Despite its high prevalence, the recognition of titanium as a structural material took place relatively recently - only in the 20th century. Its alloys compare favorably with other compounds. With a long list of benefits, they find wide application in various fields. Modern technological capabilities allow us to produce a wide variety of rolled products - pipes, sheets, hexagons, foil, tapes, plates. Let us consider in more detail all the main features of the material in the article.

general characteristics

In the periodic table of elements of D.I. Mendeleev, Ti is located in group IV of the 4th period at number 22. In the most important and most stable compounds, the metal is tetravalent. In appearance it resembles steel. Very common in nature. Its content in the earth's crust is higher than copper, lead and zinc.

The relative molecular mass of a substance shows how many times the mass of a given molecule is greater than 1/12 the mass of a carbon atom, and the relative atomic mass of an element is how many times the average mass of atoms of a chemical element is greater than 1/12 the mass of a carbon atom. Titanium in the free state exists in the form of monatomic Ti molecules. The values of its atomic and molecular masses coincide. They are equal to 47.867.

The main mechanical properties of titanium alloys include:

- Resistance to corrosive processes. This property is superior to steel. Does not corrode in air, sea water, wet chlorine and other technological solutions and reagents, so the material is indispensable in the chemical, pulp and paper, and oil industries.

- Lightness. It is in demand where a very light substance is needed that can withstand heavy loads and ultra-high temperature ranges - aircraft and rocket production.

- High specific strength. The indicator is approximately 2 times higher than iron and 6 times higher than aluminum. The tensile strength is 300–450 MPa, but it can be increased to 2,000 MPa through hardening, aging and the addition of certain elements. At the same time, the material retains its strength characteristics even when exposed to low temperatures.

- Paramagneticity. It is not magnetized in a magnetic field, but is not pushed out of it either.

- Low thermal conductivity. At room temperature the average is - 18 W/(m deg). As it warms up, the indicator increases. Thermal expansion is 3 times less than iron and 12 times less than aluminum.

- Satisfactory technological ductility of some alloys. In a hot state, various semi-finished products are obtained - sheets, rods, stampings, profiles, etc. At the same time, mechanical processing causes many difficulties.

Thus, the metal combines strength and ductility well, but most mechanical properties are determined by the content of impurities. Polymorphic transformations have a decisive role in the formation of structure. This plays an important role in the heat treatment of parts in accordance with the requirements of the drawing.

Characteristics and properties

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a shiny metal with a silvery color, low density and high strength. It is resistant to corrosion in seawater and chlorine.

The element is found in a number of mineral deposits, mainly rutile and ilmenite, which are widespread in the Earth's crust and lithosphere.

Titanium is used to produce strong light alloys. The metal's two most useful properties are corrosion resistance and its hardness-to-density ratio, the highest of any metallic element. In its unalloyed state, this metal is as strong as some steels, but less dense.

Physical properties of metal

It is a strong metal with low density, quite ductile (especially in an oxygen-free environment), shiny and metalloid white. Its relatively high melting point of over 1650 °C (or 3000 °F) makes it useful as a refractory metal. It is paramagnetic and has fairly low electrical and thermal conductivity.

On the Mohs scale, the hardness of titanium is 6. According to this indicator, it is slightly inferior to hardened steel and tungsten.

Commercially pure (99.2%) titanium has an ultimate tensile strength of about 434 MPa, which is similar to common low-grade steel alloys, but titanium is much lighter.

Chemical properties of titanium

Like aluminum and magnesium, titanium and its alloys immediately oxidize when exposed to air. It reacts slowly with water and air at ambient temperatures because it forms a passive oxide coating that protects the bulk metal from further oxidation.

Atmospheric passivation gives titanium excellent corrosion resistance almost equivalent to platinum. Titanium is able to resist attack from dilute sulfuric and hydrochloric acids, chloride solutions and most organic acids.

Titanium is one of the few elements that burns in pure nitrogen, reacting at 800°C (1470°F) to form titanium nitride. Due to their high reactivity with oxygen, nitrogen and some other gases, titanium filaments are used in titanium sublimation pumps as absorbers for these gases. These pumps are inexpensive and reliably produce extremely low pressures in ultra-high vacuum systems.

Common titanium-containing minerals are anatase, brookite, ilmenite, perovskite, rutile and titanite (sphene). Of these minerals, only rutile and ilmenite are of economic importance, but even these are difficult to find in high concentrations.

Titanium is found in meteorites and has been found in the Sun and M-type stars with surface temperatures of 3200°C (5790°F).

Currently known methods for extracting titanium from various ores are labor-intensive and expensive.

Production and manufacturing

Currently, about 50 grades of titanium and titanium alloys have been developed and used. Today, 31 classes of titanium metal and alloys are recognized, of which classes 1–4 are commercially pure (unalloyed). They differ in tensile strength depending on oxygen content, with class 1 being the most ductile (lowest tensile strength with 0.18% oxygen) and class 4 the least ductile (highest tensile strength with 0.40% oxygen). ).

The remaining classes are alloys, each of which has specific properties:

- plastic;

- strength;

- hardness;

- electrical resistance;

- specific corrosion resistance and their combinations.

In addition to these specifications, titanium alloys are also manufactured to meet aerospace and military specifications (SAE-AMS, MIL-T), ISO standards and country-specific specifications, as well as end-user requirements for aerospace, military, medical and industrial applications.

A commercially pure flat product (sheet, slab) can be easily formed, but processing must take into account the fact that the metal has a "memory" and a tendency to bounce back. This is especially true for some high-strength alloys.

Titanium is often used to make alloys:

- with aluminum;

- with vanadium;

- with copper (for hardening);

- with iron;

- with manganese;

- with molybdenum and other metals.

Areas of use

Titanium alloys in sheet, plate, rod, wire, and casting form find applications in industrial, aerospace, recreational, and emerging markets. Powdered titanium is used in pyrotechnics as a source of bright burning particles.

Because titanium alloys have a high tensile strength-to-density ratio, high corrosion resistance, fatigue resistance, high crack resistance, and the ability to withstand moderately high temperatures, they are used in aircraft, armor, naval vessels, spacecraft, and missiles.

For these applications, titanium is alloyed with aluminum, zirconium, nickel, vanadium and other elements to produce a variety of components, including critical structural members, firewalls, landing gear, exhaust pipes (helicopters) and hydraulic systems. In fact, about two-thirds of titanium metal produced is used in aircraft engines and frames.

Because titanium alloys are resistant to seawater corrosion, they are used for propeller shafts, heat exchanger rigging, etc. These alloys are used in housings and components of ocean surveillance and monitoring devices for science and the military.

Specific alloys are used in oil and gas wells and nickel hydrometallurgy for their high strength. The pulp and paper industry uses titanium in process equipment exposed to aggressive environments such as sodium hypochlorite or wet chlorine gas (in bleaching). Other applications include ultrasonic welding, wave soldering.

Additionally, these alloys are used in automotive applications, especially in automobile and motorcycle racing where low weight, high strength and stiffness are essential.

Titanium is used in many sporting goods: tennis rackets, golf clubs, lacrosse shafts; cricket, hockey, lacrosse and football helmets, as well as bicycle frames and components.

Due to its durability, titanium has become more popular for designer jewelry (particularly titanium rings). Its inertness makes it a good choice for people with allergies or those who will be wearing jewelry in environments such as swimming pools. Titanium is also alloyed with gold to produce an alloy that can be sold as 24 karat gold because 1% Ti alloyed is not enough to require a lower grade. The resulting alloy is approximately the hardness of 14 karat gold and is stronger than pure 24 karat gold.

Precautionary measures

Titanium is non-toxic even in large doses . Whether in powder or metal filing form, it poses a serious fire hazard and, if heated in air, an explosion hazard.

Marking features

In accordance with GOST 19807-91, they are designated by the letters VT, OT, PT (V, O, P - identifier of the development organization or manufacturer, T - titanium) and numbers indicating the serial number of the alloy depending on the chemical composition.

B - VIAM titanium - All-Russian Research Institute of Aviation Materials (VIAM, Moscow);

O - Experimental titanium - a joint development of VIAM and the Verkhnyaya Salda Metallurgical Production Association (VSMPO, Verkhnyaya Salda, Sverdlovsk region);

P - Prometheus titanium - Central Research Institute of Structural Materials "Prometheus" (St. Petersburg).

In addition to the general division, Ti alloys are given other special designations. They correspond to the composition and parameters:

- technical grades VT1-1, VT1-0, VT1-00 contain titanium from 99.3 to 99.9%;

- titanium sponges TG-90, TG-110, TG-150, TG-120, TG-Tv, TG-130, TG-100;

- foundry - VT20L, VT21L, VT14L, VT9L, VT6L, VT1L, VT3-1L, VT5L.

In some cases, an additional letter is placed after the serial number of the alloy:

U - improved,

M - modified,

And - special purpose,

B - with a predominance of vanadium as an alloying element.

Properties of technical titanium and industrial alloys

There are significant differences in the markings of titanium from other alloys. Therefore, before you start studying the tables, you need to understand this.

- In Russia, in practice, titanium alloys are always marked T.

- The letter T is preceded by the letter designation of the manufacturer (B - VIAM, O - experimental development of Sverdlovsk St. Petersburg and others).

- Alloys can be marked with numerical designations indicating the purity of the alloy. For example, titanium of the highest purity produced by VIAM can be marked VT1-00. In other cases, the numerical designations may not tell you anything specific.

- Sometimes additional letters may indicate some special qualities of the metal (I - special alloy, V - vanadium alloy, L - casting alloy, GT - titanium sponge).

We present the most popular letter and color markings of alloys with subsequent decoding.

Below we provide tables on the properties of titanium alloys, excluding industrial blanks.

Types of titanium alloys

Classification is carried out according to a fairly large number of characteristics.

- Based on manufacturing technology, they are divided into:

- to deformable ones. This includes alloys with aluminum (VT5), as well as additionally alloyed with tin or zirconium (VT5-1). They are characterized by increased heat resistance, high thermal stability, lack of cold brittleness, and good weldability;

foundries They use technical titanium and alloys of the VT5L, VT14L, VT6L, VT9L, VTZ-1L brands. In terms of their chemical composition, they are almost identical to the previous group, but a higher content of impurities is allowed in them. In addition, the mechanical properties are lower than the deformable ones.

- According to the level of mechanical properties:

- for alloys of low strength and high ductility. The group includes grades VT1-00, VT1-0 (technical titanium) and OT4-0, OT4-1 (Ti-Al-Mn system), AT3 (Ti-Al system with small additions of Cr, Fe, Si, B);

medium strength - VT5 and VT5-1; pseudo-a-alloys OT4, VT20; (α + β)-alloys PT3V, as well as VT6, VT6S, VT14 in the annealed state;

- high strength - achieved in grades VT6, VT14, VT3-1 due to strengthening treatment. VT22 is a high-alloy alloy that has a tensile strength σв > 1000 MPa even in the annealed state.

- According to the conditions of use:

- for cold-resistant ones - industrial domestic modifications VTbkt, VT5-1kt, PTZVkt and foreign Ti-5Al-2.5Sn ELI, Ti-6A1-4V ELI. Maintain sufficient impact strength at cryogenic temperatures;

heat-resistant - VT6, VT8-1, VT8M-1, VT25U, VT41, etc. They are solid solutions with a greater or lesser amount of a chemical compound. This provides them with increased heat resistance with a minimal decrease in ductility;

- corrosion resistant. Tantalum, niobium, molybdenum, and zirconium are often used as alloying additives.

- According to the ability to be strengthened by heat treatment:

- for hardening - (α+β) and β alloys;

non-hardening - α-alloys.

Classification of titanium-based alloys

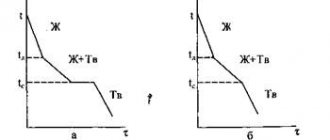

The classification according to phase types is well known: α, α + β and β. For example, in binary structures of the Ti-M system, the high-temperature β-phase remains metastable even at room temperature when the alloy composition exceeds a certain critical value. The critical value changes with the percentage of molybdenum.

Each of the types of materials under consideration exists only in a certain area. For example, an alloy with aluminum and vanadium exists in the α + β region. Titanium alloy with manganese - in the β region.

Mechanical processing of titanium alloys is carried out taking into account the area of their stable existence. It also sets the heat treatment modes. For example, titanium-manganese alloys are heat treated in the temperature range (α + β). At the same time, not only its mechanical properties improve, but also the region of stable existence of the material changes. Therefore, if the type is not determined, then it can be predicted by calculating the percentage of components.

To understand the doping behavior of the corresponding elements, the main doping vector is established, which is most accurately determined for binary compositions. This alloying vector begins at the position of pure titanium and ends when the presence of alloying metal exceeds 10%. For example, the doping vector of Ti-Al alloy falls into the α-phase field as the Al content increases, indicating that Al is an α-stabilizing substance. On the other hand, for example, V, Nb and Ta are β-stabilizing elements, since their vectors are directed towards the β-phase field. These results are consistent with the well-known behavior of the components used in titanium alloying.

Practical classification in domestic and foreign practice is carried out taking into account the areas of their optimal application.

High strength structural

Titanium's high strength and low density (about 40% lower than steel) provide many opportunities for weight reduction in all types of aircraft. The best example of this is the use of titanium alloys in the landing gear of Boeing 777 and 787 and Airbus A380 aircraft.

Most of the chassis parts are made from an alloy of titanium with iron, vanadium and aluminum. The minimum tensile strength is almost 1200 MPa, which is not much less than the same characteristic for high-strength alloy steels. Such a replacement leads to a reduction in aircraft weight by more than 580 kg. A similar example can be given for the alloy of titanium with aluminum, vanadium, molybdenum and chromium, which is used in the design of the Boeing 787 passenger airliner. The material has high strength properties and has contributed to increasing the carrying capacity of this aircraft.

The use of high-strength titanium-based structural alloys due to their increased corrosion resistance significantly reduces equipment maintenance costs.

The properties of titanium alloys make them also suitable for the manufacture of parts that perform reciprocating motion, such as connecting rods for the automotive industry. True, their cost is still high, so the use of these materials in high-class racing cars, where cost is not so important, is developing more dynamically.

The use of such alloys in structures where space is an important limitation is considered very important. The best example of this is the landing gear beam used on Boeing 737, 747 and 757 aircraft. This component, which runs between the wing and the fuselage, supports the landing gear. Other Boeing aircraft use aluminum composites for this application, but for large-body passenger jets the load is higher and the aluminum structure does not fit into the wing skin.

Heat resistant

Titanium alloys have proven themselves as heat transfer materials in the production of shell-and-tube, plate/frame and other types of heat exchangers for heating or cooling processes, especially in seawater coolers.

The efficiency of the heat exchanger can be optimized thanks to the following beneficial properties of these materials:

- exceptional resistance to corrosion and fluid erosion;

- the presence of an extremely thin oxide surface film;

- durable surface that has low roughness;

- good conditions for moisture condensation;

- sufficiently good thermal conductivity.

For pure titanium, the latter figure is lower than for copper or aluminum, but in alloyed compositions this disadvantage is removed and becomes 10...20% higher than that of conventional stainless steel grades. Due to good strength and the ability to resist corrosion and erosion from flowing turbulent liquids, the wall thickness of heat exchangers can be reduced. This minimizes resistance heat transfer (and therefore the cost of heat exchangers). The condition of the surfaces promotes droplet condensation of water vapor, thereby increasing the rate of condensation in the cooler/condensers compared to other metals.

The ability to design and operate with high flow or cooling water velocities and/or turbulence further improves overall heat transfer efficiency. All these characteristics make it possible to reduce the overall dimensions of heat exchangers and the overall costs for the initial service life.

Chemical

About 45% of the total weight of all metals used are materials additionally alloyed with aluminum and vanadium. Less frequently used are alloys of the Ti-4A1-3Mo-1V, Ti-7A1-4Mo and Ti-8Mn groups. Other chemical compounds do not find significant industrial use. Ti-6Al-4V is unique in that it combines fairly high mechanical properties with manufacturability. Therefore, smelting and subsequent forming is possible on all types of specialized rolling mills. This makes it possible to transform rolled profiles into complex products that provide reliability and economical use. It is believed that Ti-6Al-4V will remain the most commonly used titanium alloy for many years into the future.

Areas of application

An ideal material for many industries that require low weight, high strength and long service life. Widely used:

- in aviation, rocketry and space technology. In the aircraft industry, titanium is used to make products of complex spatial configurations, places for highly loaded components and assemblies, as well as engine parts. Titanium alloy with nickel is especially common in the space industry;

- shipbuilding. Indispensable for cladding, production of pump and pipeline parts. Low density makes it possible to significantly reduce the weight of the ship, while improving maneuverability and cruising range. Due to its high corrosion resistance, the casing does not require painting, and the body does not rust or break down in salt water for decades;

- mechanical engineering - in chemical, heavy, energy and transport, for light industry, food industry and household appliances. Manufactured equipment is conventionally divided into specialized serial and non-standard (for the needs of a specific machine-building plant);

- ferrous metallurgy - equipment for coke-chemical, metallurgical, steel-smelting and ferroalloy production;

- non-ferrous metallurgy ranks second among civil industries. It is most widespread in the cobalt-nickel and titanium-magnesium industries, as well as in the production of copper, zinc, lead, mercury and other metals;

- pulp and paper and food industries. The material provides reliable protection against corrosion and also meets the high sanitary and hygienic requirements of food production;

- medical industry. Commercially pure titanium and Ti6-4Eli are used in the production of surgical instruments, internal and external prostheses, crutches and wheelchairs.

Titanium industry

There are about one billion tons of confirmed titanium reserves in the world. Although titanium was discovered in the 18th century and was isolated in its pure form in the 19th century, titanium production began to take off industrially only in the 20th century. The titanium industry and the main reserves of titanium ores are concentrated in China, Russia, the USA, Japan, Kazakhstan and Ukraine. If titanium resource consumption continues at the same rate, Ti reserves will last for about another 150 years. For clarity, we have provided a summary of the titanium industry for 1996-2001.

The titanium industry in Russia is gaining momentum, VSMPO-Avisma is one of the leading manufacturers in this industry. The experience of this enterprise is very interesting and is clearly described in the Forbes magazine article - “Titanic production: how the largest titanium manufacturer in the world works.” This article states that VSMPO has two factories near the Ural Range. TG - titanium sponge is produced in Bereznyaki, Perm region, and blanks in the form of ingots and other semi-finished products are produced in Verkhnaya Sled.

The plant, where parts are made from titanium, employs about 100 people in three shifts. Products are manufactured using advanced technologies, using expensive machines and automatic machines, each costing about $5 million. The machines were delivered from the USA, with the consent of the President himself, Barack Obama. The factories' products are in demand all over the world. This enterprise produces parts for Formula 1 cars, products from Boeing, Airbus and others.

Heat treatment features

Carried out to improve performance. Depending on the chemical composition and purpose, the alloys are subjected to:

- annealing. It is one of the most common types of heat treatment and provides sufficient strength when forming heterophase structures. There are several types of annealing:

- recrystallization - temperature 520–850 °C. Its indicators increase for alloying elements. The temperature is also affected by the type of semi-finished product - higher for rods, forgings, stampings and lower for sheets;

- with phase recrystallization - the heating temperature depends on the alloy and is 750–950 °C. Thus, they reduce hardness, increase plasticity, achieve grain refinement and eliminate structural heterogeneity;

Intermetallic titanium alloys

Today, the need for fundamentally new structural materials is increasing. For example, hardened heat-resistant alloys can no longer fully meet the requirements of aerospace technology. Of the intermetallic titanium alloys, the most widely used are:

Advantages and disadvantages

Like any other metal, titanium has its strengths and weaknesses. Benefits include:

- light weight;

- corrosion resistance;

- resistance to high temperatures;

- high strength - greater than that of the best steels.

Flaws:

- Dust and chips remaining after processing titanium workpieces can ignite at a temperature of 400 degrees.

- This metal is difficult to weld and is practically impossible to cut.

- The costly method of obtaining metal from ore causes its high cost.

However, despite the existing disadvantages, the material and its alloys are widely used in various industries.

Light weight

Structural high-strength vehicles

Ultimate strength σв > 1000 MPa for grades VT6, VT14, VT3-1, VT22, VT23M. They are characterized by satisfactory weldability with all types of welding. These alloys have high corrosion resistance in the annealed and thermally strengthened states in a humid atmosphere, sea water, and many other aggressive environments.

In addition, applications will always require improvements in their performance properties through new thermal and thermomechanical treatments. Among the most promising are the VT23M. It combines high strength and crack resistance of both the base material and welded joints. In many ways it surpasses foreign analogues in properties and cost due to the reduced content of molybdenum and vanadium, the exclusion of tin and zirconium. All types of rolled, forged, pressed semi-finished products, as well as monolithic, welded and brazed structures are made from it.

Heat-resistant Ti alloys

In the 60s In the 20th century, domestic specialists developed, among others, new titanium alloys VT3-1, VT8, VT8-1, VT8M-1, VT9, VT25U, VT18U. Currently, they are inferior to the best foreign alloys IMI834 and Ti1100 only in creep resistance and at temperatures above 500 °C. Domestic VT-25 has strength indicators of up to 1150 MPa and reaches the peak of its properties at a temperature of 550 °C. At the same time, one of our best alloys used in industry can be called VT-18. It has the most strength properties at a temperature of 600 °C.

It should be noted that the prospects for increasing the heat resistance of Ti alloys remain extremely small. This is due to the fact that at a temperature of 620 °C the oxidation mechanism of the alpha phase of titanium changes dramatically. The properties deteriorate due to the penetration of oxygen through the oxide film into the thickness of the metal. And the area of application of protective coatings has yet to be studied. Now the main search for heat-resistant compounds is increasingly shifting towards titanium intermetallic compounds.

Production Features

Titanium production is a complex, time-consuming and expensive process. The element forms chemical compounds and solid solutions with many metals, and therefore requires special conditions when created.

Among the most common raw materials for titanium production are titanium-magnetite ores, from which ilmenite concentrate is obtained. The process takes several stages:

- obtaining titanium slag by reduction smelting. The concentrate and reducing agent are loaded into the electric arc furnace. They heat up to 1650 degrees Celsius. Cast iron is formed from reduced and carburized iron, and titanium oxide turns into slag, which contains 82-90% TiO2;

- obtaining titanium tetrachloride by chlorination. It is carried out in continuous mine chlorinators or in salt chlorinators. Chlorine gas acts on TiO2 at temperatures of 700–900 °C;

- production of titanium (sponge, powder) by reduction from tetrachloride. For this, magnesium or sodium is used.

Useful tips from the MAZPROM team

We would like to draw your attention to several points when choosing rolled titanium.

- Due to complex and energy-intensive technological processes, the production cycle time for titanium sheet is about 90 days. Therefore, if you come across the fact that a company offers you to purchase any brands and sizes, and thousands of tons are indicated in stock, then do not rush to believe it. Of course, with the workpieces available in production, the period can be reduced to approximately one month.

- Be sure to check the age of the material before purchasing. Although titanium retains all its properties over time, it is recommended that it be no older than 10 years. The fact is that there is still metal on sale that was manufactured back in the 1980s. It would be good if it was in storage at one of the defense enterprises, which then sold it on the market as illiquid. It is much more dangerous to buy rental equipment that may have already been used before. For example, pipes and sheets are cut from heat exchangers that are no longer in use. The danger lies not only in various defects, but also in a possible high level of radiation.

- To be sure of the quality of the product, request a sample for preliminary testing.

When you contact us, you will receive rolled titanium that fully complies with current GOSTs and TUs. For consultation, please call the phone number listed on the website.