Veresrazh 600a according to the invention Zh - 35, Raushka 1 binat Patent, Editor N Tupitsa T Order 298 T NIIPI State Committee 113035, Moscow, Production and Publishing Co. Proofreader I. Muska G 1 signature for discoveries at the State Committee for Science and Technology SSS embankment, 4/5 View

Types of burnishing depending on the fastening of the part

Burnishing can be non-free or free - depending on whether the original parts are fixed on the machine or not during processing.

The free-processing technology is simple, but has a number of disadvantages, and the main disadvantage is that it is not suitable for processing thin-walled products. However, in practice, free technology is very often used when mandrating seamless or electric-welded pipes.

The non-free burnishing technology is more preferable, although less practical, and it is suitable for processing pipes with any wall thickness.

With non-free mandrel, parts are fixed on the machine - this allows you to achieve the following effects:

- The shape of the part is completely preserved, the formation of any random bends, zigzags and irregularities is completely excluded.

- The stability and hardness of the part in all directions is completely preserved (this is especially critical in the case of the longitudinal direction).

- The surface of the part is completely cleaned of various irregularities and defects; non-free mandrel ensures high-quality processing.

To carry out non-free burnishing, the part is secured in a special vise-holder. They must meet a number of requirements - high elasticity, very high rigidity (otherwise the part will slip). If it is necessary to reduce the diameter of pipes, then mandrel burnishing can be combined with cold reduction technology - a similar practice is widely used at factories in all post-Soviet states.