The AIRE asynchronous single-phase electric motor with a squirrel-cage rotor is used to complete low-power household and industrial equipment (pumps, fans, compressors). Single-phase electric motors are powered from a 220V network. Unlike three-phase electric motors AIR, single-phase motors have a lower starting torque, lower power factor and efficiency, as well as low overload capacity.

Main technical characteristics:

- degree of protection IP54 according to GOST 17494-87;

- insulation of heat resistance class “F” according to GOST 8865-93;

- by installation method, execution: IM 1001 according to GOST 2479-79;

- climatic version U2 according to GOST 15150-69.

- operating mode S1 according to GOST 183-74.

- cooling method 1C-0151 according to GOST 20459-87.

Explanation of the symbol - AIR 80 B2 U2, 1.5 kW, 3000 rpm:

- "A" - asynchronous motor

- “I” - developed within the framework of Interelectro,

- “P” - binding of capacities to installation dimensions in accordance with GOST R 51689 (“C” - in case of binding according to CENELEK standards)

- “E” - single-phase motor with two-phase winding

- 80 — height of the axis of rotation (dimension),

- B is the length of the stator core,

- 2 - number of poles,

- U - climatic version,

- 2 — accommodation category

Price list for single-phase electric motors AIR

Design features and diagram of a single-phase 220V electric motor

The main elements of a single-phase motor are the rotor and stator. The first component is mobile during operation, the second is at rest. The stator is equipped with two types of winding: main and auxiliary. Otherwise they are called working and starting. Both types are located at an angle of 90 degrees in the core and are securely fixed in the grooves.

The main winding makes up the majority, and the auxiliary winding is allocated only 30–35%. As for the rotor design, it consists of rods made of non-ferrous metals. At the ends, the elements are closed with special rings. The free space between the rods is filled with aluminum alloy. Because of its hollow appearance, experts and designers called the rotor of a 1-phase motor a “squirrel cage”.

What is a miter saw?

A crosscut saw is a mechanism with a cutting disc designed for sawing wood and composite materials at right or other required angles. Designed to work on a flat surface. Allowed to be moved and installed in a temporarily equipped workplace. Their appearance resembles machines for cutting pipes, fittings, and stone.

There are several types of miter saws:

Pendulum - a horizontal frame with a turning circle. A lever (pendulum) is attached to the reverse side of the circle, which is where it got its name. The saw blade is mounted on this lever. The workpieces are fed along the guide bar. To make a cut, a lever with a rotating disk is recessed into the board.

Combined - everything is the same. Thanks to the hinges, the ability to rotate the lever relative to the horizontal plane has been added.

With horizontal stroke. It resembles a pendulum saw, but allows you to cut wider parts by moving the mechanism with a rotating disk along the runners back and forth.

As an addition to all trims included:

- dust bag;

- laser illumination;

- pipe for connecting a vacuum cleaner.

Connection

Calculating the values of their capacitances is relatively simple: for the working one 0.75 μF per 1 kW of power, for the starting one - 2.5 times more. Its structure is slightly different from a conventional single-phase asynchronous motor.

A circuit with a working, always-on capacitor works better in nominal mode, but has mediocre starting characteristics. The operating voltage of these capacitors should be 1.5 times higher than the network voltage, that is, for network B we take capacitors with an operating voltage of B and higher.

But despite this, they are widely used in the production of household appliances. These motors have lower efficiency values.

After assembling the electromagnetic starter circuit, you should connect the power section. Its structure is slightly different from a conventional single-phase asynchronous motor. Its power can range from five to ten kilowatts. In addition to the presence of two phases, it is required that one winding be shifted relative to the other by a certain angle.

We recommend: current volumes and standards of electrical equipment testing

Operating principle of a commutator motor

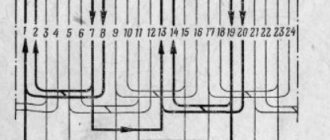

Starting scheme: Starting is carried out by a magnetic field, which rotates the moving part of the motor. Next example.

Single-phase asynchronous electric motors Design and principle of operation The power of such a single-phase motor B can, depending on the design, range from 5 W to 10 kW. On which of them there is no difference, the direction of rotation does not depend on it. Look at the photo and you can clearly see that the wire cross-sections are different. When connecting the device in question, several types of connections are made. That is, if the auxiliary winding of a single-phase motor is starting, its connection will occur only during the start-up, and if the auxiliary winding is a capacitor, then its connection will occur through a capacitor, which remains turned on during engine operation.

Connection diagram for a 220 Volt commutator motor

These electricity ratings are available in all residential premises in our country, and as a result, single-phase motors are extremely popular. We need an initial push. Current is supplied to the rotor windings through brushes in contact with the commutator plates, to which the ends of the rotor windings are connected. Connection diagram 2 Connecting an asynchronous single-phase electric motor to the network.

The function of the centrifugal switch is to cut off the starting phase when the rotor reaches its rated speed. Further rotation of the rotor is ensured by the pulsating magnetic field of the working phase, as already described in the previous paragraph. Two and three-phase motors It is possible to connect a 2 or 3-phase motor to a single-phase power source. how to connect a three-phase motor to a single-phase network

Leroy Merlin

Leroy Merlin offers excellent prices on construction tools from a large catalog of electrical goods. Popular sections include angle grinders (grinders), circular saws, welding machines, high-pressure washers and construction vacuum cleaners. The cost of carpentry tools starts from 150 rubles, and the price of high-quality tools reaches 15,000 rubles.

The Leroy Merlin catalog presents equipment options for painting, tile laying, metal scissors and wood saws. Personal protective equipment is well suited in combination with any manual or electrical appliance. You can personally add your order to the cart on the website and order delivery from the nearest store to your apartment.

Building blocks, plasters, drywall, thermal insulation and metal tiles are just a small part of the available finishing material options. We recommend purchasing construction tools from the Leroy Merlin online store so that they serve reliably for many years.

Connection diagrams for single-phase asynchronous motors

With starting winding

To connect a motor with a starting winding, you will need a button in which one of the contacts opens after switching on. These opening contacts will need to be connected to the starting winding. In stores there is such a button - this is PNDS. Its middle contact closes for the holding time, and the two outer ones remain in a closed state.

Appearance of the PNVS button and the state of the contacts after the “start” button is released"

First, using measurements, we determine which winding is working and which is starting. Typically the output from the motor has three or four wires.

Consider the option with three wires. In this case, the two windings are already combined, that is, one of the wires is common. We take a tester and measure the resistance between all three pairs. The working one has the lowest resistance, the average value is the starting winding, and the highest is the common output (the resistance of two windings connected in series is measured).

If there are four pins, they ring in pairs. Find two pairs. The one with less resistance is the working one, the one with more resistance is the starting one. After this, we connect one wire from the starting and working windings, and bring out the common wire. A total of three wires remain (as in the first option):

- one from the working winding is working;

- from the starting winding;

- general.

We work further with these three wires - we use them to connect a single-phase motor.

With all these

Connecting a single-phase motor with a starting winding via the PNVS button Connecting a single-phase motor

We connect all three wires to the button. It also has three contacts. Be sure to place the starting wire on the middle contact (which closes only during the start), the other two - on the outer ones (arbitrarily)

We connect a power cable (from 220 V) to the extreme input contacts of the PVNS, connect the middle contact with a jumper to the working one (note! not to the common one). That's the whole circuit for switching on a single-phase motor with a starting winding (bifolar) through a button

Condenser

When connecting a single-phase capacitor motor, there are options: there are three connection diagrams and all with capacitors. Without them, the engine hums, but does not start (if you connect it according to the diagram described above).

Connection diagrams for a single-phase capacitor motor

The first circuit - with a capacitor in the power supply circuit of the starting winding - starts well, but during operation the power it produces is far from rated, but much lower. The connection circuit with a capacitor in the connection circuit of the working winding gives the opposite effect: not very good performance at start-up, but good performance. Accordingly, the first circuit is used in devices with heavy starting (concrete mixers, for example), and with a working condenser - if good performance characteristics are needed.

Circuit with two capacitors

There is a third option for connecting a single-phase motor (asynchronous) - install both capacitors. It turns out something between the options described above. This scheme is implemented most often. It is in the picture above in the middle or in the photo below in more detail. When organizing this circuit, you also need a PNVS type button, which will connect the capacitor only during the start time, until the motor “accelerates”. Then two windings will remain connected, with the auxiliary winding through a capacitor.

Connecting a single-phase motor: circuit with two capacitors - working and starting

When implementing other circuits - with one capacitor - you will need a regular button, machine or toggle switch. Everything connects there simply.

Selection of capacitors

There is a rather complex formula by which you can calculate the required capacity accurately, but it is quite possible to get by with recommendations that are derived from many experiments:

- The working capacitor is taken at the rate of 0.7-0.8 µF per 1 kW of engine power;

- starting - 2-3 times more.

The operating voltage of these capacitors should be 1.5 times higher than the network voltage, that is, for a 220 V network we take capacitors with an operating voltage of 330 V and higher. To make starting easier, look for a special capacitor in the starting circuit. They have the words Start or Starting in their markings, but you can also use regular ones.

Changing the direction of motor movement

If, after connecting, the motor works, but the shaft does not rotate in the direction you want, you can change this direction. This is done by changing the windings of the auxiliary winding. When assembling the circuit, one of the wires was fed to the button, the second was connected to the wire from the working winding and the common one was brought out. This is where you need to switch the conductors.

What it might look like in practice

What is the best material to make a bed from?

Considering that the saw will emit quite noticeable vibration during operation, it is better to make the frame from metal. The tree will quickly become loose and the structure will lose its initial strength.

A channel or corners of size from 25×25 mm to 50×50mm are optimal. Thinner ones may not withstand the weight load, while thicker ones will make the structure too weighty, and they are more difficult to connect.

The frame should easily support a weight of 50 kg. On the Internet you can easily find drawings of a homemade frame. Choose any option you like or make it yourself.

It is better to make the tabletop from solid wood 30-50 mm thick or sheet metal. Since it is secured with bolts, through holes of the appropriate diameter must first be made on the frame. It is better to take thick threaded bolts with a diameter of 10 mm.

For even cutting, you can make a side stop parallel to the placement of the disk. A wooden block or metal corner is suitable for this. It can be fixed with bolts, so you need to make holes for several positions to adjust the width of the material being cut. You can also fix it with regular clamps.

bed

Having decided on the material and designed the frame, we move on to choosing an engine.

Design features and diagram of a single-phase 220V electric motor.

The main elements of a single-phase motor are the rotor and stator. The first component is mobile during operation, the second is at rest. The stator is equipped with two types of winding: main and auxiliary. Otherwise they are called working and starting. Both types are located at an angle of 90 degrees in the core and are securely fixed in the grooves.

The main winding makes up the majority, and the auxiliary winding is allocated only 30–35%. As for the rotor design, it consists of rods made of non-ferrous metals. At the ends, the elements are closed with special rings. The free space between the rods is filled with aluminum alloy. Because of its hollow appearance, experts and designers called the rotor of a 1-phase motor a “squirrel cage”.

OBI

OBI closes the ranking of the best Russian companies that sell construction tools in Moscow. Among the advantages, we can note a wide network of hypermarkets in Krasnodar, Saratov, Volgograd and Ryazan. The variety of assortment starts with garden swings and ends with professional equipment for private craftsmen and large companies.

This technique will allow you not only to hang cabinets in the kitchen, but also to break down a concrete wall, install a toilet, windows, doors and replace old wooden floors. Another option would be to buy used instruments (used) for 1-2 thousand cheaper than new analogues. As a nice bonus, there will be free delivery over 3,000 rubles.

OBI is available for online orders not only to residents of large cities. Courier and postal services deliver your order to your home as quickly as possible. In addition to equipment, you can buy building materials, garden furniture, kitchen sets, shower cabins and sinks. OBI is the best retailer of goods for the home, garden and renovation in the 2022 ranking.

How to calculate capacity

The capacity of the capacitor, which is installed in the connection circuit of a three-phase electric motor connected to a 220V network, depends on the circuit itself. There are special formulas for this.

Cр = 2800•I/U, where Ср is capacitance, I is current, U is voltage. If a triangle connection is made, then the same formula is used, only the coefficient of 2800 changes to 4800.

I would like to draw your attention to the fact that the current strength (I) is not indicated on the motor tag, so it will need to be calculated using this formula:

I = P/(1.73•U•n•cosф), where P is the power of the electric motor, n is the efficiency of the unit, cosф is the power factor, 1.73 is a correction factor, it characterizes the relationship between two types of currents: phase and linear.

Since most often the connection of a three-phase motor to a single-phase 220V network is made in a triangle, the capacitance of the capacitor (working) can be calculated using a simpler formula:

C = 70•Pn, here Pn is the rated power of the unit, measured in kilowatts and indicated on the device tag. If you look at this formula, you can understand that there is a fairly simple relationship: 7 uF per 100 W. For example, if a 1 kW motor is installed, then it requires a 70 µF capacitor.

How to determine whether the capacitor is correctly selected? This can only be checked in operating mode.

- If during operation the motor overheats, it means that the capacity of the device is greater than required.

- Low engine power means the capacity is underestimated.

Even calculations can lead to the wrong choice, because the operating conditions of the motor will affect its operation. Therefore, it is recommended to start the selection with low values, and, if necessary, increase the indicators to the required (nominal) values.

As for the starting capacity, what is first taken into account is what starting torque is needed to start the electric motor

I would like to draw your attention to the fact that the starting capacitance and the capacitance of the starting capacitor are not the same thing. The first value is the sum of the capacitances of the working and starting capacitors

As workers, you can use paper, metallized or film analogues. In this case, it is necessary to take into account the fact that the permissible voltage should be one and a half times the nominal voltage. As you can see, choosing the exact capacitor for an electric motor is quite difficult. Even calculation is an imprecise process.

Source

Petrovich

User selection

The Petrovich construction tools store was founded in 2003. They are known as a trading house for building materials, plumbing, workwear, doors and electrical equipment. The cost of delivery within the country starts from 150 rubles to the point of delivery of orders. A competent support service will help you with any questions you may have.

Petrovich sells construction tools from popular world brands: Bosch, DeWalt, Black & Decker, Hitachi and Karcher. There is a wide selection of tools for beginners and professionals on store shelves. Drills, grinders, spray guns, circular saws and planes - low prices with the ability to order online with home delivery.

Petrovich guarantees the quality of the goods and provides the necessary certificates. If the purchase is not suitable, you can return the product to the online store within 180 days. With the arrival of summer, garden tools become relevant: lawn mowers, trimmers, chainsaws, welding equipment and generators for work in the country house or garden.

AC brushed motor

Consider a brushed AC motor. Universal commutator motors can be powered from both AC and DC sources. They are often used in power tools, sewing and washing machines, meat grinders - where reverse is needed, adjustment of the rotor speed or its rotation at a frequency of more than 3000 rpm.

The stator and rotor windings of a commutator motor are connected in series. Current is supplied to the rotor windings through brushes in contact with the commutator plates, to which the ends of the rotor windings are connected.

Reversing a single-phase motor with a commutator is carried out by changing the polarity of the stator or rotor windings being connected to the network, and the rotation speed can be adjusted by changing the amount of current in the windings.

The main disadvantages of such an engine:

- high price;

- the complexity of the device, the practical impossibility of repairing it independently;

- significant noise level, difficult to control, creating radio interference.

This is interesting: The principle of operation of a four-stroke engine: we analyze it in detail

What characteristics you need to pay attention to: power, speed

The main characteristic of an electric motor is power. The following power ranges are selected for circular saws:

- up to 800 W - low-power saws for cutting small wooden workpieces;

- from 800 W to 1200 W—saws with engines in this power range are mounted in small carpentry and furniture shops with continuous production;

- over 1200 W - very powerful circular saws that ensure uninterrupted production in large woodworking shops.

If you choose the wrong power and load low-power engines with continuous work, they will soon become unusable.

The rotation speed of the circular saw blade directly depends on the number of revolutions of the engine shaft. As a rule, electric motors are selected in the range from 3000 to 6000 rpm. In this case, the optimal value is considered to be 5000 rpm, which allows:

- Easily cuts through hardwood.

- produce a more even cut line when using discs of different thicknesses.

- Avoid jamming the saw blade in the wood.

It should be noted that the temperature of the working surface during prolonged contact with the saw also depends on the rotation speed. The higher the speed, the stronger the heating.

A powerful, resourceful tool poses a great danger, and therefore requires professional use skills from the owner.

Connection diagram for a single-phase motor via a capacitor

In the second case, for motors with a working capacitor, the additional winding is permanently connected through the capacitor.

Based on the information on the motor tag, you can determine which system is used in it. The complexity of the circuit lies in the fact that the capacitance of the capacitor to equalize the magnetic field is selected taking into account current loads.

Here, each winding is used for its own operating voltage, hence the power. The capacity is calculated based on the operating voltage and current, or the nameplate power of the motor. By briefly connecting a starting capacitor on the motor shaft, a powerful starting torque is created, and the starting time is reduced significantly.

Due to the complexity of the calculation formulas, it is customary to select containers based on the above proportions. Calculating the capacitance of a motor capacitor There is a complex formula that can be used to calculate the required exact capacitance of the capacitor. In these motors, the working and starting windings are the same according to the design of three-phase windings. After discarding the device for scrap, in most cases, electric motors remain operational and can serve for quite a long time in the form of homemade electric pumps, sharpeners, machine tools, fans and lawn mowers.

Article on the topic: Types of electrical installation work according to estimates

Conclusion

The result is two differently directed flows with a rotation speed different from the main field. This is a star winding diagram. Red arrows are the voltage distribution in the motor windings, indicating that the single phase voltage in V is distributed on one winding, and the linear voltage V is distributed on the other two windings.

After starting the engine, the capacitors contain a certain amount of charge, so touching the conductors is prohibited. In this winding, which is also called the working winding, the magnetic flux changes with the frequency at which current flows through the winding. You can calculate which wires belong to which winding by measuring the resistance. The winding with less resistance is working. The stator of a single-phase electric motor contains a single-phase winding, which distinguishes it from a three-phase one.

Motors with a rotation height of more than 90 mm are available in cast iron. This scheme eliminates the electronics unit, and therefore, the motor will immediately operate at full power from the moment of start - at maximum speed, when starting, it literally explodes with force from the starting electric current, which causes sparks in the collector; There are electric motors with two speeds. This is the necessary reserve to compensate for power losses during start-up - the creation of a rotating moment of the magnetic field. Afterwards it is turned off by a special device - a centrifugal switch or a start-up relay in refrigerators.

The generator can act as an engine, and it, in turn, can act as a generator. On the body of a single-phase asynchronous electric motor there must be a connection diagram, which indicates the terminals of the main and additional windings, as well as the capacitance of the capacitor. In this case, the engine hums, the rotor remains in place. Connecting a single-phase electric motor

El Dorado

Eldorado needs no introduction, as it has an established reputation as a major Russian retailer. Among the appliances that you can purchase in Eldorado are 4K TVs, electric shavers, washing machines, vacuum cleaners and capsule coffee machines from all well-known manufacturers.

The seller provides users with a huge selection of products at discounted prices. Whirlpool, Tefal, Rowenta, Braun and Dyson are just some of the reputable brands you can buy in Eldorado. The company cares about the safety of its customers, so all payments and personal data on the site are protected from hacking.

On the shelves of an online store there are all types of goods that can be found in a retail network. In the household appliances segment, Eldorado always has a large selection of devices (audio and video equipment, gadgets, laptops, photographic equipment). You can often find special offers and products of the day on the site.

Connection

The rotor is usually a short-circuited winding, also called a “squirrel cage” because of its similarity. Information about such units is described in literature from the middle of the last century.

The disadvantages are low starting torque and efficiency. It's not difficult to fix this. Since in a three-phase electric motor the rotational torque is specified structurally using the arrangement of the windings and the phase displacement of the three-phase network, in a single-phase motor an additional starting winding is used for starting, thanks to which a rotational torque is created to displace the rotor.

The thermal relay turns off both phases of the winding if they heat up above the permissible level. Inside, the ends of the coils are connected to form a star. The operating voltage for them should be 1.5 times higher than in the electrical network in our case B. For the circuit to operate, it is necessary to select an element with a certain capacity, calculated taking into account the load current. The main disadvantage of single-phase current is its inability to generate a magnetic field that performs rotation. Regarding the other two terminals, the highest pairwise resistance will be equal to both windings connected in series. Both phases of such devices are working and are turned on all the time. A longer time under load can lead to overheating, insulation fire and mechanism failure.

Design and operating principle

Shaft with keyways at front and fan at rear;

Sealed covers with bearings; Terminal box. For example, if the current is 1. It makes no difference what kind of working winding you have and which starting winding. Its further rotation occurs under the influence of inertial force. Then two windings will remain connected, with the auxiliary winding through a capacitor. This is precisely the reason for the popularity of the engine among the population.

Even if you can’t see it from the outside, hidden by a casing, we will notice the indispensable graphite brushes, pressed by springs. The following are defects that indicate possible problems with the engine, which could be caused by improper operation or overload: Broken support or mounting slots. Connection diagram for a commutator electric motor in V Connection diagram for a single-phase asynchronous motor star diagram How it works Starting a motor with two windings arranged in a similar way will lead to the creation of currents on a squirrel-cage rotor and a circular magnetic field in the space of the motor. Connection diagrams Options for connecting a motor via a capacitor: wiring diagram for a single-phase motor using a starting capacitor; connecting an electric motor using a capacitor in operating mode; connection of a single-phase electric motor with starting and running capacitors. Connecting a single-phase motor // how to determine the working and starting windings

What is a circular saw for?

Before starting work, it is necessary to determine the main tasks of the sawing machine. If you just need to cut firewood for the winter, or do basic carpentry work like making a fence, a strong table with a slot for a saw blade is enough. These options are popular in rural areas.

Circular for working with logs

Some of these “models” have a shaft for securing the knives of a plane or jointer. As a rule, a frame is welded from a corner or channel, an electric motor from discarded factory ventilation is mounted on it, and with the help of a pulley the torque is transmitted to the disk. It makes no sense to describe in detail the manufacturing technology of such a machine.

It's another matter if you want to do carpentry work. In this case, you need a coordinate table with guides that are fixed at different angles.

Since such a stationary saw can work with small-sized workpieces, it is necessary to take care of the operator’s safety. It is advisable to provide adjustment of the rotation speed and the ability to easily change disks with different diameters.

Circular on the motor from the washing machine

You won't miss in an accident

Motor connection

The motor must be connected to a single-phase alternating voltage network of 220 volts, with a frequency of 50 hertz. These electricity ratings are available in all residential premises in our country, and as a result, single-phase motors are extremely popular. They are installed in all household appliances such as.

- Fridge.

- Vacuum cleaner.

- Juicer.

- Trimmer.

- Electric hedge trimmer.

- Sewing machine.

- Electric drill.

- Kitchen mixer.

- Fan.

- Water pump.

Types of connection

- Connection with trigger coil.

- Connection with running capacitor.

Single-phase 220 V low-power electric motors with a starting coil have a capacitor connected to the circuit during start-up. After the rotor accelerates, the coil is turned off. If the motor is made with a working capacitor, the starting circuit does not open; there is constant operation of the starting winding through the capacitor.

It is possible to use one electric motor for different purposes. The same motor can be removed from one vehicle and installed on another. A single-phase motor can be switched on in three ways.

- Electricity is temporarily switched on to the starting winding through a capacitor.

- There is a short-term voltage supply to the starting device through a resistor, without a capacitor.

- Electricity is supplied through the capacitor to the starting winding constantly, simultaneously with the operation of the working winding.

When using a resistor in the starting circuit, the winding will have a higher active resistance. There will be a phase shift sufficient to start rotation. You can use a starting winding that has higher resistance and lower inductance. In order for the winding to meet its parameters, it must have fewer turns and thinner wire.

Capacitor starting involves connecting a capacitor to the starting winding and temporarily supplying electricity. To achieve the maximum starting torque, a circular magnetic field is needed, it must perform rotation. To do this, you need to position the windings at an angle of 90 degrees. It is impossible to achieve such a shift with a resistor. If the capacitance of the capacitor is calculated correctly, it will be possible to move the windings at an angle of 90 degrees.

Wire affiliation calculation

To calculate the wires connecting the starting winding and the working winding, you need to have a device that measures ohms or a tester. It is necessary to measure the resistance of the windings. The resistance of the working winding should be less than the starting winding. For example, if measurements show 12 ohms in one winding and 30 ohms in the other, then the first of them is working, and the second is starting. The working winding will have a larger cross-section than the starting winding.

Selection of capacitor capacity

To select the capacitor capacity, you need to know how much current the electric motor consumes. If it consumes a current of 1.4 amperes, then you need a capacitor with a capacity of 6 microfarads.

Functionality check

The check should begin with a visual inspection.

- If the support of the unit was broken off, then as a result it could also work poorly.

- If the body darkens in the middle, this indicates that it has overheated excessively.

- It is possible that various foreign objects have gotten into the cut of the case; this will slow it down and contribute to overheating.

- If the bearings are dirty, overheating will occur.

- Bearing wear will cause overheating.

- If a capacitor of high capacity is connected to the 220v starting winding, it will overheat. If you suspect a capacitor, you need to disconnect it from the starting winding, turn on the motor, manually rotate the shaft, it will start and begin rotating. You need to let the engine run for about fifteen minutes, then check to see if it gets hot. If the motor did not heat up, then the reason was the increased capacitance of the capacitor. It is necessary to install a capacitor of smaller capacity.

Single-phase electric motors 220 in low power are produced in completely different models and for different purposes, and before you buy a product, you need to clearly understand what power is needed, type of fastening, number of revolutions per minute, and other characteristics.

https://youtube.com/watch?v=NW9T9xHFTuw

General concepts

An asynchronous motor 220 volts, single-phase, requires alternating electric current; the network for connecting such a unit must be single-phase. Single-phase 220 V motors operate at a network voltage of 220 volts and a frequency of 50 hertz. These electrical values are maintained in all household electrical networks, in houses, apartments, dachas, cottages throughout Russia, and in the USA the voltage in the household electrical network is 110 volts. In production in our country, the mains voltage is single-phase, three-phase, and other types of electrical networks.

Single-phase electric motor with asymmetric stator magnetic circuit

Stator

Such a single-phase motor is made with pronounced poles on an asymmetrical laminated core. Rotor

— short-circuited “squirrel cage” type.

This electric motor does not require the use of phase-shifting elements to operate. The disadvantage of this engine is low efficiency.

A single-phase motor operates using alternating electric current and is connected to single-phase networks. The network must have a voltage of 220 Volts and a frequency of 50 Hertz.

Electric motors of this type are used mainly in low-power devices:

- Household appliances.

- Low power fans.

- Pumps.

- Machines for processing raw materials, etc.

Models are available with power from 5 W to 10 kW.

The values of efficiency, power and starting torque for single-phase motors are significantly lower than for three-phase devices of the same size. The overload capacity is also higher for 3-phase motors. Thus, the power of a single-phase mechanism does not exceed 70% of the power of a three-phase mechanism of the same size.

device

Device:

- It actually has 2 phases, but only one of them does the work, which is why the motor is called single-phase.

- Like all electric machines, a single-phase motor consists of 2 parts: stationary (stator) and moving (rotor).

- It is an asynchronous electric motor, the stationary component of which has one working winding, connected to a single-phase alternating current source.

The strengths of this type of engine include the simplicity of the design, which is a rotor with a squirrel-cage winding. The disadvantages are low starting torque and efficiency.

The main disadvantage of single-phase current is its inability to generate a magnetic field that performs rotation. Therefore, a single-phase electric motor will not start on its own when connected to the network.

In the theory of electrical machines, the rule applies: in order for a magnetic field to arise that rotates the rotor, there must be at least 2 windings (phases) on the stator. It is also required to shift one winding by a certain angle relative to the other.

During operation, alternating electric fields flow around the windings:

- In accordance with this, the so-called starting winding is located on the stationary section of the single-phase motor. It is shifted 90 degrees relative to the working winding.

- A current shift can be obtained by including a phase-shifting link in the circuit. Active resistors, inductors and capacitors can be used for this.

- 2212 electrical steel is used as the basis for the stator and rotor.

Overall and connecting dimensions of AIRE electric motors

| Electric motor | Number of poles | Dimensions, mm | |||||||||||||

| l33 | h31 | d30 | b10 | b11 | l10 | l11 | l31 | d1 | l1 | b1 | h5 | h | d10 | ||

| AIRE 71B | 2,4 | 295 | 205 | 155 | 112 | 155 | 90 | 120 | 45 | 19 | 40 | 5 | 21,5 | 71 | 7 |

| AIRE 71C | 2,4 | 295 | 205 | 155 | 112 | 155 | 90 | 120 | 45 | 19 | 40 | 5 | 21,5 | 71 | 7 |

| AIRE 80B | 2,4 | 320 | 230 | 176 | 125 | 160 | 100 | 130 | 50 | 22 | 50 | 6 | 24,5 | 80 | 10 |

| AIRE 80C | 2,4 | 350 | 230 | 176 | 125 | 160 | 100 | 140 | 50 | 22 | 50 | 6 | 24,5 | 80 | 10 |

| AIRE 90L | 2,4 | 380 | 245 | 185 | 140 | 176 | 125 | 170 | 56 | 24 | 50 | 8 | 27 | 90 | 10 |

| AIRE 100S | 4 | 415 | 275 | 215 | 160 | 205 | 112 | 180 | 63 | 28 | 60 | 8 | 31 | 100 | 12 |

Asynchronous or collector: how to distinguish

In general, you can distinguish the type of engine by a plate - a nameplate - on which its data and type are written. But this is only if it has not been repaired. After all, anything can be under the casing. So if you are not sure, it is better to determine the type yourself.

This is what a new single-phase capacitor motor looks like

How do collector motors work?

You can distinguish between asynchronous and commutator motors by their structure. The collectors must have brushes. They are located near the collector. Another mandatory attribute of this type of engine is the presence of a copper drum, divided into sections.

Such motors are produced only as single-phase ones; they are often installed in household appliances, as they allow one to obtain a large number of revolutions at the start and after acceleration. They are also convenient because they easily allow you to change the direction of rotation - you just need to change the polarity. It is also easy to organize a change in the rotation speed by changing the amplitude of the supply voltage or its cutoff angle. That is why such engines are used in most household and construction equipment.

Commutator motor structure

The disadvantages of commutator motors are high operating noise at high speeds. Remember a drill, an angle grinder, a vacuum cleaner, a washing machine, etc. The noise during their operation is decent. At low speeds, commutator motors are not so noisy (washing machine), but not all tools operate in this mode.

The second unpleasant point is that the presence of brushes and constant friction leads to the need for regular maintenance. If the current collector is not cleaned, contamination with graphite (from brushes being worn out) can cause adjacent sections in the drum to become connected and the motor simply stops working.

Isolux

Isolux is a well-known online store that has been selling quality tools for many years. We have hand tools, durable building materials, insulation, heating and a reliable roof. The customer can filter the product by brand, price, power, cartridge, cable length and battery type.

Popular among buyers are construction tools under 3,000 rubles, equipment from DWT, Bosch brands and goods made in Germany. Each item in the store has a detailed description indicating characteristics (weight, country of production, type and size), customer reviews of the product and reliable photographs.

Refrigerator

This is a great place to look for new home appliances. Products available in store categories: refrigerators, washing machines, electric stoves, microwave ovens and electric kettles. Buyers receive a factory warranty on all equipment, and a promotional code on the website will help you save up to 30% when ordering.

A user-friendly user interface allows you to quickly find the things you need for your kitchen and bathroom. Large, clear images and detailed characteristics will help you make the right decision before purchasing. Subscribe to the newsletter so you don't miss promotions and save your family budget.