SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

A staircase is an essential element of a multi-story building. The safety design is complemented by railings, which play a functional and decorative role, since without railings the staircase will look unfinished. To ensure reliability, you should not only take into account the optimal parameters, but also use high-quality materials. Metal stair railings are reliable, they have an attractive appearance that complements any design.

Metal stair railings are not only reliable, but also have an attractive appearance

What are metal railings: what elements do they consist of?

Stairs connecting the floors of a house can be simple, unremarkable in design, or they can be works of art. Despite the fact that the main function of the railing is to ensure safety, the choice of design should be approached wisely, and you also need to correctly determine the type and size of steps.

The main function of the railing is to ensure safety, but design should not be forgotten either.

Fact! If you look at various photos of railings for stairs in a private house, it immediately becomes clear that most often metal structures are used for decoration.

Before you make a railing for a staircase, you need to decide what the railing is intended for and what structural details are at its core. So, if we turn to the definition of the word, a railing is a fence that includes the following elements:

- Racks and balusters. They are not only decorative, but also load-bearing and protective elements.

- Handrails. Important structural objects that act as support for a person during ascent and descent.

- Internal filling. It is a protective element of the stairs.

As for the internal filling of metal stair railings, they are also divided into types:

Racks and balusters are not only decorative elements, but also load-bearing ones

- Classic. Consists of handrails and balusters.

- Solid. Made from a single sheet of metal or other material.

- Crossbars. They have the form of crossbars that are located parallel to the main handrails.

Features of metal railings for porches and stairs

Railings in the house not only provide safety, but also help create a harmonious and complete interior design. That is why the appearance of structures is of great importance. The main reason why it is recommended to install railings on balconies and other potentially dangerous structures is to prevent injuries and accidents. It is the barriers that protect the residents of the house from falls from heights. Among the main advantages of installing metal railings for stairs in the house or on the street are the following:

- Unlike other structures, metal structures are durable and strong. Even after time, the fences will not begin to creak or deform.

- Metal is considered a universal material that can be easily combined with wood, glass or stone elements.

- Metal parts are malleable, so it is easy to make elements of various shapes from them. These can be either regular geometric shapes or a variety of fantasy elements.

Other benefits of using metal to make stair railings:

The internal filling of metal stair railings is divided into classic, solid and crossbars

- inflammability and resistance to fire;

- resistance to changes in temperature and humidity, which allows you to install railings for stairs outdoors;

- long service life without repairs or upgrades;

- ease of care;

- possibility of application in any interior style - from classic to laconic loft and hi-tech;

- increased resistance to mechanical stress;

- high strength;

- ease of processing using various tools;

- the ability to make simple options yourself.

To improve the appearance of the finished railings, several methods of finishing the main elements are used:

- Anodizing. The result is chrome-plated stair railings.

- Coloring. Using special paint, fences can be given any color that matches the surrounding environment.

- Polishing. Gives shine and smoothness to surfaces.

- Satin finish. This is done by using sandblasting equipment. In the photo of the railing you can see what such structures look like.

Anodizing, painting, polishing or satin finishing is used to improve the appearance of the railings.

Among the disadvantages is the susceptibility of metal elements to corrosion and oxidation. But modern processing technologies, which involve the use of special solutions, make it easy to cope with the problem. The main thing is to choose the right mixture and adhere to the rules of application.

Types of railings for stairs in a private house: characteristics

Depending on the manufacturing method, fences are divided into several types:

- prefabricated;

- welded;

- forged;

- cast;

- combined.

Prefabricated products are made from steel or aluminum parts. It is important to consider that after installation, all steel elements must be coated with paint, and aluminum parts must be coated with a special anti-corrosion coating. Such structures are usually inexpensive, lightweight and easy to install.

Welded railings have a more complex design. Their main advantage is the absence of joints between elements. Among the disadvantages is the high susceptibility of structures to corrosion.

Depending on the manufacturing method, metal railings are divided into prefabricated, welded, forged, cast and combined

Expert advice! To make welded railings, it is best to use argon welding, which gives a neat seam and does not form splash marks.

Forged products in most cases are made by hand, which requires significant physical and time expenditure. But the result of the work is beautiful railings with an original appearance. Most often they are made to order. The products have a high cost, but they look luxurious, especially if various methods were used during processing, through which the metal is specially “aged” or given a gilded appearance. Often, forged railings are decorated with openwork or massive elements.

To produce cast railings, special molds are used into which molten metal is poured, most often bronze, cast iron or brass. Custom-made products will be expensive, while the price of ready-made products in stores is slightly lower. Each option has a unique appearance that will fit perfectly into any interior.

When making combined railings, a combination of materials is used, often exactly those that are used to create the interior or exterior of a house. Thus, it is possible to install railings that fit perfectly into the surrounding environment.

To make welded railings, it is better to use argon welding, it has a more accurate seam

Whatever type of railing for the staircase is chosen, it is important to consider that their height should not be less than 90 cm. Railings can only be installed on one side. If the width of the structure is more than 1.25 m and there is no wall on the other side, then it is recommended to install the railings on both sides.

Filling

The infill can be made from a wide variety of building materials. By type they can be:

- The classic ones are a stand and a handrail.

- Solid , in which wide sheets of filling material are used.

- Crossbars , filled with transverse bars parallel to the handrails.

- Artistic means making various patterns. As a rule, they refer to forged railings.

In addition, you will want to learn more about outdoor insulated metal entrance doors.

The main materials used to make railings: photos of exquisite options

There are various types of metal stairs that are installed outside or inside buildings. Based on the installation method, structures are divided into stationary and mobile. Mobile options are mainly needed only for repair or household work; this also includes stepladders. Popular designs are folding or sliding systems, which are used to climb into the attic or attic floor. Let's take a closer look at other types of stairs.

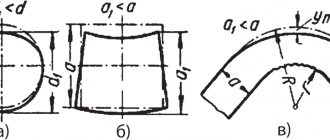

Marching. They are among the most convenient from a safety point of view for the movement of people. The structures consist of straight spans. If it is necessary to make a turn, platforms or winder steps are installed. It is not recommended to make more than 15-16 steps in one flight.

Screw. Another name is spiral stairs, which look not only beautiful, but also aesthetically pleasing. The turn is formed by smoothly curved structures. Spiral staircases are considered safe and convenient. They will not only decorate the room, but will also become an element that allows you to properly organize your movement.

When choosing material for railings, not only the preferences of the owners, but also the budget play a significant role

To make stairs and stair railings, various materials and technologies are used. A significant role in the choice is played not only by the personal wishes of the household, but also by the budget allocated for the manufacture of railings. In most cases, metal is used to create the main elements, as well as wood, which is also great for creating fences that match any interior design.

The main advantage of wooden railings is the ability to decorate them with carved or patterned details. In addition, you can use different shades of wood to make them. But wooden products will never be able to compare in strength to metal ones, which are guaranteed to last longer. Metal handrails for stairs can be made from available materials:

- pipes;

- fittings;

- metal profile;

- welded elements.

If you look at the photos of the finished options, you will notice that the railings look most attractive when complemented by decor, which includes plastic, glass, textiles, ropes and other suitable materials.

Metal stair railings can be made from pipes, profiles, fittings and welded elements

Features of handrails for stairs to a house, made of ferrous metals and cast iron

The most economical option for a porch, balcony or staircase railing is considered to be a ferrous metal fence. As you know, materials have some disadvantages, but to improve performance, powder coating or enamel is applied to the surface of the products. This allows you not only to give the handrails strength, but also to choose the desired color.

Fences can be used to equip multi-storey buildings, offices and residential buildings. Cast iron structures are in harmony with steps made of various materials; they look especially good in combination with cladding wood and marble tiles. At the same time, ready-made options may have a simple appearance or have an unusual design.

Cast iron railings are ideal for a balcony that faces the street, because the products are resistant to temperature changes and exposure to direct sunlight. It is the increased performance qualities and attractive appearance that make cast iron fencing the best option for the home.

Helpful information! Railings made of ferrous metal are susceptible to corrosion, so it is recommended to apply protective compounds to the products from time to time.

Ferrous metal railings are recommended to be periodically treated with protective compounds

If the artistic casting method is used for manufacturing, unusual weaves and patterns can be made from cast iron. The finished structure looks light, but at the same time emphasizes the richness of the structure. Almost all products are made according to a unique design, where each element is an integral part of the composition.

Related article:

Stainless steel railings: types, features, installation and care

Requirements for railings. Advantages and features of use. What types of railings are there? Self-installation and maintenance.

Using the method of casting and forging, craftsmen produce real works of art from cast iron. Such products, in addition to being attractive, are reliable structures designed to withstand heavy loads and retain an attractive appearance for several decades.

Other metals used to make metal stair railings

In terms of price, stair railings made from stainless steel will cost more than those made from ferrous metal, but they are great for installation both outdoors and indoors. Increased resistance to weathering is the reason why stainless steel fencing is most often used for porches. Metal railings retain their appearance for a long period of time and also have decorative qualities, so this option can often be seen outside and inside the house.

Most often, polished stainless steel is used for the manufacture of fences, which has many advantages:

- wear resistance;

- strength;

- simple care;

- no need to update color;

- possibility of combination with other materials.

To create unusual ornaments or geometric shapes from stainless steel, the metal is processed by cold bending. An important advantage is the absence of corrosion even without painting. The average service life is 50 years.

Steel, unlike stainless steel, is subject to corrosion, so a thin layer of powder coating must be applied to all elements. This will allow the various elements of metal handrails for stairs to be given almost any shade, thanks to which you can use the stairs in an interesting and fun way in the interior. The cost of steel fences is 20-30% less than the price of the stainless steel option.

But steel products have significant disadvantages. Thus, fences consisting of complex shaped elements are assembled from several parts, which are attached to each other by welding directly during the installation of the staircase itself. To avoid the appearance and spread of corrosion, the joints remaining as a result of welding are ground and painted.

Very often, polished stainless steel is used to make railings.

Aluminum, like stainless steel, perfectly resists the negative influence of external atmospheric factors. Important advantages of aluminum are ductility and low weight. Thanks to this, on trading floors you can find fences that differ in different geometries and colors.

A large number of advantages have become the reason that aluminum stair railings are very common in private homes. But due to the fact that aluminum is less durable than steel or stainless steel, such fences are not recommended to be installed in public or office premises.

Brass is a metal that is obtained by mixing zinc and copper, in some cases nickel or tin acts as an additional element. The material has a golden hue, which will add luxury and richness to the interior. This option is often found in classic interiors: modern, baroque, rococo and others.

Railings made of brass will look even more attractive if you use a combination of glass, wood and stone with metal. After applying a special composition, the brass surfaces of the railings acquire shine and their strength improves. It is most important to combine brass with elements of artistic forging.

Why should you seek help from our company?

First of all, due to the fact that we employ only experienced specialists who will complete the work as quickly and efficiently as possible. They will guarantee the durability and reliability of the structure. You can choose forged railings for the stairs; our employees are ready to take on work of any degree of complexity. Beforehand, you will discuss all the details of the order. If you have any questions, the specialists will definitely answer them.

Despite all the advantages, the company offers its services at the most affordable price. It is unlikely that you will be able to find similar conditions from competitors. The affordable cost is due to the fact that we have our own production. The production of structures is carried out in accordance with all standards, modern equipment is used.

You can first find a suitable option in the catalog. Here you can immediately find window bars. Immediately after the purchase, you will discuss all issues related to installation. All products offered are provided with a long warranty. We are ready to take on an individual order and complete it in a short time.

How to decide on the design of the railing: drawings of stairs

To create a harmonious interior, you should choose not only the right type, but also the design of the fences. You need to understand that a staircase without railings will not look complete, therefore, even if the structure is small, it will look better together with supports. To choose the perfect design, you should turn to ready-made options on the Internet. If your imagination allows, you can create a sketch yourself using simple computer programs.

You can improve the appearance of a metal surface using the artificial aging method. In addition, depending on the surface, it is given a gold, silver or any other shade. For example, to improve the appearance of stainless steel, it is not necessary to coat the metal with paint and varnish solutions: as in the case of aluminum, a polymer, nickel or chrome coating is used.

To emphasize the style of the railing, you should choose the handrails wisely. For safe and comfortable use, their surfaces must be smooth and free of joints, seams or other uneven or pointed elements.

Helpful advice! If you want the staircase to look finished and attractive, you need the handrails to extend 30 cm beyond the line of the bottom step. To reduce the likelihood of injury, it is better to make the edge rounded.

You can find a ready-made staircase design on the Internet or create a sketch yourself

Video description

The method of attaching balusters to dowels is shown in the video:

If supporting pillars of large cross-section are attached using this method, then instead of one central dowel, it is recommended to use 4, evenly distributing them along the plane of the end. Or install it on a long, large-diameter stud.

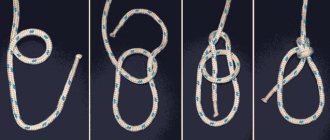

- Tongue and groove fastening.

This method of securing balusters can be used when the edge of the step protrudes slightly beyond the stringer and has a slight overhang. To do this, a trapezoid-shaped tenon is cut out at the bottom of the baluster, and a counter groove of a similar configuration is made at the end of the step. All planes of the groove and tenon are well lubricated with glue and connected, fixing the structure until the glue dries completely in a vertical position.

This joinery joint is called a “dovetail” Source airmatic.ru

Metal stair railings: main requirements for products

After you have chosen a specific fencing model, you can try to install the staircase railings yourself. But first you need to familiarize yourself with certain nuances:

- A welding machine will help secure metal railings to metal stairs;

- if the staircase is made of concrete, for reliability you need to install metal mortgages into the base;

- Bolted connecting mechanisms are used to attach supports to wooden stairs.

Before making a railing on the stairs, you need to think about the comfort of using the structure. To do this, you need to consider the following points:

- the height of the balusters should not exceed 1 m;

- there should be no visible defects on the jumpers;

- it is necessary that the handrails fit comfortably in the hand;

- the minimum load for which the fences are designed should not be less than 100 kg per square meter of fence;

- It is recommended to leave 70 cm between the posts.

To prevent a person from injuring their hands while lifting, it is necessary to maintain a sufficient distance between the wall and the handrail. It is important not to forget that the main function of the railing is to ensure safety when moving between floors, climbing onto a high porch or while being on the balcony. That is why it is necessary to strictly adhere to key parameters. So, according to SNiP and GOST standards, when installing railings on the stairs, you must adhere to the following parameters:

- in accordance with GOST 25772-83 standards, the optimal height of the barrier is 90 cm;

- handrail cross-section – 5 cm;

- distance between balusters – 10-15 cm;

- the gap from the nearest wall to the handrail is 10-20 cm.

According to the specified standards, handrails should be made continuous and at the same time maintain a cross-section of 50 mm. It is better to give preference to fire-resistant materials as filling.

The recommendations offered will help you choose the right railings, and if you follow the installation rules, you will get a comfortable and safe design. In this case, the price of handrails for stairs will depend on the selected material and additional elements. If you wish, you can choose an option that suits any budget.

According to GOST 25772-83 standards, the optimal height of the railing is considered to be 90 cm

Our new products at a discount

Railings for stairs P-001

5.00 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 5000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-002

5.00 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 6500 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-003

5.00 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 7500 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-004

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 7900 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-005

5.00 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 8000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-006

5.00 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 8000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-007

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 8700 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-008

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 9800 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-009

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 10,000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-0010

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 11,000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-0011

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 11,000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-0013

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 11900 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

Railings for stairs P-0012

0 out of 5

Frame: prof. pipe 40*20. Filling: square 10*10, square 12*12.

Price: 12,000 rub.

to the master

+7

Add to cart

Add to favorites

Compare

Quick ViewCompare

What elements should be present in the railings for spiral or marching type stairs?

Regardless of type, railings consist of three main elements:

- support pillars;

- balusters or filling;

- handrails

Support pillars on flight stairs are attached at the beginning and end of the flight, as well as at the corners of the turning platforms. On screw structures, supports are located at the beginning and end of each bend. It is with the help of these elements that the staircase is given strength. The distance between the support pillars is usually within 50-60 cm.

Metal balusters for stairs are considered optional elements, because they play a decorative role. It is with the help of balusters that the space between the supporting pillars on the steps and the bowstring is filled. Despite the fact that the elements are installed only to complement the interior, they can also increase the safety of the structure and prevent injuries. For example, for small children who like to climb where they don't need to, the padding will be an excellent barrier to prevent them from falling down the stairs.

The attractiveness of stair railings will primarily depend on the shape, material, installation method and the distance between the internal elements. If there are no children in the house, it is quite acceptable to leave the space between the pillars free. If there are children in the apartment, you need to be very careful that the child cannot, under any circumstances, stick his head between the elements.

The attractiveness of railings for stairs depends on the shape, installation method, material and distance between internal elements

Important! It is recommended to maintain a distance of 7 to 15 cm between internal parts.

The height of the handrail usually ranges from 90 to 110 cm. Here everything will depend on the average height of the residents of the house. At the same time, designers emphasize that children should not be taken into account, since they grow quickly. If desired, you can attach a temporary option parallel to the main handrail, which will make using the stairs comfortable for children. If the stairs are wide, it is recommended to install handrails on both sides.

There are different ways to fill the space between the support pillars. Some people prefer to use openwork elements, others prefer solid wide panels with patterns, drawings, or options for combining various materials. To fill the internal space, some people purchase crossbars (rails) - metal rods installed not vertically, but horizontally.

Installing racks

- First, determine where the main railing posts will be attached and mark these places with a marker. For pipes without a flange, mark one hole, with a flange - three. Have you noted everything? Now you need to drill these holes.

- Clean the drilling areas well, removing any burrs, and then fill them with an anchor. Find the hole for the flange post and insert the pin into it. Then get rid of any excess chemical anchor.

- What about other holes? A wood grouse and an anchor are inserted into them. Simply open the anchor, insert the stand pipe and secure with a screw. Next, you need to take the anchor head and tighten it all the way with a hex wrench. All that remains is to put the washer and groover on the pin, and also fix it until it stops. We are done with the main racks, now we can cover them with a lid.

- Secondary racks are attached according to the same principle, and the distance between them should not be more than two steps.

[my_custom_ad_shortcode5]

How to weld a railing with your own hands: necessary tools, main stages of work

Even though the design is modest, metal railings can be made in a variety of ways. For example, when creating complex structures, a welding method is used that is suitable for steel and ferrous metals. The main thing is that the joints are absent or barely noticeable. Before welding a metal staircase, you need to prepare the following tools:

Usually, railings are made from a profile pipe using welding.

- grinder with cutting and grinding disc;

- drill with metal drills;

- welding machine;

- vice;

- level and squares, with the help of which marking of structural parts is carried out;

- suitable fasteners.

Typically, welding is used to produce railings from a profile pipe. For manufacturing you will need 2 pipes of suitable length and diameter. You should not do the work by eye; to obtain the ideal product, it is first recommended to make a simple drawing taking into account the dimensions of the opening.

When creating the simplest option, you will need to weld a supporting frame from pipes or channels, to which the corners are then welded, serving as the basis for the steps. After the frame is ready, all seams need to be sanded and ensure that there are no metal burrs or other irregularities that could scratch your hands.

Having completed the welding work, proceed to the next stage: a primer or paint for metal surfaces is applied to the finished product. This must be done to protect the product from corrosion and give the railings an attractive appearance.

The simplest version of the staircase is a supporting frame made of channels, to which the corners are welded, which are the basis for the steps

Both handrails and vertical supports are made from a profile pipe, which can be easily welded to a finished metal staircase using the same welding machine. A finished staircase with railings can last 30 years or longer if properly used. The main thing is to prevent the development of corrosion in time.

Helpful advice! Installing a metal railing with your own hands is a task that most craftsmen can handle, but you should resort to making your own fence if you have not only the necessary tools, but also knowledge. You need to understand that working with metal is not at all the same as working with wood.

How to equip a staircase with handrails yourself: important installation tips

The simplest method is to purchase a ready-made fence, which contains the necessary elements, fasteners, drawings and instructions for self-assembly. For installation, you will need a minimum set of tools and skills; the main thing is to follow the manufacturer’s recommendations flawlessly.

If you decide to install the railings yourself, you need to remember that their main task is safety, so you need to approach the installation carefully. There are 2 main installation methods. If the staircase is located close to the wall, the handrail is attached to its surface. For installation, cast or hinged brackets are used, with the help of which the optimal distance between the wall and the handrail is set. Usually this is 7-10 cm. It is important to consider that it is the hinged brackets that allow you to adjust the angle of inclination of the handrail if necessary.

Balusters are attached to the steps using one anchor or flange mounting using several self-tapping screws

As for how to attach balusters to railings and steps, you can choose one of the following methods:

- the single method involves attaching the rack using one anchor;

- The flange mounting option involves using several flange screws.

The listed methods are considered very simple, but far from the most reliable. Anti-vandal fastening using a drill is considered the most stable. During installation, holes are drilled in the steps, where the embedded parts are placed, onto which the railing posts are then attached.

Important! If you decide to install handrails on the steps, you should understand that the width of the stairs will decrease. If we are talking about a narrow structure, it is better to give preference to the fastening method from the end side.

When installing metal railings with your own hands, you need to remember that their main task is safety.

Step-by-step instructions for installing handrails yourself

Before starting installation, you first need to pre-mark the structure for the racks. To do this, you should step back from the edge of the step by 5-10 cm, leaving 30-60 cm between the holes. As already noted, the first and last racks are initially installed, and then the procedure will depend on the chosen installation method:

- For single fastening, holes with a diameter of 1.6 cm are drilled, and they need to be deepened by no less than 1.2-1.5 cm. Dowels are inserted into the finished cavities under the balusters.

- If flange mounting is assumed, 3 holes are made for installing dowels 8 cm long and 1.2 cm in diameter.

Before you begin installing the balusters, a cord is stretched between the pre-installed posts. It is important to ensure that the elements are not fastened in places where the railings are broken or where there is a difference in height. If you are installing stainless steel handrails, first cut them to length, while marking the places for the balusters. After this, it is mounted on hinges and securely fixed. Stainless steel handrails can be attached to balusters using self-tapping screws or from the end side to flanges.

Stainless steel railings can be attached to balusters using self-tapping screws and welding

When the main filling elements are crossbars, they are cut and markings are applied to the mounting points on the racks. If you plan to install glass panels, you must first attach the holder to the rack.

Installation of the racks on the side of the step is optimal when the minimum distance between the flights does not exceed 70 cm. In this case, they are fixed with expansion anchors, which are secured using an intermediate sleeve. To do this, 2 holes are made at the end of the railing, where an anchor is inserted through intermediate elements. The protruding end is closed with a cap nut. Sometimes it is allowed to use anchors without bushings. If fences are installed on concrete stairs, it is possible to use liquid nails.

Helpful advice! Before installing railings on the street, you need to make sure that the material will withstand environmental influences without losing its appearance. Even some stainless steel products are recommended for use only indoors or under a canopy.

Content

- Content

- Installation sequence

- Support post mounting options Single mount

- Flange mounting

Do-it-yourself installation of stainless steel railings is quite accessible for people who have skills in working with plumbing and power tools.

To perform installation you will need:

- angle grinder (grinder);

- electric drill;

- drills for working with stainless steel and wood;

- curly screwdrivers;

- building level;

- mount and hexagon for it.

Some ideas for creating beautiful metal railings

When choosing railings, you need to take into account not only individual wishes, but also the harmonious combination of products with the interior. Some stairs look original without railings, but the question of safe use remains open. Therefore, it is better to supplement any design with handrails. Attractive design options:

For a classic interior with elements of aristocracy, forged and cast railings are best suited

- cast iron stairs look bulky and massive, but are not suitable for every interior;

- forged and cast railings will fit into a classic interior with elements of aristocracy;

- various patterns will fill the room with a palace motif;

- an openwork version of metal railings will add lightness to the staircase and transform any design

- a wooden staircase with metal railings will emphasize the rustic style, chalet interior or classic style;

- Using a variety of weaves, shapes and geometric shapes will help create a real work of art in the house.

A staircase is an integral element of a house or apartment of several floors. The entire structure is a continuation of the interior. Railings that continue the pattern of the walls will look very beautiful and harmonious. When choosing a railing design, you should not forget about safety rules. Metal is a durable material, but even despite this, you should properly install the railings and take care of them, only in this case you will be able to create not only a beautiful, but also a safe interior.

Certificates

We have developed a technology for high-quality assembly of metal structures. We use materials only from the best manufacturers.

By clicking on the “Submit” button, you consent to the processing of your personal data Personal data processing policy