So, your drill sparks on the brushes and you don’t know what to do in this situation. This article will tell you why this happens, whether it needs to be fixed, and if so, how.

It is immediately worth noting that the presence of the specified sparking during operation is a completely acceptable phenomenon. This is true only if the sparks are small and there are not so many of them. If they just fall out, this may indicate a malfunction.

Note that on a new, working power tool, the brushes may also spark strongly at first, since they need to first get used to. Grinding in usually takes 10-15 minutes of work. If after this everything remains as it was, then it is better to take the instrument back to the store with a claim.

If your drill is no longer under warranty, you can try to fix it yourself.

But first we will describe the reasons for this phenomenon.

Why do brushes spark in an electric motor?

Sparks, including on a working engine, appear due to mechanical action between the brushes and the commutator. The brush, moving along the commutator from one of its contacts to another, alternately forms and breaks a connection with each of them. Now remember what happens if you unplug any working electrical appliance from the socket - usually at such a moment a spark jumps between the plug and the socket. In the case of a brushed motor, this is the same phenomenon.

Therefore, a small spark even on a working electric motor is acceptable, since connections and ruptures constantly occur here.

Control Panel

Automatic washing machines produced by other brands are equipped with an electronic control module.

He adjusts the washing parameters and is responsible for ensuring that the machine operates with minimal human intervention. Sparks when the control unit breaks down occur extremely rarely. The malfunction at the initial stage is manifested by failures in washing programs and blinking indicators. Then the control panel will stop responding to button presses, the machine will not turn on or refuse to perform its functions.

Repairs are possible, but are rarely done. More often, a complete replacement of the control unit is required to ensure flawless operation of the equipment.

Causes of severe sparking and how to eliminate them

Now let's move on to strong sparking. It occurs mainly for the following reasons:

- contamination of collector contacts with carbon deposits

- graphite dust getting between the collector contacts

- interturn short circuit in the armature winding

Let's go through each point separately.

1) Soot contamination occurs as a result of engine overheating. The presence of carbon deposits leads to even more friction, which leads to even faster overheating and even more carbon deposits. Which very quickly leads to breakdown.

What to do if the drill sparks after purchase

In 80% of cases, the drill starts sparking after purchase. The reasons for this phenomenon may be different. Most often this happens due to the fact that the brushes have not yet “grown in” to the commutator. To eliminate sparking, you need to run it a little at idle for 30-50 seconds.

If the new drill sparks and continues to spark, most likely the reason lies in the following:

- poor assembly at the factory;

- poorly balanced anchor;

- unevenly installed stator.

Replacing Bosch, Makita, DeWALT drill brushes and other types of repairs

There are three types of faults that lead to the formation of a dense stream of sparks on the collector. What to do if the brushes of a drill motor spark, according to the recommendations of experts:

- Check how worn the brushes are by pressing them one by one against the commutator with a screwdriver or a probe with a handle made of dielectric material and pressing the start button. If significant play is detected, and the motor begins to operate noticeably more stable, the brushes in the drill will need to be replaced. It is best to change them together with the holders - this ensures correct interaction of the elements.

- If the brushes are in order, but there are sparks and a burning smell, there is most likely excessive contamination of the surface of the commutator lamellas and the gaps between them. It is best to clean the lamellas with fine sandpaper on a lathe, and the spaces between them - manually, using the tip of a knife, cutter, etc.

- In the case where the condition of the brushes and commutator is satisfactory, but not only a large flow of sparks is observed, but also overheating of the tool, it is necessary to ring the electric motor windings using an ohmmeter. If there is a large difference in the resistance of the armature windings among themselves or if the resistance of the stator winding does not correspond to the rated value, an interturn short circuit is likely to occur.

Both the replacement of brushes on drills Interskol, Skil, Stanley, and the diagnosis of any other malfunctions and repair of power tools in Chelyabinsk will be quickly, inexpensively and technically flawless in the workshops of the Udachnaya Tekhnika Service center.

Why the drill does not turn on: the main reasons

First you need to examine the contacts of the power cord with the tool. To do this, disassemble the case, find the contacts and test them with a multimeter. If this is not the problem, then check the switch. The contacts may oxidize; in this case, they are cleaned with fine-grained sandpaper. Also, quite often one of the wires breaks. You can determine this problem using a multimeter or resort to the simplest diagnostic method - connecting a light bulb and battery to this circuit.

READ How to Make a Drill Stand

Also possible reasons are:

- malfunction of the connecting wires going from the switch to the motor brushes;

- damage to the brush assembly;

- a more complex breakdown - damage to the armature or stator windings;

- clogging the gap between the armature and the brushes with a lump of dust.

Basic drill malfunctions

An electric drill is a tool that occupies an important place not only in the home, but also in any repair shop. The breakdown of this equipment is quite a significant nuisance that must be eliminated as soon as possible. Let's look at the most common causes of tool failure.

How to avoid vacuum cleaner breakdowns

First of all, you need to monitor the engine temperature. Overheating will damage not only the motor itself, but also damage the electronics. If the body of the vacuum cleaner gets too hot, you should turn off the device and give it time to cool down. Most budget and mid-budget models need a rest after 15-20 minutes of continuous work.

An ordinary vacuum cleaner is designed for the same ordinary dirt. When collecting metal shavings, soot or construction debris, the filter becomes clogged in a matter of seconds, and the engine temperature rises before our eyes. If the device is not designed for wet cleaning, then the ingress of water, albeit not immediately, will lead to the growth of corrosion of the metal elements of the unit.

Moisture compacts dust, and its accumulation on the impeller can cause an imbalance in the operation of the element. HEPA fine filters, which are responsible for the quality of the outlet air, are also picky about water. Due to increased moisture, the fibers begin to swell, and soon mold appears.

Consequences

The sparking of contacts does not pass without a trace. There are side effects that reduce the service life of switching devices:

- contacts burn out;

- the elastic plates of the contact group are weakened;

- relays and sockets overheat;

- in the presence of a powerful shutdown current, a spark can cause a fire and cause burns to operating personnel.

Burnt contacts can stick, causing the electrical equipment to malfunction. If such a nuisance occurs in protective switching devices, it can lead to unpredictable situations.

Recommendations for selection

When selecting brushes, first of all you should pay attention to the material for their manufacture: good electrical conductivity and the strength (hardness) of the product itself, which affects its durability, are important here. One of the important characteristics of parts is active resistance, which is taken into account when calculating data on the motor winding and the rating of ballasts

Carbon brushes fully meet these requirements. The carbon material has an additional advantage: when a voltage arc appears, welding to metal surfaces does not occur (when the engine is running, an electric arc occurs quite often).

Many branded carbon brushes are equipped with an automatic shut-off mechanism: a special spring with a non-conductive tip made of ceramic is installed in the part. Having reached a certain level of wear, the spring pushes out the tip and the power tool turns off. When worn out, without this mechanism, the brush holder spring or brush drive may affect the commutator, leading to armature breakage (it is recommended to analyze the condition of the brush assembly and the brushes themselves from time to time).

Generator brushes have the shortest service life. Such parts, in addition to their own wear and tear, also negatively affect the operation of the engine. These products are made from almost pure copper, with a slight addition of coal components, graphite and other impurities. These parts are designed for a current value corresponding to the value in the generators (significantly greater than that of the engine). You cannot put them in power tools: such actions can immediately cause a short circuit. If the armature has time to work, then the high voltage and elevated temperature will damage the winding, which will require expensive repairs.

Important! Armature commutator copper can be hard or soft. For soft copper you need to choose special soft brushes

If rigid products are installed in this case, the collector may completely wear out in a short period of time, and repairs to replace the armature will be required. When installing soft parts on a hard commutator, the brushes themselves will fail.

Question from a reader

Reader Alexander contacted me by email with the following request:

Good evening. I came across your blog where you repair a Bosch drill. I have a similar problem, but I have almost nothing to do with electronics. Stupidly I disassembled the trigger of a Bosch GSB 1600 RE drill. Everything worked great before, I put it together somehow, but now the soft start doesn’t work. Perhaps I’m putting the parts in the wrong order and in the wrong place. I am attaching a photo of the disassembled one. I hope this helps, the drill is good.

Photo of a disassembled Bosch drill button:

Bosch drill repair. The disassembled trigger is a button with a speed control.

Bosch drill repair. Disassembled trigger - button

I don't know how to help the reader. Maybe someone can share their experience?

I suggest reading a book that describes various curious inventions:

If you liked the article, vote for it here and now:

Voting for the authors of the summer competition

Prevention of collector devices

In order to extend the life of the armature, and, accordingly, the electric tool itself, it is necessary to follow a few simple rules. These measures are as follows:

- Do not allow the device to operate for a long time at low speeds under a significant load, and especially not to allow the cutting part to bite. When an electric motor jams, a short blocking time is enough for it to burn out.

- If the device is jammed, it must be carefully released and allowed to idle for two minutes. During this time, due to natural cooling, the heated parts will cool down a little.

- Observe the timing of adding or replacing lubricants.

- If vibration or noise occurs, it is necessary to carry out a preventive inspection by disassembling the housing and cleaning both the collector and the entire space inside from dirt.

It is recommended not to carry out any independent work on repairing power tools, not only angle grinders, until the end of the warranty period. Manufacturers do not welcome unauthorized intervention into the equipment. This does not apply only to replacing brushes without opening the case, but in other cases it is better to seek help from an authorized service center.

Originally posted 2018-07-04 08:07:49.

We will fix the defect for 1200 rubles excluding parts

Below you can see the latest repairs of our clients who addressed the problem “the drill does not gain momentum.” The price presented is final, taking into account replaced spare parts and diagnostics performed. All repairs are guaranteed. There are daily discounts on the service.

Click on the repair you need to find out more.

Average time: 5.2 days

|

Average price of work: 1127 rub.

|

Average price of spare parts: 263 rubles.

Why is a sparking socket dangerous?

The sparking of the outlet ultimately causes the surrounding elements to ignite and, as a result, a fire . Electric discharges themselves, the temperature of which can reach several thousand degrees Celsius, and simply heating of the socket conductors, which causes sparking, are to blame for this.

Also, in certain cases, sensitive electrical equipment and devices plugged into such an outlet may burn out.

In any case, if you notice that your outlet is sparking, you must immediately stop using it, and do not start without identifying and eliminating the cause of the problem.

Prevention

The problem of sparking grinder brushes can be prevented by taking preventive measures:

- follow the operating rules;

- regularly change the lubricant in the gearbox and bearing sections, reducing mechanical and thermal loads (factory lubricant must be replaced before starting any work);

- promptly replace bearings while maintaining the structural integrity of the armature shaft;

- install a new set of brushes before the old ones start sparking.

If you notice that the brushes spark and burn, you should immediately check the tool or contact a specialist. The lack of timely diagnostics of angle grinders leads to the fact that the sparking brush block ultimately breaks the entire power tool.

You will learn how to replace faulty brushes in an angle grinder in the following video.

It’s hard to imagine a home craftsman’s arsenal without such a popular power tool as an angle grinder or an angle grinder (popular name). The angle grinder gained its popularity due to its versatility, since this tool can be used for cutting, grinding, sawing, polishing, stripping, sharpening and other work. Moreover, absolutely any materials can be processed. During the operation of the tool, various breakdowns occur, and one of the most common is sparking brushes on angle grinders. Not many people know why brushes on an angle grinder spark, so let’s look into this issue, and also find out why they burn out and how to replace them.

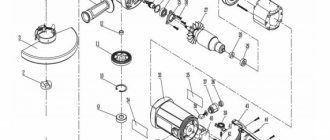

Engine diagram

For a more visual understanding of the operating principle of a commutator motor, there are two visual types of representation - simplified and detailed. The first format (Fig.

below) is a conventional diagram focusing on connecting the windings to the network

More complex designs (Fig. below) have additional taps on the rotor and stator. For example, to power automation or regulate speed. The presence of thermal protection allows you to minimize the likelihood of overheating of the upper layer of the unit winding. This element removes voltage when the relay is activated, stopping the operation of the shaft.

The tachogenerator reflects the rotation speed of the engine. As an alternative, a Hall sensor is installed on some models. The device receives signals through the contacts of the collector panels.

The device is broken - what to do?

There are two ways to solve the problem. The first is to try to fix the problem yourself by studying the information on the Internet, the second is to submit it for repair to any one of 18 Umedia services. This is not the first time we have fixed the problem “the drill does not pick up speed” and we want to share our experience with you, orient you on the cost and terms indicated in the table below.