Restoring a Phillips screwdriver

Since this type of screwdriver is the most common, and its slots do not have sufficient contact area with the walls of the fastener, it happens that over time the tool’s slots wear out, and it is no longer possible to achieve the desired effect.

Then the question arises of how to restore the instrument so that it functions as before. Of course, it will no longer be possible to achieve the same condition that the instrument was in after purchase, but with a little effort you can achieve a noticeable effect. Typically, the screwdriver slots are worn away in such a way that only a thin continuation of the rod remains from them, which, resting against the bottom of the fastener, prevents the remaining slots from catching on the walls of the slots in the bolt or screw. In this case, the splines need to be sharpened.

First you need to cut off the excess part of the rod until the remaining slots begin. This can be done using a grinder. You can then use the same grinder to cut new grooves that will serve as spline separators. This must be done carefully, with the tool firmly secured in a vice, wearing a protective mask or goggles. Having cut the grooves a little with a grinder, then you need to do everything with a triangular file with medium dusting.

The file is inserted into the groove so that its lower corner is in the cut groove, and the wall is adjacent to the future slot. Using translational movements, the file is moved back and forth until the required depth is reached. Then you need to move to the next slot and repeat the procedure.

Originally posted 2018-03-28 15:30:30.

Screwdriver selection criteria

In order for the purchased tool to serve for a long time and to be comfortable to use, you need to choose the right one.

First you need to decide on the scope of work:

When purchasing, pay attention to the quality of the material from which the rod and handle are made. The handle should be made of thick plastic and have rubber inserts. This will ensure comfortable use.

The right screwdriver not only speeds up the work process, but also makes it more efficient. A wide range makes it easy to choose the right one.

Source

Kinds

There are quite a large number of types of slotted screwdrivers.

Dielectric screwdrivers are a device consisting of a metal base with a tip and a plastic or often rubber handle, which, due to insulation, does not allow current to pass through. Such screwdrivers are used mainly by electricians who need to work under powered conditions.

But there is also a difference in the types of splines:

- straight slot is one of the most common options;

- cross-shaped slot with a hole in the center of the working part for guides;

- a spline with a combination of straight and cross spline parts;

- one of the options for a cross slot is a model that combines a cross and a square section;

- model with a cross-shaped working part and 4 rays;

- square slot option;

- square slot with a hole in the center of the guide;

- star slot;

- “star” option, but using a pin in the center;

- the same “star”, but with shorter and less sharp rays;

- five-pointed star with hole;

- hex key or Allen key;

- the same hex key with a hole for the guide;

- screwdriver with three-wing slot, rare variant;

- asymmetrical cross slot, which has a tighter tightening than other slots;

- a slot similar to a two-pronged fork;

- eight-pointed star with a hole in the middle, a rare specimen;

- pentagonal slot, a rare alternative to hexagonal;

- the twelve-pointed star was used on some Volkswagen vehicles;

- narrowly targeted type of slot, used mainly in various models of American electrical engineering;

- triangular slot, used in toys, electrical appliances or household appliances.

Flat head screwdrivers come in the following sizes:

| Width, mm | 2 | 2,5 | 3 | 3,5 | 4 | 4,5 | 5 | 5,5 | 6,0 | 6,5 | |||||||

| Thickness, mm | 0,3 | 0,4 | 0,4 | 0,5 | 0,5 | 0,6 | 0,6 | 0,8 | 0,6 | 0,8 | 0,8 | 0,8 | 1 | 1 | 1,2 | 1 | 1,2 |

| Width, mm | 7 | 8 | 9 | 10 | 12 | 13 | 14 | 16 | 18 | ||||

| Thickness, mm | 1 | 1,2 | 1,2 | 1,6 | 1,4 | 1,6 | 1,6 | 2 | 1,5 | 2 | 2,5 | 2,5 | 3 |

Screwdriver operation

Screwdrivers are used to pry up removable panels, scrape off various contaminants, separate stuck-on linings, and even use them as a chisel and chisel. Any use will result in tool wear. Therefore, repair and restoration of the instrument is required.

Let's start with sharpening. Many people try to sharpen the product, but not everyone knows how to do it correctly. First of all, the tip of the screwdriver must be blunt. The principle of sharpening is similar to the process of sharpening skates, but only in the case of a flat slot. The cross blade should be sharpened only in extreme cases.

Next, you should magnetize the screwdriver. Most often, modern models already have a magnetized tip. If this is not the case, then it is enough to leave it next to a powerful magnet for a while or simply attach it to a magnet.

Signs and symptoms of diseases

Crunching is one of the characteristic symptoms of various inflammatory and degenerative pathologies, as well as congenital anomalies of the musculoskeletal system. But not the main one. Therefore, at an appointment with a pediatric orthopedist, parents should describe all the signs of the disease that worry them, the frequency of occurrence, intensity, and relationship with any provoking factor. This will significantly speed up diagnosis and allow you to quickly begin treatment.

| Disease in infants, manifested by crunching in the joints | Characteristic clinical manifestations |

| Arthritis | Common signs for all types of arthritis are a gradual increase in pain, the formation of inflammatory edema over the affected joint, limited mobility, increased local and general temperature, decreased appetite |

| Rheumatism | Rheumatic fever is manifested by arthralgia, swelling, swelling, local redness of the skin, increased temperature, and a sharp limitation of movements of the affected joints |

| Hip dysplasia | Underdevelopment of the joint is indicated by shortening of the hip, asymmetrical arrangement of skin folds, and limited abduction of the hip. The most informative symptom of Marx-Ortolani slip is a click or crunch that occurs when the femoral head is reduced into the acetabulum. |

History of invention

The need for such a tool appeared with the invention of screws, which were mentioned back in the 16th century. At first, these fasteners were unscrewed with keys, because the screw head was 6-sided. The screws did not always screw in and out easily, so a groove was made in their head into which the flat part of a blunt chisel was inserted, which later received its modern name.

It is generally accepted that the screwdriver was invented in the 17th century. At that time, it was widely used in the manufacture of weapons and precision mechanical products. This is proven by the presence of slotted screws in pistols and muskets of that century. Until the twentieth century there were no other types of splines. The evolution of the tool occurred when Canadian traveling salesman Peter Robertson had a minor accident: while tightening a screw, the working part of the tool slipped out of a straight groove and injured his hand. As a result, he came up with a screw head design not with a through slot, but with a square recess in the center.

The know-how was called the “Robertsonian screw,” and to tighten such screws, a tool with a modified shape of the working part was required. Thanks to the innovation, the following was provided:

- better centering;

- screwing safety;

- increase in effort.

The new fasteners began to be used in mechanical engineering, in particular.

The invention was patented by American Henry Phillips. Phillips propellers were used in the production of bomber aircraft in the 1940s.

With the development of fastener designs and areas of their application, new designs of shaped screwdrivers were developed, each of which corresponds to a specific slot shape. There are more than 10 types of instruments.

Varieties

Today there are dozens of types of screwdrivers. However, the most common types are the flathead screwdriver and the Phillips slotted screwdriver. On their basis, other types of this tool are developed and created. Let's take a closer look at them.

Flat head screwdriver

The very first type of tools with a flat slot has been known since the 15th century. It has been preserved with certain changes to this day. Due to its versatility, it can be used for various types of fasteners, including screws. The flat one holds perfectly in the groove and allows you to create good torque without any problems. The flat design is also distinguished by the following characteristics:

- In addition to standard use, they are well used in tuning electrical circuits ; they allow you to open locks with slotted grooves;

- Flat splines are found on many tools , for example, plates, knives. This means that a screw that is not too tight can be unscrewed using the specified tools;

- Such accessories are good to use for finishing work , including spring mechanisms.

At the same time, there is one serious drawback - weak stability. A small lateral force is enough and it will slide out of the groove. Fixation in only one plane does not prevent the slot from sliding along the entire screw.

Phillips screwdriver

It is a modernized version of the flat design. The goal was to eliminate the disadvantages of the flat spline. The latter tried to jump out of the groove, and when the screw was tightened all the way, the head could break.

The solution was found by Phillips, who developed the slot described above. Due to this, a slight vertical deviation will not lead to the tool being pulled out. Side shift stops securely hold the spline in the fastener. The convenience was immediately appreciated by joiners and carpenters. This was especially important when screwing screws into wooden structures. Productivity has increased almost several times. However, they also have disadvantages:

- Great effort is required to operate the tool. This leads to rapid wear of the cross splines ;

- A constant force must be applied to keep the tool in the desired plane. As a result, the employee gets tired quickly ;

- The cross is limited in size . Very small ones with a similar slot are not produced, since they will not be in demand.

Despite these disadvantages, the Phillips slot has gained considerable popularity among representatives of blue-collar professions. 75 percent of fasteners are manufactured specifically for this modification.

Recently, an improved version of the Phillips slot has been developed called Torx. He is not afraid of strong fixation. Allows you to effectively protect complex products from unauthorized repairs. A production with replaceable cross heads, called bits, has also been launched. Such tools should be in every household of an experienced craftsman.

Types of screwdrivers and their purpose

A universal bench screwdriver is a tool that is found in almost every home.

Thanks to a screwdriver, you can perform repair work of varying degrees of complexity; the main thing is to know what type and diameter is suitable in each specific case.

You can find out what types of screwdrivers there are if you delve deeper into the topic.

A distinctive feature of all types is the different thickness of the rod.

The most popular are screwdrivers with a round and square cross-section, with a straight or Phillips slot.

However, technological progress does not stand still and, along with new types of fasteners, professional screwdrivers appear for screwing in bolts, screws and other elements.

All this is done to make things easier for consumers.

• At the moment, in addition to universal models, there are several more modernized types of screwdrivers for various jobs.

For example, an adjustable screwdriver is distinguished by its versatility, because... on one side of the rod it is flat, and on the other it is cross-shaped.

Some adjustable models have several different tips, which increases the versatility of the tool.

• A precision or, as it is also called, a thin screwdriver – suitable for repairing mobile phones, its marking corresponds to the zero designation.

The product is produced with a small slot size, no more than 2mm, which allows for precise work with small parts.

• The two-component screwdriver has acquired special ergonomic properties; its distinctive feature is a durable handle made of combined materials.

Polypropylene and rubber were used to cover the handle.

The two-component coating ensures a secure grip so that the product can no longer slip out of your hands.

• To work with thin parts, watch screwdrivers are used; they are used to repair watch mechanisms.

The size of the tip of the product is no more than a millimeter.

The classification of professional mounting screwdrivers does not end there; there are many more types of models designed for specific purposes.

Functional features of screwdrivers

Some screwdrivers have unusual, but very useful, additional functions.

- Telescopic screwdriver. Using the special structure of the rod, which resembles a fishing rod, you can adjust its length, and a special locking mechanism will reliably fix the required length. The tips of such screwdrivers are usually magnetic, which allows you to work in difficult conditions or reach a fallen part in a hard-to-reach place.

- Impact screwdriver . It may happen that a threaded connection may become rusty, stuck, or coated with paint. Dismantling such a connection is not easy, because it requires a lot of force. For such purposes, there are impact screwdrivers that are made of high-strength steel. On the handle of such screwdrivers there is an anvil for impact or a shank for gripping with a key, which allows you to increase the leverage and thereby increase the moment of force. There is also a type of impact screwdriver that has a flat shank. When struck with a hammer, it converts the impact force into rotational force, which makes it possible to apply an even greater moment of force to the element being eliminated.

- Precision screwdriver . This type of screwdriver is used when working with small parts. It has small dimensions and a slot size of up to several millimeters, which allows you to carry out work as accurately and accurately as possible.

- Clock screwdriver. This is the smallest type of screwdriver. Used for repairing and replacing watch mechanisms. The size of its tip sometimes barely reaches one millimeter. There is a flat area on the top of the handle that allows you to hold the screwdriver in one place with one finger while the rod rotates freely. This allows the smallest parts to be screwed or unscrewed without having to reposition the tip and ensures high precision.

- Indicator screwdriver. An indispensable thing when performing work related to electricity. Thanks to a special mechanism built into the handle, the indicator screwdriver allows you to detect the presence of voltage on the element. There is a special contact on the handle to which you need to place your finger. If the part is energized, the built-in LED will light up.

- Dielectric screwdriver . A more serious type of screwdriver designed for working with electricity. The handle is made of a material with high insulating properties; sometimes the shaft of the screwdriver is also covered with this material, leaving only its tip exposed. This design allows you to carry out work even on open terminals of high-voltage equipment, withstanding voltages up to 1000 V.

- Cordless screwdriver . A small battery is built into the handle of such a screwdriver, allowing it to work as a screwdriver. You don't need to apply any force at all, and the tightening torque will be slightly greater than if you tighten it by hand. Such a tool can significantly speed up the process of repairing or assembling various products.

- Torque screwdriver . This type of screwdriver is used in high-tech industries, aviation, mechanics, and astronautics. On the handle of such screwdrivers there is a small screen that allows you to measure the tightening force, or a special scale that allows you to set the required torque and install all connections with exactly the same force.

Photos of screwdrivers

Types of screwdrivers: what do we know about this tool

The screwdriver entered human life around the 16th century, along with the advent of such a fastening element as a screw. At first it was some kind of wrench, but later, when the screw head acquired a more or less modern appearance and received such a structural element as a slot, the screwdriver turned into an independent class of tool. Wise heads even divide it into its component elements.

- A tip called a sting. The most important element of any screwdriver is the so-called working part. It is the tip in most cases, or rather its shape, that determines the main differences between one screwdriver and another. This shape determines which screws or screws the screwdriver you choose can screw in and out.

- Kernel. It can have different lengths and thicknesses, and this is not without reason - not every fastener can be placed on the surface of the part. Often they are recessed deep into a hidden hole, which, by the way, can differ in its width. Moreover, the thickness of the rod also affects the size of screws that can be unscrewed using a particular screwdriver.

- Lever. The main requirement for this part of the screwdriver is ergonomics, that is, ease of use. Today, two types of screwdriver handles are widely used - a regular cylindrical one with various anti-slip devices and a T-shaped one. The latter type of handle allows you to create greater torque - these screwdrivers are very good for unscrewing stuck and rusted screws.

Some screwdrivers, or rather even their handles, can be equipped with a metal tip at the end - it can be either flat (this is an impact screwdriver that can be hit with a hammer) or hexagonal. The latter variety is designed to create maximum torque.

Manufacturers

Among the masters, Swiss and German instruments occupy a special place.

They are reliable, durable, have high quality workmanship and a good margin of safety.

Today, some domestic manufacturers are trying to keep up with their foreign counterparts, offering really good screwdrivers and their sets with a quality guarantee.

As for instruments from China, it should be remembered that the years of “Chinese junk” are long behind us.

Products from modern China are offered in two versions: cheap disposable and high-quality at an affordable price.

Among the Chinese instruments you can find high-quality and inexpensive specimens, and this is due to the low cost of production.

For rare minor home repairs, a simple Chinese tool is also suitable.

But its reliability is always in question.

It happens that on the very first day of use the tip splits into two parts right in the slot.

A more common occurrence is the handle turning, when it rotates freely in both directions, but the rod remains in place.

In any case, the specialists themselves know which tool they need from which manufacturer.

And beginners will choose good options for themselves, based on their future experience and the recommendations of more “advanced” comrades.

«>

How to choose a ratchet screwdriver

What do you need to know to buy a good quality product? Initially, you need to decide for what purpose the tool will be used. If you plan to use it in rare cases, then inexpensive models of Chinese origin are suitable for such purposes.

When choosing the devices in question, you should pay attention to the following parameters:

- Rod design. The rod must be made of good steel alloys. The characteristics of the tool must be indicated, so strength indicators must be in the range from 47 to 52 units. If the strength value is lower, then there is a high probability that the rod will simply break off during operation. A strength value above 52 units is unjustified and increases the cost of the tool

- Material of manufacture. Rods and bits (if included) should be made from an alloy such as Chrome-Vanadium. It is from this material that many modern wrenches are made, providing them with strength and reliability.

- Lever. The ease of use of the tool depends on the quality of the handle. If the manufacturer wants to save on the production of the product, then the handle is not covered with an additional layer. The best option is a handle coated with polyurethane and rubberized inserts.

- Equipment. The tool is sold both in a set with a certain number of bits and without them. It is recommended to buy a screwdriver separately only if you have replacement bits in your arsenal

Another important indicator is the manufacturing company. Buying branded products indicates quality, but the buyer overpays for the company. There are about 15 companies known that produce good quality reverse screwdrivers. Most products from Chinese companies are supplied in unsatisfactory quality, so after the first use of the product, the reverse mechanism fails.

Reversible tool brand SIBRTECH

Some of the popular manufacturers producing the products in question are:

- Intertool

- BISON

- Mastertool

- TopTul

- Makita

- Einhell

- Stanley

Although a reversible type product is not a mandatory tool in a home craftsman’s kit, it will never be superfluous. With its help, it not only simplifies the work of the master, but also increases the possibilities. The average cost of a set is from 2000 rubles. There are also cheaper products, but it is not recommended to buy them as a set. In a separate form, the cost of an average quality instrument is from 1000 rubles.

Quality and prices

For home use or infrequent use, an inexpensive but acceptable quality tool from Stayer, Fit, Matrix, costing about one hundred rubles, is suitable. If you are planning a professional activity, it is recommended to purchase a more expensive instrument. It is represented, for example, by the companies Kraftool, Arsenal, costing one hundred fifty to two hundred rubles. The most durable screwdrivers are produced by Gedoro. The cost of his models can exceed a thousand rubles.

Tips for choosing a tool

Here are some recommendations that will tell you how to choose a screwdriver in the store.

Specialized varieties justify themselves only if they are used frequently. For example, a modification with a flexible shaft is justified among furniture assemblers, and a dielectric one is worth buying if a home craftsman is able to deal with wiring and repairing an outlet.

The same goes for the ratchet mechanism (allows you to rotate the rod while the handle is held tightly in your palm). For one-time manipulations, a budget screwdriver without additional functions will suffice.

A straight handle is not always effective. Where increased force and high torque are required, a tool with a T-handle will help.

If you need to remove a bolt that is rusted or covered with a layer of paint, it is better to use an impact type of screwdriver. They are made of durable alloy, and the handle has an additional element - an anvil. You can not only hit it with auxiliary tools, but also grab the protruding part with a key to increase the applied force.

If you want to buy a cordless screwdriver, give preference to well-known manufacturers. Otherwise, your mini-screwdriver will bring nothing but disappointment. This tool is not suitable for major repairs or long-term use and requires frequent battery charging.

Choose screwdrivers carefully and use them correctly, then you can easily deal with the smallest and most stubborn bolt.

Handle modifications

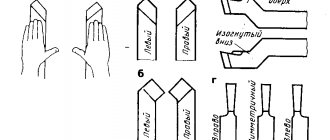

Not only the convenience, but also the scope of its application depends on the shape of the screwdriver handle. There is a familiar, and probably the very first, form of a screwdriver - straight , which has a wide range of applications due to the variety of sizes. But there are also improved forms of the handle that greatly simplify the use of a screwdriver.

- Screwdriver with T-handle . Not all work can be done using a straight-handled screwdriver; it is versatile, but has limitations. If you need to transfer a lot of torque to a part, it is advisable to use a screwdriver with a T-handle. The closer it is to the T-shape, the greater the leverage and the greater the moment of force will be. The handle can be additionally equipped with a hinge, which allows you to change the angle between the axis of the screwdriver rod and the axis of the handle, thereby adjusting the length of the lever. Such screwdrivers can have interchangeable attachments, which makes them universal.

- L-shaped screwdriver. Otherwise they are called L-shaped keys. They have a hexagonal slot or a slot in the shape of a six-pointed star - TORX. To be able to work at certain angles, they can be additionally equipped with spherical tips.

- Fracture screwdriver . The handle of such a screwdriver can be “broken” and fixed in the position you need, or even in several. Thus, it can imitate a T- or L-shaped handle, which makes it universal and very comfortable.

Professional screwdrivers

In addition to household tools, professional tools are also widely used. They have a special shape. This tool is most often not suitable for home craftsmen, since their scope of application is very narrow. These types of screwdrivers, the names of which are indicated in the markings, should be considered in more detail.

Products with a pin located in the center are called Torx. The special Torg-Set tool is used only in aviation. Its shape has an asymmetry of a cruciform section. This allows the screws to be tightened very tightly.

A double-blade screwdriver is called a spanner. It is used in the creation or repair of elevators. This uniform prevents vandalism and inappropriate jokes.

The Tri-Wing section is also intended for aviation. But it is also used for repairing electrical equipment. The shape of this screwdriver is made in the form of a trefoil.

Self-production

You can also make a screwdriver yourself. Take a nail and grind it like a flat slot. Bend the other end like a handle. If you have bits, you can make a portable tool using a bolt and washers.

The cross is made from an old key of the appropriate shape. They are highly durable and will serve for a long time. It can be carried along with a bunch of keys and will always be at hand.

We looked at the main types of screwdrivers, their features and operation. Although this is a fairly common tool, it can be improved and made independently. We hope that you have received a lot of new information and will be able to use it for its intended purpose.

Types of indicator screwdrivers

Voltage indicators, made in the form of an ordinary screwdriver, have a general operating principle, but may differ in design, functionality and design.

They are contact and non-contact.

The indicator in various models can be either a sound signal, a small LED, or even a digital screen.

Model with neon lamp

A test screwdriver with a neon lamp is the simplest tester.

The disadvantage of this contact type tool is the fairly high voltage indication threshold - from 60V.

Used to determine the phase in an AC circuit.

Not suitable for searching for broken wires.

An indicator screwdriver of the UNO type is popular in everyday life - a single-pole voltage indicator, the operating range of which is limited to the upper mark of 500V.

Used when connecting electricity meters, fuses, switches, etc.

The principle of operation of a screwdriver with a neon light bulb is that it glows when the tip comes into contact with a current-carrying conductor.

Electricity passes through the resistance resistor and is closed to the person by the second contact located at the end.

Simply put, the lamp will light up if you touch the phase wire with the tip and touch the end contact with your finger, thereby closing the circuit.

With display

Simple indicator screwdrivers equipped with displays do not use batteries, and the presence of voltage in the phase is indicated by an icon appearing on the LCD screen.

Works by reading the electrostatic field.

Typically, these tools are compact in size and the body is made of plastic.

Universal

Inside the universal indicator screwdrivers there is a microcircuit that will expand the capabilities of the tool.

There is a slider on the case - a switch through which the operating mode is selected:

• Contact testing

The presence of voltage is indicated by a built-in light.

• Contactless verification

The presence of voltage is indicated by a light bulb. The mode is characterized by low sensitivity

• Non-contact testing with high sensitivity

The presence of current is indicated by both a light indication and an audible signal.

This mode will allow you to find current-carrying wires even under a layer of plaster.

These multifunctional indicator screwdrivers are very easy to use and, most importantly, effective.

It should be remembered that the presence of additional elements in the device increases the cost of the tool.

In addition, batteries are used for power supply, which have to be changed frequently.

With LED

The principle of operation of an indicator with an LED does not differ from options with neon lamps.

But the good thing about this tool is that it works perfectly with electrical networks with voltages less than 60V.

The LED indicator screwdriver includes a self-contained power supply and a bipolar transistor, which makes this tool multifunctional with all its simplicity.

Allows you to determine the presence of a phase using both contact and non-contact methods, and check the integrity of wires and fuses.

Electronic indicator instruments

A modern version of the voltage indicator is an electronic screwdriver with a display, sound and light indicator.

In fact, this is a full-fledged multifunctional voltage indicator, the “little brother” of the multimeter.

The presence of electric current in the circuit is indicated by a phase indicator light and an audible buzzer.

The voltage value is displayed on the LCD screen.

This device is capable of working with DC and AC networks, which allows it to be used to test the networks of vehicles powered by batteries.

As a rule, this option is not common among professional electricians due to the high cost.

Battery operated

By using an autonomous power source, battery-powered indicators allow you to determine the presence of current in a phase using a non-contact method, check the integrity of electrical wiring, and find wires hidden under plaster.

No batteries

Indicator screwdrivers without an independent power source have limited functionality.

They allow you to determine the presence or absence of a phase on a conductor using the contact method.

In this case, it is necessary to close the chain with your finger, touching the contact on the end side of the tool.

This is important because the human body has natural resistance and acts as part of the circuit

Sonic screwdriver for checking current

Crimping pliers

Among the many similar tools, a special slotted screwdriver stands out, which consists of the same materials as a simple one, but also includes a device that signals with sound and a light sign the presence of electric current in the wired network, and also shows its rating and load.

Screwdriver with indicator

This device is often used to check the presence of current in the wiring panel and determine its power. It is not recommended to use a sonic screwdriver as a tool for unscrewing or tightening screws, since its tip is very thin, and if excessive force is applied, the metal can be deformed, and the mechanism inside the handle can turn and fail completely. This device can only be used for its intended purpose, to determine the current strength and load on the network.

If the screwdriver is equipped with a speaker, then when the screw rod touches the circuit breaker, a certain sound is heard, which signals the presence of power in the network. Often such screwdrivers are equipped with diode lamps as an additional signal. There are two types of diodes on the handle, red and green, each of which performs a specific function and task.

It is worth noting that there is no Phillips screwdriver with such a device, since to safely touch live wires you need a very thin tip, and there is no point in producing Phillips screwdrivers with a built-in indicator.

Types of reversible screwdrivers

For ease of operation, reversible screwdrivers with interchangeable bits of several types are used.

Rotary

A screwdriver with a rotating head is a handle connected to the head by a hinge.

This design allows you to work with fasteners in hard-to-reach places, changing the angle of the handle relative to the axis of the tip or removable bit if necessary.

Pistol type

Screwdrivers with a handle shaped like the letter “G” or “T” are called pistol screwdrivers.

Such a tool fits comfortably in the hand, and the lever formed by the special shape of the handle allows you to apply less force.

Various reviews and testing of pistol-type screwdrivers are often carried out using the example of car repairs, since they are excellent for such work.

Lever

The design of the lever screwdriver allows you to bend the handle relative to the working head at various angles, up to 90 degrees.

In other words, a straight screwdriver can be turned into an L-shaped one with one movement of the hand.

Allows you to pull fasteners well, or “tear” them out of place when unscrewing.

For precision work

Reversible screwdrivers for precision work are lightweight and small tools.

Designed for repairing watch mechanisms, various electronics and any devices that use miniature fasteners.

As a rule, ratchet switches have a ring switch. Equipped with an extension cord (the most common length is 120mm), a set of “small-caliber” bits and socket heads.

Equipment

The features of the splines are discussed in detail above, so we will focus on the remaining components of the kit - the handles and rods.

Handles

Handles are made of plastic or polycomposite. To reduce slipping, a rubber coating, recesses or notches are used. The coating makes the tool ergonomic and comfortable.

- The ratchet mechanism is an attachable ratchet handle similar to those used in compound socket wrenches. During operation, the rod and tip rotate freely, and the handle remains motionless in the hand.

The model does not require unnecessary movements, therefore it is optimal for large-scale work.

- T-shaped - Swivel type models with a curved or solid top that supports the installation of an auxiliary arm.

- With a heel - most often found in impact screwdriver sets. Instead of recessing into the handle, a through stroke is used. The rod at the end free from the nozzle has a thickening - a heel, which softens the load from blows with a hammer.

Modified handles make screwing/unscrewing easier or increase torque. Most often, functionality is set by a button or reverse switch on the handle.

Rods

Shaft modifications allow you to add additional functionality to the tool.

- Non-standard length - elongated or shortened models of screwdrivers. Length restrictions apply to the shaft and handle. Suitable for processing hard-to-reach places. More often found in combo or flexible models.

- With a tip change function - the tool in this configuration is equipped with a ratchet mechanism or a standard handle. The option without a mechanism involves the use of a universal combo rod. For splines of such models, the kit includes replacement bits.

- Faceted rod - option with a square or hexagonal cross-section (standard - round). Supports the use of leverage to add torsional force. The lever is the tool at hand.

Bits and sockets are typical bit attachments.

There are magnetic models that support the grip of fasteners in inconvenient conditions. External parameters correspond to standard types of splines.

Special screwdrivers

In addition to the main types, there is a whole set of special screwdrivers designed for highly specialized work.

Often such tools are made by manufacturers of branded products, thereby wanting to protect their products from counterfeiting and unauthorized opening.

Specialized types of tools include: hex models, screwdrivers with an asterisk, trefoil, spanner, etc.

Such products have a non-standard spline shape, which allows you to screw in fasteners with a special thread.

Read more about the types of specialized screwdrivers

1. Star screwdriver (TORX marking) – has a tip in the shape of a six-pointed star.

The tool is rarely used - screws for this type are installed if the manufacturer wants to limit unauthorized unproblematic access to technically important parts.

The product is mainly used for repairing small household appliances, mobile phones, etc.

2. The hexagonal spline is a product marked HEX.

A distinctive feature of this model is the high level of torque, which is many times greater than all of the above options.

This type of tool is used for work in the furniture industry, as well as in those places where a reliable connection is especially necessary.

3. Another version of hex screwdrivers is called hexagons and the difference from the previous type is the convex part of the tip.

4. The three-beam screwdriver has a non-standard slot shape in the form of a trefoil, which is actually its advantage.

Fasteners of this form are almost impossible to disassemble on your own; this feature ensures reliability and protection of equipment from unauthorized entry into systems, such as audio equipment.

5. U-shaped screwdriver or “Spanner” - has a tip in the form of two pins.

The spanner is used in the repair of household appliances and elevators; thanks to the unusual shape of the tool, it is often possible to avoid the consequences of vandals.

6. Asymmetrical cross - such a slot of hardware is almost impossible to find in everyday life.

A special feature of this slot shape is that the tool is used in the aerospace industry.

Another advantage of this type is the strong tightening torque, which is not found in any other model.

7. A square screwdriver is also a rare type that has a narrow scope of application, because its tip is made in the form of a square.

This is a kind of hexagonal model.

The unusual shape of the tips of specialized screwdrivers allows you to screw in and unscrew screws with complex threads quickly and without much effort.

Model overview

A huge number of manufacturers produce the presented types of tools. There are shapes and types of screwdriver bits similar to hand tools. Only they are more often used in screwdrivers.

To choose the right type of tool, you need to evaluate the frequency of its use. If you need a screwdriver from time to time for household needs, you can purchase inexpensive models. Brands such as Fit, Stayer, and Matrix have proven themselves well in the low-price segment.

For frequent use in professional activities, it is necessary to give preference to more expensive varieties. Due to their increased strength, their service life is much longer. Kraftool also produces well-known products of similar quality.

The most expensive, but very high quality screwdrivers are the Gedoro brand. They are purchased exclusively by professionals. These improvised means wear out 8 times slower than other models.

Areas of use for professional screwdrivers

The tool is equipped with additional kits for performing operations depending on the requirements for screwdrivers and types of work.

Electrical installation area

Basically, bolts are attached to equipment, hidden live wiring is detected, and the tool is equipped with protection against electric shock:

- screwdrivers with dielectric braiding allow you to perform work under voltage, while the insulation can withstand up to 1 thousand volts, the handles of such models are painted red;

- probes and testers are equipped with a device for finding working and hidden wiring in the wall and the presence of current in a socket or other electrical equipment;

- indicators signal the existing voltage by glowing; for visual perception, the instrument has a transparent body.

Operation in complex and hard-to-reach places

Some models have features to make it easier to work in places that are inaccessible to conventional tools. Screwdrivers with a flexible rod, inside of which there is a reinforced frame, a spring base or a magnetic bit, are used; different sizes of screwdrivers are used.

If unscrewing is difficult due to corrosion, reinforced models are used that can withstand the impact forces of a chisel or hammer to remove rust. The tool is made of metal; when struck by a hammer, the slot rotates to a certain angle.

Long-term unscrewing of fasteners requires repeated movements of the same type; for this work, screwdrivers with reverse action or a ratcheting mechanism are used. The device consists of a rotating tip and rod, which rotate due to a special “ratchet” of reverse rotation. The handle remains motionless in the hand and records the number of circles. A large volume of bolts or screws is not a problem for a cordless screwdriver, which is a small compact screwdriver.

When working with different types of bolts and screws, it is necessary to change screwdrivers due to the need to use slotted flat, Phillips or other tips. They take combined models, where replaceable bits are inserted into the handle, the rearrangement is carried out by turning the rod. Another option is removable spline tips, held in the socket by a magnet.

The screwdriver handles are rubber coated and have notches or bulges to reduce slipping under great force. To support the installation of an additional lever, a tool with a T-shaped top handle is used. Modified models with special handles are designed to increase the force of the turning action, and the mechanism is started using a button or switch on the handle.

specialized screwdrivers

Design

A screwdriver is a rod with a tip at one end, designed for a certain type of slot, and a handle at the other. The material and size of the handle is of great importance It can be made of plastic, wood or rubber . The shape of the handle must be chosen depending on the size of the palm: the handle that suits you will fit comfortably in your hand.

The diameter of the handle varies from 10 to 40 mm. The choice depends on the size of the connection; the larger the threaded connection, the larger the handle should be. This way you will need to apply less force, since the handle directly transmits torque to the part. For small parts , choose thin screwdrivers with a small handle. A correctly selected size will prevent the handle from being destroyed or the slot being torn off. Some screwdrivers have a hole in the handle , which helps to apply even more force when tightening, using an additional wrench. Screwdrivers with replaceable tips may have a cavity in the handle for storing bits.

Main characteristics

The handles are made of injection molded or powder plastic.

The first option has a soft base and is characterized by elasticity, making the tool comfortable to hold in your hand.

Powdered plastic is fragile, but at the same time hard.

A good tool usually has a rubberized handle.

In addition to being ergonomic, it has water-repellent properties.

This tool hardly gets dirty, and to clean it, just wipe the surface with a damp cloth.

In addition, the rubber layer has dielectric properties, which means that such a screwdriver is very convenient for working with live elements of electrical networks.

Another condition for a high-quality handle is its resistance to aggressive chemical compounds.

For this, again, special rubber is used that can withstand contact with chemical components.

However, with prolonged contact with solvents or gasoline, the coating will be destroyed.

In this case, a plastic handle would be a suitable option.

The most common types of reversible screwdrivers are:

• With reversible rotary handle.

As a rule, they are equipped with an adapter extension for socket heads.

Such handles are often used to work with heads sizes 5 - 13 and profile bits SL - SL6, PH0 - PH2, PZ2, T6 - T30, SP4, TW2, TW3, HEX4 - HEX6.

• With reversible handle for precision work.

The dimensions of the tool are much smaller; most kits are equipped with a flexible extension.

Often, such screwdrivers are used to work in tandem with heads of sizes 2.5 - 5.5 and profile bits SL1 - SL4, PH000 - PH1, T4 - T10, HEX0.9 - HEX2, SP2.6, A0.8 - A1.2.

Screwdrivers with a set of bits and heads have a hardness of 45 - 50 units (Rockwell scale).

Made from chrome vanadium alloy.

The handle is covered with plastic and/or thermoplastic rubber.

Operating mode switches can be ring-type (part of the handle rotates relative to the longitudinal axis), flag-type (a small lever is installed on the body) or slider-type.

What is a reversible screwdriver

The instrument in question received its name due to the presence of a reversing mechanism in the design. Screwdrivers with reverse are equipped with a ratchet with a ratcheting mechanism, which makes it possible to operate the tool with one hand. This method of using the product is very convenient, especially when working in hard-to-reach places.

Switching reverse allows you to change the direction of rotation of the handle relative to the rod. This is very convenient when work is done with one hand or when a conventional screwdriver is inconvenient to work with.

The appearance and shape of the tool differs depending on the purpose. Typically, such products go on sale complete with a set of replacement bits. These bits, depending on their number, are intended for unscrewing fasteners of different configurations. In addition, reversing tools can be either mechanical (using physical force) or electrical.

Example of a set of star bits

Due to the fact that the fasteners used everywhere are very different, it is convenient to have not a single attachment, but a whole set. A set with different types and a large number of sizes is desirable. At the same time, it would be good to decide initially in what area you plan to work and with what fasteners - this greatly influences the composition of the kit.

Example of a set of star bits

How to choose a set of sprockets, a tool - a whole philosophy. The best thing to do is to consider the classification of the proposed sets, evaluate their composition in terms of standard bit sizes and listen to the recommendations.

The offers of regular and online stores are filled with sets of various configurations. The kit may include either exclusively bits or other additional items. The number of bits itself can vary: from 2-3 pieces to several dozen. Quality does not necessarily depend on quantity.

As for other items, the supply may contain an extension cord, adapter, hand screwdriver or wrench. The screwdriver can be straight or with a bending handle. There are many options with a ratchet - such mechanization will save a lot of effort during long-term monotonous work.

A huge number of different kits are produced, for example, the one described below.

WERA Bit-Check 30 TX Universal 1

This set from the wera brand is very compact and easy to use due to its low weight. The product is usually offered with a guarantee - this is a sign of the quality of the product.

Star bits: WERA Bit-Check 30 TX Universal 1

- It contains 30 items: bits of various shapes and a universal type holder.

- The material of manufacture is high-strength tool grade steel.

- Bit length – 25 mm, holder length – 165 mm.

- The bits of the set are hardened for universal use for various purposes and on any materials.

- The holder is equipped with a locking ring and a permanent magnet.

- Packaging: a plastic case, suitable not only for storage, but also as a carrying case.

- Total weight – 300 grams.

Phillips screwdrivers

The most popular are the cross types. The dimensions of screwdrivers are the main feature of their classification. The markings of such products include the letters PH and a cross.

The smallest varieties are designated 000. Their tip diameter is only 1.5 mm. This tool is suitable for repairing special digital equipment. It is also very rare that screwdrivers with sizes 00 (up to 1.9 mm) and 0 (2 mm) are used at home.

Standard kits for household use usually include products marked from 1 (2-3 mm). But the most popular is the screwdriver number 2 (3-5 mm). It is most often produced with a magnetic tip. Product number 3 can also be used in everyday life. Its size reaches 7 mm.

To repair cars or large equipment in production conditions, they can use a Phillips-type screwdriver number 4. Its diameter exceeds 7.1 mm.

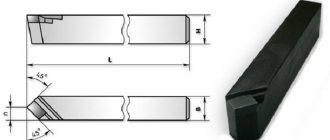

Markings and dimensions of a slotted screwdriver

Pulse soldering iron gun

Branded products have markings placed on the longitudinal surface or on the end of the handle. It meets the requirements of the international classification of hand tools. If you need a tool for household needs: unscrew and tighten screws, then you need to understand what the marking of the tool means: SL , PH , PZ :

- SL – regular flat spline;

- PH – Phillips screwdriver;

- PZ – the same with the presence of thin ray lines.

The marking can be in the form of a circle, inside which the pepper section of the tip is depicted. So, for example, flat screwdrivers are indicated by a stripe, Phillips screwdrivers - by a cross in a circle. All indicator instruments have a flat tip. Accordingly, shaped screwdrivers in the marking are displayed by the type of tip profile.

Hardware with various slot shapes

Around the circle, the manufacturer indicates the dimensions of the slot and the length of the rod. Marking with a circle with a stripe inside it. The dimensions of a slotted screwdriver are marked on the rim: 1.2 x 6.5 x 125 mm means that this is a flat screwdriver, designed to work with screws whose slots have dimensions of 1.2 x 6.5 mm, the length of the rod is 125 mm.

A marking with a cross containing the inscription PH 1 x 80 mm means a Phillips screwdriver of the following dimensions: 1 – fastener head diameter number, shaft length – 80 mm.

Cross School

Additional features

An electric screwdriver is often equipped with additional functionality that allows you to expand its scope of application.

Thus, to enable uninterrupted use in extreme cold conditions, some devices are equipped with a nickel-cadmium rechargeable battery, and to increase operating time without additional recharging, some models are sold with a replaceable battery or a small autonomous charger.

This allows you to take the instrument with you on business trips, long country trips, or keep it inside the trunk, without fear that by the time you start using it, the battery will be discharged and the device itself will be useless.

How to find out the size

The user must match the size of the screw with the size of the screwdriver. The Phillips blade has a blunt tip and the screw slots will bend where they intersect. The Torx blade has a star-shaped end for screws in appliances and garden equipment.

Measure the standard screw head spline. You can take a tape measure or a ruler: if you use a screwdriver that is too wide and too thick, it will not be possible to install it in the slot. When the user picks up a tool that is too narrow or thin, it will slip off easily.

To install screws in inconvenient places, use special shaped screwdrivers, choosing short ones when space is limited.

What is a slotted screwdriver

A slotted screwdriver is a metalworking tool designed for fixing or dismantling threaded hardware. These include a variety of screws, screws or self-tapping screws.

The tip of the tool has a special shape in the form of small protrusions. They are necessary for securely fixing the screwdriver in the head.

The tip can have different configurations, which allows you to choose the most suitable tool.