Before you start welding metal products, you need to prepare them. The actual preparation of metal for welding consists of several stages. First, the metal is straightened, then the product is marked and cut, cleaned and heated. At the final stage, bending and edge processing are performed. These procedures are necessary in order to achieve high-quality connection of structural elements.

It is worth remembering: rust, metal particles, and other elements remaining on the surface prevent high-quality welding.

Therefore, proper preparation of parts for welding is important, which improves weldability. The number of procedures that must be performed when preparing parts for welding may vary depending on the specific situation - the degree of contamination, deformation of the workpieces, the amount of work, etc. Moreover, all stages of preparation are regulated in accordance with GOST 5264-80.

Edit

During storage and transportation, parts of the future welded joint may lose their shape. Distortions include:

- dents;

- bulging;

- warping;

- waviness;

- curvature.

Correct metal cold and when heated. Corrections of heated metal are easier. Editing can be done either by machine or manually. The machine method is used in industry. It is convenient to carry out manual editing using an anvil. Thick steel or cast iron plates are also suitable.

To carry out the straightening process, it is necessary to prepare a metalworking tool. First of all, you can return it to its original shape using a hammer. However, not just any one will do, but one made of soft material. In some cases, you can even use rubber. The shape of the striker is preferably round - a square one will leave marks on the metal. The surface of the striker must be polished. In addition to a hammer, you can use a wooden or metal smoother.

Convexity and undulation are corrected by hitting the edges and gradually moving towards the center. As you approach the central part, they strike more often, but the force of the strikes is reduced. To adjust thin products, it is advisable to use smoothing bars. The straightening of hardened metal is carried out with a straightened hammer.

Wood cutting

During the preparation of the material, chamfering is carried out. In production, an edge planer is used for this. A gas cutting machine, guillotine or special scissors can also be used. The work is still being done with a chisel. It can be ordinary manual or pneumatic.

Metal cutting is carried out according to risks. Usually they are applied in quantities of 2 pieces. Parallel lines may be used instead. The outer line is always at the bottom of the chamfer. The inner line marks its top edge. If there are no risks, then the worker uses a ruler.

Advice! Before cutting, the sheets must be carefully secured.

Marking

Preparing metal for welding includes bringing the dimensions of the parts into line with those indicated in the drawings. Before you start cutting, you need to mark them. For marking, use a sharp object, chalk, pen, thin felt-tip pen, or pencil. Tools you will also need are a ruler, tape measure, square, and caliper. In large production, templates are used.

In addition to the outline of the parts, the places of bends are marked on the metal part.

Assembly and welding accessories

For more productive and high-quality production of welded structures, special devices for assembly and welding are used:

- universal clamp for mounting and assembling cylindrical parts;

- manual clamp for assembling profile and sheet metal;

- manual spring clamp for assembling profile metal;

- rotary screw clamp for assembly and fastening of parts in mass production;

- clamp for assembling parts of different profiles;

- corner clamp made of bolts for assembling large structures from sheet metal;

- tack bracket with a crowbar for structures that are assembled overlapping in installation conditions;

- comb on tacks for large sheet structures;

- tack washers with strips and wedges for sheet structures;

- screw tie for attracting parts;

- compression ring for large diameter pipelines;

- flexible clamp with eccentric clamp for cylindrical parts;

- screw expansion and tension mechanism for sheet structures and flat products;

- a hook with a crowbar for tightening the edges;

- screw spacer for cylindrical parts;

- spacer for assembling parts of mechanical engineering structures;

- screw stop bracket for parts of limited dimensions;

- one-sided screw stop for assembling truss profiles and other structures;

- one-sided stop for assembling structures at stationary posts.

cutting

This is one of the most important stages in preparing metal for welding. A metal element cut downwards can be immediately classified as defective. It's good if there is an opportunity to use it for other purposes. It is not very successful if an adjustment of a few millimeters is required, since such a process is quite difficult to carry out.

Cutting Tools:

- metal scissors;

- guillotine;

- Bulgarian.

For thick parts, welding can be used. To do this, you need to melt the part, and then remove the metal so that you get not a seam, but a through hole. If you follow the intended line, you will get a cut, although not too neat. Thermal cutting is applicable for parts of various configurations. Arc welding and oxygen torch are widely used.

Cutting machines are used in industrial production.

Modern welding technologies

Modern companies offering metal welding services use not only proven, but also the latest technologies to increase the speed of the process and simplify its management. For example:

- hybrid laser technology for joining refractory steel grades;

- double-arc welding for large-sized structures;

- a gentle technique based on the use of special mixtures of protective gases to obtain more accurate seams;

- two-component methodology used in the field of railway transport;

- orbital argon arc technology used in the aerospace industry;

- SMT technology based on cold metal transfer;

- plasma welding used for metals of different thicknesses.

Image No. 9: plasma welding

All articles ›

Stripping

Preparing metal for welding includes cleaning it. Failure to complete this step will result in defects. Even small particles of dirt can cause cracking of the part, the appearance of pores in the structure of the weld, and the emergence of stress spots in the metal.

Cleaning metal surfaces is the easiest preparatory process, but it is very important. You don't need any particularly complex tools. Metal brushes and grinders are used. In production, this process is taken more seriously and shot blasting and sandblasting machines are used.

We should not forget about the need to remove rust, as well as the oxide film, which is formed when the metal comes into contact with atmospheric oxygen. To remove traces of paint and oil stains, a small part can be immersed in a container of solvent. The metal surface must be dried before welding.

Welder's Handbook

Welding work requires not only certain skills, but also a well-prepared workplace, as well as tools. In addition, it is necessary to know certain safety rules when carrying out any welding work. After all, the health of not only the welder himself, but also those around him directly depends on this. Several negative factors can be identified here:

• Burns from molten metal;

• Electric shock;

• Negative effects on the eyes;

• Poisonous gases and fumes during operation;

• Getting various foreign objects into the eyes.

So, preparation for welding work begins with studying safety precautions and personal protective equipment. Safety rules for welding work largely coincide with the general principles of industrial safety: smoking in the workplace, working near flammable materials, etc. are prohibited.

Therefore, before starting work you need:

1. Check the electrical network for reliability.

2. Check the serviceability of the cable insulation.

3. Make sure that various auxiliary equipment is in working order.

In addition, when working inside or on containers, there are safety measures and rules for welding work. For example, preparation for welding work here involves:

1. Installation of special valves or plugs for fencing from other parts of communications.

2. Cleaning and removal of residual substances from the work area, as well as treatment with special fireproof solutions.

3. Covering funnels and drain trays associated with sewers, where various vapors and flammable gases accumulate.

4. Establishing good ventilation of the facility.

As you know, there are several types of welding and welding work. This is, as a rule, automatic and semi-automatic welding, welding with non-consumable or coated electrode, etc. At the same time, each type of work has its own characteristics in the preparation of welding work:

• Universal automatic welding (flux). Its peculiarity is that the work is performed on direct current in reverse polarity. Therefore, you should set up the devices in advance and connect the working cables correctly. The feed rollers on the machine should rotate smoothly, without jerking. Contact between welding wire and nozzle. At the same time, the welding wire must be free of traces of rust or oil. It is recommended to perform automatic welding using flux in the lower position, with the head tilted to the horizon up to +8º.

• Preparation of semi-automatic welding machine for work in shielding gas. First of all, you should check whether the internal guide channel in the torch and the tip according to the wire diameter are selected correctly. Clear the working nozzle of metal, select the required feed speed of a suitable welding wire and ground the product with the return wire.

• Manual argon arc welding. First of all, the burner and gas supply hoses need to be purged with argon for about 30 seconds. You should check the argon cylinder, mouthpiece, tightness of the working hoses, reliability of the tungsten electrode and select the appropriate welding mode. In addition, the hoses are washed with alcohol every month and the insulation level of the burner handle is measured annually.

• Manual standard arc welding. In this case, it is necessary to check the reliability of the clamping of the working electrode, the insulation of the cable connection handle and the fastening of the welding cable itself.

Preparing for welding work will not take much time if you constantly follow safety rules and timely check the work area and tools.

Edge preparation

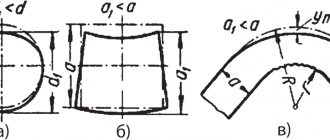

To improve the conditions of the welding process, the edges of the product are processed. This is especially important when welding thick products. Preparation of edges for welding can be done by thermal and chemical methods. The result of processing is the acquisition of a shape that promotes better connection of parts. Grooving increases the width of the seam.

Milling machines, special edge planers, pneumatic chisels, and flame cutting are used in industry. Simpler options are grinding and cutting. For mechanical cutting, metal scissors, a grinder, a chisel, and a file are used. The main parameters are the bevel, cutting angle, gap width, and the amount of bluntness. A bevel is formed when a piece of metal is removed at an angle or rounded.

If welding is performed at an angle, then cutting the edges can be carried out only when the thickness of the parts is more than 3 cm. The presence of a bevel plays an important role when parts of different thicknesses are welded. Sometimes you have to resort to dulling the edges. This is advisable if they have a sharp shape at the end. Otherwise, this may cause the formation of burns, deformation of the seam, the creation of additional stress, and a decrease in the strength of the connection.

The cuts can be on one side only or double-sided. Different types of bevels are used for different connections:

- The one-sided bevel of one or both edges has the shape of the letter “V”. Suitable for use in a wide range of thicknesses. Is the most popular. When cutting both edges, the angle is 60 degrees, and only one - 50.

- The double-sided bevel of both edges resembles the letter "X". Used for products with a thickness of 10-60 mm. Angle - 60 degrees.

- The bevel in the shape of the letter "U" is made on one side. This curved shape is used for metals with a thickness of 20-60 mm. For beginners, the method is difficult.

- A bevel in the shape of the letter “K” is rarely used. In this case, a double-sided bevel is made for one of the edges, and a one-sided bevel for the second.

The designation on the drawings is for the bevel “β” and the opening angle “α”. The bevel should not have any differences. Templates can be used to control cutting.

A separate option is preparing edges for welding pipes. In this process, it is necessary to control the perpendicularity of the end of the pipe to its axis. The requirements are set out in the regulatory document RD 153-34.1-003-01. The total opening angle formed by the two circular edges of both pipes is 60-70 degrees. Blunting is done at a size of 2-2.5 mm.

Preparation of pipes for welding involves gradation according to the wall thickness of the pipes being welded. For small sizes, V- or X-shaped bevels are used. For larger thicknesses, a U-shaped bevel is made.

Preparing pipes for welding also involves discarding. Welding is unacceptable if the difference in the internal diameters of the pipes prepared for welding is more than 3 mm. If the ends have mechanical defects, they are trimmed.

Sheet metal welding technology

Welding of rolled metal can be carried out end-to-end or with an overlap. It is recommended to make vertical seams butt, and circular waist joints are best made with an overlap. The first step is to weld the transverse seams, and only then work on the longitudinal seams.

The gaps between the connected products should be about 1 mm. This is necessary to prevent product deformation. It is recommended to weld sheet metal from the middle, gradually moving towards the edges.

Welding is performed at an angle of 70-90 degrees. In this position, maximum weld penetration occurs.

By welding any sheet metal according to the recommendations, you obtain high-quality welded products of proper strength.

Bending

Preparatory and welding work includes, if necessary, bending of metals. If the parts are in the form of sheets or strips, then sheet bending machines are used. Parts with a profile are bent using special presses.

If it is necessary to bend a small diameter, as well as with a large thickness, then preheating is recommended. This will make the metal more pliable and less effort will be required.

Tack workpieces

This process is required to secure the prepared parts before welding. As a result, they will be in the correct position after the work has been carried out. In most cases, it is not enough to simply place the workpiece next to it or secure it with a tool. Welding is often performed at the beginning and end of the joint being created. The main condition of the procedure is that the parts should not move. After tacking, the structure is allowed to be moved to carry out the main process. Without this procedure, a horizontal suture is rarely created.

The process is carried out by a current whose strength is 20% greater than the amperes used later. The length of the tacks must not exceed 20 mm, and their thickness must be 2 times less than the same parameter of the weld.

Fixation

Preparing parts for welding includes securing them securely to each other. This will ensure the correct position when welding and prevent them from shifting. A method that guarantees reliable fixation is tack welding. This refers to small seams made across the connection of parts.

The size of their section is limited - it should not exceed half the width of the seam. The length of each tack is no more than 2 cm. Pipeline assembly involves making longer tacks. The distance between them is from 10 to 80 cm depending on the length of the seam. The step size also depends on the thickness of the materials. For short seams, point joints are used at their edges. The height of the tacks should not be too high.

Small seams prevent movement of parts in joints, maintain a constant gap between them and give the structure additional rigidity. This is especially important for large connections. Tacks are performed in one pass.

Tacks are divided into temporary ones, which are removed after the weld is completed, and those that remain. They are performed on the reverse side of the connection. Before starting the process, it is necessary to do the same cleaning of the surfaces as for the main seam.

Sheet metal welding methods

Metal sheets of medium thickness are welded in a stepwise manner. The entire welding strip is conventionally divided into sections of 10-20 cm, after which these sections are welded alternately. Each subsequent seam overlaps the previous seam by 1 cm. This technology allows you to avoid temperature deformations of the metal.

Welding of thin sheets of metal is usually done end-to-end, with flanged edges. Butt joints on a lining, without flanging, are also allowed. There is welding of cylindrical products. For example, welding to a flanged bottom of a cylindrical body or welding to a flanged bottom body.

Welding thick metal (more than 4 mm) is performed in several passes. This is the so-called multilayer welding. The weld seam is filled several times. Before applying each subsequent layer, the previous layer is cleaned of scale. Multilayer welding is more reliable, but leads to an increase in consumables.

Product assembly

Preparation of the metal surface for welding ends with their assembly. The accuracy of the relative position will affect the quality of the connection. Before assembly begins, all parts are checked to ensure their dimensions comply with the requirements of the drawings. Templates can be used for assembly, and in mass production, jigs are used to facilitate the assembly process.

Assembly for welding is carried out on special stands. The use of supports and clamps is allowed. As the seam is formed, they are removed.

Selecting gas welding modes

When choosing gas welding modes, they are guided by the grade of the metal or alloy being welded and its thickness. And also the type and purpose of the product being welded. The main characteristics of the gas welding mode include: the power of the welding torch, the type of gas flame, the brand and diameter of the filler rod or wire, the gas welding method and welding technique.

Selecting the power of the welding torch

The thermal power of a welding torch is determined by the flow rate of acetylene passing through it. The required acetylene consumption can be determined by the formula:

Q=AS, where Q is acetylene consumption, l/h; S—thickness of the metal being welded, mm; A is a coefficient that is calculated empirically. When welding carbon steels, coefficient A=100-130l/(h*mm); when welding copper A=150 l/(h*mm), when welding aluminum A=75 l/(h*mm).

The recommended flame power for the right-hand gas welding method is determined by the acetylene consumption of 120-150 l/h, and for the left-hand welding method the acetylene consumption is determined at the rate of 100-130 l/h per millimeter of thickness of the metal being welded.

It must be borne in mind that an increase in acetylene consumption leads to an increase in the power of the welding torch. But if its power is excessive, there is a risk of burning through the metal. The power must be optimal and this must be taken into account.

The power of the gas flame is regulated by replaceable tips that come complete with welding torches.

Edge surface quality control

The inspection of the surface of the edges is primarily carried out by the welder himself, visually inspecting for defects, and also measuring the bevel angle and bluntness. Next, the edges are checked by a level II–III welding specialist (this is a welding master or engineer). This is a standard control scheme at enterprises. If non-destructive testing is required, the inspection is also carried out by a flaw detector.

When carrying out control, the following is checked:

- Distance of stripped metal from cutting.

- Edge bevel angle and bluntness dimensions.

- Are there any unacceptable defects on the surface (metal peeling, cracks and rough nicks).

- If the part being welded is critical, in some cases non-destructive testing of edges is used (ultrasonic, magnetic or PVC)

Designations on the drawings

The main types of edge preparation for welding are not indicated in the drawings. When designating a weld seam, the drawing indicates the regulatory document in accordance with which the seam is made, as well as the type of connection itself, its symbol. You can read more about how welding seams are designated in a drawing in our article - How welding seams are designated in drawings - welding symbol.