Gluing glass to metal - choosing adhesive

Usually, a transparent glue is selected for gluing metal to glass, because it will provide the most aesthetic seam, which will be practically invisible from the outside. This quality of glue is especially important if you plan to glue glass decor to a metal base. But the absence of color and invisibility are not the only requirements for the material. The best glue also has the following properties:

- Strength. If the product will withstand high loads, you should buy glue only with increased adhesion, for example, compounds that become even stronger under the influence of UV irradiation and glue the parts almost forever.

- Tightness and moisture resistance. Some products act as a sealant. They are indispensable for gluing glass to metal if the joint will be exposed to moisture. Most often, sealants are used when inserting car glass and gluing an aquarium on its own. There are even black sealants that make the future product stylish, with expressive contours.

- Hardening speed. Some products dry in just a few seconds, others polymerize over a long period of time under the influence of ultraviolet light.

If the transparency of the composition is not critical, you can use homemade glue. Its components are as follows: 2.5 parts each of gypsum, lead litharge, chalk, 3.5 parts rosin. This mass is diluted with drying oil to obtain a mixture with the consistency of putty. It will firmly adhere to metal and glass, as well as rubber and metal. Among purchased adhesives, there are different products that have different compositions and properties.

Cyanoacrylate

How to tightly glue dissimilar parts to each other? It is worth using cyanoacrylate or superglue. The product is better, faster than others, and provides reliable pairing; it can be one-component or two-component. Superglue drying time rarely exceeds 5-10 seconds. When purchasing, you should immediately check whether the glue is moisture-resistant, since some cyanoacrylates cannot be used in a damp environment. Most adhesives are very easy to use: the parts need to be lubricated and pressed together. If the composition includes epoxy resin, before work you need to mix the two components of the glue together.

Sealant

How to glue glass to metal if the seam will be regularly exposed to moisture or even be in water? A transparent sealant will help here, as it provides a high degree of insulation from moisture and can withstand aggressive factors and temperature fluctuations. The sealant has two disadvantages: its degree of adhesion may be lower than that of superglue, and it takes an order of magnitude longer to dry. But there are special heat-resistant sealants that can be used to repair stoves and ovens. They do not respond to action:

- high temperatures (up to +300 degrees and above);

- fat and oils;

- household chemicals;

- frost.

After gluing, you can use the item one day after the repair. Before applying the sealant, it is very important to thoroughly degrease the base and dry it, otherwise the bond will not be strong.

Moment-Crystal

This product is absolutely transparent and leaves no traces. It is ideal for colored materials and has minimal evaporation time. “Moment-Crystal” can glue not only metal and glass, but also porcelain, ceramics, cork, wood, plexiglass, PVC in various combinations. If there is excess adhesive left on the surface, no solvent will be required. You need to wait for the product to dry, then carefully roll it into a small ball and put it away. The downside is the unsuitability of “Moment” for products in contact with food.

“Moment-Crystal” is suitable for substrates subject to load, because the adhesive seam will be quite elastic. After the impact ceases, the layer returns to its original state without deformation. The glue is one-component, it is convenient to use, since there is no need to dilute or mix the components with each other.

Automotive glue

What glue should a car owner use when repairing a car? There are transparent and black automotive adhesives; you can choose the color based on the task at hand and the required degree of invisibility of the seam. All auto adhesives have increased adhesion and are resistant to aggressive environments. Before gluing the parts, it is usually recommended to warm them well so that the joint is more reliable.

Home Remedies

You can get out of a difficult situation when you need to glue glass products together not only by using store-bought products. Some home craftsmen use homemade adhesive mixtures.

- To prepare the simplest remedy, you will need bone glue and ash. Mix the ingredients well. Before applying the composition, be sure to warm up the glass.

- You can also prepare a mixture of casein and silicate glue. These substances are taken in a ratio of 1:10.

- If you need to fix a small piece of light glass, then ordinary garlic juice can help you with this.

- You can glue glass products to wooden ones using a composition prepared on the basis of wood ash and wood glue.

- Sometimes in everyday life there is a need to glue a window frame, an aquarium or a large vase. For this you can use the following tool. Take 100 g of rosin, 50 g of drying oil, 50 g of chalk powder and 10 g of beeswax. Mix all ingredients, bring to a boil, cool to +50 degrees, and then add 25 g of cement.

Surface preparation

Regardless of what composition you choose for gluing, you need to prepare the glass product for repair.

Types of transparent glue

Among the transparent adhesives, depending on the base, the following stand out:

- Silicone. These are usually highly elastic sealants that form a strong and invisible connection. Their polymerization occurs within 12-24 hours.

- Silicate. They contain liquid glass, they are durable, heat-resistant, moisture-resistant, and also have sealant properties. They perfectly glue all types of dissimilar materials, suitable even for large surfaces and decorating products.

- Polyurethane. Such compositions are most often used for repairing cars and equipment; they contain urethane components and other fillers, polymers, and plasticizers. The finished connection is very strong.

What substance should I use?

First of all, you need to decide which substance to use to connect the two materials. How to glue metal to glass - such a question is considered solely taking into account the characteristics of the selected adhesive. They may be as follows:

Heat-resistant sealant for oven glass

Gluing a metal surface to a glass surface or vice versa should be done only taking into account the manufacturer’s basic recommendations.

As a rule, instructions for use are located on the back of the package.

How to glue correctly - technology

To work, you will need the glue itself, carefully prepared parts, means for degreasing and washing them, and rags. A UV lamp may be needed to heat the surface and irradiate it, and a press or vice may be needed to fix the parts.

Preparing the base

Before starting work, it is important to clean the surface, since the presence of even a small amount of rust, dust, and dirt greatly reduces adhesion. If the metal is not coated with anything, it is simply wiped with a solvent (acetone, white spirit), you can also use alcohol or vodka. Do the same with glass or wash it with any detergent and thoroughly rinse off the foam.

After washing, it is worth wiping the part again with alcohol, because any household chemical leaves a film on the surface. Paint and varnish applied to metal must be cleaned off manually (with sandpaper) or with a grinder, then degreased. Immediately before work, all surfaces are thoroughly dried.

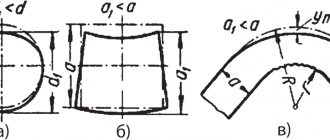

Gluing stages

The parts to be glued must be heated to a temperature of +40...+50 degrees - this will make adhesion even more reliable. Care should be taken when heating the glass; it may crack if the temperature rises sharply. You cannot use an open flame; it is better to use the hot air of a regular or hair dryer. Heating will also help to completely dry the parts and remove unnoticeable condensation. After cooling, the risk of internal stress in the material will be minimal.

Further recommendations for work are as follows:

- carefully apply glue to both parts to be glued;

- rub the product, forming a thin layer;

- carefully work out the edges of the products;

- relate the parts to each other, put them together;

- place the products under the press, ensuring uniform pressure.

The press should not be heavy, otherwise there is a risk of damage to the product. It is advisable to remove all spilled drops immediately, because not every glue can be rolled up and removed after drying.

Using UV lamp for gluing

To form an even stronger seam, it is recommended to use ultraviolet lamps. Be sure to preheat the parts to a temperature of +60 degrees. Then you should apply a thin layer of adhesive and attach the products to each other. Next, you need to irradiate the joint with a UV lamp twice. This is done to achieve maximum strength of the seam (after a single irradiation, the degree of adhesion will be 70% of the possible, after the second - 100%).

The operating time of the lamp will depend on its power. For the first stage, 10-120 seconds are usually enough, for the second - 60-300 seconds. Following the technology without skipping steps will help securely fix the parts and get the strongest joint that will be impossible to tear or break.

Brief summary

There are many adhesive compositions; when making a purchase, you should carefully read the description of the product, and sometimes consult the seller, specifying the purpose of using the solution. As has already become clear, transparent specimens are very popular, the seam is invisible and will not spoil the interior of the home, the mixture is suitable for implementing decorative processes.

At the time of work, it is better not to deviate from the sequence specified in the instructions; only professionals use this algorithm of actions. Therefore, the technology of conventional fixation and the use of a UV lamp is considered effective; over the course of several years, specialists have achieved extremely positive results. By refusing to comply with at least one of the generally accepted rules, a person risks creating a connection of poor quality, which over time will simply disappoint the owner of the building.

How to glue metal to glass

The reliability of gluing depends on the conditions of use of the item. If a moisture-resistant sealant is needed for aquariums and exterior work, then it is better to carry out internal repairs with a non-toxic composition.

Some adhesives cannot withstand temperature changes or do not provide elasticity to the hardened seam. Transparent mixtures are suitable for decorative and outdoor works. For parts subject to loads and vibrations, the seams must be elastic.

Cyanoacrylate

This is ordinary superglue, sold in all hardware stores. Sets in 5 seconds. Easy to use. Suitable for surfaces protected from moisture, as water can destroy the seam.

To glue the surfaces, you need to lubricate them and press them tightly together for 5-10 seconds.

It is better to use a two-component composition in your work. It is waterproof and dries quickly. Even before mixing the glue, you need to prepare the surfaces (degrease and clean).

Sealant

The sealant is suitable for durable connection of parts under possible sudden temperature changes. It is used when moisture resistance is more important than the degree of rupture and the permissible mechanical load on the seam. Surfaces must be cleaned and degreased in advance. You need to squeeze the parts tightly for at least 10-15 seconds. You can use the part/item the next day.

Moment Crystal

The composition is suitable if an elastic (elastic) seam is needed. When pressure is applied to such a connection, temporary deformation should be observed (with subsequent restoration of shape). The glue is transparent, which means it does not leave marks and does not stain the surface. Moment Crystal ohm can be used to glue glass, porcelain, ceramics, as well as cork, wood, and PVC. Excess drops easily roll into a ball and are removed from the surface (only after drying). Not suitable for dishes. The glue is immediately ready for use after purchase.

Automotive glue

The frozen seam remains resistant to aggressive environments and moisture. Not suitable for outdoor use due to black color. Most often used in auto repair shops. The composition is more like rubber. It is recommended to warm up the surfaces thoroughly immediately before joining. The application of glue should be gradual.

Gluing surfaces must be done while they are still warm. The layer should be as uniform as possible, and excess should be removed immediately.

Automotive adhesive is the best choice for windshield repairs.

When working in a cool room, there is a risk that over time the seam will lose its tightness and integrity.

Two-component adhesive

Can be used in work where heat resistance of the seam is not required. The epoxy-based adhesive is waterproof and protects against current (dielectric). The connected parts must be fixed for 3-5 hours.

You can speed up the drying of the seam only by gradually heating it with a hair dryer.

UV glue

This is a heat-resistant adhesive with maximum seam strength. One-component and easy to use in everyday life. The disadvantage is the presence of a strong unpleasant odor. To ensure maximum strength, the seam is exposed to ultraviolet rays.

Types of transparent glue

To glue glass parts to metal, you can use:

Sealant remains the best choice for aquarium restoration.

Among the most popular ones, the red Soudal Gasket Seal composition stands out, which serves as a reliable gasket between the parts. And WEICON Silicone F sealant is used to obtain a reliable transparent seam. The latter can withstand heating up to +185 °C, but is not “afraid” of the influence of atmospheric factors. A sealed seam takes longer to dry and is inferior to other adhesives in terms of adhesion.

Conditions for using adhesives

Are you wondering how to glue glass? When working with glass glue, a number of requirements and specific rules must be observed. So, you need to act with extreme caution, because the transparent material may become stained due to improper use of the adhesive mixture.

Remember that the glass surface is quite fragile, so you cannot apply excessive mechanical pressure to it. When drops of glue accidentally fall on the front surface of the glass, wash off its remains using special solvents. If you are going to interact with an aggressive adhesive, then take care to protect your hands.

Useful tips

Despite the fact that glass gluing seems complicated, it can be done quite quickly and without difficulty. To do this, just follow the instructions from the manufacturer and take care of your own safety.

It is recommended to purchase products for gluing glass exclusively in specialized stores in Moscow, which can provide the correct storage conditions for the goods. Expired transparent glass adhesive should not be used. The properties of compounds with an expired shelf life are lost.

To clearly understand the features of transparent glass adhesive, we recommend watching the thematic video: