Spread the love

Perhaps you are planning to upgrade your existing machine or are building a new router from scratch and need a good spindle for your hobby CNC machine.

In this guide, I have compiled a list of the best CNC spindles available in the market today.

Choosing the best CNC spindle for your machine will depend on the hardness of the materials you want to machine and the speed at which you need to do it. You can read a more scientific, theoretical approach to spindle selection in the article on spindle selection

If you don't have the time or patience to manually change the tool, you can opt for an automatic tool change (ATC) spindle, but it is more expensive compared to regular spindles.

The factors I considered when compiling this list were power output, spindle build quality, collet size, and cooling system.

I sorted them by power output, starting with the low power spindles and working my way up to the 4kW spindle.

At the end of this article, I discussed the factors to consider when choosing a spindle for your CNC.

| CNC spindle | Power |

| HONGYC HY-775PH 20000RPM 775 CNC | — |

| Guangzhou LiChi Electromechanical | 0.5 kW |

| HYCNC water cooled CNC spindle | 0.8 kW |

| Water Cooled Spindle Kit | 1.5 kW |

| CNC Spindle Motor 2.2KW | 2.2 kW |

| CNC Spindle Motor 4kw | 4 kW |

1.5KW Water Cooled Spindle Kit

1.5KW Water Cooled Spindle Kit

1 & 220v 1.5kw ER16 water cooled spindle 4 bearings 80x220mm

1 & 220v 1.5kw 1000Hz inverter/VFD

1 & 80mm spindle bracket/holder

1 & 220v 75w water pump and 5m pipes

The balance between quality and power is what you get with the G-Penny machine 1.5KW ER16 spindle kit.

The spindle has a diameter of 3.14 inches and can be mounted to a CNC router using the included clamp.

This spindle kit includes a 1.5kW ER16 spindle, 80mm clamp and 220V VFD.

You can increase the speed of this motor up to 24,000 rpm at 1.5 kW power using a 220V power supply. But can only rotate clockwise. The speed can be changed using the variable frequency drive included in the kit.

However, the lowest stable speed you can achieve with this kit is 6000 RPM. You can use another VFD to reduce the speed.

The spindle has a pre-installed ER16 collet and can hold tools in the range of 0.02-0.354 in. (0.5-9 mm) with 0.002 in. runout.

This is a water cooled spindle made of stainless steel. The pump and cooling pipes are included in the kit. This spindle is suitable for engraving and cutting wood, aluminum and other soft materials.

The kit includes spindle, 220V 400Hz variable frequency drive, 220V 80W water pump, 16ft pipe.

Main parameters of VMS

The main parameters: engine power and torque, rotation speeds, permissible cutting forces, were assigned based on an analysis of the processing modes of steel and aluminum workpieces with face, long-edge, end, disk cutters, as well as boring, drilling and thread-processing tools (drills, reamers, cutters and etc.). Hard alloy and ceramics were used as tool materials. When choosing processing modes, we took into account the fact that when accelerating the above-determined rotation speeds, a gap may arise in the conical connection of the mandrel and spindle, which must be eliminated. The main parameters of the VMS developed within the framework of the state contract are presented in the table.

Fig.5. VMS HSK 100 (longitudinal section)

In Fig. Figure 5 shows the design of a VMS with a HSK-A100 cone. The rotor 1 of the electric motor is installed with interference to transmit torque to the spindle 2. The influence of the electromagnetic fields of the motor is reduced by rings 3 made of non-magnetic material, which can also be used for balancing. Spindle 2, together with the electric motor rotor and other rotating parts, is balanced until a residual imbalance is achieved, at which the center of gravity of the spindle shifts by no more than 1...2 µm. The stator 4 with a cooling jacket 7 is installed in the VMS housing 5 and is cooled when liquid is supplied to the cavity 6 of this jacket. The same system is used to cool the bearings. The front support of the spindle is double angular contact ball bearings 8 and 9, the tension in which is provided by springs 10 (at high rotation speeds) and pneumatic cylinder 11 (at lower frequencies and higher loads). The tool is installed in a mandrel 12, which is secured using a clamping mechanism 13 on the spindle, based in a connection 14 of the HSK-A type. The release of the mandrel 12 is carried out by supplying oil under pressure into the right cavity 15 of the hydraulic cylinder 16, the movable body of which is connected to the spindle 2 through the clamp 17. Thus, when the mandrel 12 is released, the axial force of the spring release is perceived only partially by the spindle supports. The angular position of the spindle is monitored by a sensor, which consists of a magnetized disk 18 mounted on the spindle and a reading head 19 mounted on the housing flange. The vibration sensors 20 and the movement of the front end 22 are located in the VMS housing. Temperature sensors are located in close proximity to the outer rings of the supports and in Fig. 5 are not shown. The coolant supply is carried out through the nozzles 23 or through the hole in the rod 24 of the clamping mechanism 13.

CNC Spindle Motor 2.2KW

CNC Spindle Motor 2.2KW

| Diameter | 3.14 inches (80 mm) |

| Maximum speed | 24 000 |

| Force | 2.2 kW |

| Collet | ER20 |

| Tool shaft diameter | 0.039–0.512 in (1–13 mm) |

| Cooling | Water cooled |

A complete CNC spindle kit for your new CNC build that can cut soft materials is what you get with this CNC spindle motor kit.

The spindle weighs 5 kg, and the entire kit weighs about 10 kg and includes the spindle motor, VFD, water pump, 16-foot water pipes, 2.75-inch dust brush, 13 ER20 collets, and 10 drill bits.

You can also buy a spindle without a kit by contacting the seller by email.

You can install the spindle on any frame that can accommodate a 3.14-inch diameter spindle. The kit comes with ER20 collets and has a runout of 0.0002 inches, which is pretty good accuracy.

You can change the spindle speed from 0 to 24,000 rpm using a variable frequency drive that provides 2.2 kW of power. The VFD supplied with the spindle speed control kit is a 220V, 0-400Hz unit.

The CNC machine spindle is water cooled and comes with a 220V submersible pump, making it suitable for long-term operation.

The spindle, VFD, and water pump together can draw about 15A of current, so you may have to provide the appropriate breakers to set it up.

The connectors used are aircraft type plugs and provide good waterproofing.

Well-labeled wires, documentation and videos will guide you through the installation process. There are also plenty of videos on Youtube about setting up these spindles to help you along the way.

Adjustment and Settings

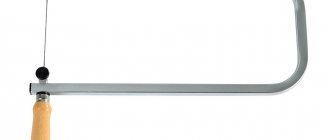

On traditional machines with a spindle fixed in one position, engine speed adjustment is carried out in a classic, mechanical way, using a gearbox. The image shows the spindle speed adjustment lever on a traditional router:

On spindles with a built-in electric motor, adjustment is performed electrically by decreasing and increasing the current supplied to the electric motor.

The spindle itself does not require special settings before operation. Attention is paid to the correct positioning and secure fastening of the cutter, according to the operating instructions for each machine. An incorrectly inserted cutter may not cut at the intended depth or may jump out of the clamp during operation.

CNC Spindle Motor 4kw

CNC Spindle for CNC machine 4 kW

This spindle weighs around 8kg and is a sturdy spindle. Its size is 100 mm.

With this spindle, you get an ER20 collet that accepts tools with shaft diameters ranging from 0.039 to 0.512 inches and has a runout of 0.0004 inches.

HongYang also produces ER11 1.5KW, ER25 4KW, ER32 7.5KW spindles, all of which are available on AliExpress

You can change the spindle speed from 1 to 24,000 rpm. To control the spindle speed, you need to connect it to the VFD.

It is rated at 220V, can produce 4kW of power and draw a maximum current of 10A at 400Hz.

The spindle is water cooled and can be used for routing or engraving wood, stone and soft metals such as aluminum.

These spindles are quiet and well balanced, providing good stability when working at high speeds.

The construction material is durable and can last a long time.

Tailstock

The support unit designed to support the workpiece in alignment with the spindle head is called the tailstock. The tailstock includes a quill - a movable device that is moved along the axis of the workpiece using a screw driven by the feed flywheel.

The numbers indicate:

- Feed handwheel.

- Body fixing eccentric lever.

- Quill lock.

- Tailstock housing.

- Pinol.

- Center.

- Technological holes.

- Body base.

- Body transverse movement bolt.

Before starting work, it is recommended to move the tailstock towards the spindle and check their alignment visually. In case of doubt, one end of the test rod (workpiece) is clamped in the spindle head, and the second end is supported with the center of the tailstock moved into place. Then a rigidly fixed micrometer is moved along the frame guides along the entire length of the rod. The probe of the device must touch the rod - this is how the axial runout of the workpiece is checked. If runout exists, then thin adjustment plates are placed under the base of the tailstock, trying to reduce the axial runout to minimum values or to zero.

The tailstock can serve not only as a supporting element, but also as a holder for some types of tools. Drill, tap, internal cutter - many of these items can be mounted in a quill.

The inside of the quill is machined to a Morse taper, so the tool shanks must also have this taper. The design of the tailstock is made in such a way that when rotated back, the quill is retracted into the body to a certain depth. At this time, the end of the screw moving it rests against the end of the tool inserted into the quill. In this way the tool is pushed out of the quill.

The simplicity of the tailstock design does not eliminate the need for its adjustment, tuning or repair.

After long-term operation or as necessary, the tailstock is inspected. In the case of repairs, after completing all the necessary work or replacing parts, the tailstock is adjusted, which is called adjustment.

When performing any work on adjusting and tuning metal-cutting machines, adjustment plates made of wood are not used because of their softness.

Which spindle to use for steel machining

Generally, steel machining requires low RPM (compared to the RPM of aluminum and wood) and high power of a CNC spindle.

The ability to machine steel also depends on the rigidity of your machine and the tools you use. For steel, it is recommended to select a spindle with high power at low speeds.

The forces acting on the tool and therefore on the spindle are greater when machining hard materials such as steel.

It is advisable to choose a spindle with a steel body, rigid structure and ceramic bearings. Ceramic bearings can withstand more beating than metal ball bearings.

The power and speed of a CNC router spindle is also determined by the type of machining operation you are going to perform.

For example, drilling steel requires more energy than milling or turning steel.

Typically, when processing steel, the milling speed is 50% higher than the drilling speed.

In the case of turning, the speed can be 100% higher than when drilling.

For businesses that need to do heavy production work, I highly recommend ATC spindles over regular CNC spindles.

For woodworking machines

Woodworking milling machines use practically the same spindles as metalworking ones. Simple machines use straight shafts with a chuck or collet to clamp the cutter. Also shafts with a threaded clamp for attachment cutters.

The image shows the spindle of a simple wood router with a disk-mounted cutter.

Milling cutters of various profiles are mounted on them, for selecting a groove/tenon for lining, plinth profiles, tenons for splicing, processing cylindrical parts in two passes (on both sides in a semicircle), etc.

Modern computer-controlled woodworking milling machines use complex spindles with their own electric motor, described above.

Feature of spindles for woodworking at higher speeds. At the same time, the lubricant in the bearings is prone to overheating, so heat-resistant lubricants are used for high-speed components.

Factors to consider when choosing a spindle for your CNC router

Size and weight.

The size of the motor determines whether it can be installed correctly on your CNC router. It is also important to consider the shape of the spindle as there are cylindrical and square spindles.

Make sure your CNC router frame is strong enough to support the weight of the spindle. In stepper motors, the axes must have sufficient torque to handle the weight of the motor.

Speed and power

Spindle speed determines the range of work you can do. For example, cutting soft materials requires low speed because large pieces of material can be cut off easily.

In the case of metals, cutting large pieces of metal is difficult and therefore the amount of material removed in one pass is significantly reduced.

To achieve high cutting speeds, you will have to increase the spindle speed to make more cuts per minute.

Spindle power is another limiting factor for your projects. A spindle with sufficient power can ensure smooth cutting and prevent damage to the workpiece. On the other hand, a spindle without sufficient power can cause it to stall.

Cooling type

Very high RPM spindles tend to heat up quickly, so it is important to ensure the spindle is properly cooled.

The most common types of cooling available for spindles are air cooling and water cooling. Water has a higher heat capacity than air and therefore can remove more heat from the engine. It is better to use distilled water instead of regular water to avoid damaging the spindle.

Air-cooled spindles generally have better torque characteristics than water-cooled spindles due to their design. But air-cooled spindles produce more noise than water-cooled spindles.

In general, water-cooled spindles last longer and provide better accuracy than air-cooled spindles.

The main problem when operating a water-cooled spindle is the influence of climatic conditions. Because in cold weather, water can freeze and prevent the spindle from rotating.

Water cooling is preferred over air cooling if the spindle is used for extended periods of time.

Speed control

The low power spindle can be controlled by PWM (Pulse Width Modulation) motor drivers.

VFD (Variable Frequency Drive) is preferred for high-power spindles as it provides better control and stable performance.

It is necessary to select the correct VFD for your spindle. An incorrect configuration can immediately damage your spindle. Make sure the voltage, current and spindle frequency ratings match your VFD (if you already have a VFD).

You can also control the spindle speed using a controller that runs your stepper motors. I talk about GRBL CNC Controllers in detail here - Best GRBL CNC Controllers for Hobbyists.

Advantages

The capabilities of a CNC milling machine are determined by the type of spindle chosen and its technical characteristics. Milling spindles have the following advantages:

- The overall strength of the machine structure increases significantly.

- Equipment efficiency increases.

- Modern mechanisms are made from high-quality materials that can withstand heavy loads.

To ensure that the equipment lasts longer and the workpieces do not deteriorate during processing, we must not forget about installing a cooling system. If water cooling is chosen, you need to figure out where to hide the hoses for supplying liquid and install a container with the liquid itself. When choosing an air cooling system, we must not forget about cleaning the filters, which become clogged when working with various materials.