Stainless steel is constantly used by people in various fields of activity: both in the domestic sphere and in production. Accordingly, stainless steel can be technical or food grade. Many may have a logical question: what is the difference between food-grade stainless steel and technical stainless steel?

It should be noted that such concepts are used exclusively “by the people.” There are no officially stated differences. However, there are ways in which you can distinguish one species from another.

First of all, it is worth understanding these concepts themselves. The answer is already in the title:

- Food grade stainless steel is used in the food segment (dairy plant, restaurant business, etc.) and in everyday life (housewives in the kitchen).

- Technical stainless steel is used in production (production of various parts: valves, fittings, pipes).

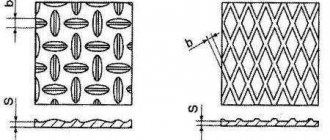

Is it possible for the average user to determine the difference between food-grade stainless steel and non-food grade stainless steel? The main difference lies in the processing of the coating material. Initially, they are distinguished simply visually. After all, the material that comes into direct contact with food will have a slippery surface, without pimples. But the material used in production has a matte surface.

"Yellow flow" or "white fork"

There are many types of sparks: “fork”, “twig”, “arrow”, etc. You learn to distinguish them with experience, but even an untrained person will be able to distinguish a dense and short stream of flashes from the long and rare sparks characteristic of stainless steel. The presence of dark red sparks coming out from under the grinding wheel indicates a high content of nickel, tungsten carbide and cobalt.

If a medium-density stream appears during the grinding process, and the sparks are straw-yellow at the base and white at the end, you have stainless steel. A long stream of sparks, reaching 1.5 meters, indicates the presence of nitrogen in the composition. In this case, it is not difficult to determine the grade of stainless steel: nitrogen alloys are quite rare and there are only a few of them (Nitrobe 77, Sandvik™ 14C28N, Böhler N680, etc.).

Importance of chromium and labeling

Steels marked according to Russian GOST determine the number of alloyed elements. Let's look at the example of 12X15G9ND.

- Digital index 12 indicates 12% carbon content;

- The alphanumeric index X15 determines the content of 15% chromium;

- The G9 index regulates the amount of manganese at about 9% of the total composition of the alloy;

- The H index indicates the content of 1% nickel;

- Index D in the labeling indicates the presence of 1% copper.

Chrome determines the most important quality of this steel: corrosion resistance .

The amount of chromium determines how much steel has these properties:

- The minimum chromium content for steel to be classified as stainless steel must be at least 12%;

- In the range of 12-17%, steel is slightly rusty, i.e., with constant contact with water or short-term contact with even mildly aggressive acids, pitted corrosion may appear on the surface;

- With a chromium content of 18% or more, steel has the full properties of stainless steel.

Magnetic stainless steel

AISI 430 steel (analogous to 08X17, which contains 15% chromium) has magnetic properties. It is used to produce wire mesh, pipes for transporting petroleum products, and elements of gas and oil refining process plants. Steel grade AISI 630 contains up to 5% nickel and chromium, as well as a large number of additives: copper, titanium, molybdenum. It is used in instrument making and metallurgy.

Stainless steel can be identified even if it is magnetic. To do this, place a sample of the material in 2% vinegar or another aggressive medium for 1-2 days. Corrosion-resistant alloys will pass this test without visible changes, but metals that are susceptible to corrosion will darken.

Copper sulfate will also help determine magnetic stainless steel at home. First clean the metal surface with sandpaper, and then apply a few drops of a concentrated substance (rusting alloys are covered with a red film).

What brands of stainless steel have proven themselves?

is engaged in the sale of high quality stainless steel fittings - AISI 304 and AISI 316. The website presents a large number of products for various purposes.

If we talk about the food segment, then model 12Х18Н10Т (analogous to AISI 321) is the most popular. Along with it - 08Х18Н10 (analogue of AISI 304), which is quite capable of becoming the most widely used due to its low cost.

But, in fact, all these materials are not very different from each other: their characteristics are similar, the difference can only be in price and manufacturer.

Technical stainless steel is mainly represented by the AISI 430 grade. It is well processed and does not corrode. The brand is used in various equipment, is present in household appliances, and is widely popular in design and architecture.

Advantages of stainless steel

Stainless steel has earned its popularity due to the combination of a number of properties that simplify the cooking process and make food safe. Many other advantages also played an important role in the popularization of stainless steel. Modern housewives value stainless cookware for the following qualities:

Durability. With careful use, a stainless steel container can last up to a hundred years or more. Even scratches on the surface of a worn product will not be a contraindication for use.- Strength. High strength characteristics are characteristic of any steel products. High-quality stainless steel cookware is thick enough to resist warping and scratches.

- Hygiene. Corrosion-resistant steel is protected from oxidation. Bacteria do not accumulate on the surface.

- Attractive appearance. A high-quality processed product retains excellent decorative properties for a long time. The ability to use electric polishing for processing such steels helps to create a perfectly smooth surface.

- Easy to care for. Contaminants from the surface of the material are easily removed. Stainless steel has no contraindications to the use of any detergents and tolerates cleaning well in the dishwasher.

Spark test

Testing metal for spark color is a common method of sorting scrap metal, which is used even by specialists. The grade of stainless steel can be determined by the following factors:

- the number of sparks and flashes, which is directly proportional to the volume of carbon in the alloy;

- the color of the sparks, which indicates the composition of the metal (the lighter it is, the higher the likelihood that this is low-carbon steel);

- the presence of shiny white sparks, which indicates a high titanium content in the composition.

To carry out the test, an angle grinder (grinder) is required. Start grinding the surface of the steel and observe the reaction. The color, length and shape of the sparks will help you accurately determine metal or stainless steel.

Rules of care

Each piece of kitchen utensil needs proper use and care. This way you can achieve the longest service life of the product and maintain its attractive appearance. Here are the basic rules for using stainless cookware:

- It is recommended to wash products immediately after use.

- Wash dishes with warm water and liquid detergents.

- It is allowed to use sponges of low and medium hardness for washing.

- Items can be washed in the dishwasher if marked accordingly. If it is not there, you will have to make the decision yourself. Typically, any stainless steel cookware can withstand machine washing well.

- When cleaning, it is not allowed to use hard brushes or compounds containing abrasive substances.

- It is strictly forbidden to use products containing chlorine and ammonia for cleaning.

- It is not recommended to store cooked food in stainless steel containers for a long time.

- Do not preheat empty containers to high temperatures to avoid the appearance of tarnish. If they appear, you can eliminate the defect with vinegar or lemon juice.

- It is not recommended to salt cold water to avoid salt settling on the walls of the dish. It is better to add salt while boiling and stirring at the same time.

- Do not use abrasives to remove burnt-on stains. You can fill the container with warm salt water, leave it for several hours, and then wash it in the usual way.

- A glossy surface that has become cloudy and scratched during use can be restored to its original condition using special polishing products.

Dishes and other kitchen utensils made from food-grade stainless steel have long earned popularity. They combine durability and safety of use. Items made of high-quality stainless steel, with proper use and care, will last for many decades and make the cooking process convenient and enjoyable.

- Author: admin

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Food grade stainless steel according to GOST

There is no official concept of food grade or technical stainless steel. This is the name given to any brand that is suitable for making cookware. Requirements for products intended for contact with products are set out in GOST 27002-86.

The list of possible alloys includes grades with an amount of carbon of at least 12%, chromium of at least 13%, possible presence of nickel in an amount of 5-13%, and molybdenum of about 2%.

Their selection is influenced by the following criteria:

- will the cookware be used for cooking?

- how long the contact is expected to last.

Also, there are no alloys that are used only for the manufacture of dishes, cutlery, etc. Dishes, pipes and tools can be made from the same grade. In this case, the final thermomechanical treatment can be applied in the same way.

Preferably, 12X13 stainless steel is used to make utensils that do not come into contact with food for a long time and are not subject to shock or heat.

Grade 12Х18Н10Т is a classic version of food-grade stainless steel, and since it is used in the mass production of not only tableware, its second name is medical steel.

The most expensive types of stainless steel

The cost is affected by the amount of nickel in the alloy: in the cheapest types its content does not exceed 5%. The most expensive are high-alloy alloys containing nickel from 12%. The expensive scrap includes plumbing fittings and rings, wire and various electrical connectors (connectors, adapters, etc.). Matte (a by-product of non-ferrous metallurgy) with a nickel content of over 35% is also highly valued, although it is classified as slag.

But the most common steel grade is A2, containing approximately 10% nickel and 18% chromium. It is usually used to make household items. To find out the exact price, visit our collection point: to evaluate scrap, specialists must inspect the metal, assess the degree of contamination, composition and properties.

How to evaluate quality?

The quality of stainless steel depends on various factors - from the amount of additives to the joining method. In places where welds are formed, the anti-corrosion properties of the metal deteriorate significantly, which over time leads to the appearance of rust and gradual destruction of the material. Painted profiled sheets will have to be cleaned of the coating and sanded, damaging the protective layer on the surface. Accordingly, the metal will become less resistant to moisture, its quality will deteriorate, and therefore the price of such scrap will be lower. You can preliminary evaluate the properties of steel using a salt solution. It should not leave stains on the surface of high-alloy steel. And water will leave yellowish stains on low-quality stainless steel.

Types and grades of non-magnetic steels

If the origin of the product is known, the reaction with a magnet can roughly determine the type of stainless steel. The following brands are not magnetic:

- AISI 409 (analogue 08X13) - this ferritic steel is used to produce containers for cargo transportation, parts for car exhaust systems, etc. (plasticity and lack of magnetic properties are due to the extremely low C content - less than 0.03%);

- AISI 304 (analogue 8-12X18h20) - household items are made from it, as well as utensils and equipment for the food and pharmaceutical industries;

- 12Х21НБТ (ЭИ8П) is an austenitic-ferritic steel for use in medium-aggressive environments, from which containers and equipment for the chemical and pharmaceutical industries are produced.

Stainless steel grades AISI 402-420, which contain from 11 to 14% chromium and less than 0.07% carbon, are not magnetic.

Popular stainless steel grades

Most often, austenitic and ferritic-austenitic grades of group 300 are used as food grade stainless steel.

They contain more than 18% chromium and 8–12% nickel, and a small percentage of molybdenum and titanium is also added to increase strength. Three hundred grades have excellent weldability and corrosion resistance at temperatures of 600-1100 degrees, depending on alloying additives. The crystal structure of austenite does not increase hardness during heat treatment and has no magnetic properties. Some ferritic grades of 400 group steel are also used. Popular brands of food grade stainless steel:

- AISI 304 (08Х18Н10) is the most widely used brand. Chromium content 17.5-20%, nickel 8-11%. When adding carbon up to 12% it is called “medical steel”. Increases tensile strength at low temperatures, and decreases at elevated temperatures. The metal is prone to corrosion in chlorine-containing environments. By reducing carbon to 3% and increasing nickel to 11% (AISI 304L, 03Х18Н11), the alloy gains an advantage in weldability. Due to the absence of carbide deposition, the labor intensity of work is reduced, and welds will be more resistant to aggressive environments;

- AISI 316 (10Х17Н13М2) – has a higher chromium content (17-18.5%), 12-14% nickel and 2% molybdenum. Due to the addition of molybdenum, the alloy is more durable and wear-resistant. Can be used at high temperatures and under pressure. The addition of up to 1% titanium (AISI 316Ti, 10Х17Н13М2Т) increases the operating temperature of the alloy to 800-1100 degrees and provides resistance to chlorine-containing environments;

- AISI 321 (08Х18H10Т) – chromium content 17-19%, nickel 9-12% and up to 1% titanium. The alloy is resistant to oxidation, withstands short-term temperature effects up to 850 degrees Celsius, constant at lower temperatures;

- AISI 430 (12Х17) is one of the most widely used alloys in mildly aggressive environments. The composition is based on 16-18% chromium, carbon – 0.08%, manganese – 1%, phosphorus – 0.04%, sulfur – 0.03%, silicon – 1%.