Reciprocating saws are a type of tool that will never be superfluous to have in your home kit. A reciprocating saw is a very versatile tool that can simultaneously replace several types of power tools with similar purposes. It is worth considering that such versatility is only possible when using different types of blades, each of which is designed for cutting a different type of material. Therefore, having several different blades available, with a reciprocating saw it is possible to cut not only simple soft materials, such as wood, plastic or drywall, but also hard ones: stone, concrete, metal, tile.

Reciprocating saw blades have standardized shanks that are suitable for any model from different manufacturers. This is quite convenient, as there is no need to adapt to different models when choosing the fastening of the canvases.

The blades themselves can be produced in different lengths: from 10 to 40 cm. The length is selected based on the thickness of the material that will be cut. You can try several options and then use the most suitable one for the job.

It is necessary to take into account the size of the teeth on the reciprocating saw blade. Large teeth are designed for sawing softer materials, and the smaller the teeth, the better for harder ones. For example, it is more convenient to cut tree branches with saws with the largest teeth. And if you use a file with small teeth for this, then this process can slow down significantly. On the other hand, fine teeth allow for better cuts, while files with large teeth are designed more for rough cuts.

What is a reciprocating saw and what is it used for?

The reciprocating saw is a highly maneuverable, easy-to-use multifunctional cutting unit. During processing, the cutting blade performs a reciprocating movement, the frequency and magnitude of which depends on the specific operating conditions. The working stroke of the blade for different samples can vary from 80 to 350 mm.

Depending on the power, the weight of a household or semi-professional class reciprocating saw ranges from 2 to 5 kg, and for powerful professional models up to 10 kg. Since the comfort of its use depends on the weight of the reciprocating saw, when choosing it is necessary to clearly understand the scope of application and the type of material with which you will be working.

Due to their maneuverability and ability to process various types of materials, reciprocating saws are successfully used for:

- Construction and repair;

- Production of joinery;

- Cutting pipes of various diameters;

- Pruning trees and bushes;

- Harvesting firewood.

Depending on the power and stroke of the working blade, one or another model can be used for a certain type of work. There are also universal modifications, but their cost is significantly higher than that of household and amateur samples.

The technical characteristics and possible scope of application of various models of reciprocating hacksaws will be discussed in more detail below, but we note here that the use of this tool can significantly reduce labor costs and increase work safety. In addition, the price range for this type of cutting tool allows you to choose the most suitable option for solving specific problems.

Blade for sawing aerated concrete as designated

For cutting aerated concrete or foam concrete, blades with the designation HM or CV are used. The abbreviation HM stands for “hard material”, the degree of hardness of which reaches 79 HRC on the Rockwell scale. The nozzle with the designation CV is chrome vanadium, and they also have increased hardness, which is very important when processing materials such as aerated concrete, tiles, fiberglass, and fiberglass. To increase the strength parameters, the teeth of such blades have pobedite soldering.

This is interesting!

The presence of the CT designation indicates that the equipment is made of carbide tipped. These hard alloys include tungsten, titanium, cobalt, tantalum and others.

Can a reciprocating saw replace a circular saw, grinder, or electric jigsaw?

In this section of our review, it should be noted, first of all, that any universal tool is inferior to a special one when performing a single job. Despite this, universal reciprocating saws are widely used due to their ability to perform a large number of operations. Let's take a closer look at the possibility of an alternative use for a reciprocating saw.

A circular saw

The benefits of a circular saw include:

- Cleanliness of the cut;

- Processing precision;

- High performance.

In these parameters, the circular saw is noticeably superior to all existing models of hacksaws. On the other hand, the use of reciprocating saws provides:

- Ability to work in hard-to-reach places;

- Processing of curved contours;

- High maneuverability and mobility.

Based on this, we can draw the following conclusion:

Replacing a circular saw with a reciprocating saw is quite acceptable if there are low requirements for the quality of the cut and for working in hard-to-reach places. If there are increased demands on the cleanliness and quality of the cut, it is more advisable to use a circular saw.

Bulgarian

Using an angle grinder allows you to achieve:

- High performance;

- High-quality cutting of hard and especially hard materials;

- Significant savings in money, since abrasive discs are much cheaper than saber blades.

Using an electric hacksaw as an alternative is advisable when working with wood, since cutting wood with a grinder can lead to serious injuries. In addition, the reciprocating saw has the following advantages:

- Replacing the cutting blade does not require much time;

- The cut quality is quite acceptable;

- Various types of saber blades provide the ability to work with any materials.

Based on the above, we can say:

The grinder has a noticeable advantage when working with hard and especially hard materials. On the other hand, reciprocating saws work effectively with wood and are safer during operation.

Electric jigsaw

Cutting various materials using an electric jigsaw allows you to:

- Carry out decorative cutting;

- Cut plastic, laminate, plywood, various types of plastics;

- Ensure high cleanliness and precision of the cut.

In addition, the use of special files makes it possible to process sheet metal of small thickness. A reciprocating hacksaw is more often used for less precise work, since the width of the reciprocating blade is much larger than that of a jigsaw blade, which limits the turning radius. At the same time, an electric hacksaw has its advantages:

- Relatively high power;

- High performance;

- Ability to cut almost any material.

By comparing the characteristic features of a jigsaw and a reciprocating hacksaw, we can draw the following conclusion:

For dismantling and cutting that does not require high precision and cleanliness of the cut, it is more effective to use a reciprocating tool. When decorative sawing, cutting laminate, plastic and other finishing materials, it is advisable to use an electric jigsaw.

In conclusion of this section of our review, it should be emphasized that reciprocating saws, due to their versatility, in some cases can easily replace an electric jigsaw, circular saw and angle grinder, but in some cases such a replacement will not provide the required quality of cutting.

By width, thickness and pitch of teeth

The width is selected taking into account the requirements for the work results. Wide products are more stable, so they can be cut at high speed without deviations. If you need a high-quality sawn curve, narrower files that are easy to make turns are also suitable. The teeth should be located on the drive axis - this makes the tool more controllable.

The thickness determines how strong the deviation of the file from the vertical will be. Thick blades best provide a perpendicular, even cut, but are unlikely to be suitable for jigsaws with a quick-release mechanism.

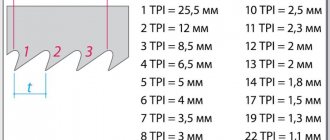

The pitch of the teeth is the distance between their tips. Most countries use the designation TPI (“teeth per inch”). Measured by the number of teeth per inch of length. If the TPI is 5, for example, that means there are five teeth per inch of blade. For cross-cutting wood, it is more advisable to use a saw with TPI 7−4. For regular work, 7-9 is enough. A file with TPI13−10 will help you make an extremely accurate cut.

Criterias of choice

Since an electric hacksaw is a fairly expensive tool, choosing the right model is of great importance. This section will outline the main criteria to consider when choosing a reciprocating saw.

First of all, you should clearly understand the scope and specifics of the work that will be performed most often. The main criteria that you should pay special attention to are:

1. Estimated work intensity.

Depending on the frequency of use and duration of operation, you should choose one of three modifications:

- Household;

- "Hobby";

- Professional.

Household models do not have high performance and are not designed for heavy loads. The power of such a tool ranges from 350 to 600 W, and the cost is quite affordable for a wide range of consumers.

Hobby class models are designed for more intensive work. They are often used for work in the garden or in the country. The power of models in this class ranges from 600 to 1000 W, and the price can vary significantly depending on the manufacturer and the functionality of the instrument.

Professional reciprocating hacksaws with a power of 1000 to 1500 W can work for a long time without interruption at maximum load. The cost of a professional “saber” is significantly higher than that of the two previous modifications, so using such a tool in everyday life and on a personal plot is most often not advisable.

2. Power.

The performance of the tool depends on this parameter, however, with an increase in this parameter, the weight and overall dimensions inevitably increase, as well as its cost. As statistics show, the most universal are electric hacksaws, whose power ranges from 0.8 to 1.1 kW.

3. Availability of speed control mechanism

allows you to select the optimal speed of movement of the blade depending on the material being processed. There are two adjustment methods:

Directly using the start key, while the speed of the reciprocating movement of the saw smoothly increases when pressed;

Using a slider or wheel installed in a certain position. Further adjustment is carried out by pressing the start button, while the maximum speed of the blade will not exceed the speed mode even when the start button is fully pressed.

4. Possibility of pendulum movement

allows you to significantly increase the cutting speed and reduce the heating of the blade, which has a positive effect on its service life. This effect is achieved due to the fact that during the reverse movement the saber slightly deviates from the direction of the cut, thereby simplifying the removal of chips.

5. Possibility of using a support shoe.

If an electric hacksaw is equipped with this element, when used correctly, the accuracy and quality of the cut significantly increases, and operator fatigue is also reduced. This is due to the fact that the support shoe stabilizes the blade relative to the cutting plane.

6. Method of replacing the cutting blade.

To work with various materials, appropriate files are used. The simplicity and speed of blade replacement affects not only productivity, but also increases work comfort.

7. Presence of safety clutch

makes it possible in case of jamming or reverse impact to avoid failure of the tool and injury to the worker.

8. Possibility of soft start

allows you to protect the electrical network from possible overloads with starting currents and ensures a gradual approach to the required speed limit.

9. Overload protection mechanism

independently disconnects the unit from the power supply in case of overheating or other critical situation.

10. Type of power supply

is important when choosing an electric hacksaw. Cordless saws are distinguished by greater maneuverability and mobility, and in terms of their operational parameters they are not much inferior to units operating from the mains. The disadvantages of this equipment include high cost and limited operating time on one battery.

Having carefully analyzed the criteria outlined above, you can safely begin to select the required model.

Product classification

Hacksaw blades are a narrow strip, at the ends of which there are two holes for attaching to the tool. There are three main criteria for their classification:

- purpose (for hand/electric hacksaws);

- material of manufacture;

- teeth parameters.

The division into groups according to the first criterion occurs like hacksaws - there are blades for manual (mechanical) and electric (sometimes called machine) tools. The dimensions of the working elements vary. So, for manual ones, canvases with a length of 250-300 mm, a width of 12-25 mm, and a thickness of 0.63-1.25 mm are used. An example is a domestically produced blade made of Kh6VF steel with parameters 1.25x12x300, which will cost the buyer 30 rubles per piece.

The parameters of files for power tools vary from 150 mm in length, to 55 mm in width, from 1.25 to 2.5 mm in thickness. An example is a blade for a reciprocating saw HAMMER RS BL 001, the parameters of which are 150x19x1.25 mm, and the cost is 100 rubles per piece.

Another difference between saw blades for hand and reciprocating saws is the number of holes for fastening. The first ones have two, the second ones have one.

Blade for electric hacksaw

The second classification criterion is the material used to make the canvas. Steel products are distinguished:

- carbon (the least durable, suitable for non-ferrous or soft metal; marked as HCS); for example, Bosch HCS TF 350 M 408 mm GFZ for 1400 rubles;

- high-speed (they have the most wear-resistant teeth, but are fragile and high in price; HSS marking); Gross HSS 18TPI 300 mm - 160 rubles per pair;

- bimetallic blades (an innovation on the market that is displacing analogues; the base is carbon steel, on top of which a high-speed strip is welded, serving as the basis for the teeth; designated BIM); Gross Variozahn 300 mm BIM from 300 rubles per pair.

There are also alloy steel blades (designated HM), but more often they are used for cutting brick, concrete or stone.

The size of the teeth for hacksaws for metal is 2-2.5 mm. This parameter is considered “small”, since there are products with larger teeth (for example, for wood saws it is 4-6 mm).

International standardization provides for a different principle of dividing the canvases. So, the number of teeth per 1 inch of file is taken into account. This figure is given in the marking before the letters PPI (points per inch) or TPI (formula “PPI - 1”). The higher the number, the smaller the tooth represented on this canvas.

When choosing products for a hacksaw, the user does not have to guess for a long time - most well-known files have a tooth pitch of 18 or 24. This is how branded products for construction are designated (for example, Standart 24 TPI 300 mm, Kraft-Flex 18 TPI blade from the manufacturer Kraftool).

The main classification of blades for metal hacksaws is based on the given criteria

It is important to know that the presence of set teeth is welcome if the user expects comfortable work without pauses or tool breakdowns. Now about how to properly install a hacksaw blade in a manual or electric tool

Rating of the best household and professional reciprocating saws

This section provides a brief overview of the most popular electric hacksaws, their performance characteristics and approximate cost and reviews from owners.

Household tool

Enkor SPE-710/115E

is a compact universal saw that can be effectively used for cutting various materials of small thickness. The metal body ensures reliability and long service life of the tool.

Performance characteristics:

- Power consumption: 0.71 kW

- Maximum rotation speed: 2800 rpm

- Blade stroke: 20 mm

- Maximum thickness of processed wood/metal: 120/25

- Weight: 2.6 kg

Advantages:

- Availability of quick release mount

- Possibility of soft start

- Double stroke frequency adjustment available

Flaws:

- No speed control

- No pendulum swing

Estimated cost of a reciprocating saw: 3100 rubles.

SPEC BPS-800

a medium-power household unit, effectively used when working in the garden and when cutting thin materials. The delivery includes a set of blades for processing various materials.

Performance characteristics:

- Power consumption: 0.8 kW

- Maximum rotation speed: 2500 rpm

- Blade stroke: 21 mm

- Maximum thickness of processed wood/metal: 65/8

- Weight: 3.2 kg

Advantages:

- Availability of quick release mount

- Possibility of soft start

- Smooth speed control

Flaws:

- No pendulum swing

Estimated cost 3900 rub.

PATRIOT RS 808

One of the few reciprocating saws that can be used for artistic cutting along the contour. The handle of the tool is rubberized, which significantly reduces vibrations. The unit has a 6-mode speed controller.

Performance characteristics:

- Power consumption: 0.85 kW

- Maximum rotation speed: 2800 rpm

- Blade stroke: 28 mm

- Maximum thickness of processed wood/metal: 105/6

- Weight: 2.7 kg

Advantages:

- Quick release mount

- Possibility of illumination of the working area

- Speed adjustment

Flaws:

- No pendulum swing

- No soft start

Estimated cost 4100 rub.

GRAPHITE 58G960

The reciprocating saw is used to perform minor repair work related to cutting wood, metal, plastic and other materials of small thickness. The durable aluminum alloy body provides the tool with reliability and durability.

Performance characteristics:

- Power consumption: 0.35 kW

- Maximum rotation speed: 2500 rpm

- Blade stroke: 17 mm

- Maximum thickness of processed wood/metal: 60/6

- Weight: 1.7 kg

Advantages:

- Quick release mount

- Light weight and compact

- Speed adjustment

Flaws:

- No pendulum swing

- No soft start

Estimated cost 4800 rub.

Einhell TH(TC)-AP 650 E

most effective when working in the garden or country house. The tool has a durable body that reliably protects internal mechanisms from mechanical damage and an ergonomic rubberized handle that significantly reduces vibration levels.

Performance characteristics:

- Power consumption: 0.65 kW

- Maximum rotation speed: 3000 rpm

- Blade stroke: 20 mm

- Maximum thickness of processed wood/metal: 150/10

- Weight: 2.8 kg

Advantages:

- Quick release mount

- Possibility of soft start

- Speed adjustment

- The presence of a pendulum stroke

Flaws:

- No backlight

- High price

The estimated cost of a reciprocating saw is 5,000 rubles.

Industrial tool

Einhell TE-AP 1050 E

Designed for working with fragile materials and high-speed cutting. The housing has special holes for cooling the electric motor.

Performance characteristics:

- Power consumption: 1.05 kW

- Maximum rotation speed: 2700 rpm

- Blade stroke: 29 mm

- Maximum thickness of processed wood/metal: 200/20

- Weight: 3.8 kg

Advantages:

- Quick release mount

- Possibility of soft start

- Speed adjustment

- The presence of a pendulum stroke

Flaws:

- No backlight

- High price

Estimated cost 8200 rub.

Makita JR3050T

It is distinguished by the manufacturer's traditional reliability, high performance and long service life. The unit is equipped with a support shoe, a 4 m long power cable and a quick blade replacement mechanism.

Saw performance characteristics:

- Power consumption: 1.01 kW

- Maximum rotation speed: 2800 rpm

- Blade stroke: 28 mm

- Maximum thickness of processed wood/pipe: 255/130

- Weight: 3.2 kg

Advantages:

- Quick release mount

- Ergonomic rubberized handle

- Speed adjustment

Flaws:

- No pendulum motion

- No soft start system

- High price

Estimated cost 9100 rub.

AEG US 1300 XE

. The reciprocating saw can be used to process a wide variety of materials. It has proven itself to be a highly productive and reliable tool.

Performance characteristics:

- Power consumption: 1.3 kW

- Maximum rotation speed: 2800 rpm

- Blade stroke: 30 mm

- Maximum thickness of processed wood/metal: 20/250

- Weight: 3.8 kg

Advantages:

- Quick release mount

- Ergonomic rubberized handle

- Speed adjustment

Flaws:

- No pendulum motion

- No soft start system

- No backlight

- High price

The approximate price of a reciprocating hacksaw is 10,600 rubles.

Hitachi CR13V2

The saw is most effective for dismantling, but can also be successfully used in other industries. The tool is easy to use and maintain.

Performance characteristics:

- Power consumption: 1.01 kW

- Maximum rotation speed: 2800 rpm

- Blade stroke: 29 mm

- Maximum thickness of processed wood/pipe: 300/19

- Weight: 3.2 kg

Advantages:

- Quick release mount

- Ergonomic rubberized handle

- Speed adjustment

Flaws:

- No pendulum swing

- No soft start system

- High price

Estimated cost 12,000 rubles.

Makita JR 3060

T is mainly used in construction and demolition. The unit has a shock-resistant housing that provides maximum protection from mechanical damage and is characterized by reliability and long service life.

Performance characteristics:

- Power consumption: 1.25 kW

- Maximum rotation speed: 2800 rpm

- Blade stroke: 32 mm

- Maximum thickness of processed wood/pipe: 255/130

- Weight: 4.2 kg

Advantages:

- Quick release mount

- Possibility of pendulum movement

- Speed adjustment

Flaws:

- No backlight

- No soft start system

- High price

The approximate price of a reciprocating saw is 14,000 rubles.

Along with the rating data, for the optimal choice of an electric hacksaw, it makes sense to read the reviews below from owners of “sabers” who have assessed in practice the advantages and disadvantages of a particular model.

Patriot RS 505

.

The tool was originally intended for cutting dry branches and twigs in the country, but in the process of work I came to the conclusion that the saw could well be used for other purposes. I changed the blade and tried cutting old water pipes, and was pleasantly surprised by the result. In addition, the price of the saber is quite affordable. Andrey, Kharkov.

Ryobi R18RS7

.

I’ll say right away that I’m very pleased with the purchase. The blade is very easy to change, but the fastening is so reliable that the saw does not move to the side when cutting. I worked with metal, wood, plastic and God knows what else, and for two years there were no complaints. It’s a bit expensive, it’s true, but the tool has fully justified itself. Dmitry, Saratov

.

Metabo SSE 18 LTX Compact 602266890

.

In principle, there are no complaints about the instrument, but its cost is clearly overpriced. I used it for cutting different materials and was always pleased with the result, the main thing is to choose the right blade. A good all-purpose tool and no wires to pull. Nikita, Nikolaev.

AEG BUS18BL.

Great tool!

The battery works great for 5-6 hours and charges quickly. He saws everything he can get his hands on, I convinced myself. At the dacha I cut pipes and floorboards, just like a knife through butter. I am very pleased with the purchase, I recommend it to everyone. Vasily, Smolensk.

Special BPS-800.

Although the saw is domestic, it may well compete with the most famous brands!

I’ve been working with it for two years under the harshest conditions and I haven’t had any complaints, and the reasonable price will completely shut the damned capitalists’ mouths! Sergey, Moscow region.

The thickness of the blades affects the deflection of the nozzle

Another factor that influences the quality of the cut is the thickness of the saw attachment. They come in two types - thick and thin. Each type has its own advantages and disadvantages, as well as a corresponding purpose.

- Thin blades provide an even and accurate cut, but during the sawing process they vibrate strongly, which depends on the hardness of the material being processed. In addition, their advantage is the low load on the tool, and the disadvantage is that they cannot be used for corner cuts.

- Thick files provide an even perpendicular cut and can be used for angular cutting of materials. Their disadvantage is that due to their size they increase the load on the engine and gearbox of the tool, so they cannot be used on low-power jigsaws

Even thick attachments are not suitable for the quick-clamping mechanism of the saw holder, so it is necessary to choose medium and small blades in thickness.

Professional advice on choosing a tool

- First of all, you should clearly define the range of tasks to be performed and the operating conditions of the tool. It is not advisable to buy an expensive modification of a reciprocating saw for household needs, since its cost is unlikely to be recouped.

- For household needs and minor repair work, a 600 W unit is sufficient. For work in the garden and country house, you can choose a saw with a power of 800-1000 W, but for construction work and dismantling you will need a tool with a power of 1 kW or more.

- When choosing a model, its cost plays an important role. Equipment used exclusively for domestic purposes can cost from 3,500 to 5,500 rubles. An electric hacksaw for working in the garden and country house can be purchased for 6,000-8,000 rubles, and to purchase a powerful professional unit you will need at least 8,500 rubles.

Which saw blades are suitable for sawing cast iron?

There are often disputes among tool owners about whether it is possible to use metal blades for cutting cast iron. Of course it is possible, only ordinary equipment for cutting metal in this case will quickly become dull and become unusable. For processing cast iron, it is recommended to use bimetallic blades coated with tungsten carbide or diamond. Moreover, diamond-coated blades cope not only with cast iron, but also glass, as well as other similar heavy-duty materials - ceramics, porcelain stoneware, concrete, reinforced concrete and others.

Possible faults

Like any other equipment, a reciprocating saw can fail during operation due to various reasons. Let's look at the most common faults and possible methods for eliminating them.

Mechanical breakdowns

1. The fixing device does not provide reliable fixation of the canvas. Most likely the retainer has worn out. In this case, it is necessary to replace the worn part. However, in some cases, the cause may be a mismatch between the standard sizes of the holder and the blade; in this case, you should simply replace the file.

2. Poor quality of cut and strong vibration. Most often, such symptoms occur when brass guide bushings wear out. The only way to repair can be to replace the failed parts.

3. During operation, extraneous noise is heard and an increase in vibration is observed. Such problems may be the result of bearing failure. Most often, the cause is insufficient lubrication and high loads. The functionality of the tool can be restored by replacing the bearings and ensuring effective lubrication.

Electrical faults

Typical malfunctions of reciprocating saws can be considered:

- Failure of the start key or speed controller;

- Abrasion of graphite brushes;

- Lack of contact in electrical terminals.

- Wear of motor windings

Despite the fact that the causes of these problems may be different, repairs are carried out by replacing worn out parts.

As can be seen from the material presented above and the visual demonstration of the operation of various models of reciprocating saws, the use of this tool can significantly simplify the process of cutting both sheet and any other materials. The versatility and mobility of reciprocating hacksaws allows them to be used effectively both at home and for industrial purposes.

Feasibility of use

For a long time, the reciprocating saw was not popular in Russia.

Read also: How to measure chest circumference correctly

Today, the reciprocating saw is greatly inferior to jigsaws and grinders. But in Western countries, especially in the USA, the tool is in high demand due to its simplicity, safety and versatility. Some experts do not see the point in buying another expensive tool, making do with others with similar functions. However, the benefits of a reciprocating saw still outweigh the costs that must be incurred to purchase it.

- Nikolay, 38 years old, Moscow

We almost never buy reciprocating saws, especially builders and repairmen. It is believed that this is a female device, an electric version of a garden hacksaw. I don't agree with this. I work on the construction of low-rise housing and private houses. If we are talking about frames, then here it is simply irreplaceable: cut it off here, then there. The trimmer is cumbersome and can only be used on the ground. The jigsaw has a thin blade. In short, the device is good, it occupies its niche. A professional must have a lot of tools - this is his bread and butter.

- Vadim, 45 years old, Nizhny Novgorod

He built the house himself, with an assistant. Naturally, I stocked up on a good tool to make it easier. There was a cool Bulgarian woman on the farm. A neighbor advised her to buy a disc with teeth so that she could cut boards and timber faster, without using her hands. I followed his advice. True, for work I had to remove the protective casing. It jerks a little when cutting. I worked like this for two days, on the third disc it bit on a nail that unexpectedly found itself inside. As a result, a couple of teeth flew off and the grinder was pulled out of my hands. He escaped with a very big scare and a dislocated wrist. After that I bought myself a “saber”. Health is more valuable.

- Alexander, 65 years old, Krasnodar

I have a large garden, fruit trees. Constant work on pruning, crown molding, knots, etc. There were loppers and a bunch of different hacksaws on the farm, until I bought a reciprocating saw. Now everything is in the barn. Very convenient: any branch, any twig will be sawed off in a moment. I even sawed the trunks - there are no centuries-old oaks, the diameter of the trunk allows. If you have a lot of trees, then that's it.

Purpose

A reciprocating saw of this type is used primarily for cutting durable metal, which includes structures such as steel profiles, various pipes, fittings and non-ferrous metal products. Since a wide range of different blades can be found for this tool, the range of materials for which it is used is also very wide:

- stainless steel;

- aluminum;

- hardened metal.

The purpose of the saw can be classified according to the type of work.

Reciprocating saw blades. Finalization

- Work on cutting metal by weight. The reciprocating saw is convenient because its design minimizes the load on your hands, unlike other types of devices.

- Before assembling any structures, it may be necessary to cut metal parts.

- The tool is used when creating figured cuts.

- For operational safety, aesthetic appearance of structures and other purposes, the ends of parts are rounded using a reciprocating electric saw.

- Repair work that requires the dismantling of metal structures, such as radiators.