What is an autotransformer, how to assemble a LATRA with your own hands and a diagram

An autotransformer is a type of transformer that has one winding on a multilayer core.

It is similar to a two-winding transformer, but differs in that part of the winding is common to both the primary and secondary sides.

In the load state, part of the current is transmitted directly from the power source, and the remaining part is transmitted from the action of the device itself. Thus, the device acts as a voltage regulator.

Laboratory autotransformer (LATR)

Autotransformer device

There is one common winding located on the magnetic core of the LATR, and three additional terminals extend from it. Older autotransformer models have a current-collecting contact on the secondary winding, which allows:

- output voltage is smoothly adjustable;

- at one moment change one voltage value to another;

- change the heating intensity of the soldering iron tip;

- regulate electric lighting.

The most common type of autotransformer is a toroidal magnetic circuit. It is a ring-shaped core made of electrical steel.

Copper wire, or winding, is wound around the core. In addition, the design of the device has an additional tap - a tap from the winding. In total, there are exactly three contacts.

For large transformations, it is best not to use LATR. The reasons are as follows:

- The chances of resulting in a short circuit are too high. Electronic circuits specially adapted for this purpose or additional resistance will help deal with the problem.

- A conventional transformer is more suitable for many reasons, such as higher efficiency, lower steel costs, reduced dimensions and weight, and reduced tool costs.

Where are they used?

The main areas of application of the devices are:

- Compensation for potential drop in distribution systems, which is produced by increasing supply voltage values.

- Control systems for asynchronous and synchronous motors, where the presence of an autotransformer with several taps makes starting easier.

- In research laboratories, when it is necessary to vary electrical variables within wide limits.

These devices are also used to adjust the brightness of light; Such devices are called dimmers. In these cases, special attention is paid to the correct selection of fuses, otherwise a higher supply voltage may end up at the secondary terminals.

Electronic device circuit

Buying a reliable LATR with the available range is not an easy task. There are too many low quality products on the market. As an option, you can purchase an industrial design, but the prices are quite high, and the dimensions are rather large. In this case, a more acceptable option would be to create an autotransformer with your own hands.

Materials required for assembly

The materials that will definitely be needed to assemble a homemade electronic LATR on a field-effect transistor are as follows:

- copper wire (winding);

- heat-resistant varnish;

- rag tape;

- magnetic circuit (both rod and toroidal types are suitable);

- a housing with fixed connectors to which power and load will be connected.

LATR winding calculation

First, you need to decide within what limits the LATR will operate on thyristors. The optimal network supply value is 220 V. The secondary voltage values are 127, 180 and 250 V, respectively. The power with these parameters should not exceed 300 W. But you can determine these values yourself, the main thing is that everything corresponds to each other.

Now you need to calculate the winding. It must be calculated based on the larger current. The highest current value can be obtained by converting a voltage of 200 V to 127 V. Under such conditions, the autotransformer becomes a step-down one. The maximum current that passes in the winding of both networks is calculated as follows:

I = I2 - I1 = P / U2 - P / U1 (I, I2, I3 - currents in the corresponding sections of the circuit, A, P - power, W, U1, U2 - voltages of the primary and secondary circuit, V).

Wire diameter d is calculated by the formula:

There is a special table according to which the type and cross-section of the wire is determined. They are selected taking into account the calculated current and the average current density for LATR, equal to 2 A/mm².

Formula for calculating the transformation ratio n:

Formula for calculating the design power Pp:

Pp = P * k * (1 - 1/n) (k is a coefficient taking into account the efficiency of the autotransformer)

What is an electronic LATR?

Autotransformers are needed to smoothly change current voltage with a frequency of 50-60 Hz during various electrical work. They are also often used when it is necessary to reduce or increase alternating voltage for household or building electrical equipment.

Transformers are electrical equipment that is equipped with several windings connected inductively. It is used to convert electrical energy by voltage or current level.

By the way, electronic LATR began to be widely used 50 years ago. Previously, the device was equipped with a current-collecting contact. It was located on the secondary winding. This made it possible to smoothly adjust the output voltage.

When various laboratory devices , there was an option to quickly change the voltage. For example, if desired, you could change the degree of heating of the soldering iron, adjust the speed of the electric motor, the brightness of the lighting, etc.

Currently, LATR has various modifications. In general, it is a transformer that converts alternating voltage of one value to another. Such a device serves as a voltage stabilizer. Its main difference is the ability to adjust the voltage at the output of the equipment.

There are different types of autotransformers:

The last type is three single-phase LATRs installed in a single structure. However, few people want to become its owner. Both three-phase and single-phase autotransformers are equipped with a voltmeter and an adjustment scale .

Scope of application of LATR

Autotransformer is used in various fields of activity, among them:

- Metallurgical production;

- Utilities;

- Chemical and petroleum industries;

- Production of equipment.

In addition, it is needed for the following work: manufacturing household appliances, researching electrical equipment in laboratories, setting up and testing equipment, creating television receivers.

In addition, LATR is often used in educational institutions to conduct experiments in chemistry and physics lessons. It can even be found in some voltage stabilizer devices.

Also used as additional equipment for recorders and machine tools.

In almost all laboratory studies, it is LATR that is used as a transformer, since it has a simple design and is easy to operate.

An autotransformer, unlike a stabilizer, which is used only in unstable networks and produces a voltage of 220V at the output with a varying error of 2-5%, produces the exact specified voltage.

According to climatic parameters, the use of these devices is allowed at an altitude of 2000 meters, but the load current must be reduced by 2.5% for every 500 m rise.

The main disadvantages and advantages of an autotransformer

The main advantage of LATR is higher efficiency , because only some of the power is transformed. This is especially important if the input and output voltages are slightly different.

Their disadvantage is that there is no electrical insulation between the windings. Although in industrial electrical networks the neutral wire is grounded, so this factor will not play a special role, moreover, less copper and steel are used for the windings for the cores, as a result, less weight and dimensions. As a result, you can save a lot.

The first option is a voltage changer

If you are a novice electrician, then it is better to first try to make a simple LATR model, which will be regulated by a voltage device - from 0-220 volts. According to this scheme, the autotransformer has a power of 25-500 W.

To increase the regulator power to 1.5 kW, you need to place thyristors VD 1 and 2 on radiators. They are connected in parallel to the load R 1. These thyristors pass current in opposite directions.

When the device is connected to the network, they are closed, and capacitors C 1 and 2 begin to charge from resistor R 5. If necessary, they also change the voltage value during load.

In addition, this variable resistor, together with the capacitors, forms a phase-shifting circuit.

This technical solution makes it possible to use two half-cycles of alternating current at once. As a result, full power is applied to the load rather than half.

The only drawback of the circuit is that the shape of the alternating voltage during load, due to the specific operation of the thyristors, is not sinusoidal. All this leads to interference on the network. To correct the problem in the circuit, it is enough to build filters in series with the load. They can be pulled out of a broken TV.

The second option is a voltage regulator with a transformer

The device, which does not cause interference in the network and produces a sinusoidal voltage, is more difficult to assemble than the previous one. LATR, the circuit of which has a biopolar VT 1 , in principle, can also be done independently.

Moreover, the transistor serves as a regulating element in the device. The power in it depends on the load. It works like a rheostat.

This model allows you to change the operating voltage not only under reactive loads, but also active ones.

However, the presented autotransformer circuit is also not ideal. Its disadvantage is that a functioning control transistor generates a lot of heat. To eliminate the shortcoming, you will need a powerful heat sink with an area of at least 250 cm².

. It should have a secondary voltage of about 6-10 V and a power of about 12-15 W.

The diode bridge VD 6 rectifies the current, which subsequently passes to the transistor VT 1 in any half-cycle through VD 5 and VD 2.

The base current of the transistor is regulated by a variable resistor R 1, thereby changing the characteristics of the load current.

Voltmeter PV 1 is used to control the voltage levels at the output of the autotransformer. It is used to calculate voltages from 250-300 V. If there is a need to increase the load, then it is worth replacing the diodes VD 5-VD 2 and transistor VD 1 with more powerful ones. Naturally, this will be followed by an expansion of the radiator area.

As you can see, to assemble an LATR with your own hands, you may only need to have a little knowledge in this area and purchase all the necessary materials.

- Alexander Romanovich Chernyshov

How to make an electronic LATR?

The main reason for creating an electronic LATR with your own hands is the abundance of unreliable regulators on the electrical goods market. A way out of the situation may be an industrial-type sample, but such specimens are expensive and have impressive dimensions, which makes it difficult to use at home.

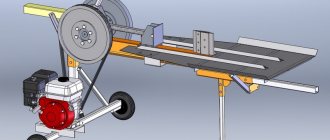

Electronic LATR device diagram.

What is the device

It is worth mentioning that laboratory autotransformers (LATR) were widely used half a century ago. Previous versions of the device had a current-collecting contact, which was located on the secondary winding. This made it possible to smoothly change the output voltage (its value).

If all kinds of laboratory instruments were connected, there was an option to quickly change the voltage. For example, if necessary, it was easy to influence the degree of heating of the soldering iron, adjust the brightness of the lighting, the speed of the electric motor, and much more. This is a kind of regulating power supply.

Figure 1. Scheme of a simple version of LATR.

The current version of LATR has various modifications.

In general, it can be considered a transformer in which an alternating voltage of one value is transformed into an alternating voltage of another.

The device is widely used as a voltage stabilizer. The main feature is the ability to change the voltage at the output of the device. LATRs come in several versions:

- single-phase;

- three-phase.

The three-phase version consists of three single-phase laboratory autotransformers mounted in a single housing. By the way, there are significantly fewer people who want to become the owner of a three-phase option.

A simple device for regulation

There is a very simple version of LATR, which is available even for beginners; its diagram is shown in Fig. 1. The voltage range regulated by such a device is within 0-220 volts. This homemade regulator has a power of 25-500 W. The power of the device can be increased by installing thyristors VD1 and VD2 on radiators.

Semiconductor devices (we are talking about thyristors VD1 and VD2) should be connected in parallel with the load R1. The current they pass has opposite directions.

When the device is connected to the network, the thyristors remain closed, unlike capacitors C1 and C2, which are charged by resistor R5.

If there is a need, using resistor R5 you can change the voltage that is obtained during load. The resistor and capacitors create a phase-shifting circuit.

Figure 2. LATR with a bipolar transistor.

A phase-shifting circuit is an electrical four-port network, the harmonic signal at the output of which is shifted in phase relative to the input signal. They are common in self-propelled guns as adjustment devices that provide stability and the necessary quality of control. Special cases are differentiating and integrating chains.

This technical solution allows you to use not half the power for the load, but full power. This is achieved due to the fact that both half-cycles of alternating current are used.

The disadvantages include the form of alternating voltage at the load. In this version it is not strictly sinusoidal. The specific operation of semiconductor devices is the main reason.

The presence of such a feature can cause interference in the network. But they can be eliminated by additionally installing chokes (series load filters) on the circuit.

Such filters can be found even in a faulty TV.

Voltage regulator: version with transformer

A laboratory autotransformer, which will not cause interference in the network and is capable of producing a sinusoidal voltage at the output, is a little more complicated than the previous one.

Its circuit (Fig. 2) contains a bipolar transistor VT1. It acts as a regulatory element in such a device. The power of this transistor is determined depending on the required load.

In the circuit, it is connected in series with the load and functions as a rheostat.

This option provides the ability to adjust the operating voltage during both active and reactive loads.

Unfortunately, there is a drawback here too. It lies in the fact that the activated control transistor generates too much heat. To eliminate it, you will need a heat sink that will have sufficient power. In this case, the area of such a radiator must be at least 250 cm².

This model uses transformer T1, which must have a power of 12 to 15 W and a secondary voltage of 6 to 10 V. The current is rectified using a VD6 diode bridge.

The rectified current to transistor VT1 in any half-cycle version passes through the bridge of diodes VD2 and VD5. To adjust the base current of transistor VT1, you must use the variable resistor R1.

Thus, the load current parameters change.

Using the PV1 voltmeter, the voltage value at the output of the device is monitored. The voltmeter is taken with the expectation of a voltage from 250 to 300 V. If there is a need to increase the load power, you should replace the transistor VD1 and diodes VD2-VD5 with more powerful ones. This, of course, will be followed by an increase in the radiator area.

As you can see, self-assembly of the LATR is possible; you just need to have knowledge in this area and acquire the necessary materials.

Decoding the main parameters

Windings are usually designated by capital letters (A, B, C, etc.), while the common neutral connection is designated N or n. For secondary taps, digital index numbers are used for all tap points along the primary winding. And indices usually start with the number “1” and continue increasing.

The designation of domestically produced household autotransformers manufactured in accordance with GOST 7518-83 includes:

- Letter indices that determine the class of the device - transitional (APB) or adjustable (APB);

- Reactive power rating, kVA, for which the windings are designed.

GOST 7518-83 provides for the indication of the highest voltage on the secondary winding separately in the absence and presence of an external load.

Separate markings are adopted for laboratory autotransformers - LATRs: after the letter designation the rated power of the device is indicated in kW.

How to make a laboratory LATR with your own hands?

A transformer that has an electrical connection between the windings is called a laboratory autotransformer, or LATR. The load circuit voltage is directly proportional to the secondary circuit winding.

Depending on the design, obtaining the desired output voltage is done by connecting to the appropriate terminals or rotating a manual regulator (Fig. 1).

This article describes how to make LATR at home.

- 1 Preparation of material

- 2 Wire calculation

- 3 Assembly process

- 4 Check

Preparation of material

To assemble the LATR you will need the following materials and devices:

- Copper winding;

- Toroidal or rod magnetic circuit. Can be purchased at a specialized store or removed from damaged equipment;

- Heat-resistant varnish;

- Rag tape;

- Housing with fixed connectors for connecting load and power.

For a laboratory LATR with a variable transformation ratio, you may additionally need:

- Digital or analog voltmeter.

- Rotary mechanism, including a handle and a slider with a carbon brush. It will regulate the voltage.

Wire calculation

It is not advisable to use an autotransformer for large transformations for the following reasons:

- There is a high risk of receiving currents close to a short circuit. This is compensated by special electronic circuits or additional resistance. For small loads it is more profitable to use an electronic LATR.

- The advantages over transformers are lost: high efficiency, saving on conductor and steel, small dimensions and weight, cost.

We are determining within what limits the LATR will operate. We select 220 V for the network supply. We select 127, 180 and 250 V as secondary voltages. We limit the power to 300 W. You can choose your own values and make similar calculations using the example of this article.

The winding is calculated based on the larger current. The highest current will be when converting a voltage of 220 to 127 V. The autotransformer in this case is a step-down one, and circuit 1 is suitable for it. Based on the provided circuit, we calculate the maximum current I passing in the winding of both circuits:

I = I2 – I1 = P / U2 – P / U1 = 300 / 127 – 300 / 220 = 1 A

- where I, I2, I3 are currents in the corresponding sections of the circuit, A;

- P – power, W;

- U1, U2 – primary and secondary circuit voltages, V.

The wire diameter is calculated using the formula:

d = 0.8 * √I = 1 mm.

From Table 1, select the wire type and cross-section. We make the choice taking into account the calculated current and the average current density for transformers - 2 A/mm².

The LATR transformation coefficient n is calculated using the formula:

n = U1 / U2 = 220 / 127 = 1.73

For further calculation, we calculate the design power Pр:

Pр = P * k * (1 – 1/n) = 300 * 1.2 * (1 – 1/1.73) = 151.92 W

where k is a coefficient that takes into account the efficiency of the autotransformer.

To determine the number of turns per 1 volt, it is necessary to calculate the cross-sectional area of the core S and determine the type of magnetic circuit:

S = √ Pр = √ 151.92 = 12.325 cm²

W0 = m / S = 35 / 12.325 = 2.839

- where W0 is the number of turns per 1 volt;

- m – 50 for rod and 35 for toroidal magnetic cores.

If the steel is not of very high quality, it is worth increasing the W0 value by 20-30%. Also, when calculating turns, their number should be increased by 5-10% to avoid voltage sag. We calculate the number of turns for selected voltages 127, 180, 220 and 250 V:

w = W0 * U

We get 360, 511, 624 and 710 turns.

To calculate the length of the wire, we wrap one turn around the magnetic circuit and measure its length. Then we multiply by the maximum number of turns and add 25-30 centimeters for each terminal to the terminal.

Build process

To assemble an adjustable LATR, we select a toroidal magnetic core (Fig. 2). We insulate the place where the winding is applied with rag tape. We bring out the wire for the first power terminal. We bring out all subsequent wires without breaking them.

We fix the first turn on the magnetic core and begin to wind the calculated amount. When a turn corresponding to one of the selected voltages is reached, we remove the loop and continue winding the wire.

Figure 3 shows the winding process on a wooden frame.

After applying the winding, we varnish LATR. We fill the container with the selected varnish and dip the autotransformer into it. Leave to dry for a long time.

After drying, place the autotransformer in the housing. We connect the first output wire to the power connector.

This connector must be electrically connected to the common load terminal, so we connect them together with some kind of conductor. We connect the loop output for 220 V to the second power terminal.

We connect the remaining wires to the corresponding terminals of the secondary circuit. “Scheme” 2 shows the wire terminals.

For a laboratory autotransformer with a variable transformation ratio, we add a housing and make a mount for the regulator handle. We attach a slider with a carbon brush to the handle. The brush should touch the top of the winding tightly.

We mark the area over which the brush will move, and in this place we get rid of the insulation. This way the brush will have direct electrical contact with the secondary winding. We replace the secondary voltage terminals, in addition to the common one, with one connected to a carbon brush (diagram 3).

When connecting, secure the voltmeter.

If you follow the written article, you can easily make LATR with your own hands.

Examination

To ensure the smooth and reliable operation of the device, we perform the following points:

- We connect the autotransformer to a 220 V network;

- We check for the absence of smoke, burning smell, strong noise;

- We use a voltmeter to check the compliance of the output values;

- After 10 - 20 minutes of operation, turn off the LATR. Check to see if the winding is overheated.

- We turn the LATR back into the network and connect the load for a long time.

If there are no problems, the autotransformer is ready for operation.

Classification of species

Typically, the devices in question are used in industrial and domestic applications that are designed for low power consumption. They are also effective for connecting systems operating at different voltages. This explains the variety of types of autotransformers.

The products in question are:

- According to the degree of external protection of the case - devices intended to operate outside are equipped with a waterproof case.

- According to technical characteristics - operating frequency range, maximum primary and secondary voltage values, maximum secondary current, power and temperature.

- According to the type of electrical network in which they operate - single-phase or three-phase.

Single-phase (left) and three-phase (right) - Depending on the output voltage, autotransformers can be step-up or step-down. A special class is formed by devices with sliding taps. An important characteristic that is taken into account when choosing is the type of core - laminated, split and toroidal.

1a – transformer, 1b – step-down, 1c – step-up

Main types of autotransformers

- VU-25-B - serves to equalize secondary currents in differential protection of power transformers.

- ATD - power 25 W, takes a long time to saturate, has an old design and is therefore used very rarely.

- LATR-1 - designed for networks with a voltage of 127 V.

- LATR-2 - used with a voltage of 220 V.

- DATR-1 - designed for light loads.

- RNO - designed for heavy loads.

- ATCN - used in measuring television devices.