For wood processing, there are many different models of professional machines used in technological operations. Among other woodworking equipment, oscillating spindle grinding machines Jbos-5, Scheppach OSM-100 stand out. They are used for processing wood products. You can assemble such a machine yourself to work at home. It is important to comply with all technical conditions and safety precautions.

Using Oscillating Spindle Grinders

For wood processing, many models of professional machines used in technological operations are produced. The list of woodworking equipment includes oscillating spindle grinding machines Jbos-5, Scheppach OSM-100 used in the processing of wood products. If necessary, you can assemble a machine with your own hands to work at home, observing the necessary technical conditions and safety requirements.

Professional class oscillating spindle grinding machine Jbos-5

How to Make a Spindle Oscillating Wood Sander

A spindle sanding machine is used for uniform processing of wooden products. Factory models provide the greatest efficiency. But due to their high cost, purchasing is not always advisable. An alternative option is to make it yourself.

Functional Features of Spindle Grinding Machine

Factory model of spindle grinding machine

During the end processing of wooden workpieces, special requirements are placed on the quality of grinding. Making them manually is problematic and often leads to defects. For these purposes, it is best to use a spindle grinding machine made by yourself.

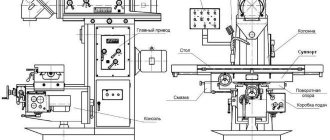

Unlike other types of woodworking equipment, this machine is large in size. This is due to the specifics of its design. It consists of a power unit, a spindle and a support frame. The above-described components are mounted on the latter.

The spindle is positioned vertically, and sandpaper is attached to its surface. An oscillating grinding machine is used for continuous production. The difference lies in the additional movement of the spindle along the vertical axis.

This ensures maximum processing quality.

When making such equipment with your own hands, the presence of an oscillating spindle is not provided. This is due to possible problems and laboriousness of the work.

The main characteristics of a spindle grinding machine that you can make yourself:

- electric motor parameters. The optimal power is from 0.6 to 2 kW. Rotation speed - 2000 rpm;

- spindle diameter. It is recommended to make several removable models mounted on the motor shaft. The diameter can vary from 20 to 180 mm. The higher this indicator, the faster the processing will take place;

- weight of the desktop. During operation of a self-made encryption machine, vibrations will inevitably appear. To eliminate them, it is recommended to increase the weight of the work table or perform a rigid fastening to another work surface.

The size of the tabletop directly depends on the dimensions of the workpieces. When processing small parts, you will need a platform of 50*50 cm. If their size is large, you need to make a large tabletop.

Features of the use of spindle machines

The products of world leaders in the production of woodworking equipment are well known in Russia:

- Jet (Switzerland);

- Scheppach (Germany),

producing oscillating spindle grinding machines:

- Jbos-5;

- Jovs-10;

- Joss-S;

- Scheppach OSM 100;

- Scheppach 450 B.

Oscillating spindle grinding machine Scheppach OSM 100

Jbos-5 machines are also produced at production facilities in China under license from a Swiss company.

Oscillating spindle machines consist of the main units:

- Electric motor.

- Desktop tiltable up to 45° on some models.

- A set of spindles with sleeves.

- A special oscillating mechanism placed in an oil bath, which can significantly extend the service life.

- Protective housing with stand for spindles.

- A set of table inserts with round holes.

- A set of table inserts with oval holes designed for inclined grinding operations.

- A special device for connecting the exhaust of generated waste.

- Control unit.

Structurally, the machine consists of a spindle on which pulleys of different sizes are installed. When connected using a gear, the pulleys may have the same diameter, but the number of teeth may be different. The main working pulley is rigidly mounted on the shaft, and another equipped with an eccentric is installed on the end part. It must be taken into account that the height of the motor pulley must coincide with the range of vertical movement of the spindle. Due to the difference in speed, a reciprocating motion is created.

The main parts of the machine are made of cast iron, due to which its stability is achieved when processing workpieces. And the use of an oil bath to lubricate the oscillating mechanism allows you to extend its service life. The most widely used machines are Jbos-5, which have a compact size, good performance, reliability and low price.

Before starting the work process, the grinding sleeve necessary to remove burrs from the workpiece is selected. Next, a flange is selected, which should have a tight fit.

The washer is installed on the spindle from below with further selection of the bushing and shaft. The flange must fit tightly and be placed on the spindle in a special hole. Next, the sleeve and shaft are installed on the spindle, and the upper spindle is secured with a washer and nut. It is also necessary to take into account that when finishing on the machine, the workpiece is fed into the working area from right to left, and the sleeve rotates counterclockwise.

Oscillating machines are mainly used for processing shaped edges of workpieces and wood parts using a sleeve that performs a rotational and oscillatory movement. They are easy to use, characterized by high quality of product processing, and do not require complex setup and adjustment of equipment. Durable with proper use and compliance with technical maintenance regulations.

Working on an oscillating grinding machine

An oscillating spindle sander is used when working on products made of wood or similar materials. The most productive is the use of professional machines. But using such models at home is impractical due to their high cost. Therefore, many create woodworking machines with their own hands.

Oscillating spindle wood grinding machines from such brands as:

- the German company Scheppach, which produces the Scheppach OSM 100m and Scheppach 450 B models;

- Swiss company Jet, which produces models Jbos-5, Jovs-10, Joss-S.

The most popular is the Jbos-5 model, which has a small size, moderate cost, high performance and good strength.

Main components of spindle grinding machine:

- Disc sanding machine for wood;

- working surface;

- set of spindles and sleeves;

- a protective case on which there is a stand for spindles;

- oscillating mechanism located in a container with oil;

- Control block;

- chip suction;

- set of pulleys.

Factory models also include a spare spindle, tool stand, rubber roller and cleaning tool.

All machine components are mounted on a support frame. The spindle, covered with sandpaper, is placed vertically. There are pulleys on it. They have different diameters, although if the connection occurs through a gear drive, then pulleys of the same size can be used, but differing in the number of teeth.

The main working pulley is rigidly attached to the shaft. At the end of the machine there is a pulley equipped with an eccentric. The range of vertical movement of the spindle must correspond to the height of the motor pulley. Due to the difference between speeds, a reciprocating motion occurs.

The base of the machine is made of cast iron, which gives it the necessary stability. Thanks to the oil container in which the oscillating mechanism is located, the wear rate is reduced.

Spindle grinding machines have the following technical parameters:

- weight (from 10 to 140 kg);

- desktop settings;

- electric motor power (from 0.8 to 1.3 kW);

- angle of inclination of the working surface (up to 45⁰);

- maximum height of the workpiece (from 100 to 160 mm);

- number of spindle revolutions per minute (1300–1400);

- number of spindle oscillations per minute (from 30 to 60 times);

- size of the grinding tool (up to 250 mm).

Working with the machine

Before starting work, the machine must be fixed on a stable surface using clamps.

First you need to decide on the grinding sleeve. Selection is carried out in accordance with the size and shape of the workpiece. Then you need to select the appropriate flange.

A washer is placed at the bottom of the spindle, then a bushing and the corresponding shaft are put on. Then a flange is placed on the spindle and installed in a special hole. It should fit as closely as possible to the sleeve. The sleeve and shaft are placed on the spindle. A washer is placed on the upper spindle and secured with a nut. Starting and shutting down is done using the same button.

The bushing rotates counterclockwise. The product can only be fed from the right, gradually shifting it to the left. If you do the opposite, the workpiece may be thrown off the work surface.

Commutator brushes deteriorate very quickly, as they are made of carbon. Their condition must be monitored every 30 hours. If the length of the brushes does not exceed 3.5 mm, then they need to be replaced.

Main performance characteristics

Models of grinding machines manufactured by various companies have certain characteristics:

- Electric motors with a power of 0.8 - 1.3 kW.

- A certain desktop size.

- The permissible height of the workpiece for processing is 100-160 mm.

- The spindle speed is 1300-1400 rpm.

- Possible spindle oscillation frequency is 30-60 times per minute.

- The permissible spindle stroke is 25-40 mm.

- Possible tilt of the work table is from 15 to 45°.

- The permissible size of the processing tool is up to 250 mm.

- Certain weight characteristics - from 10 to 140 kg.

Grinding machine Jbos-5 with the table working position installed at an angle of 45°

The machines are also equipped with special devices that allow the removal of waste generated during the processing of parts.

Technical conditions for machine maintenance

The operation of oscillating machines requires certain regulations for carrying out preventive maintenance.

For the normal functioning of the grinding machine, it is necessary to periodically perform certain operations:

- once every 30 hours. the condition of the commutator brushes is checked and, if necessary, replacement is made (if the length of the brushes is less than 3.5 mm);

- Constantly clean the bottom flange and washer from dust;

- Constantly lubricate the working mechanisms of the machine.

Making your own grinding machine

If it is necessary to carry out wood processing operations, you can assemble a household machine with your own hands - a structure that must meet certain requirements:

- The electric motor must be attached to the front pillar and connected to the grinding wheel using a shaft.

- Circles can have different surfaces:

- made of abrasive material;

- felt;

- special fabric.

- The base for mounting the electric motor must be movable and rotatable in any direction.

- The electric motor must have sufficient power and shaft speed.

The use of oscillating spindle grinding machines allows us to achieve high quality processing of wood products, significantly increasing labor productivity and reducing the time required to complete operations.

Catalog

Woodworking sanding machines allow you to process workpieces made of wood, non-solid ceramics, MDF, glued hollow facades and other similar materials. Depending on the characteristics of the models, the equipment effectively performs fitting of molds, removing coatings, leveling surfaces, sharpening tools, and brushing. The wide range includes models of various equipment, configurations and functionality, with power parameters of 230 and 400 V, electric motor power up to 11 kW.

Wood sanding machines

Woodworking grinding machines according to their functionality and design features are divided into:

disc-tape;

- disc-shaped;

- oscillating spindle;

- for grinding edges, including with oscillation;

- drum type;

- double-drum grinding and calibrating;

- brushing (brush-grinding).

This equipment is used to process internal and external surfaces, curved edges, external grinding of round and spherical surfaces, and preparation of products for decoration, varnishing and painting.

For work in personal workshops, it offers budget models with desktop placement, designed for basic grinding operations and small volumes of work. And to equip professional workshops and production facilities - massive structures with floor installation, wide functionality, the possibility of modernization and powerful engines for continuous operation.

Equipment and features

- Most models include additional devices that ensure high grinding accuracy and save time on operations, including stops, mechanisms for adjusting the angle of inclination and height of the working surface, and devices for controlling the shaft rotation speed.

- All machines are made of wear-resistant materials, which ensures stable placement, absence of vibrations and long service life. To remove dust and chips, the structures have holes for connecting an aspiration system.

- Machines with an oscillating function allow you to achieve better grinding results and, at the same time, contribute to more uniform wear of abrasive materials.

- Brushing machines or models with the possibility of converting the grinding shaft to a brush one allow you to obtain the effect of artificial aging of wood, with the appearance of the pattern of the species.

Jet wood sanding machines provide high quality woodworking, solving complex and non-standard problems, increasing productivity in the workshop and comfortable working conditions. You can buy grinding machines for professional and personal use from us at prices from a direct supplier.