Characteristics of steel grade 40

Steel 40 is a structural carbon quality steel with limited weldability. Welding is carried out without heating and without subsequent heat treatment, methods: manual arc welding, automatic submerged arc welding and gas protection, ESW. Preheating and subsequent heat treatment are recommended. CTS without restrictions.

Not prone to flake sensitivity, no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at HB 170 and σв=530 MPa, K υ solid. spl=1.2 and Kυ b.st=1.05. Forging is carried out at temperatures from 1250 to 780 0C, with air cooling of workpieces with a cross-section of up to 400 mm. Steel 40 is used to make axles, crankshafts, pinion shafts, rods, gears, pipes, forgings, fasteners, shafts, discs, rotors, flanges, gears, bushings for long and very long service at temperatures up to 425 degrees.

Vanadium in Russia and abroad

The fact that vanadium is highly valuable for the production of steel alloys was discovered back in the days of the Soviet Union.

However, at that time, industrial equipment was not so advanced that with its help it became possible to fully study the effects of adding this element as an alloying element to various alloys. Aircraft design engineers were most interested in the data obtained.

Their attention was attracted by such properties of vanadium alloys as:

- High temperature resistance

- Plastic

- Corrosion protection even under unfavorable conditions

- Strength and resistance to mechanical damage

- Low specific gravity

Today, alloys with the addition of vanadium are widely used in aircraft and rocket production. Every year there is an increasing demand for them in mechanical engineering. Such alloys are used in chemical and shipbuilding industries. A patent was received in Germany for a vanadium-titanium alloy containing 30-49% vanadium. Titanium-vanadium alloys are widely used in the United States of America and other developed countries of the world. Naturally, this interest is primarily due to the super strength that even a small vanadium content in alloys provides. If such sustainable materials are used for equipment, it will be durable and wear-resistant.

Supply steel 40

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| Metal forming. Forgings | GOST 8479-70; |

| Long and shaped rolled products | GOST 2591-2006; GOST 8319.0-75; GOST 2879-2006; GOST 9234-74; GOST 11474-76; GOST 1133-71; GOST 2590-2006; |

| Sheets and strips | GOST 82-70; GOST 14918-80; GOST 19903-74; GOST 16523-97; GOST 103-2006; |

| Ribbons | GOST 3560-73; |

| Long and shaped rolled products | GOST 8560-78; GOST 8559-75; GOST 1051-73; GOST 7417-75; GOST 10702-78; GOST 14955-77; GOST 1050-88; |

| Sheets and strips | GOST 4405-75; GOST 4041-71; GOST 1577-93; |

| Ribbons | GOST 10234-77; GOST 2284-79; |

| Steel pipes and connecting parts for them | GOST 20295-85; GOST 3262-75; GOST 24950-81; |

| Low carbon steel wire | GOST 1526-81; GOST 5663-79; GOST 792-67; |

| Medium and high carbon steel wire | GOST 17305-91; GOST 26366-84; GOST 9850-72; GOST 7372-79; GOST 3920-70; GOST 3110-74; GOST 9389-75; |

Portrait of an ideal screwdriver

As a summary, let’s try to create an identikit of an ideal screwdriver that will last for many years.

| Kernel | Steel SVCM or S2 Section - square or hexagon Finish - mirror chrome |

| Tip | Milling without scoring or burring Hardening 52-56 HRC Magnetization |

| Lever | Triangular cross profile Two-component composition Anti-friction second layer or pads Petrochemical resistant |

| Additional options | Hole in the handle Slot for power rotation Hammer head |

We thank the companies Pride, World of Tools, hypermarkets Leroy Merlin and Obi for their participation in the preparation of the material.

Mechanical properties of rolled steel 40

| GOST | Forging condition | Section, mm | σв(MPa) | δ5 (δ4 ) (%) | ψ % | KCU, J/cm2 | NV, no more |

| no less | |||||||

| 1050-88 | Hot-rolled, forged, calibrated and silver steel of the 2nd category after normalization | 25 | 570 | 19 | 45 | 59 | — |

| Calibrated steel, category 5: | |||||||

| after cold hardening | |||||||

| after annealing or high tempering | Samples | 610 | 6 | 35 | — | — | |

| Steel calibrated and calibrated with special finishing after tempering and annealing | Samples | 510 | 14 | 40 | — | — | |

| 10702-78 | Heat-treated sheet of category 1-2 | — | Up to 590 | — | 40 | — | 197 |

| 4041-71(Transverse samples) | 4-14 | 510-650 | 21 | — | — | 167 | |

| Normalized and hot rolled sheets | |||||||

| 1577-93 | Annealed or high tempered sheets | 80 | 560 | 20 | — | — | — |

| Normalized or hot rolled strips | 80 | 520 | 21 | — | — | — | |

| Hot rolled sheet | 6-25 | 570 | 19 | 45 | — | — | |

| 16523-70 (Transverse samples) | Up to 2 | 510-660 | -16 | — | — | — | |

| Cold rolled sheet | 2-3,9 | -17 | — | — | — | ||

| Up to 2 | 510-660 | -17 | — | — | — | ||

| 2284-79 | Cold rolled strip: | 2-3,9 | -18 | — | — | — | |

| annealed | |||||||

| cold-worked strength class H2 | 0,1-4 | 450-700 | -14 | — | — | — | |

| 10234-77 | Annealed flattened tape | 0,1-4 | 850-1050 | — | — | — | — |

| 0,1-4 | Up to 700 | 10 | — | — | — | ||

Properties of vanadium

In appearance, the element is similar to steel, also having a silver-gray tint. However, unlike low-carbon iron, vanadium metal is characterized by ductility. This property is retained in the substance up to a temperature of 300 0C, exceeding which sharply reduces ductility and the metal becomes brittle. Impurities of hydrogen, nitrogen or oxygen in the metal have a similar effect.

In the photo: vanadium metal

Vanadium is a refractory metal, with a corresponding temperature limit of 1887 0C. This explains its low heat resistance - a property characteristic of transition elements, due to the friability of the oxides formed on their basis. Vanadium is resistant to creep deformation up to a temperature of 675 0C, which is facilitated by vanadium pentoxide. A film of this compound is formed during the oxidation of the metal, maintaining a strong connection with its surface up to the specified temperature limit.

Vanadium in the periodic table

Vanadium is a chemical element V, which, according to its own valence, belongs to the fifth group of the Periodic Table. Its atomic characteristics: number – 23, mass – 50.9. In nature, two isotopes of the element are distinguished: the most common –51V and the radioactive one – 50V, the share of which is 0.25%. The radioactivity of the 50V isotope is rather weak; in fact, it can be considered stable, since the half-life significantly exceeds trillions of years.

The crystal structure of vanadium is characterized by a body-centered cubic lattice, which is also characteristic of refractory metals. Its density is 6.11 grams per cubic meter. see. The metal is forged, easy to process by pressure.

The V content within the earth's crust reaches 0.0015%, which characterizes it as an abundant element. On the other hand, vanadium is a dispersed metal, since it does not have independent minerals or concentrated deposits. The substance can be found in its sulfide - patronite, vanadinite, as well as a number of other rocks: roscoelite, decloysite, carnotite.

Mechanical properties of steel 40 forgings

| Heat treatment | Section, mm | KP | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | NV, no more |

| Normalization | 300-500 | 215 | 215 | 430 | 18 | 40 | 44 | 123-167 |

| 500-800 | 16 | 35 | 39 | |||||

| 100-300 | 245 | 245 | 470 | 19 | 42 | 39 | 143-179 | |

| 300-500 | 17 | 35 | 34 | |||||

| Up to 100 | 275 | 275 | 530 | 20 | 40 | 44 | 156-197 | |

| 100-300 | 17 | 38 | 34 | |||||

| Hardening. Vacation | 300-500 | 275 | 275 | 530 | 15 | 32 | 29 | 156-197 |

| 500-800 | 13 | 30 | 29 | |||||

| 100-300 | 315 | 315 | 570 | 14 | 35 | 34 | 167-207 | |

| Up to 100 | 345 | 345 | 590 | 18 | 45 | 59 | 174-217 |

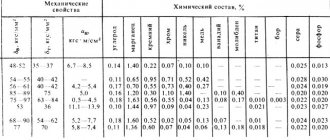

Structural alloy steel 13HFA

Structural steels are usually called carbon or alloy alloys, which are given certain physical, mechanical and chemical properties. Most often, each grade, for example, 40xfa steel, is used for the manufacture of certain parts and components of components produced for the needs of construction and mechanical engineering.

Only alloyed structural steels, which contain special elements that significantly increase the corrosion resistance of the metal and its strength, can be classified as high-quality or high-quality. Alloying elements can be different components, which in the Russian designation of the alloy grade are designated by certain letters:

- X – chromium (Cr)

- N – nickel (Ni)

- D – copper (Cu)

- F – vanadium (V)

- G – manganese (Mn)

- C – silicon (Si)

- A – nitrogen (N)

- B – tungsten (W), etc.

A certain combination and concentration of alloying elements allows the alloy to be endowed with specific characteristics and properties. In the case of the 40xfa alloy, we are dealing with high-quality structural alloyed chrome vanadium steel, which has the following chemical composition:

96%

- Cr – 0.8-1.1%

- V – 0.1-0.18%

- Mn – 0.5-0.8%

- C – 0.37-0.44%

- Si – 0.17-0.37%

- Cu – no more than 0.3%

- Ni – no more than 0.3%

- S – no more than 0.025%

- P – no more than 0.025%

Mechanical properties of steel 40 at elevated temperatures

| Test temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % |

| Sample with a diameter of 6 mm and a length of 30 mm, rolled. Deformation speed 16 mm/min. Strain rate 0.009 1/s | ||||

| 700 | 99 | 140 | 48 | 85 |

| 800 | 70 | 110 | 53 | 97 |

| 900 | 54 | 71 | 55 | 100 |

| 1000 | 28 | 58 | 69 | 100 |

| 1100 | 24 | 37 | 60 | 100 |

| 1200 | 16 | 26 | 87 | 100 |

| 1300 | 12 | 18 | 56 | 100 |

Unique properties of vanadium

Why does vanadium (ferrovanadium) have such a powerful effect on alloys? The reason for this is the unique properties of this element. It is capable of forming carbides. Their separation from the solid mass of vanadium ferroalloys occurs before the formation of cementite, a chemical compound otherwise called iron carbide.

Thus, the system in this case looks like this: Fe—V—C.

Carbides formed by vanadium, as well as complex vanadium-containing carbides, are formed from a solid solution in a finely dispersed form. These substances are very difficult to dissolve in austenite (solid solution of carbon in iron) or ferrite (oxide compounds of iron with other metals). When they are added, significant structural refinement of steel and cast iron occurs. Another phenomenon characteristic of this process is a slowdown in the intensity of grain growth at the time of heating. The small amount of vanadium not contained in the carbides forms a solid solution in the ferrite. Thanks to this property of the substance in question, the solubility of oxygen in it significantly increases. This factor, in turn, has a positive effect on the process of purifying ferrite from oxide-type compounds that negatively affect its strength.

Mechanical properties of steel 40 at normal temperature

| Type of rental | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Heat treated sheet, GOST 4041-71 | 4-14 | 510-660 | 21 | |||||

| Cold rolled pipes. | 580 | 320 | 17 | Normalization | ||||

| Hot rolled pipes. | 600 | 340 | 16 | |||||

| The rod is calibrated, GOST 10702-78 | 590 | 40 | Annealing | |||||

| Rolled products annealed, GOST 1050-88 | 510 | 14 | 40 | |||||

| Rolled products cold-hardened, GOST 1050-88 | 610 | 6 | 35 | |||||

| Rolled products, GOST 1050-88 | up to 80 | 570 | 335 | 19 | 45 | Normalization | ||

| Cold-worked tape, GOST 2284-79 | 690-1030 | |||||||

| Annealed tape, GOST 2284-79 | 440-690 | 14 | ||||||

| Strip, GOST 1577-93 | Jun.60 | 570 | 335 | 19 | 45 | Normalization |

Rolled vanadium

Today, metal is not only available in ingots, lumps or powder. Vanadium can actually be purchased in the form of rolled products produced in accordance with TU 48-4-373-76. The main types of implementation are:

vanadium sheet;

rod;

tubular profile.

Similar to ingots, vanadium wire is also produced in three grades VnPr-0, 1 and 2. Their purity is similar to the corresponding grades of metal in ingots. Along with rods, wire, and rolled sheets, vanadium tubes are in high demand.

Vanadium strip is produced in two grades VnPl-1 and VnPl-2, differing in the degree of purity of the base metal. Sheet metal products are distinguished by their originality of execution. For example, vanadium tape comes in a wide variety of widths and thicknesses, and has rounded edges for safety. Additionally, rolled strips can have a special coating for use in unfavorable climatic conditions.

Mechanical properties of steel 40 depending on tempering temperature

| Temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | HB |

| Hardening 850 °C, oil | ||||||

| 200 | 750 | 930 | 7 | 45 | 29 | 267 |

| 300 | 710 | 860 | 8 | 51 | 69 | 247 |

| 400 | 640 | 790 | 10 | 57 | 88 | 225 |

| 500 | 550 | 730 | 12 | 62 | 127 | 208 |

| 600 | 450 | 660 | 16 | 66 | 167 | 188 |

| 700 | 380 | 620 | 17 | 71 | 206 | 170 |

Other brands in this category:

Physical properties of steel 40

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| 0C | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.13 | 51.5 | 7850 | 483 | 160 | |

| 100 | 2.01 | 11.6 | 50.6 | 486 | 221 | |

| 200 | 1.98 | 12.7 | 48.1 | 497 | 296 | |

| 300 | 1.9 | 13.5 | 45.6 | 512 | 387 | |

| 400 | 1.85 | 14.5 | 41.9 | 529 | 493 | |

| 500 | 1.79 | 14.5 | 38.1 | 550 | 619 | |

| 600 | 1.67 | 14.9 | 33.5 | 574 | 766 | |

| 700 | 1.6 | 15.15 | 30 | 628 | 932 | |

| 800 | 12.5 | 24.8 | 674 | 1110 | ||

| 900 | 13.5 | 25.7 | 657 | 1150 | ||

| 1000 | 14.5 | 26.9 | 653 | 1180 | ||

| 1100 | 15.2 | 28 | 649 | 1207 | ||

| 1200 | 15.8 | 29.5 | 649 | 1230 |

Hardening process

The process of treating 40X steel and other alloys at high temperatures is called hardening. It is worth considering that heating is carried out to a certain temperature, which was determined through numerous tests. The holding time after which cooling is carried out, as well as other points, can be found in special tables. Heating at home is quite difficult, since in the case under consideration it is necessary to reach a temperature of about 800 degrees Celsius.

Chemical composition of steel 40Х

The result of strong heating and exposure of 40X metal for a certain time, followed by sharp cooling in water, is an increase in hardness and a decrease in ductility. The result depends on the following indicators:

- metal heating speed 40X;

- holding time;

- on the cooling rate.

When working at home, the processing temperature and cooling time should be taken into account.

Mechanical properties of 40X steel depending on tempering temperature

When choosing a surface heating method, you should pay attention to HDTV. This method is more popular than conventional volumetric processing due to the fact that the required temperature is achieved in a shorter time.

At home, HDTV is used extremely rarely. After carrying out the work, using HDF increases the operational strength of the part, which is associated with the appearance of surface compressive stresses.

You can carry out 40X hardening using the example of an M24 bolt product as follows:

- the electric oven is heating up;

- it should be heated to 860 °C, which in some cases requires 40 minutes;

- the time required for austenitization, after which cooling is carried out, is 10-15 minutes. The uniform yellow color of the product is a sign of the correct completion of the 40X hardening process;

- The final stage is cooling in a bath of water or other liquid.

It is impossible to independently determine the moment after which the metal should be cooled in industrial and domestic conditions. That is why, according to research, it was accepted that heating metal in electric furnaces requires 1.5-2 minutes per millimeter, after which the structure can be overheated.

Hardness determination is carried out using the Rockwell method. The improvement made by tempering or quenching can be measured using the HRC designation. Standard designation HR, to which a letter is added according to the type of test performed. The designation HRC is the most common, the last letter indicating the use of a 120° diamond cone when testing.

Hardness of steel grade 40

| Hardness steel 40, heat-treated sheet GOST 4041-71 | HB 10 -1 = 167 MPa |

| Hardness steel 40 Rolled calibrated cold-worked GOST 1050-88 | HB 10 -1 = 241 MPa |

| Hardness steel 40 Hot rolled products GOST 1050-88 | HB 10 -1 = 217 MPa |

| Hardness steel 40 Rolled calibrated annealed GOST 1050-88 | HB 10 -1 = 197 MPa |

| Hardness steel 40 Hot-rolled annealed products GOST 1050-88 | HB 10 -1 = 187 MPa |

Product classification and scope

In accordance with the chemical components present in the composition, a distinction is made between chromium, chromium-nickel (for example, grade 40ХН), chromium-nickel-molybdenum, chromium-nickel-molybdenum-vanadium, chromium-manganese and many other steels. Along with the structure after cooling, there are such classes of products as pearlitic, carbide, martensitic and austenitic.

Based on the number of added metals in relation to the total mass, the following types of steels are distinguished: low-alloy (less than 3%), medium-alloy (3-10%, in particular, grade 50HFA), high-alloy (more than 10%). Stainless steel is one that contains at least 12% chromium.

It is impossible to find an area of industry where alloy steel is not used. Various tools and structures are made from it, for example, cutters, pendants, shafts, and measuring devices. Most often it is used in construction, mechanical engineering and the aviation industry.

Endurance limit steel 40

| σ-1, MPA | Steel condition |

| 231 | Annealing 850 °C, σ0.2 =275 MPa, σв =520 MPa Quenching 845 °C, water. Tempering 550 °C, σ0.2 =600 MPa, σv =710 MPa, HB 209 Quenching 845 °C, oil. Vacation 430 °C, σ0.2 =415 MPa, σв =630 MPa |

| 393 | |

| 230 | |

| σ4001/100000 = 100 MPa, σ4501/100000= 50 MPa, σ5001/100000 = 30 MPa, σ4001/10000= 260 MPa, σ5001/10000= 70 MPa, σ4001/100000 = 190 MPa, σ5001/100000 = 44 MPa | |

Steel 40hfa: application

This alloy is supplied to the workshops of industrial enterprises in the form of calibrated, ground rods and forged blanks. In addition, 40x sheet is very popular, used for the production of overpasses and bridge structures. Chrome-vanadium high-quality alloy steel is designed for use in the production of parts and assemblies whose operating temperature does not exceed 400°C. These are rods, splined shafts, traverses, set screws, etc. 40xfa steel, hardened and low tempered, is used for the manufacture of parts with increased wear resistance, for example, worm shafts.

Foreign analogues steel 40

| USA | 1040, 1042, G10400, G10420 |

| Germany | 1.0511, 1.1186, C40, C40E, C40R, C42D, Ck35, Ck40, Cm40 |

| Japan | S40C, S43C, SWRCH38K, SWRCH40K |

| France | 2C40, C40E, FR38, XC3841, XC38H1, XC42, XC42H1, XP42HI |

| England | 060A40, 080A40, 080M40, C40, C40E, CS40 |

| European Union | 1.1186, C35, C40, C40E |

| Italy | C40, C40E, C40R |

| Belgium | C40-2 |

| Spain | C40E |

| China | 40, ML40 |

| Sweden | 1555, 1650 |

| Bulgaria | 40, C40E |

| Hungary | C40E |

| Poland | 40, 40A, 40rs, D40, P40 |

| Romania | OLC40, OLC40X |

| Czech | 12041 |

| Australia | 1040, M1040 |

| South Korea | SM40C |

- Structural steel

- Tool steel

Vanadium cost

The main deposits of refractory metal are located in the USA, China, Russia, South Africa and Armenia. The current level of annual vanadium production is about 90 thousand tons. China holds the lead in metal production, accounting for more than half of the supply. As a result, it is the Celestial Empire that turns out to be the main regulator of the price of vanadium.

Extraction of vanadium ore from deposits in Russia

The current trend towards increasing the cost of vanadium has persisted for more than a decade. This is due to the increase in metal consumption. The main contribution to the demand for the element is made by the growing production of alloy steels. According to experts, the price of vanadium today has not yet reached its maximum; its growth is predicted at least until 2022. These prospects are quite conservative, since the use of structural steels is increasing annually. Thus, selling vanadium will not be difficult for several decades.

Speaking in the language of numbers, we can highlight another feature of the metal - vanadium. Its price per kg is determined by the type of product.

So, the most expensive is the rental: strip, wire - about $2000. A rod is a hundred dollars cheaper. VnM-1 grade metal ingots themselves cost $200, which is an order of magnitude cheaper than rolled metal. The cost of vanadium pentoxide is even less: $35 – 40 per kilogram. The figures are given taking into account metal prices by the beginning of 2022.

Vacation and normalization

Tempering is carried out immediately after completion of hardening, since there is a high probability of cracks occurring in the structure. In this case, the product is heated to a point below the critical point, held for a certain period of time, and cooled. Tempering improves the structure, eliminates stress and increases ductility, eliminating the brittleness of 40X steel.

Mechanical properties of 40X steel depending on tempering temperature

There are three types of heat treatment under consideration:

- Low tempering determines the heating of the surface to 250 °C with exposure and cooling in air. It is used to relieve stress and slightly increase ductility with virtually no loss of hardness. In the case of a structural alloy, it is used extremely rarely.

- The average tempering allows the product to be heated up to 500 °C. In this case, the viscosity increases significantly and the hardness decreases. This heat treatment method is used to produce springs, leaf springs and some tools.

- High allows you to heat the part up to 600 °C. In this case, martensite decomposes to form sorbitol. This structure is represented by the best combination of strength and ductility. Impact strength also increases. This heat treatment method is used to produce parts used under shock loads.